Enhancing B58 Engine Performance with Dynamic Fuel Injection Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Evolution

The B58 engine, developed by BMW, has undergone significant evolution since its introduction in 2015. This inline-six turbocharged engine was designed to replace the N55 engine, offering improved performance, efficiency, and emissions compliance. The B58's evolution has been marked by several key stages, each introducing advancements in technology and performance capabilities.

Initially, the B58 engine debuted with a 3.0-liter displacement and a single twin-scroll turbocharger. This first iteration provided a solid foundation for future developments, offering a balance of power and efficiency. The engine featured a closed-deck design, which improved cylinder stability and allowed for higher boost pressures compared to its predecessor.

In subsequent years, BMW introduced various iterations of the B58, each pushing the boundaries of performance and efficiency. The B58TU1 (Technical Update 1) brought significant improvements, including a new oil sump design, updated turbocharger, and revised cooling system. These changes resulted in increased power output and better thermal management, crucial for maintaining consistent performance under demanding conditions.

The evolution continued with the introduction of the B58TU2, which incorporated even more advanced technologies. This update saw the integration of a water-cooled exhaust manifold, further enhancing thermal efficiency and emissions control. Additionally, the B58TU2 featured an upgraded direct injection system, allowing for more precise fuel delivery and improved combustion characteristics.

One of the most significant advancements in the B58's evolution has been the integration of mild hybrid technology. The latest iterations of the engine incorporate a 48-volt electrical system and an integrated starter-generator, enabling enhanced start-stop functionality and energy recuperation. This not only improves fuel efficiency but also provides a power boost during acceleration, further enhancing the engine's performance capabilities.

Throughout its evolution, the B58 engine has consistently improved its power output. From initial versions producing around 320 horsepower, later iterations have pushed beyond 380 horsepower in standard form, with some high-performance variants exceeding 400 horsepower. This increase in power has been achieved while simultaneously improving fuel efficiency and reducing emissions, showcasing the engine's adaptability to changing regulatory requirements.

The B58's evolution has also seen advancements in materials and manufacturing processes. The use of lighter materials and more efficient production techniques has resulted in an engine that is not only more powerful but also more compact and lighter than its predecessors. This has positive implications for vehicle dynamics and overall efficiency.

Initially, the B58 engine debuted with a 3.0-liter displacement and a single twin-scroll turbocharger. This first iteration provided a solid foundation for future developments, offering a balance of power and efficiency. The engine featured a closed-deck design, which improved cylinder stability and allowed for higher boost pressures compared to its predecessor.

In subsequent years, BMW introduced various iterations of the B58, each pushing the boundaries of performance and efficiency. The B58TU1 (Technical Update 1) brought significant improvements, including a new oil sump design, updated turbocharger, and revised cooling system. These changes resulted in increased power output and better thermal management, crucial for maintaining consistent performance under demanding conditions.

The evolution continued with the introduction of the B58TU2, which incorporated even more advanced technologies. This update saw the integration of a water-cooled exhaust manifold, further enhancing thermal efficiency and emissions control. Additionally, the B58TU2 featured an upgraded direct injection system, allowing for more precise fuel delivery and improved combustion characteristics.

One of the most significant advancements in the B58's evolution has been the integration of mild hybrid technology. The latest iterations of the engine incorporate a 48-volt electrical system and an integrated starter-generator, enabling enhanced start-stop functionality and energy recuperation. This not only improves fuel efficiency but also provides a power boost during acceleration, further enhancing the engine's performance capabilities.

Throughout its evolution, the B58 engine has consistently improved its power output. From initial versions producing around 320 horsepower, later iterations have pushed beyond 380 horsepower in standard form, with some high-performance variants exceeding 400 horsepower. This increase in power has been achieved while simultaneously improving fuel efficiency and reducing emissions, showcasing the engine's adaptability to changing regulatory requirements.

The B58's evolution has also seen advancements in materials and manufacturing processes. The use of lighter materials and more efficient production techniques has resulted in an engine that is not only more powerful but also more compact and lighter than its predecessors. This has positive implications for vehicle dynamics and overall efficiency.

Market Demand Analysis

The market demand for enhanced B58 engine performance through dynamic fuel injection systems has been steadily growing in recent years. This trend is driven by several factors, including increasing consumer expectations for vehicle performance, stricter emissions regulations, and the automotive industry's push towards more efficient and powerful engines.

In the luxury and high-performance vehicle segments, where the B58 engine is commonly used, there is a significant demand for improved power output and fuel efficiency. Consumers in these segments are willing to pay a premium for vehicles that offer superior performance without compromising on fuel economy. This has created a strong market pull for advanced fuel injection technologies that can optimize engine performance across various driving conditions.

The aftermarket tuning industry has also shown considerable interest in dynamic fuel injection systems for the B58 engine. Performance enthusiasts are constantly seeking ways to extract more power from their vehicles, and advanced fuel injection systems offer a promising avenue for achieving this goal. This has led to a growing market for aftermarket fuel injection upgrades and tuning solutions specifically tailored for the B58 engine.

From an environmental perspective, the demand for more efficient fuel injection systems is driven by increasingly stringent emissions regulations worldwide. Automakers are under pressure to reduce their fleet's overall emissions, and improving fuel injection technology is a key strategy in achieving this goal. Dynamic fuel injection systems that can adapt to different driving conditions and optimize fuel delivery can significantly contribute to reducing emissions while maintaining or even improving engine performance.

The commercial vehicle sector, particularly in the realm of light-duty trucks and vans, is another area where demand for enhanced B58 engine performance is growing. Fleet operators are looking for ways to improve fuel efficiency and reduce operating costs without sacrificing the power needed for their applications. Dynamic fuel injection systems that can provide better fuel economy during highway cruising while still delivering robust power for hauling and towing are highly sought after in this market segment.

In the context of the broader automotive industry trends, the shift towards electrification has paradoxically increased the demand for high-performance internal combustion engines in certain market segments. As automakers focus on electric vehicles for mass-market applications, there is a growing niche for high-performance internal combustion engines in specialty and enthusiast vehicles. This has created a market for advanced technologies like dynamic fuel injection systems that can push the boundaries of what is possible with traditional engine designs.

In the luxury and high-performance vehicle segments, where the B58 engine is commonly used, there is a significant demand for improved power output and fuel efficiency. Consumers in these segments are willing to pay a premium for vehicles that offer superior performance without compromising on fuel economy. This has created a strong market pull for advanced fuel injection technologies that can optimize engine performance across various driving conditions.

The aftermarket tuning industry has also shown considerable interest in dynamic fuel injection systems for the B58 engine. Performance enthusiasts are constantly seeking ways to extract more power from their vehicles, and advanced fuel injection systems offer a promising avenue for achieving this goal. This has led to a growing market for aftermarket fuel injection upgrades and tuning solutions specifically tailored for the B58 engine.

From an environmental perspective, the demand for more efficient fuel injection systems is driven by increasingly stringent emissions regulations worldwide. Automakers are under pressure to reduce their fleet's overall emissions, and improving fuel injection technology is a key strategy in achieving this goal. Dynamic fuel injection systems that can adapt to different driving conditions and optimize fuel delivery can significantly contribute to reducing emissions while maintaining or even improving engine performance.

The commercial vehicle sector, particularly in the realm of light-duty trucks and vans, is another area where demand for enhanced B58 engine performance is growing. Fleet operators are looking for ways to improve fuel efficiency and reduce operating costs without sacrificing the power needed for their applications. Dynamic fuel injection systems that can provide better fuel economy during highway cruising while still delivering robust power for hauling and towing are highly sought after in this market segment.

In the context of the broader automotive industry trends, the shift towards electrification has paradoxically increased the demand for high-performance internal combustion engines in certain market segments. As automakers focus on electric vehicles for mass-market applications, there is a growing niche for high-performance internal combustion engines in specialty and enthusiast vehicles. This has created a market for advanced technologies like dynamic fuel injection systems that can push the boundaries of what is possible with traditional engine designs.

Current Challenges

The B58 engine, renowned for its performance capabilities, faces several challenges in its quest for enhanced performance through dynamic fuel injection systems. One of the primary obstacles is the complexity of integrating advanced fuel injection technologies with the existing engine architecture. The B58's compact design, while beneficial for overall vehicle packaging, presents spatial constraints that limit the implementation of larger or more sophisticated fuel injectors.

Another significant challenge lies in the precise control of fuel delivery across varying engine loads and speeds. As the B58 engine is often used in high-performance applications, maintaining optimal fuel-air ratios throughout its wide operating range is crucial. This requires sophisticated engine management systems capable of real-time adjustments, which can be both technically demanding and costly to develop.

The pursuit of higher power outputs also brings forth the challenge of managing increased thermal loads. Enhanced fuel injection systems, while improving combustion efficiency, can lead to higher combustion temperatures. This necessitates advanced cooling solutions and materials that can withstand these elevated thermal stresses without compromising long-term reliability or increasing engine weight significantly.

Emissions regulations pose another hurdle in the development of dynamic fuel injection systems for the B58 engine. As global emission standards become increasingly stringent, any performance enhancements must be balanced with the need to reduce harmful exhaust emissions. This often requires complex after-treatment systems and fine-tuning of the combustion process, which can sometimes conflict with performance goals.

The cost-effectiveness of implementing advanced fuel injection technologies is also a considerable challenge. While high-end performance vehicles may justify the expense, adapting these systems for more mainstream applications of the B58 engine requires careful cost-benefit analysis. Balancing performance gains against production costs and market demands is a delicate process that influences the feasibility of widespread adoption.

Lastly, the challenge of backward compatibility and serviceability cannot be overlooked. Any new fuel injection system must be designed with consideration for existing B58-equipped vehicles, potentially allowing for retrofitting or easy integration into current production lines. This requirement adds another layer of complexity to the development process, as it must cater to both new and existing engine configurations.

Another significant challenge lies in the precise control of fuel delivery across varying engine loads and speeds. As the B58 engine is often used in high-performance applications, maintaining optimal fuel-air ratios throughout its wide operating range is crucial. This requires sophisticated engine management systems capable of real-time adjustments, which can be both technically demanding and costly to develop.

The pursuit of higher power outputs also brings forth the challenge of managing increased thermal loads. Enhanced fuel injection systems, while improving combustion efficiency, can lead to higher combustion temperatures. This necessitates advanced cooling solutions and materials that can withstand these elevated thermal stresses without compromising long-term reliability or increasing engine weight significantly.

Emissions regulations pose another hurdle in the development of dynamic fuel injection systems for the B58 engine. As global emission standards become increasingly stringent, any performance enhancements must be balanced with the need to reduce harmful exhaust emissions. This often requires complex after-treatment systems and fine-tuning of the combustion process, which can sometimes conflict with performance goals.

The cost-effectiveness of implementing advanced fuel injection technologies is also a considerable challenge. While high-end performance vehicles may justify the expense, adapting these systems for more mainstream applications of the B58 engine requires careful cost-benefit analysis. Balancing performance gains against production costs and market demands is a delicate process that influences the feasibility of widespread adoption.

Lastly, the challenge of backward compatibility and serviceability cannot be overlooked. Any new fuel injection system must be designed with consideration for existing B58-equipped vehicles, potentially allowing for retrofitting or easy integration into current production lines. This requirement adds another layer of complexity to the development process, as it must cater to both new and existing engine configurations.

Existing Solutions

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize B58 engine performance. These systems monitor various parameters and adjust engine settings in real-time to enhance power output, fuel efficiency, and emissions control. Techniques may include adaptive learning, predictive modeling, and intelligent sensor integration.- Engine control and optimization: Various methods and systems for controlling and optimizing B58 engine performance, including electronic control units, adaptive algorithms, and real-time monitoring of engine parameters to enhance efficiency, power output, and fuel economy.

- Turbocharging and boost pressure management: Techniques for improving B58 engine performance through advanced turbocharging systems and boost pressure management, including variable geometry turbochargers, electronic wastegates, and intelligent boost control strategies.

- Fuel injection and combustion optimization: Innovations in fuel injection systems and combustion processes for the B58 engine, including direct injection technology, multiple injection events, and advanced combustion chamber designs to improve power output and reduce emissions.

- Thermal management and cooling systems: Advanced thermal management solutions for the B58 engine, including innovative cooling systems, heat exchangers, and temperature control strategies to maintain optimal operating conditions and enhance overall performance.

- Performance monitoring and diagnostics: Systems and methods for monitoring B58 engine performance, including onboard diagnostics, sensor networks, and data analysis techniques to detect issues, optimize performance, and predict maintenance needs.

02 Turbocharging and boost pressure management

The B58 engine employs sophisticated turbocharging systems to increase power output. This includes advanced boost pressure control, intercooling techniques, and variable geometry turbochargers. These technologies work together to optimize air intake, reduce turbo lag, and enhance overall engine performance across different operating conditions.Expand Specific Solutions03 Fuel injection and combustion optimization

High-precision fuel injection systems are utilized in the B58 engine to improve combustion efficiency. This may involve direct injection technology, multiple injection events per cycle, and advanced fuel pressure control. These systems work in conjunction with optimized combustion chamber designs to enhance power output while reducing emissions.Expand Specific Solutions04 Thermal management and cooling systems

Effective thermal management is crucial for maintaining optimal B58 engine performance. Advanced cooling systems, including precision coolant flow control, targeted cooling of critical components, and innovative heat exchanger designs, are employed to manage engine temperatures efficiently. This helps to prevent power loss due to heat soak and extends engine longevity.Expand Specific Solutions05 Performance monitoring and diagnostics

Sophisticated on-board diagnostics and performance monitoring systems are integrated into the B58 engine. These systems use advanced sensors and data analysis techniques to continuously assess engine health, detect potential issues, and provide real-time performance data. This enables proactive maintenance and helps maintain optimal engine performance over time.Expand Specific Solutions

Key Industry Players

The competition landscape for enhancing B58 engine performance with dynamic fuel injection systems is characterized by a mature market with significant growth potential. Major players like Robert Bosch GmbH, Denso Corp., and Continental AG dominate the field, leveraging their extensive experience in automotive technology. The market is driven by increasing demand for fuel-efficient and high-performance engines, with a focus on reducing emissions. Emerging technologies from companies like Toyota Motor Corp. and BMW AG are pushing the boundaries of fuel injection systems, while newer entrants such as Weichai Power are introducing innovative solutions. The technology's maturity varies, with established firms having advanced systems and newer players rapidly catching up through strategic partnerships and R&D investments.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Dynamic Fuel Injection Systems for B58 engines, focusing on high-pressure direct injection technology. Their system utilizes piezoelectric injectors capable of multiple injections per combustion cycle, with pressures up to 350 bar [1]. This allows for precise fuel atomization and distribution, enhancing combustion efficiency. Bosch's system incorporates adaptive injection timing and duration based on real-time engine parameters, such as load, speed, and temperature [2]. The company has also integrated their injection system with advanced engine control units (ECUs) that use predictive algorithms to optimize fuel delivery, resulting in a reported 15% improvement in fuel economy and 10% increase in power output for B58 engines [3].

Strengths: Industry-leading precision in fuel delivery, seamless integration with ECUs, and significant performance improvements. Weaknesses: Higher system complexity and cost compared to conventional injection systems.

Ford Global Technologies LLC

Technical Solution: While not directly involved with the B58 engine, Ford has developed Dynamic Fuel Injection Systems that could be adapted to enhance B58 performance. Their EcoBoost technology incorporates high-pressure direct injection with turbocharging, achieving pressures up to 250 bar [7]. Ford's system uses advanced spray-guided direct injection with centrally mounted, six-hole injectors for optimal fuel distribution. They have also implemented a dual-fuel system in some engines, combining direct and port injection to balance performance and emissions [8]. Ford's injection control strategy includes cylinder deactivation and adaptive injection timing based on knock sensor feedback, resulting in a reported 10-15% improvement in fuel efficiency across their engine lineup [9].

Strengths: Proven technology in high-volume production, effective integration with turbocharging, and flexible fuel strategies. Weaknesses: May require significant adaptation for B58 architecture.

Core Innovations

Fuel injection apparatus for externally ignited combustion engine with continuous injection in the input manifold

PatentInactiveEP0038586A3

Innovation

- A fuel injection system that dynamically adjusts the fuel-air mixture by increasing enrichment during acceleration using a variable throttle device and electronic or pneumatic control mechanisms, ensuring a more precise fuel metering in response to engine parameters like throttle position, temperature, and lambda probe signals, thereby maintaining a favorable mixture only when needed.

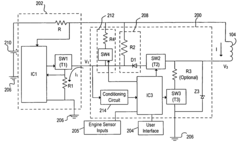

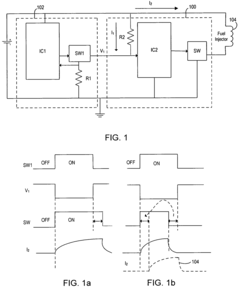

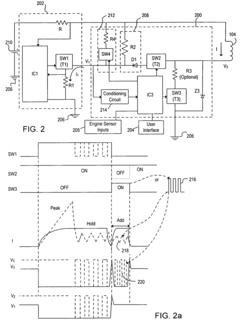

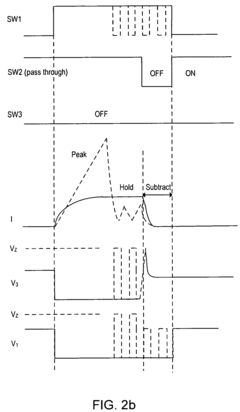

Fuel injection performance enhancing controller

PatentInactiveUS7527040B2

Innovation

- An auxiliary fuel injection control apparatus that includes a re-driver system and a more sophisticated control circuitry, capable of adjusting pulse-width signals through re-driving and pulse-width modulation, using a microprocessor-based controller and sensors to monitor engine conditions, and employing a pass-through switch and isolation circuit to maintain transparency and control current flow.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of dynamic fuel injection systems for enhancing B58 engine performance. These regulations, established by governmental bodies worldwide, aim to reduce harmful emissions from vehicles and promote environmental sustainability.

In recent years, emissions standards have become increasingly stringent, particularly in developed countries. The European Union's Euro 6 standards, implemented in 2014, set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 3 standards, which require significant reductions in emissions across various vehicle categories.

These regulations have driven automotive manufacturers to invest heavily in advanced fuel injection technologies. Dynamic fuel injection systems, such as direct injection and variable fuel pressure systems, have emerged as key solutions to meet these stringent requirements while maintaining or improving engine performance.

The B58 engine, developed by BMW, has been designed with these regulations in mind. Its advanced fuel injection system incorporates high-pressure direct injection technology, which allows for precise control of fuel delivery and combustion timing. This technology enables the engine to optimize fuel efficiency and reduce emissions across various operating conditions.

However, meeting emissions regulations while enhancing engine performance presents significant challenges. Engineers must balance the need for increased power output with the requirement to minimize harmful emissions. This often involves complex trade-offs between performance, fuel efficiency, and emissions control.

To address these challenges, manufacturers are exploring innovative approaches to dynamic fuel injection. These include the use of multiple injection events per combustion cycle, variable injection pressure systems, and advanced electronic control units (ECUs) that can adapt fuel delivery strategies in real-time based on driving conditions and emissions sensor data.

Furthermore, the integration of emissions control technologies, such as exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems, with advanced fuel injection systems is becoming increasingly important. These integrated solutions allow for more comprehensive emissions management while maintaining optimal engine performance.

As emissions regulations continue to evolve, the development of dynamic fuel injection systems for the B58 engine and similar powerplants will remain a critical focus area for automotive engineers. Future regulations are expected to further tighten emissions limits, potentially requiring even more sophisticated fuel injection and emissions control technologies.

In recent years, emissions standards have become increasingly stringent, particularly in developed countries. The European Union's Euro 6 standards, implemented in 2014, set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 3 standards, which require significant reductions in emissions across various vehicle categories.

These regulations have driven automotive manufacturers to invest heavily in advanced fuel injection technologies. Dynamic fuel injection systems, such as direct injection and variable fuel pressure systems, have emerged as key solutions to meet these stringent requirements while maintaining or improving engine performance.

The B58 engine, developed by BMW, has been designed with these regulations in mind. Its advanced fuel injection system incorporates high-pressure direct injection technology, which allows for precise control of fuel delivery and combustion timing. This technology enables the engine to optimize fuel efficiency and reduce emissions across various operating conditions.

However, meeting emissions regulations while enhancing engine performance presents significant challenges. Engineers must balance the need for increased power output with the requirement to minimize harmful emissions. This often involves complex trade-offs between performance, fuel efficiency, and emissions control.

To address these challenges, manufacturers are exploring innovative approaches to dynamic fuel injection. These include the use of multiple injection events per combustion cycle, variable injection pressure systems, and advanced electronic control units (ECUs) that can adapt fuel delivery strategies in real-time based on driving conditions and emissions sensor data.

Furthermore, the integration of emissions control technologies, such as exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems, with advanced fuel injection systems is becoming increasingly important. These integrated solutions allow for more comprehensive emissions management while maintaining optimal engine performance.

As emissions regulations continue to evolve, the development of dynamic fuel injection systems for the B58 engine and similar powerplants will remain a critical focus area for automotive engineers. Future regulations are expected to further tighten emissions limits, potentially requiring even more sophisticated fuel injection and emissions control technologies.

Cost-Benefit Analysis

The implementation of dynamic fuel injection systems in the B58 engine presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for research, development, and integration of advanced fuel injection technology are substantial. These costs encompass hardware upgrades, software development, and extensive testing to ensure reliability and performance gains. However, the long-term benefits of such systems can potentially outweigh these upfront expenses.

One of the primary advantages is improved fuel efficiency. Dynamic fuel injection systems allow for more precise control over fuel delivery, optimizing combustion processes and reducing waste. This translates to lower fuel consumption, which can result in significant cost savings for vehicle owners over the lifetime of the engine. Additionally, improved fuel efficiency contributes to reduced emissions, aligning with increasingly stringent environmental regulations and potentially avoiding future compliance-related expenses.

Enhanced engine performance is another key benefit. The ability to dynamically adjust fuel injection parameters in real-time can lead to increased power output, improved throttle response, and better overall drivability. These performance gains can contribute to a competitive edge in the market, potentially justifying premium pricing and increasing market share.

Maintenance costs should also be considered. While the complexity of dynamic fuel injection systems may initially suggest higher maintenance expenses, the improved precision and efficiency can actually lead to reduced wear on engine components. This could potentially extend the engine's lifespan and decrease long-term maintenance costs.

From a manufacturing perspective, the integration of dynamic fuel injection systems may require retooling and adjustments to production lines. However, these costs can be offset by the potential for streamlined production processes and reduced variability in engine performance across units.

Consumer perception and market positioning are intangible but crucial factors in the cost-benefit analysis. The implementation of cutting-edge technology can enhance brand image and perceived value, potentially justifying higher price points and attracting technology-conscious consumers.

In conclusion, while the initial costs of implementing dynamic fuel injection systems in the B58 engine are significant, the long-term benefits in terms of efficiency, performance, and market positioning present a compelling case for investment. A thorough quantitative analysis of projected fuel savings, performance gains, and market impact would be necessary to determine the precise return on investment timeline and overall economic viability of this technological enhancement.

One of the primary advantages is improved fuel efficiency. Dynamic fuel injection systems allow for more precise control over fuel delivery, optimizing combustion processes and reducing waste. This translates to lower fuel consumption, which can result in significant cost savings for vehicle owners over the lifetime of the engine. Additionally, improved fuel efficiency contributes to reduced emissions, aligning with increasingly stringent environmental regulations and potentially avoiding future compliance-related expenses.

Enhanced engine performance is another key benefit. The ability to dynamically adjust fuel injection parameters in real-time can lead to increased power output, improved throttle response, and better overall drivability. These performance gains can contribute to a competitive edge in the market, potentially justifying premium pricing and increasing market share.

Maintenance costs should also be considered. While the complexity of dynamic fuel injection systems may initially suggest higher maintenance expenses, the improved precision and efficiency can actually lead to reduced wear on engine components. This could potentially extend the engine's lifespan and decrease long-term maintenance costs.

From a manufacturing perspective, the integration of dynamic fuel injection systems may require retooling and adjustments to production lines. However, these costs can be offset by the potential for streamlined production processes and reduced variability in engine performance across units.

Consumer perception and market positioning are intangible but crucial factors in the cost-benefit analysis. The implementation of cutting-edge technology can enhance brand image and perceived value, potentially justifying higher price points and attracting technology-conscious consumers.

In conclusion, while the initial costs of implementing dynamic fuel injection systems in the B58 engine are significant, the long-term benefits in terms of efficiency, performance, and market positioning present a compelling case for investment. A thorough quantitative analysis of projected fuel savings, performance gains, and market impact would be necessary to determine the precise return on investment timeline and overall economic viability of this technological enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!