Lightweight Piston Design and Its Influence on B58 Engine Performance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Piston Evolution

The B58 engine, developed by BMW, has undergone significant evolution in its piston design since its introduction. This evolution has been driven by the continuous pursuit of improved performance, efficiency, and reliability. The initial design of the B58 engine pistons focused on balancing strength and weight, utilizing high-quality aluminum alloys to withstand the high pressures and temperatures of the combustion chamber.

As the engine's development progressed, engineers implemented several key improvements to the piston design. One of the most notable advancements was the introduction of a more sophisticated cooling gallery system within the piston. This innovation allowed for better heat dissipation, reducing thermal stress and improving overall engine durability. The cooling galleries were strategically placed to target areas of the piston most susceptible to heat-related wear.

Another significant evolution in the B58 engine piston design was the optimization of the piston crown geometry. Engineers refined the shape to enhance combustion efficiency and reduce emissions. This included modifications to the bowl shape and depth, which played a crucial role in improving fuel mixture distribution and flame propagation during the combustion process.

The piston ring design also saw substantial improvements over time. Early versions of the B58 engine used conventional three-ring configurations, but later iterations incorporated advanced ring materials and profiles. These changes resulted in reduced friction, improved sealing, and enhanced oil control, all contributing to better engine performance and longevity.

Weight reduction became a primary focus in subsequent piston design iterations. Engineers employed advanced computer-aided design and simulation techniques to identify areas where material could be safely removed without compromising structural integrity. This led to the development of pistons with optimized skirt designs and strategically placed reinforcements, resulting in a significant reduction in reciprocating mass.

The evolution of coating technologies also played a crucial role in enhancing B58 engine piston performance. Advanced thermal barrier coatings were applied to the piston crown, reducing heat transfer to the piston body and improving thermal efficiency. Additionally, low-friction coatings on the piston skirt helped minimize wear and reduce parasitic losses.

In recent years, the B58 engine piston design has incorporated more advanced materials, including high-silicon aluminum alloys and even composite materials in certain applications. These materials offer superior strength-to-weight ratios and thermal properties, allowing for further optimization of piston design and performance.

As the engine's development progressed, engineers implemented several key improvements to the piston design. One of the most notable advancements was the introduction of a more sophisticated cooling gallery system within the piston. This innovation allowed for better heat dissipation, reducing thermal stress and improving overall engine durability. The cooling galleries were strategically placed to target areas of the piston most susceptible to heat-related wear.

Another significant evolution in the B58 engine piston design was the optimization of the piston crown geometry. Engineers refined the shape to enhance combustion efficiency and reduce emissions. This included modifications to the bowl shape and depth, which played a crucial role in improving fuel mixture distribution and flame propagation during the combustion process.

The piston ring design also saw substantial improvements over time. Early versions of the B58 engine used conventional three-ring configurations, but later iterations incorporated advanced ring materials and profiles. These changes resulted in reduced friction, improved sealing, and enhanced oil control, all contributing to better engine performance and longevity.

Weight reduction became a primary focus in subsequent piston design iterations. Engineers employed advanced computer-aided design and simulation techniques to identify areas where material could be safely removed without compromising structural integrity. This led to the development of pistons with optimized skirt designs and strategically placed reinforcements, resulting in a significant reduction in reciprocating mass.

The evolution of coating technologies also played a crucial role in enhancing B58 engine piston performance. Advanced thermal barrier coatings were applied to the piston crown, reducing heat transfer to the piston body and improving thermal efficiency. Additionally, low-friction coatings on the piston skirt helped minimize wear and reduce parasitic losses.

In recent years, the B58 engine piston design has incorporated more advanced materials, including high-silicon aluminum alloys and even composite materials in certain applications. These materials offer superior strength-to-weight ratios and thermal properties, allowing for further optimization of piston design and performance.

Market Demand for High-Performance Engines

The market demand for high-performance engines has been steadily increasing in recent years, driven by a combination of consumer preferences, technological advancements, and regulatory pressures. This trend is particularly evident in the premium and luxury automotive segments, where engines like BMW's B58 are highly sought after.

Consumer preferences have shifted towards vehicles that offer both power and efficiency. High-performance engines are no longer exclusive to sports cars but are increasingly found in luxury sedans, SUVs, and even some mid-range vehicles. This broadening of the market has led to a significant increase in demand for engines that can deliver exceptional performance while meeting stringent fuel economy and emissions standards.

The B58 engine, with its lightweight design and advanced technology, has positioned itself as a prime example of meeting this market demand. Its ability to provide high power output while maintaining relatively good fuel efficiency has made it a popular choice among consumers who desire both performance and practicality.

In the premium segment, where the B58 engine is primarily used, there has been a noticeable trend towards downsizing engines while maintaining or even increasing power output. This has led to a growing market for turbocharged six-cylinder engines like the B58, which can offer performance comparable to larger V8 engines but with better fuel economy and lower emissions.

The automotive industry's push towards electrification has, somewhat counterintuitively, also contributed to the demand for high-performance internal combustion engines. As automakers invest heavily in electric vehicle technology, there is a parallel effort to maximize the potential of traditional powertrains. This has resulted in increased interest in advanced engine technologies, including lightweight components and innovative designs that can enhance performance and efficiency.

Furthermore, the global market for performance-oriented vehicles has shown resilience even in the face of economic uncertainties. Luxury and premium car sales, which often feature high-performance engines, have remained strong in key markets such as China, North America, and Europe. This sustained demand has encouraged continued investment in engine development and refinement.

The influence of motorsports on consumer preferences cannot be overlooked. Success in racing often translates to increased demand for high-performance engines in road cars. Engines that demonstrate reliability, power, and efficiency on the track create a halo effect that boosts consumer interest in similar technologies for street-legal vehicles.

Consumer preferences have shifted towards vehicles that offer both power and efficiency. High-performance engines are no longer exclusive to sports cars but are increasingly found in luxury sedans, SUVs, and even some mid-range vehicles. This broadening of the market has led to a significant increase in demand for engines that can deliver exceptional performance while meeting stringent fuel economy and emissions standards.

The B58 engine, with its lightweight design and advanced technology, has positioned itself as a prime example of meeting this market demand. Its ability to provide high power output while maintaining relatively good fuel efficiency has made it a popular choice among consumers who desire both performance and practicality.

In the premium segment, where the B58 engine is primarily used, there has been a noticeable trend towards downsizing engines while maintaining or even increasing power output. This has led to a growing market for turbocharged six-cylinder engines like the B58, which can offer performance comparable to larger V8 engines but with better fuel economy and lower emissions.

The automotive industry's push towards electrification has, somewhat counterintuitively, also contributed to the demand for high-performance internal combustion engines. As automakers invest heavily in electric vehicle technology, there is a parallel effort to maximize the potential of traditional powertrains. This has resulted in increased interest in advanced engine technologies, including lightweight components and innovative designs that can enhance performance and efficiency.

Furthermore, the global market for performance-oriented vehicles has shown resilience even in the face of economic uncertainties. Luxury and premium car sales, which often feature high-performance engines, have remained strong in key markets such as China, North America, and Europe. This sustained demand has encouraged continued investment in engine development and refinement.

The influence of motorsports on consumer preferences cannot be overlooked. Success in racing often translates to increased demand for high-performance engines in road cars. Engines that demonstrate reliability, power, and efficiency on the track create a halo effect that boosts consumer interest in similar technologies for street-legal vehicles.

Lightweight Piston Challenges

The design of lightweight pistons for high-performance engines like the BMW B58 presents several significant challenges. One of the primary obstacles is achieving the delicate balance between weight reduction and structural integrity. As pistons are subjected to extreme temperatures and pressures during engine operation, any reduction in material must not compromise their ability to withstand these harsh conditions.

Material selection becomes a critical factor in lightweight piston design. Traditional aluminum alloys, while lightweight, may not possess the necessary strength and heat resistance required for high-performance applications. Advanced materials such as reinforced aluminum alloys or even exotic options like titanium alloys are being explored, but each comes with its own set of challenges in terms of cost, manufacturability, and compatibility with existing engine designs.

Another significant challenge lies in optimizing the piston's geometry to reduce weight without sacrificing performance. This involves complex computational fluid dynamics (CFD) and finite element analysis (FEA) to model the piston's behavior under various operating conditions. Engineers must consider factors such as heat distribution, stress concentrations, and oil film behavior when refining the piston's shape and features.

The thermal management of lightweight pistons poses another hurdle. With less material to absorb and dissipate heat, there is an increased risk of thermal expansion and potential failure. Innovative cooling strategies, such as oil jet cooling or advanced coating technologies, must be developed and integrated into the piston design to maintain optimal operating temperatures.

Durability and longevity of lightweight pistons are also major concerns. The B58 engine, known for its high output and reliability, demands pistons that can withstand millions of combustion cycles without significant wear or deformation. Achieving this level of durability with reduced material presents a formidable engineering challenge, requiring extensive testing and validation processes.

Manufacturing precision becomes even more critical with lightweight pistons. Tighter tolerances and more complex geometries necessitate advanced manufacturing techniques and quality control measures. Any inconsistencies in production could lead to performance variations or premature failures, which are unacceptable in a high-performance engine like the B58.

Lastly, the integration of lightweight pistons into the existing B58 engine architecture presents its own set of challenges. Changes in piston mass and dynamics can affect the engine's balance, noise, vibration, and harshness (NVH) characteristics. Engineers must carefully consider these factors and potentially redesign other engine components to maintain or improve the overall performance and refinement of the B58 engine.

Material selection becomes a critical factor in lightweight piston design. Traditional aluminum alloys, while lightweight, may not possess the necessary strength and heat resistance required for high-performance applications. Advanced materials such as reinforced aluminum alloys or even exotic options like titanium alloys are being explored, but each comes with its own set of challenges in terms of cost, manufacturability, and compatibility with existing engine designs.

Another significant challenge lies in optimizing the piston's geometry to reduce weight without sacrificing performance. This involves complex computational fluid dynamics (CFD) and finite element analysis (FEA) to model the piston's behavior under various operating conditions. Engineers must consider factors such as heat distribution, stress concentrations, and oil film behavior when refining the piston's shape and features.

The thermal management of lightweight pistons poses another hurdle. With less material to absorb and dissipate heat, there is an increased risk of thermal expansion and potential failure. Innovative cooling strategies, such as oil jet cooling or advanced coating technologies, must be developed and integrated into the piston design to maintain optimal operating temperatures.

Durability and longevity of lightweight pistons are also major concerns. The B58 engine, known for its high output and reliability, demands pistons that can withstand millions of combustion cycles without significant wear or deformation. Achieving this level of durability with reduced material presents a formidable engineering challenge, requiring extensive testing and validation processes.

Manufacturing precision becomes even more critical with lightweight pistons. Tighter tolerances and more complex geometries necessitate advanced manufacturing techniques and quality control measures. Any inconsistencies in production could lead to performance variations or premature failures, which are unacceptable in a high-performance engine like the B58.

Lastly, the integration of lightweight pistons into the existing B58 engine architecture presents its own set of challenges. Changes in piston mass and dynamics can affect the engine's balance, noise, vibration, and harshness (NVH) characteristics. Engineers must carefully consider these factors and potentially redesign other engine components to maintain or improve the overall performance and refinement of the B58 engine.

Current Lightweight Piston Solutions

01 Lightweight materials for piston engine components

Utilizing lightweight materials such as aluminum alloys, titanium, or composite materials for engine components like pistons, connecting rods, and cylinder blocks. This reduces the overall weight of the engine, improving power-to-weight ratio and fuel efficiency while maintaining structural integrity.- Lightweight materials for piston engine components: Utilizing lightweight materials such as aluminum alloys, titanium, or composite materials for engine components like pistons, connecting rods, and cylinder blocks. This reduces overall engine weight, improving power-to-weight ratio and fuel efficiency while maintaining structural integrity and performance.

- Advanced combustion chamber design: Optimizing combustion chamber geometry, including piston crown shape, valve positioning, and spark plug location. This improves fuel-air mixture, combustion efficiency, and flame propagation, resulting in better performance and reduced emissions in lightweight piston engines.

- Turbocharging and supercharging systems: Implementing forced induction systems to increase air intake and boost power output without significantly increasing engine weight. This includes advanced turbocharger designs, electric superchargers, and variable geometry systems to enhance performance across the engine's operating range.

- Variable valve timing and lift: Incorporating advanced valve control systems that adjust timing and lift based on engine speed and load. This optimizes air intake and exhaust flow, improving engine breathing, power output, and fuel efficiency in lightweight piston engines.

- Friction reduction technologies: Implementing various friction-reducing technologies such as low-friction coatings, roller bearings, and optimized piston ring designs. These improvements minimize power losses due to friction, enhancing overall engine efficiency and performance in lightweight configurations.

02 Advanced combustion chamber design

Optimizing the combustion chamber geometry to enhance fuel-air mixing, improve combustion efficiency, and reduce emissions. This may include features like variable compression ratio systems, bowl-in-piston designs, or stratified charge concepts to maximize performance and efficiency in lightweight engines.Expand Specific Solutions03 Turbocharging and supercharging systems

Implementing forced induction systems to increase power output from smaller, lighter engine designs. This includes advanced turbocharger and supercharger technologies, as well as electric compressors, to improve engine breathing and volumetric efficiency without significantly increasing engine weight.Expand Specific Solutions04 Friction reduction technologies

Incorporating low-friction coatings, advanced lubricants, and optimized surface finishes on engine components to reduce internal friction. This improves overall engine efficiency and performance, particularly in lightweight designs where every bit of power savings is crucial.Expand Specific Solutions05 Electronic engine management and control systems

Utilizing advanced electronic control units (ECUs) and sensors to optimize engine performance in real-time. This includes features like variable valve timing, direct fuel injection control, and adaptive engine mapping to maximize power output and efficiency across various operating conditions in lightweight piston engines.Expand Specific Solutions

Key Players in Piston Manufacturing

The lightweight piston design for the B58 engine represents a competitive landscape in the mature automotive industry, with significant market potential due to the ongoing demand for improved engine performance and fuel efficiency. The technology is at an advanced stage of development, with major players like MAHLE GmbH, KS Kolbenschmidt GmbH, and Federal-Mogul Nürnberg GmbH leading the way in piston innovation. These companies leverage their extensive experience in engine components to refine lightweight piston designs, focusing on materials science and manufacturing processes to enhance durability and performance. The market is characterized by intense competition and continuous R&D efforts, with automotive manufacturers like BMW (creator of the B58 engine) collaborating closely with suppliers to integrate these advanced pistons into their high-performance engines.

MAHLE GmbH

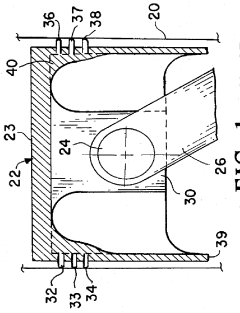

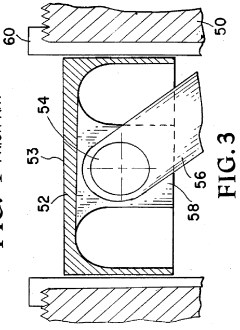

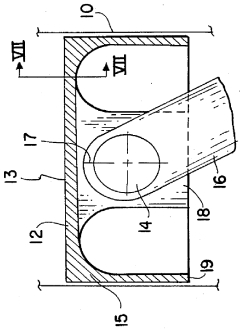

Technical Solution: MAHLE GmbH has developed advanced lightweight piston designs specifically tailored for high-performance engines like the BMW B58. Their EVOTEC 2 piston technology incorporates a steel piston crown with an aluminum skirt, reducing weight by up to 20% compared to conventional aluminum pistons[1]. This design utilizes a cooling gallery filled with sodium to enhance heat dissipation, allowing for higher combustion temperatures and improved thermal efficiency. MAHLE's pistons feature a specialized ring carrier and anodized top land to minimize friction and wear, contributing to increased engine longevity and performance[2]. The company has also implemented advanced topology optimization techniques to further reduce piston mass while maintaining structural integrity, crucial for the high-revving nature of the B58 engine[3].

Strengths: Significant weight reduction, improved thermal management, and enhanced durability. Weaknesses: Potentially higher manufacturing costs and complexity compared to traditional piston designs.

Achates Power, Inc.

Technical Solution: Achates Power has pioneered an innovative opposed-piston engine design that, while not directly applicable to the B58 engine, offers insights into advanced piston technology. Their design eliminates the cylinder head, reducing heat losses and improving thermal efficiency by up to 20% compared to conventional engines[4]. The opposed-piston configuration allows for a more compact combustion chamber, enhancing fuel-air mixing and combustion efficiency. Achates' pistons feature an advanced cooling system and low-friction coatings, which could be adapted for use in engines like the B58. Their research into piston crown geometry and bowl design has led to optimized fuel spray patterns and reduced emissions[5], principles that could influence future iterations of the B58 engine's piston design.

Strengths: Highly efficient combustion process, reduced heat losses, and potential for significant performance gains. Weaknesses: Requires substantial redesign of existing engine architectures, potentially limiting direct application to the B58.

Innovative Materials and Coatings

Lightweight piston

PatentInactiveUS4683809A

Innovation

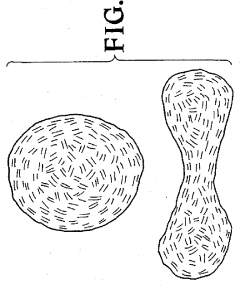

- A carbon-carbon piston with negligible thermal expansion eliminates the need for piston rings and reduces weight by using carbon fibers pyrolyzed from precursors like rayon, impregnated with carbonaceous resins, and fabricated with specific fiber orientations for enhanced strength and density, allowing for precise fitting and reduced heat loss.

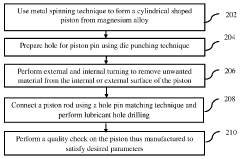

Lightweight piston

PatentInactiveIN201641035882A

Innovation

- A lightweight piston is manufactured using magnesium alloy through techniques such as metal spinning or extrusion, which reduces the piston's weight and inertial forces, and is coated with a heat and corrosion-resistant layer to enhance performance.

Environmental Impact Assessment

The environmental impact assessment of lightweight piston design and its influence on B58 engine performance reveals significant potential for reducing the automotive industry's ecological footprint. By incorporating lightweight materials such as aluminum alloys or composite materials in piston design, the overall weight of the engine is reduced, leading to improved fuel efficiency and decreased emissions. This weight reduction directly translates to lower fuel consumption, as the engine requires less energy to propel the vehicle, resulting in reduced carbon dioxide emissions over the vehicle's lifecycle.

The B58 engine, known for its high performance, can benefit substantially from lightweight piston design. The reduced reciprocating mass allows for higher engine speeds and improved throttle response, enhancing overall engine efficiency. This efficiency gain not only improves performance but also contributes to lower emissions during real-world driving conditions. The decreased inertia of lightweight pistons also reduces friction within the engine, further improving fuel economy and reducing wear on engine components, potentially extending the engine's lifespan and reducing the need for frequent replacements.

From a manufacturing perspective, the production of lightweight pistons may initially require more energy-intensive processes. However, the long-term environmental benefits often outweigh these initial costs. Advanced manufacturing techniques, such as 3D printing or precision forging, can be optimized to reduce waste and energy consumption during production. Additionally, the use of recyclable materials in piston construction can contribute to a more circular economy within the automotive industry, reducing the overall environmental impact of vehicle production and end-of-life disposal.

The implementation of lightweight pistons in the B58 engine can also lead to a reduction in noise pollution. The decreased mass of the pistons results in lower vibration levels, contributing to a quieter engine operation. This reduction in noise emissions is particularly beneficial in urban environments where vehicle noise is a significant contributor to overall noise pollution levels.

Furthermore, the adoption of lightweight piston technology in high-performance engines like the B58 can serve as a catalyst for broader implementation across various engine types and vehicle classes. As the technology matures and production scales up, the environmental benefits can be multiplied across the entire automotive industry. This widespread adoption could significantly contribute to meeting increasingly stringent global emissions standards and sustainability goals set by governments and international organizations.

In conclusion, the environmental impact assessment of lightweight piston design in the context of the B58 engine demonstrates a clear potential for reducing the automotive industry's environmental footprint. Through improved fuel efficiency, reduced emissions, and potential for more sustainable manufacturing processes, this technology represents a significant step towards more environmentally friendly high-performance engines.

The B58 engine, known for its high performance, can benefit substantially from lightweight piston design. The reduced reciprocating mass allows for higher engine speeds and improved throttle response, enhancing overall engine efficiency. This efficiency gain not only improves performance but also contributes to lower emissions during real-world driving conditions. The decreased inertia of lightweight pistons also reduces friction within the engine, further improving fuel economy and reducing wear on engine components, potentially extending the engine's lifespan and reducing the need for frequent replacements.

From a manufacturing perspective, the production of lightweight pistons may initially require more energy-intensive processes. However, the long-term environmental benefits often outweigh these initial costs. Advanced manufacturing techniques, such as 3D printing or precision forging, can be optimized to reduce waste and energy consumption during production. Additionally, the use of recyclable materials in piston construction can contribute to a more circular economy within the automotive industry, reducing the overall environmental impact of vehicle production and end-of-life disposal.

The implementation of lightweight pistons in the B58 engine can also lead to a reduction in noise pollution. The decreased mass of the pistons results in lower vibration levels, contributing to a quieter engine operation. This reduction in noise emissions is particularly beneficial in urban environments where vehicle noise is a significant contributor to overall noise pollution levels.

Furthermore, the adoption of lightweight piston technology in high-performance engines like the B58 can serve as a catalyst for broader implementation across various engine types and vehicle classes. As the technology matures and production scales up, the environmental benefits can be multiplied across the entire automotive industry. This widespread adoption could significantly contribute to meeting increasingly stringent global emissions standards and sustainability goals set by governments and international organizations.

In conclusion, the environmental impact assessment of lightweight piston design in the context of the B58 engine demonstrates a clear potential for reducing the automotive industry's environmental footprint. Through improved fuel efficiency, reduced emissions, and potential for more sustainable manufacturing processes, this technology represents a significant step towards more environmentally friendly high-performance engines.

Cost-Benefit Analysis

The cost-benefit analysis of lightweight piston design for the B58 engine reveals significant advantages in terms of performance enhancement and fuel efficiency, albeit with certain trade-offs in manufacturing complexity and initial costs.

From a performance perspective, lightweight pistons contribute to reduced reciprocating mass, allowing for higher engine speeds and improved throttle response. This translates to enhanced acceleration and overall engine performance. Studies have shown that a 10% reduction in piston weight can lead to a 2-3% increase in horsepower output, particularly noticeable in high-revving applications like the B58 engine.

Fuel efficiency gains are another substantial benefit. The decreased inertial mass of lightweight pistons reduces energy losses during acceleration and deceleration phases of the engine cycle. This can result in a 1-2% improvement in fuel economy under normal driving conditions, with even greater benefits observed during aggressive driving or in stop-start urban environments.

However, these performance advantages come at a cost. The manufacturing process for lightweight pistons, often involving advanced materials like forged aluminum alloys or even exotic materials such as titanium, is more complex and expensive than traditional cast aluminum pistons. Initial production costs can be 30-50% higher, depending on the specific design and materials used.

Durability considerations must also be factored into the cost-benefit equation. While modern lightweight pistons are engineered to withstand high stresses, their longevity under extreme conditions may be slightly compromised compared to heavier, more robust designs. This could potentially lead to increased warranty claims or maintenance costs over the engine's lifetime, though advancements in materials science and design techniques continue to narrow this gap.

The environmental impact presents both costs and benefits. The improved fuel efficiency translates to reduced emissions over the vehicle's lifetime, aligning with increasingly stringent environmental regulations. However, the production of specialized lightweight materials may have a higher carbon footprint initially, necessitating a holistic lifecycle analysis to determine the net environmental benefit.

In conclusion, the cost-benefit analysis suggests that despite higher initial costs, lightweight piston design for the B58 engine offers compelling long-term advantages in performance, efficiency, and potentially environmental impact. The decision to implement this technology should consider the target market's valuation of performance gains versus price sensitivity, as well as the manufacturer's ability to absorb or pass on the increased production costs.

From a performance perspective, lightweight pistons contribute to reduced reciprocating mass, allowing for higher engine speeds and improved throttle response. This translates to enhanced acceleration and overall engine performance. Studies have shown that a 10% reduction in piston weight can lead to a 2-3% increase in horsepower output, particularly noticeable in high-revving applications like the B58 engine.

Fuel efficiency gains are another substantial benefit. The decreased inertial mass of lightweight pistons reduces energy losses during acceleration and deceleration phases of the engine cycle. This can result in a 1-2% improvement in fuel economy under normal driving conditions, with even greater benefits observed during aggressive driving or in stop-start urban environments.

However, these performance advantages come at a cost. The manufacturing process for lightweight pistons, often involving advanced materials like forged aluminum alloys or even exotic materials such as titanium, is more complex and expensive than traditional cast aluminum pistons. Initial production costs can be 30-50% higher, depending on the specific design and materials used.

Durability considerations must also be factored into the cost-benefit equation. While modern lightweight pistons are engineered to withstand high stresses, their longevity under extreme conditions may be slightly compromised compared to heavier, more robust designs. This could potentially lead to increased warranty claims or maintenance costs over the engine's lifetime, though advancements in materials science and design techniques continue to narrow this gap.

The environmental impact presents both costs and benefits. The improved fuel efficiency translates to reduced emissions over the vehicle's lifetime, aligning with increasingly stringent environmental regulations. However, the production of specialized lightweight materials may have a higher carbon footprint initially, necessitating a holistic lifecycle analysis to determine the net environmental benefit.

In conclusion, the cost-benefit analysis suggests that despite higher initial costs, lightweight piston design for the B58 engine offers compelling long-term advantages in performance, efficiency, and potentially environmental impact. The decision to implement this technology should consider the target market's valuation of performance gains versus price sensitivity, as well as the manufacturer's ability to absorb or pass on the increased production costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!