Analyzing the B58 Engine's Nitrided Crankshaft Durability

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Crankshaft Evolution and Objectives

The B58 engine, developed by BMW, represents a significant evolution in inline-six engine design. Its crankshaft, a critical component, has undergone substantial improvements to enhance durability and performance. The evolution of the B58 crankshaft can be traced through several key stages, each marking a significant advancement in materials, manufacturing processes, and design optimization.

Initially, the B58 engine's crankshaft was manufactured using traditional forged steel, offering a balance between strength and cost-effectiveness. However, as performance demands increased, BMW engineers recognized the need for enhanced durability, particularly in high-stress applications such as motorsports and high-performance road cars.

The introduction of nitriding treatment marked a pivotal moment in the B58 crankshaft's evolution. This surface hardening process significantly improved wear resistance and fatigue strength, addressing the limitations of conventional forged steel crankshafts. Nitriding creates a hard, wear-resistant layer on the crankshaft's surface, effectively increasing its lifespan and ability to withstand higher loads.

Concurrent with material improvements, the B58 crankshaft design underwent refinements to optimize weight distribution and reduce rotational mass. These changes aimed to improve engine responsiveness and efficiency, crucial factors in modern high-performance engines. Advanced computer modeling and simulation techniques played a vital role in this process, allowing engineers to fine-tune the crankshaft's design for optimal performance and durability.

The primary objectives driving the B58 crankshaft's evolution include enhancing durability under extreme operating conditions, improving power transmission efficiency, and reducing friction losses. These goals align with broader industry trends towards increased power density and improved fuel efficiency in internal combustion engines.

Another key objective has been to extend the service life of the crankshaft, reducing maintenance requirements and improving overall engine reliability. This is particularly important given the B58 engine's application in a wide range of vehicles, from sports cars to luxury sedans, each with different usage patterns and performance expectations.

Looking forward, the continued evolution of the B58 crankshaft is likely to focus on further weight reduction without compromising strength, possibly through the exploration of advanced materials or innovative manufacturing techniques. Additionally, ongoing research into surface treatments and coatings may yield new ways to enhance the nitrided crankshaft's durability and performance characteristics.

Initially, the B58 engine's crankshaft was manufactured using traditional forged steel, offering a balance between strength and cost-effectiveness. However, as performance demands increased, BMW engineers recognized the need for enhanced durability, particularly in high-stress applications such as motorsports and high-performance road cars.

The introduction of nitriding treatment marked a pivotal moment in the B58 crankshaft's evolution. This surface hardening process significantly improved wear resistance and fatigue strength, addressing the limitations of conventional forged steel crankshafts. Nitriding creates a hard, wear-resistant layer on the crankshaft's surface, effectively increasing its lifespan and ability to withstand higher loads.

Concurrent with material improvements, the B58 crankshaft design underwent refinements to optimize weight distribution and reduce rotational mass. These changes aimed to improve engine responsiveness and efficiency, crucial factors in modern high-performance engines. Advanced computer modeling and simulation techniques played a vital role in this process, allowing engineers to fine-tune the crankshaft's design for optimal performance and durability.

The primary objectives driving the B58 crankshaft's evolution include enhancing durability under extreme operating conditions, improving power transmission efficiency, and reducing friction losses. These goals align with broader industry trends towards increased power density and improved fuel efficiency in internal combustion engines.

Another key objective has been to extend the service life of the crankshaft, reducing maintenance requirements and improving overall engine reliability. This is particularly important given the B58 engine's application in a wide range of vehicles, from sports cars to luxury sedans, each with different usage patterns and performance expectations.

Looking forward, the continued evolution of the B58 crankshaft is likely to focus on further weight reduction without compromising strength, possibly through the exploration of advanced materials or innovative manufacturing techniques. Additionally, ongoing research into surface treatments and coatings may yield new ways to enhance the nitrided crankshaft's durability and performance characteristics.

Market Demand for High-Performance Engines

The market demand for high-performance engines has been steadily increasing over the past decade, driven by a combination of factors including consumer preferences, technological advancements, and regulatory pressures. The B58 engine, with its nitrided crankshaft, represents a significant advancement in engine technology, catering to the growing demand for powerful yet efficient powertrains.

In the luxury and sports car segments, there is a persistent demand for engines that can deliver exceptional performance without compromising on fuel efficiency or reliability. The B58 engine, particularly its nitrided crankshaft, addresses these market needs by offering improved durability and performance characteristics. This aligns with the trend of downsizing engines while maintaining or increasing power output, a strategy adopted by many manufacturers to meet stringent emissions regulations without sacrificing performance.

The automotive industry has seen a shift towards turbocharged engines, with the B58 being a prime example. This trend is expected to continue, with the global market for turbocharged engines projected to grow significantly in the coming years. The durability of components like nitrided crankshafts becomes crucial in this context, as they need to withstand higher stresses and temperatures associated with forced induction.

Performance enthusiasts and aftermarket tuners represent another significant market segment driving demand for high-performance engines. These consumers often push engines beyond their stock capabilities, making the durability of critical components like crankshafts even more important. The B58's nitrided crankshaft offers potential for increased power output and longevity, making it attractive for this market segment.

Environmental concerns and stricter emissions standards are also shaping market demand. Consumers are increasingly looking for vehicles that offer high performance without excessive fuel consumption or emissions. The B58 engine's design, including its durable nitrided crankshaft, allows for a balance between power and efficiency, meeting both regulatory requirements and consumer expectations.

The commercial vehicle sector, particularly in the light-duty truck market, is another area where demand for high-performance engines is growing. Durability and reliability are paramount in this segment, making innovations like nitrided crankshafts particularly relevant. As businesses seek to improve fleet efficiency and reduce downtime, engines that offer both performance and longevity become increasingly attractive.

In emerging markets, there is a growing appetite for premium vehicles with advanced powertrains. The durability and performance characteristics of engines like the B58 with nitrided crankshafts align well with the expectations of consumers in these markets, who often prioritize reliability and prestige.

In the luxury and sports car segments, there is a persistent demand for engines that can deliver exceptional performance without compromising on fuel efficiency or reliability. The B58 engine, particularly its nitrided crankshaft, addresses these market needs by offering improved durability and performance characteristics. This aligns with the trend of downsizing engines while maintaining or increasing power output, a strategy adopted by many manufacturers to meet stringent emissions regulations without sacrificing performance.

The automotive industry has seen a shift towards turbocharged engines, with the B58 being a prime example. This trend is expected to continue, with the global market for turbocharged engines projected to grow significantly in the coming years. The durability of components like nitrided crankshafts becomes crucial in this context, as they need to withstand higher stresses and temperatures associated with forced induction.

Performance enthusiasts and aftermarket tuners represent another significant market segment driving demand for high-performance engines. These consumers often push engines beyond their stock capabilities, making the durability of critical components like crankshafts even more important. The B58's nitrided crankshaft offers potential for increased power output and longevity, making it attractive for this market segment.

Environmental concerns and stricter emissions standards are also shaping market demand. Consumers are increasingly looking for vehicles that offer high performance without excessive fuel consumption or emissions. The B58 engine's design, including its durable nitrided crankshaft, allows for a balance between power and efficiency, meeting both regulatory requirements and consumer expectations.

The commercial vehicle sector, particularly in the light-duty truck market, is another area where demand for high-performance engines is growing. Durability and reliability are paramount in this segment, making innovations like nitrided crankshafts particularly relevant. As businesses seek to improve fleet efficiency and reduce downtime, engines that offer both performance and longevity become increasingly attractive.

In emerging markets, there is a growing appetite for premium vehicles with advanced powertrains. The durability and performance characteristics of engines like the B58 with nitrided crankshafts align well with the expectations of consumers in these markets, who often prioritize reliability and prestige.

Nitrided Crankshaft Technology Status and Challenges

Nitrided crankshafts have become a cornerstone technology in high-performance engines, particularly in the B58 engine developed by BMW. The current status of this technology showcases significant advancements in durability and performance, yet it also faces several challenges that require ongoing research and development.

The nitriding process, which involves diffusing nitrogen into the surface layer of the crankshaft, has proven highly effective in enhancing wear resistance and fatigue strength. This has led to increased longevity of engine components, reduced friction, and improved overall engine efficiency. In the case of the B58 engine, the nitrided crankshaft has contributed to its reputation for reliability and power output.

However, the technology is not without its challenges. One of the primary issues is the depth of the nitrided layer. While current processes can achieve depths of up to 0.5mm, there is a constant push for deeper case depths to further improve durability. This is particularly crucial in high-stress applications like the B58 engine, where power outputs continue to increase.

Another significant challenge lies in the uniformity of the nitrided layer. Achieving consistent nitrogen diffusion across complex geometries, such as the crankshaft's journals and counterweights, remains a technical hurdle. Non-uniform nitriding can lead to localized weak points, potentially compromising the crankshaft's overall durability.

The nitriding process itself is time-consuming and energy-intensive, which presents both economic and environmental challenges. Researchers are actively seeking ways to optimize the process, reduce treatment times, and lower energy consumption without compromising the quality of the nitrided layer.

Material compatibility is another area of ongoing research. While nitriding works well with many steel alloys, finding the optimal base material that synergizes with the nitriding process to maximize durability is an active field of study. This is particularly relevant for the B58 engine's crankshaft, which must withstand high temperatures and stresses.

Lastly, as engines evolve to meet stricter emissions standards and performance demands, the nitriding process must adapt. There is a growing need for nitrided crankshafts that can withstand higher combustion pressures and temperatures, especially in turbocharged engines like the B58. This necessitates continuous refinement of the nitriding process and exploration of new nitriding techniques.

In conclusion, while nitrided crankshaft technology has made significant strides, particularly in applications like the B58 engine, it continues to face challenges in areas such as case depth, uniformity, process efficiency, material optimization, and adaptation to evolving engine designs. Addressing these challenges is crucial for the continued advancement of high-performance engine technology.

The nitriding process, which involves diffusing nitrogen into the surface layer of the crankshaft, has proven highly effective in enhancing wear resistance and fatigue strength. This has led to increased longevity of engine components, reduced friction, and improved overall engine efficiency. In the case of the B58 engine, the nitrided crankshaft has contributed to its reputation for reliability and power output.

However, the technology is not without its challenges. One of the primary issues is the depth of the nitrided layer. While current processes can achieve depths of up to 0.5mm, there is a constant push for deeper case depths to further improve durability. This is particularly crucial in high-stress applications like the B58 engine, where power outputs continue to increase.

Another significant challenge lies in the uniformity of the nitrided layer. Achieving consistent nitrogen diffusion across complex geometries, such as the crankshaft's journals and counterweights, remains a technical hurdle. Non-uniform nitriding can lead to localized weak points, potentially compromising the crankshaft's overall durability.

The nitriding process itself is time-consuming and energy-intensive, which presents both economic and environmental challenges. Researchers are actively seeking ways to optimize the process, reduce treatment times, and lower energy consumption without compromising the quality of the nitrided layer.

Material compatibility is another area of ongoing research. While nitriding works well with many steel alloys, finding the optimal base material that synergizes with the nitriding process to maximize durability is an active field of study. This is particularly relevant for the B58 engine's crankshaft, which must withstand high temperatures and stresses.

Lastly, as engines evolve to meet stricter emissions standards and performance demands, the nitriding process must adapt. There is a growing need for nitrided crankshafts that can withstand higher combustion pressures and temperatures, especially in turbocharged engines like the B58. This necessitates continuous refinement of the nitriding process and exploration of new nitriding techniques.

In conclusion, while nitrided crankshaft technology has made significant strides, particularly in applications like the B58 engine, it continues to face challenges in areas such as case depth, uniformity, process efficiency, material optimization, and adaptation to evolving engine designs. Addressing these challenges is crucial for the continued advancement of high-performance engine technology.

Current Nitriding Techniques for Crankshafts

01 Nitriding process for crankshaft durability

Nitriding is a surface hardening process applied to crankshafts to improve their durability and wear resistance. This process involves diffusing nitrogen into the surface of the crankshaft, creating a hard, wear-resistant layer. The nitrided surface enhances the crankshaft's ability to withstand high loads and reduces friction, ultimately improving the engine's performance and longevity.- Nitriding process for crankshaft durability: Nitriding is a surface hardening process applied to crankshafts to improve their durability and wear resistance. This process involves diffusing nitrogen into the surface of the crankshaft, creating a hard, wear-resistant layer. For B58 engines, nitriding can significantly enhance the crankshaft's ability to withstand high stresses and temperatures, thereby increasing its overall durability and lifespan.

- Crankshaft material selection: The choice of material for the crankshaft plays a crucial role in its durability. High-strength alloy steels are often used for B58 engine crankshafts, which can be further enhanced through nitriding. The material selection considers factors such as strength, toughness, and fatigue resistance to ensure optimal performance under the high-stress conditions experienced in the engine.

- Crankshaft design optimization: Optimizing the design of the crankshaft can significantly impact its durability. This includes considerations such as journal diameter, fillet radius, and overall geometry. Advanced computer-aided design and finite element analysis techniques are used to optimize the crankshaft's shape and structure, minimizing stress concentrations and improving overall durability, especially when combined with nitriding.

- Lubrication system improvements: Enhancing the lubrication system can contribute to the durability of nitrided crankshafts in B58 engines. This may involve optimizing oil flow paths, using high-performance lubricants, and implementing advanced filtration systems. Proper lubrication reduces friction and wear, complementing the benefits of nitriding and extending the crankshaft's lifespan.

- Quality control and testing: Implementing rigorous quality control measures and testing procedures is essential for ensuring the durability of nitrided crankshafts in B58 engines. This includes non-destructive testing methods, such as ultrasonic and magnetic particle inspection, as well as performance testing under simulated operating conditions. These processes help identify any potential defects or weaknesses in the crankshaft before it is installed in the engine.

02 Crankshaft material selection

The choice of material for the crankshaft plays a crucial role in its durability. High-strength alloy steels are often used for B58 engine crankshafts, as they provide excellent mechanical properties and respond well to nitriding. The material selection considers factors such as strength, toughness, and fatigue resistance to ensure optimal performance under the high stresses experienced in the engine.Expand Specific Solutions03 Crankshaft design optimization

The design of the crankshaft is optimized to enhance its durability. This includes considerations such as journal diameter, fillet radius, and counterweight design. Advanced computer-aided engineering tools are used to analyze stress distribution and optimize the crankshaft geometry, reducing stress concentrations and improving overall durability.Expand Specific Solutions04 Lubrication system improvements

Enhanced lubrication systems are implemented to improve crankshaft durability. This includes optimized oil passages, improved oil pump designs, and the use of high-performance lubricants. Proper lubrication reduces friction and wear on the crankshaft bearings, contributing to increased durability and longevity of the nitrided crankshaft.Expand Specific Solutions05 Quality control and testing

Rigorous quality control measures and testing procedures are implemented to ensure the durability of nitrided crankshafts. This includes non-destructive testing methods, such as ultrasonic and magnetic particle inspection, as well as fatigue testing and surface hardness measurements. These processes help identify any defects or inconsistencies in the nitriding process and ensure that the crankshafts meet the required durability standards.Expand Specific Solutions

Key Players in Engine and Crankshaft Manufacturing

The competition landscape for analyzing the B58 Engine's Nitrided Crankshaft Durability is in a mature stage, with established players and ongoing research. The market size is significant, given the importance of engine durability in the automotive industry. Technologically, the field is advanced but still evolving, with companies like Toyota Motor Corp., BMW, and Honda Motor Co., Ltd. leading in engine innovation. Specialized firms such as Maschinenfabrik ALFING Keßler GmbH and Tianrun Industry Technology Co., Ltd. contribute expertise in crankshaft manufacturing. Research institutions like Xi'an University of Technology and Bundesanstalt für Materialforschung und -prüfung are advancing the understanding of materials and testing methodologies, indicating ongoing technological development in this area.

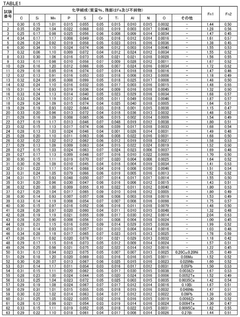

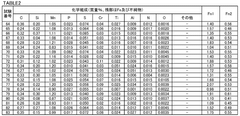

NIPPON STEEL CORP.

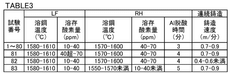

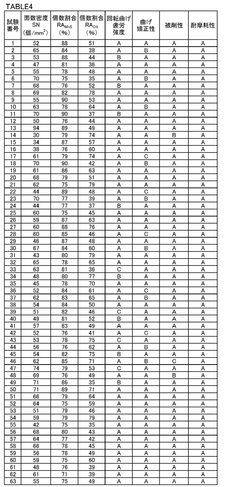

Technical Solution: Nippon Steel has developed advanced steel alloys and nitriding processes specifically tailored for high-performance engine components like crankshafts. Their approach involves a two-step nitriding process: first, a gas nitriding stage to create a deep diffusion zone, followed by a plasma nitriding stage to enhance surface properties [4]. This combination results in a graded microstructure with excellent wear resistance and fatigue strength. The company's proprietary steel compositions are optimized for nitriding, containing carefully controlled amounts of nitride-forming elements such as chromium, molybdenum, and vanadium [5]. These alloying elements promote the formation of fine, stable nitrides during the nitriding process, further enhancing the crankshaft's durability. Nippon Steel's process can achieve case depths of up to 0.6 mm, providing substantial improvement in fatigue life compared to conventional nitriding methods [6].

Strengths: Superior fatigue resistance, deep case depth, and tailored microstructure for optimal performance. The two-step process allows for better control of surface properties. Weaknesses: The complex process may result in higher production costs and longer processing times compared to single-stage nitriding.

JTEKT Corp.

Technical Solution: JTEKT Corporation, a leading supplier of automotive components, has developed an innovative approach to crankshaft nitriding that focuses on optimizing the nitriding process for large-scale production. Their method employs a controlled gas nitriding process with precise regulation of the nitriding potential (KN) throughout the treatment [7]. This approach allows for consistent and uniform nitriding across batches of crankshafts, ensuring reliable performance in high-volume production scenarios. JTEKT's process incorporates in-situ monitoring of the nitriding atmosphere composition and temperature, enabling real-time adjustments to maintain optimal nitriding conditions [8]. Additionally, the company has developed post-nitriding surface finishing techniques that further enhance the crankshaft's tribological properties, reducing friction and wear in critical bearing surfaces [9].

Strengths: High consistency and uniformity in large-scale production, excellent process control, and improved tribological properties. Weaknesses: May require significant capital investment in specialized equipment and monitoring systems.

Innovative Patents in Crankshaft Nitriding

Steel material and crankshaft formed of said steel material

PatentWO2022249349A1

Innovation

- A steel material with a specific chemical composition (C: 0.25-0.35%, Si: 0.05-0.35%, Mn: 0.85-1.20%, P: 0.080% or less, S: 0.030-0.100%, Cr: 0.10% or less, Ti: 0.050% or less, Al: 0.050% or less, N: 0.005-0.024%, and controlled inclusions) that, when subjected to nitriding, forms a nitrided layer with optimized hardness and inclusion distribution for improved bending fatigue strength, wear resistance, and machinability.

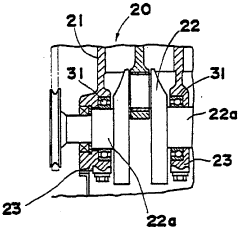

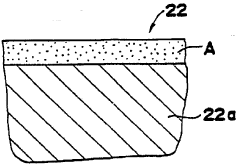

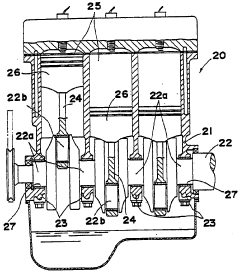

Crankshaft and method of manufacturing thereof

PatentWO1992008820A1

Innovation

- A hard nitride layer is formed on the surface of the crankshaft journal portion by heating it in a fluorine-based gas atmosphere to create a fluoride film, followed by nitriding, which enhances surface hardness without increasing material costs or weight, and ensures uniform nitriding by activating the surface before nitriding.

Environmental Impact of Nitriding Processes

The nitriding process used to enhance the durability of crankshafts in the B58 engine has significant environmental implications that warrant careful consideration. This surface hardening technique, while effective in improving component performance, involves the use of potentially hazardous materials and energy-intensive processes.

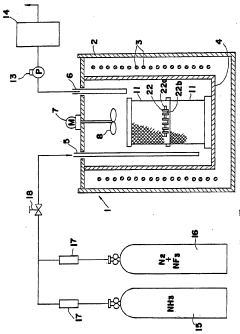

One of the primary environmental concerns associated with nitriding is the use of nitrogen-containing gases, such as ammonia. These gases can contribute to air pollution if not properly managed and controlled during the manufacturing process. Ammonia, in particular, is a known irritant and can have adverse effects on both human health and ecosystems if released into the environment.

The high temperatures required for the nitriding process also contribute to its environmental impact. Typically conducted at temperatures between 500°C and 550°C, the process consumes substantial amounts of energy, often derived from fossil fuel sources. This energy consumption translates to increased carbon emissions, contributing to the overall carbon footprint of engine manufacturing.

Waste management is another critical environmental aspect of the nitriding process. The treatment of spent nitriding salts and gases requires specialized disposal methods to prevent soil and water contamination. Improper handling of these waste products can lead to long-term environmental degradation and potential health risks for surrounding communities.

However, it is important to note that the environmental impact of nitriding should be balanced against its benefits in terms of engine durability and efficiency. The increased lifespan and improved performance of nitrided crankshafts can lead to reduced material consumption and waste generation over the long term, potentially offsetting some of the initial environmental costs.

Advancements in nitriding technologies are continually being developed to mitigate environmental concerns. Plasma nitriding, for instance, offers a more environmentally friendly alternative to traditional gas nitriding, with reduced gas consumption and lower processing temperatures. Similarly, the development of closed-loop systems for gas recycling and more efficient heating methods are helping to minimize the environmental footprint of the nitriding process.

As automotive manufacturers like BMW strive for greater sustainability, the environmental impact of manufacturing processes such as nitriding is likely to receive increased scrutiny. Future developments in this field may focus on further reducing energy consumption, minimizing hazardous waste production, and exploring alternative surface hardening techniques that offer comparable performance with reduced environmental impact.

One of the primary environmental concerns associated with nitriding is the use of nitrogen-containing gases, such as ammonia. These gases can contribute to air pollution if not properly managed and controlled during the manufacturing process. Ammonia, in particular, is a known irritant and can have adverse effects on both human health and ecosystems if released into the environment.

The high temperatures required for the nitriding process also contribute to its environmental impact. Typically conducted at temperatures between 500°C and 550°C, the process consumes substantial amounts of energy, often derived from fossil fuel sources. This energy consumption translates to increased carbon emissions, contributing to the overall carbon footprint of engine manufacturing.

Waste management is another critical environmental aspect of the nitriding process. The treatment of spent nitriding salts and gases requires specialized disposal methods to prevent soil and water contamination. Improper handling of these waste products can lead to long-term environmental degradation and potential health risks for surrounding communities.

However, it is important to note that the environmental impact of nitriding should be balanced against its benefits in terms of engine durability and efficiency. The increased lifespan and improved performance of nitrided crankshafts can lead to reduced material consumption and waste generation over the long term, potentially offsetting some of the initial environmental costs.

Advancements in nitriding technologies are continually being developed to mitigate environmental concerns. Plasma nitriding, for instance, offers a more environmentally friendly alternative to traditional gas nitriding, with reduced gas consumption and lower processing temperatures. Similarly, the development of closed-loop systems for gas recycling and more efficient heating methods are helping to minimize the environmental footprint of the nitriding process.

As automotive manufacturers like BMW strive for greater sustainability, the environmental impact of manufacturing processes such as nitriding is likely to receive increased scrutiny. Future developments in this field may focus on further reducing energy consumption, minimizing hazardous waste production, and exploring alternative surface hardening techniques that offer comparable performance with reduced environmental impact.

Cost-Benefit Analysis of Nitrided Crankshafts

The implementation of nitrided crankshafts in the B58 engine represents a significant technological advancement, but it also comes with associated costs and benefits that warrant careful analysis. From a financial perspective, the initial investment in nitriding equipment and process integration can be substantial for manufacturers. However, this upfront cost must be weighed against the long-term benefits of improved durability and performance.

Nitrided crankshafts offer enhanced wear resistance and fatigue strength, potentially extending the engine's lifespan and reducing maintenance costs over time. This improved durability can lead to fewer warranty claims and increased customer satisfaction, which may justify the higher production costs. Additionally, the superior surface hardness of nitrided crankshafts allows for tighter tolerances and improved overall engine efficiency, potentially resulting in better fuel economy and performance.

From a manufacturing standpoint, the nitriding process may increase production time and complexity. This could lead to higher labor costs and potentially slower production rates. However, these drawbacks may be offset by reduced material costs, as nitriding allows for the use of less expensive base materials while still achieving the desired mechanical properties.

Environmental considerations also play a role in the cost-benefit analysis. Nitrided crankshafts' increased durability can contribute to longer engine life, potentially reducing the environmental impact associated with premature engine replacements. However, the nitriding process itself may have environmental implications that need to be factored into the overall assessment.

Market positioning is another crucial aspect to consider. The use of nitrided crankshafts in the B58 engine may provide a competitive advantage, allowing manufacturers to differentiate their products in a crowded market. This could potentially command higher prices or increase market share, offsetting the additional production costs.

In terms of research and development, ongoing investments may be necessary to further optimize the nitriding process and explore new applications. While this represents an additional cost, it also presents opportunities for innovation and potential patents that could provide long-term value to the company.

Ultimately, the cost-benefit analysis of nitrided crankshafts in the B58 engine must consider both short-term financial impacts and long-term strategic advantages. While the initial costs may be higher, the potential for improved performance, durability, and market positioning could provide significant returns on investment over the engine's lifecycle.

Nitrided crankshafts offer enhanced wear resistance and fatigue strength, potentially extending the engine's lifespan and reducing maintenance costs over time. This improved durability can lead to fewer warranty claims and increased customer satisfaction, which may justify the higher production costs. Additionally, the superior surface hardness of nitrided crankshafts allows for tighter tolerances and improved overall engine efficiency, potentially resulting in better fuel economy and performance.

From a manufacturing standpoint, the nitriding process may increase production time and complexity. This could lead to higher labor costs and potentially slower production rates. However, these drawbacks may be offset by reduced material costs, as nitriding allows for the use of less expensive base materials while still achieving the desired mechanical properties.

Environmental considerations also play a role in the cost-benefit analysis. Nitrided crankshafts' increased durability can contribute to longer engine life, potentially reducing the environmental impact associated with premature engine replacements. However, the nitriding process itself may have environmental implications that need to be factored into the overall assessment.

Market positioning is another crucial aspect to consider. The use of nitrided crankshafts in the B58 engine may provide a competitive advantage, allowing manufacturers to differentiate their products in a crowded market. This could potentially command higher prices or increase market share, offsetting the additional production costs.

In terms of research and development, ongoing investments may be necessary to further optimize the nitriding process and explore new applications. While this represents an additional cost, it also presents opportunities for innovation and potential patents that could provide long-term value to the company.

Ultimately, the cost-benefit analysis of nitrided crankshafts in the B58 engine must consider both short-term financial impacts and long-term strategic advantages. While the initial costs may be higher, the potential for improved performance, durability, and market positioning could provide significant returns on investment over the engine's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!