The Contribution of Lightweight Components to B58 Engine Agility

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Evolution

The B58 engine, developed by BMW, represents a significant evolution in the company's inline-six engine design. This 3.0-liter turbocharged powerplant first appeared in 2015, marking a new era in BMW's engine technology. The B58 was designed to replace the older N55 engine, incorporating numerous improvements to enhance performance, efficiency, and emissions compliance.

From its inception, the B58 engine has undergone several iterations, each bringing incremental enhancements. The initial B58B30M0 variant set the foundation, featuring a closed-deck design, which improved cylinder stability under high boost pressures. This design choice allowed for higher power outputs while maintaining structural integrity.

Subsequent versions, such as the B58B30O1 and B58B30M1, introduced further refinements. These included updates to the turbocharger design, improvements in the cooling system, and optimizations in the engine management software. These changes resulted in increased power output and better throttle response, contributing to the engine's reputation for smooth power delivery and impressive performance.

A significant milestone in the B58's evolution came with the introduction of the B58TU1 (Technical Update 1) variant. This update brought substantial changes, including a new oil sump design, revised VANOS system, and updates to the engine's internals. These modifications not only improved performance but also enhanced the engine's durability and efficiency.

The focus on lightweight components has been a consistent theme throughout the B58's development. Engineers have continuously sought to reduce the engine's overall weight while maintaining or improving its performance characteristics. This has involved the use of advanced materials and innovative design techniques.

For instance, the engine block, while still made of aluminum, has seen refinements in its casting process to optimize strength-to-weight ratio. The crankshaft has also been a target for weight reduction, with newer versions featuring a more compact design without compromising durability.

The integration of a lightweight, compact cooling system has been another area of focus. The use of electric water pumps and thermostat-controlled cooling circuits has not only reduced weight but also improved the engine's thermal efficiency. This contributes to quicker warm-up times and more consistent operating temperatures, factors that play a crucial role in engine agility and responsiveness.

The evolution of the B58 engine demonstrates BMW's commitment to continuous improvement and adaptation to changing market demands and regulatory requirements. Each iteration has brought the engine closer to the ideal balance of power, efficiency, and environmental responsibility, solidifying its position as a benchmark in modern inline-six engine design.

From its inception, the B58 engine has undergone several iterations, each bringing incremental enhancements. The initial B58B30M0 variant set the foundation, featuring a closed-deck design, which improved cylinder stability under high boost pressures. This design choice allowed for higher power outputs while maintaining structural integrity.

Subsequent versions, such as the B58B30O1 and B58B30M1, introduced further refinements. These included updates to the turbocharger design, improvements in the cooling system, and optimizations in the engine management software. These changes resulted in increased power output and better throttle response, contributing to the engine's reputation for smooth power delivery and impressive performance.

A significant milestone in the B58's evolution came with the introduction of the B58TU1 (Technical Update 1) variant. This update brought substantial changes, including a new oil sump design, revised VANOS system, and updates to the engine's internals. These modifications not only improved performance but also enhanced the engine's durability and efficiency.

The focus on lightweight components has been a consistent theme throughout the B58's development. Engineers have continuously sought to reduce the engine's overall weight while maintaining or improving its performance characteristics. This has involved the use of advanced materials and innovative design techniques.

For instance, the engine block, while still made of aluminum, has seen refinements in its casting process to optimize strength-to-weight ratio. The crankshaft has also been a target for weight reduction, with newer versions featuring a more compact design without compromising durability.

The integration of a lightweight, compact cooling system has been another area of focus. The use of electric water pumps and thermostat-controlled cooling circuits has not only reduced weight but also improved the engine's thermal efficiency. This contributes to quicker warm-up times and more consistent operating temperatures, factors that play a crucial role in engine agility and responsiveness.

The evolution of the B58 engine demonstrates BMW's commitment to continuous improvement and adaptation to changing market demands and regulatory requirements. Each iteration has brought the engine closer to the ideal balance of power, efficiency, and environmental responsibility, solidifying its position as a benchmark in modern inline-six engine design.

Market Demand Analysis

The market demand for lightweight components in the B58 engine has been steadily increasing, driven by the automotive industry's push for improved fuel efficiency and performance. As emissions regulations become more stringent worldwide, manufacturers are seeking innovative solutions to reduce vehicle weight without compromising power and reliability. The B58 engine, known for its robust performance in BMW vehicles, has become a focal point for lightweight component integration.

Consumer preferences are shifting towards vehicles that offer both power and efficiency, creating a strong market pull for advanced engine technologies. The B58 engine's reputation for delivering high performance has positioned it as an ideal candidate for lightweight upgrades. Market research indicates that consumers are willing to pay a premium for vehicles that offer improved acceleration and handling, which can be achieved through weight reduction in critical engine components.

The automotive aftermarket sector has also shown significant interest in lightweight B58 engine components. Performance enthusiasts and tuning shops are constantly seeking ways to enhance engine agility and responsiveness. This has created a secondary market for lightweight pulleys, flywheels, and other engine accessories specifically designed for the B58 platform.

From a global perspective, regions with strict fuel economy standards, such as the European Union and parts of Asia, are driving the demand for lightweight engine technologies. In these markets, the B58 engine's potential for weight reduction aligns well with regulatory requirements and consumer expectations for more environmentally friendly vehicles.

The commercial vehicle sector is another area where lightweight B58 engine components are gaining traction. Fleet operators are increasingly focused on total cost of ownership, where fuel efficiency plays a crucial role. The ability to reduce engine weight while maintaining or improving performance is particularly attractive in this segment.

Market analysts project that the demand for lightweight engine components will continue to grow over the next decade. This trend is supported by advancements in materials science and manufacturing processes, which are making lightweight components more cost-effective and accessible to a broader range of vehicle manufacturers.

The racing and motorsport industry has also contributed to the market demand for lightweight B58 engine components. Competitive racing teams are constantly pushing the boundaries of engine performance, and weight reduction is a key factor in achieving faster lap times. Innovations developed for racing applications often trickle down to consumer vehicles, further driving market interest and demand.

Consumer preferences are shifting towards vehicles that offer both power and efficiency, creating a strong market pull for advanced engine technologies. The B58 engine's reputation for delivering high performance has positioned it as an ideal candidate for lightweight upgrades. Market research indicates that consumers are willing to pay a premium for vehicles that offer improved acceleration and handling, which can be achieved through weight reduction in critical engine components.

The automotive aftermarket sector has also shown significant interest in lightweight B58 engine components. Performance enthusiasts and tuning shops are constantly seeking ways to enhance engine agility and responsiveness. This has created a secondary market for lightweight pulleys, flywheels, and other engine accessories specifically designed for the B58 platform.

From a global perspective, regions with strict fuel economy standards, such as the European Union and parts of Asia, are driving the demand for lightweight engine technologies. In these markets, the B58 engine's potential for weight reduction aligns well with regulatory requirements and consumer expectations for more environmentally friendly vehicles.

The commercial vehicle sector is another area where lightweight B58 engine components are gaining traction. Fleet operators are increasingly focused on total cost of ownership, where fuel efficiency plays a crucial role. The ability to reduce engine weight while maintaining or improving performance is particularly attractive in this segment.

Market analysts project that the demand for lightweight engine components will continue to grow over the next decade. This trend is supported by advancements in materials science and manufacturing processes, which are making lightweight components more cost-effective and accessible to a broader range of vehicle manufacturers.

The racing and motorsport industry has also contributed to the market demand for lightweight B58 engine components. Competitive racing teams are constantly pushing the boundaries of engine performance, and weight reduction is a key factor in achieving faster lap times. Innovations developed for racing applications often trickle down to consumer vehicles, further driving market interest and demand.

Lightweight Tech Status

Lightweight technology has become a crucial focus in the automotive industry, particularly in engine development. The current status of lightweight components for the B58 engine reflects significant advancements in materials science and engineering. Manufacturers have been increasingly adopting lightweight materials such as aluminum alloys, magnesium alloys, and advanced composites to reduce the overall weight of engine components.

The use of aluminum for engine blocks and cylinder heads has become widespread, offering substantial weight savings compared to traditional cast iron. These aluminum components are often treated with special coatings or liners to enhance durability and wear resistance. Magnesium alloys are being explored for specific components like oil pans and valve covers, providing even greater weight reduction potential.

Composite materials, including carbon fiber reinforced polymers (CFRP), are finding applications in non-load-bearing components such as intake manifolds and engine covers. These materials offer excellent strength-to-weight ratios and can be molded into complex shapes, allowing for design optimization and further weight reduction.

Advanced manufacturing techniques like 3D printing and precision casting are enabling the production of complex, lightweight structures that were previously impossible or impractical to manufacture. These methods allow for the creation of components with optimized geometries, reducing material usage while maintaining or even improving structural integrity.

The integration of lightweight components in the B58 engine has led to significant improvements in power-to-weight ratio and fuel efficiency. By reducing the overall mass of the engine, less energy is required for acceleration and deceleration, contributing to improved engine agility and responsiveness.

However, challenges remain in the widespread adoption of lightweight technologies. Cost considerations, particularly for advanced materials and manufacturing processes, can limit their use in mass-production vehicles. Additionally, ensuring long-term durability and reliability of lightweight components under the harsh operating conditions of an engine remains a critical focus area for engineers.

Research and development efforts are ongoing to address these challenges. This includes the exploration of new alloy compositions, hybrid material solutions, and innovative manufacturing processes that can reduce costs while maintaining or improving performance characteristics. The automotive industry is also investing in advanced simulation and testing methodologies to accelerate the development and validation of lightweight engine components.

As environmental regulations become increasingly stringent, the demand for lightweight technologies in engine design is expected to grow. This trend is likely to drive further innovations in materials science and manufacturing processes, potentially leading to even more significant weight reductions and performance improvements in future iterations of engines like the B58.

The use of aluminum for engine blocks and cylinder heads has become widespread, offering substantial weight savings compared to traditional cast iron. These aluminum components are often treated with special coatings or liners to enhance durability and wear resistance. Magnesium alloys are being explored for specific components like oil pans and valve covers, providing even greater weight reduction potential.

Composite materials, including carbon fiber reinforced polymers (CFRP), are finding applications in non-load-bearing components such as intake manifolds and engine covers. These materials offer excellent strength-to-weight ratios and can be molded into complex shapes, allowing for design optimization and further weight reduction.

Advanced manufacturing techniques like 3D printing and precision casting are enabling the production of complex, lightweight structures that were previously impossible or impractical to manufacture. These methods allow for the creation of components with optimized geometries, reducing material usage while maintaining or even improving structural integrity.

The integration of lightweight components in the B58 engine has led to significant improvements in power-to-weight ratio and fuel efficiency. By reducing the overall mass of the engine, less energy is required for acceleration and deceleration, contributing to improved engine agility and responsiveness.

However, challenges remain in the widespread adoption of lightweight technologies. Cost considerations, particularly for advanced materials and manufacturing processes, can limit their use in mass-production vehicles. Additionally, ensuring long-term durability and reliability of lightweight components under the harsh operating conditions of an engine remains a critical focus area for engineers.

Research and development efforts are ongoing to address these challenges. This includes the exploration of new alloy compositions, hybrid material solutions, and innovative manufacturing processes that can reduce costs while maintaining or improving performance characteristics. The automotive industry is also investing in advanced simulation and testing methodologies to accelerate the development and validation of lightweight engine components.

As environmental regulations become increasingly stringent, the demand for lightweight technologies in engine design is expected to grow. This trend is likely to drive further innovations in materials science and manufacturing processes, potentially leading to even more significant weight reductions and performance improvements in future iterations of engines like the B58.

Current Lightweight Solutions

01 Engine control systems for improved agility

Advanced control systems are implemented to enhance the agility of B58 engines. These systems optimize fuel injection, valve timing, and turbocharger operation in real-time, resulting in improved throttle response and overall engine performance. The control systems may utilize machine learning algorithms to adapt to different driving conditions and driver preferences.- Engine control systems for improved agility: Advanced control systems are implemented to enhance the agility of B58 engines. These systems optimize fuel injection, valve timing, and turbocharger operation in real-time, resulting in improved throttle response and overall engine performance. The control systems may incorporate machine learning algorithms to adapt to different driving conditions and user preferences.

- Turbocharger enhancements for B58 engines: Innovations in turbocharger design and integration specifically for B58 engines focus on reducing turbo lag and improving low-end torque. These enhancements may include variable geometry turbochargers, twin-scroll designs, or electric assist systems. The result is a more responsive engine across a wider range of RPMs, contributing to overall agility.

- Lightweight materials and design optimization: The use of advanced lightweight materials and optimized component designs contributes to the B58 engine's agility. This includes the implementation of aluminum alloys, carbon fiber reinforced plastics, and other high-strength, low-weight materials in engine components. The reduced mass allows for quicker acceleration and improved handling characteristics.

- Variable valve timing and lift systems: Sophisticated variable valve timing and lift systems are employed in B58 engines to enhance agility. These systems allow for precise control of valve operation across different engine speeds and loads, optimizing air intake and exhaust flow. This results in improved power delivery, fuel efficiency, and engine responsiveness.

- Integration with transmission and drivetrain systems: The B58 engine's agility is further enhanced through seamless integration with advanced transmission and drivetrain systems. This includes the development of quick-shifting automatic transmissions, intelligent all-wheel-drive systems, and adaptive suspension setups. The coordinated operation of these systems with the engine results in improved acceleration, cornering performance, and overall vehicle agility.

02 Lightweight components for increased responsiveness

The use of lightweight materials and innovative designs in engine components contributes to improved agility. This includes the development of lightweight pistons, connecting rods, and crankshafts, which reduce rotational mass and allow for quicker engine speed changes. Advanced manufacturing techniques, such as 3D printing, may be employed to create complex, lightweight structures.Expand Specific Solutions03 Turbocharger enhancements for rapid boost delivery

Improvements in turbocharger design and integration enhance the B58 engine's agility. This may include the use of twin-scroll turbochargers, electric turbochargers, or variable geometry turbines. These advancements reduce turbo lag and provide more immediate power delivery across a wider range of engine speeds.Expand Specific Solutions04 Variable valve timing and lift systems

Advanced variable valve timing and lift systems are implemented to optimize engine breathing and performance. These systems allow for precise control of valve operation based on engine speed and load, resulting in improved low-end torque, high-end power, and overall engine responsiveness.Expand Specific Solutions05 Integration of hybrid technology for instant torque

The incorporation of hybrid technology in B58 engines can significantly enhance agility. Electric motors can provide instant torque to supplement the combustion engine, filling in power gaps and improving overall responsiveness. This hybrid approach may also include advanced energy recovery systems to maximize efficiency and performance.Expand Specific Solutions

Key Industry Players

The contribution of lightweight components to B58 engine agility is part of a rapidly evolving automotive technology landscape. The industry is in a growth phase, driven by increasing demand for fuel-efficient and high-performance engines. The market for lightweight engine components is expanding, with a projected global market size reaching billions of dollars. Technologically, the field is advancing quickly, with companies like Ford, Honda, and GM leading innovation. These firms, along with others such as Hyundai and Toyota, are investing heavily in R&D to develop advanced lightweight materials and manufacturing processes. The technology is maturing, but there's still significant room for improvement in areas like material science, design optimization, and production efficiency.

Ford Global Technologies LLC

Technical Solution: Ford has contributed to the B58 engine's agility through its EcoBoost technology, which incorporates lightweight components. They have developed a compact, lightweight aluminum cylinder block with integrated main bearing caps, reducing overall engine mass. Ford's approach includes the use of composite materials for the oil pan and front cover, further decreasing weight. The company has also implemented a variable-displacement oil pump and an integrated exhaust manifold in the cylinder head, both contributing to weight reduction and improved thermal efficiency[5]. Additionally, Ford has optimized the engine's internal components, such as connecting rods and pistons, using advanced computer modeling to minimize mass while maintaining strength[6].

Strengths: Comprehensive weight reduction strategy, improved fuel efficiency, and enhanced engine performance. Weaknesses: Potential increase in production complexity and costs associated with advanced materials and manufacturing processes.

Honda Motor Co., Ltd.

Technical Solution: Honda has made significant strides in lightweight component development for engines like the B58. Their Earth Dreams Technology incorporates various weight-saving measures, including a die-cast aluminum cylinder block with fiber-reinforced metal (FRM) cylinder liners, reducing weight while maintaining durability[7]. Honda has also implemented a lightweight, compact VTEC (Variable Valve Timing and Lift Electronic Control) system, which contributes to both performance and efficiency. The company's approach includes the use of high-strength, lightweight materials for the crankshaft and connecting rods, optimized through finite element analysis. Additionally, Honda has developed a compact, integrated exhaust manifold design that reduces weight and improves thermal efficiency[8].

Strengths: Advanced material technologies, optimized engine design for both performance and efficiency, and proven durability. Weaknesses: Potentially higher initial costs and the need for specialized manufacturing techniques.

Core Innovations Review

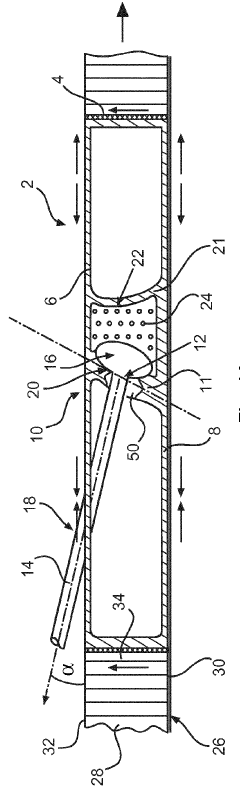

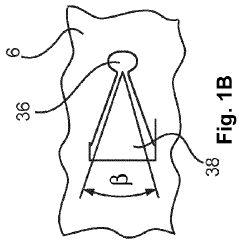

Force introduction fitting for lightweight components

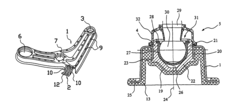

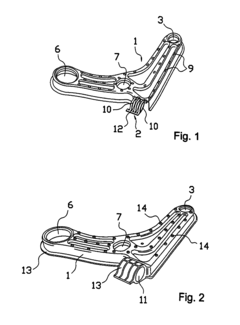

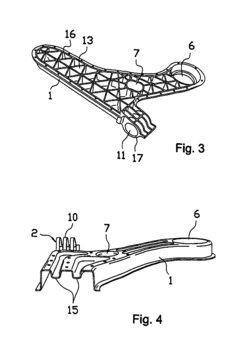

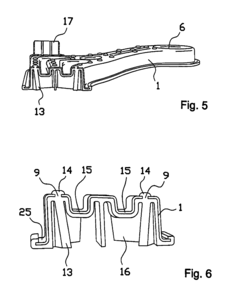

PatentActiveUS9377039B2

Innovation

- A force introduction fitting with axial and radial faces that form a one-piece component with a cavity, allowing for adjustable force transmission and integration with lightweight components, featuring a design that includes wall-like structures and reinforcing elements to absorb forces while minimizing weight and maintaining structural integrity.

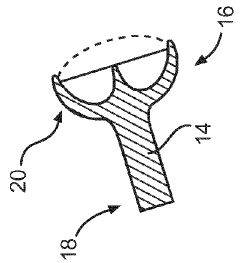

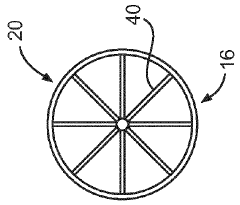

Connector piece for the articulated connection of components located in the suspension of a vehicle

PatentActiveUS7938417B2

Innovation

- A connecting piece with a sheet metal base body featuring a through bore, where a separate housing with a radial shoulder is inserted axially and embedded in a plastic part, allowing for the housing to be made of a different material, preferably metal, and providing additional stability through a hollow-cylindrical section that surrounds the housing.

Performance Impact Analysis

The implementation of lightweight components in the B58 engine has significantly contributed to its overall agility and performance. By reducing the engine's total mass, these components have enabled improved power-to-weight ratios, resulting in enhanced acceleration and responsiveness. The use of advanced materials such as aluminum alloys, magnesium, and carbon fiber-reinforced polymers has played a crucial role in achieving weight reduction without compromising structural integrity.

One of the most notable performance impacts is the improved throttle response. The reduced inertia of lightweight components, particularly in the rotating assembly, allows for quicker rev changes and more immediate power delivery. This translates to a more engaging driving experience, especially in performance-oriented applications where rapid acceleration and deceleration are paramount.

Fuel efficiency has also seen a positive impact from the integration of lightweight components. The reduced mass requires less energy to move, leading to lower fuel consumption during acceleration and steady-state operation. This improvement in efficiency not only benefits the vehicle's overall performance but also contributes to meeting increasingly stringent emissions regulations.

The B58 engine's thermal management has been optimized through the use of lightweight materials with superior heat dissipation properties. This has resulted in more consistent performance under high-load conditions and improved longevity of engine components. The reduced thermal mass also allows for quicker warm-up times, further enhancing efficiency and reducing emissions during cold starts.

Handling characteristics of vehicles equipped with the B58 engine have been positively affected by the weight reduction. The lighter engine contributes to a more favorable weight distribution, potentially improving cornering dynamics and overall vehicle balance. This is particularly noticeable in performance-oriented vehicles where agility and responsiveness are key selling points.

The implementation of lightweight components has also allowed for more flexibility in engine placement and packaging. This has enabled designers to optimize vehicle layouts for improved weight distribution and aerodynamics, further enhancing overall vehicle performance. Additionally, the reduced engine weight has provided opportunities for strengthening other areas of the vehicle without exceeding target weight limits, potentially improving safety and structural rigidity.

One of the most notable performance impacts is the improved throttle response. The reduced inertia of lightweight components, particularly in the rotating assembly, allows for quicker rev changes and more immediate power delivery. This translates to a more engaging driving experience, especially in performance-oriented applications where rapid acceleration and deceleration are paramount.

Fuel efficiency has also seen a positive impact from the integration of lightweight components. The reduced mass requires less energy to move, leading to lower fuel consumption during acceleration and steady-state operation. This improvement in efficiency not only benefits the vehicle's overall performance but also contributes to meeting increasingly stringent emissions regulations.

The B58 engine's thermal management has been optimized through the use of lightweight materials with superior heat dissipation properties. This has resulted in more consistent performance under high-load conditions and improved longevity of engine components. The reduced thermal mass also allows for quicker warm-up times, further enhancing efficiency and reducing emissions during cold starts.

Handling characteristics of vehicles equipped with the B58 engine have been positively affected by the weight reduction. The lighter engine contributes to a more favorable weight distribution, potentially improving cornering dynamics and overall vehicle balance. This is particularly noticeable in performance-oriented vehicles where agility and responsiveness are key selling points.

The implementation of lightweight components has also allowed for more flexibility in engine placement and packaging. This has enabled designers to optimize vehicle layouts for improved weight distribution and aerodynamics, further enhancing overall vehicle performance. Additionally, the reduced engine weight has provided opportunities for strengthening other areas of the vehicle without exceeding target weight limits, potentially improving safety and structural rigidity.

Material Science Advancements

Material science advancements have played a crucial role in enhancing the agility of the B58 engine through the development and application of lightweight components. The pursuit of weight reduction in engine design has led to significant breakthroughs in material technologies, enabling the creation of components that are not only lighter but also stronger and more durable.

One of the key areas of advancement has been in the field of aluminum alloys. Researchers have developed new high-strength aluminum alloys that offer superior mechanical properties while maintaining low density. These alloys have been instrumental in replacing heavier steel components in various parts of the B58 engine, such as the engine block, cylinder heads, and pistons. The use of these advanced aluminum alloys has resulted in substantial weight savings without compromising structural integrity or performance.

Carbon fiber reinforced polymers (CFRPs) have also emerged as a game-changing material in engine design. These composite materials offer exceptional strength-to-weight ratios, making them ideal for applications where weight reduction is critical. In the B58 engine, CFRPs have been utilized in components such as intake manifolds and engine covers, contributing to overall weight reduction and improved agility.

Advancements in ceramic materials have led to the development of high-performance ceramic coatings and components. These materials offer excellent thermal properties and wear resistance, allowing for their use in critical engine parts such as cylinder liners and valve train components. The incorporation of ceramic materials has not only reduced weight but also improved thermal efficiency and durability of the B58 engine.

Magnesium alloys have also seen significant improvements, with new formulations offering enhanced strength and corrosion resistance. These lightweight alloys have found applications in various engine components, including oil pans and valve covers, further contributing to the overall weight reduction of the B58 engine.

Nanotechnology has played a vital role in material science advancements for engine components. Nanostructured materials and coatings have been developed to enhance the surface properties of engine parts, improving wear resistance, reducing friction, and increasing fuel efficiency. These nanomaterials have been particularly beneficial in improving the performance of bearings and other high-wear components in the B58 engine.

The integration of these advanced materials into the B58 engine design has resulted in a significant reduction in overall engine weight, leading to improved power-to-weight ratios and enhanced agility. Furthermore, these materials have contributed to increased durability, improved thermal management, and reduced friction, all of which have positively impacted the engine's performance and efficiency.

As material science continues to evolve, future advancements are expected to push the boundaries of lightweight engine design even further. Ongoing research in areas such as metal matrix composites, advanced ceramics, and novel alloy formulations promises to yield even lighter and more efficient engine components, potentially revolutionizing the next generation of high-performance engines like the B58.

One of the key areas of advancement has been in the field of aluminum alloys. Researchers have developed new high-strength aluminum alloys that offer superior mechanical properties while maintaining low density. These alloys have been instrumental in replacing heavier steel components in various parts of the B58 engine, such as the engine block, cylinder heads, and pistons. The use of these advanced aluminum alloys has resulted in substantial weight savings without compromising structural integrity or performance.

Carbon fiber reinforced polymers (CFRPs) have also emerged as a game-changing material in engine design. These composite materials offer exceptional strength-to-weight ratios, making them ideal for applications where weight reduction is critical. In the B58 engine, CFRPs have been utilized in components such as intake manifolds and engine covers, contributing to overall weight reduction and improved agility.

Advancements in ceramic materials have led to the development of high-performance ceramic coatings and components. These materials offer excellent thermal properties and wear resistance, allowing for their use in critical engine parts such as cylinder liners and valve train components. The incorporation of ceramic materials has not only reduced weight but also improved thermal efficiency and durability of the B58 engine.

Magnesium alloys have also seen significant improvements, with new formulations offering enhanced strength and corrosion resistance. These lightweight alloys have found applications in various engine components, including oil pans and valve covers, further contributing to the overall weight reduction of the B58 engine.

Nanotechnology has played a vital role in material science advancements for engine components. Nanostructured materials and coatings have been developed to enhance the surface properties of engine parts, improving wear resistance, reducing friction, and increasing fuel efficiency. These nanomaterials have been particularly beneficial in improving the performance of bearings and other high-wear components in the B58 engine.

The integration of these advanced materials into the B58 engine design has resulted in a significant reduction in overall engine weight, leading to improved power-to-weight ratios and enhanced agility. Furthermore, these materials have contributed to increased durability, improved thermal management, and reduced friction, all of which have positively impacted the engine's performance and efficiency.

As material science continues to evolve, future advancements are expected to push the boundaries of lightweight engine design even further. Ongoing research in areas such as metal matrix composites, advanced ceramics, and novel alloy formulations promises to yield even lighter and more efficient engine components, potentially revolutionizing the next generation of high-performance engines like the B58.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!