Exploring Seamless Shifting Dynamics with B58 and ZF Transmission

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 and ZF Evolution

The B58 engine and ZF transmission have undergone significant evolution since their inception, marking key milestones in automotive engineering. The B58, a 3.0-liter inline-six turbocharged engine developed by BMW, was introduced in 2015 as a successor to the N55 engine. It represented a leap forward in terms of power output, efficiency, and emissions compliance.

Initially, the B58 was designed to meet Euro 6 emissions standards while delivering improved performance. The first generation, known as B58B30M0, featured a closed-deck design, which enhanced structural rigidity and allowed for higher boost pressures. This version produced up to 340 horsepower and 500 Nm of torque, depending on the application.

As environmental regulations tightened, BMW introduced the B58TU1 (Technical Update 1) in 2019. This update brought significant changes, including a new particulate filter to meet stricter emissions standards. The engine also received a revised turbocharger and cooling system, resulting in power outputs of up to 382 horsepower in some models.

Concurrently, ZF Friedrichshafen AG has been refining its transmission technology to complement the advancements in engine design. The ZF 8HP series, an eight-speed automatic transmission, has been a popular choice for pairing with the B58 engine. Introduced in 2008, the ZF 8HP has seen several iterations, each improving on shift quality, efficiency, and integration with hybrid powertrains.

The ZF 8HP50 was one of the earlier versions used with the B58, offering smooth shifts and improved fuel economy compared to its predecessors. As the B58 evolved, so did the transmission. The ZF 8HP75 was introduced to handle higher torque outputs, featuring strengthened internals and revised software for faster, more precise shifts.

In recent years, both the B58 engine and ZF transmission have embraced electrification. The B58 has been adapted for use in plug-in hybrid vehicles, working in tandem with electric motors to provide enhanced performance and efficiency. Similarly, ZF has developed hybrid-compatible versions of its transmissions, such as the 8HP75h, which integrates an electric motor for mild-hybrid applications.

The latest iterations of both components focus on seamless integration of power delivery and gear changes. Advanced electronic controls and machine learning algorithms have been implemented to predict driver behavior and optimize shift patterns. This evolution has resulted in powertrains that offer not only improved performance and efficiency but also a more refined driving experience.

Initially, the B58 was designed to meet Euro 6 emissions standards while delivering improved performance. The first generation, known as B58B30M0, featured a closed-deck design, which enhanced structural rigidity and allowed for higher boost pressures. This version produced up to 340 horsepower and 500 Nm of torque, depending on the application.

As environmental regulations tightened, BMW introduced the B58TU1 (Technical Update 1) in 2019. This update brought significant changes, including a new particulate filter to meet stricter emissions standards. The engine also received a revised turbocharger and cooling system, resulting in power outputs of up to 382 horsepower in some models.

Concurrently, ZF Friedrichshafen AG has been refining its transmission technology to complement the advancements in engine design. The ZF 8HP series, an eight-speed automatic transmission, has been a popular choice for pairing with the B58 engine. Introduced in 2008, the ZF 8HP has seen several iterations, each improving on shift quality, efficiency, and integration with hybrid powertrains.

The ZF 8HP50 was one of the earlier versions used with the B58, offering smooth shifts and improved fuel economy compared to its predecessors. As the B58 evolved, so did the transmission. The ZF 8HP75 was introduced to handle higher torque outputs, featuring strengthened internals and revised software for faster, more precise shifts.

In recent years, both the B58 engine and ZF transmission have embraced electrification. The B58 has been adapted for use in plug-in hybrid vehicles, working in tandem with electric motors to provide enhanced performance and efficiency. Similarly, ZF has developed hybrid-compatible versions of its transmissions, such as the 8HP75h, which integrates an electric motor for mild-hybrid applications.

The latest iterations of both components focus on seamless integration of power delivery and gear changes. Advanced electronic controls and machine learning algorithms have been implemented to predict driver behavior and optimize shift patterns. This evolution has resulted in powertrains that offer not only improved performance and efficiency but also a more refined driving experience.

Market Demand Analysis

The market demand for seamless shifting dynamics in B58 engines and ZF transmissions has been steadily growing, driven by the automotive industry's pursuit of enhanced performance, fuel efficiency, and driver comfort. This demand is particularly pronounced in the premium and luxury vehicle segments, where consumers expect smooth and responsive driving experiences.

In recent years, there has been a significant shift towards more sophisticated transmission systems that can seamlessly integrate with high-performance engines like the B58. The global automotive transmission market, which includes advanced systems compatible with B58 engines, is projected to expand at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is largely attributed to the increasing adoption of automatic and dual-clutch transmissions in premium vehicles.

The B58 engine, known for its robust performance and efficiency, has created a niche market for transmission systems that can effectively harness its power. ZF Friedrichshafen AG, a leading manufacturer of transmission systems, has seen an uptick in demand for their advanced transmissions that pair well with the B58 engine. This demand is not limited to a single automotive brand but spans across multiple premium car manufacturers who utilize the B58 engine in their lineups.

Consumer preferences are also shaping the market demand for seamless shifting dynamics. Drivers are increasingly valuing smooth gear transitions, quick acceleration, and improved fuel economy – all of which can be achieved through the optimal pairing of B58 engines with advanced ZF transmissions. This trend is particularly evident in markets such as North America, Europe, and China, where premium vehicle sales continue to grow.

Furthermore, the push towards electrification and hybrid powertrains has created a new dimension in the market for seamless shifting dynamics. Hybrid vehicles that combine the B58 engine with electric motors require sophisticated transmission systems to manage power distribution effectively. This has opened up new opportunities for innovation in transmission technology, driving further demand for advanced solutions.

The aftermarket sector has also shown significant interest in upgrading transmission systems for B58-equipped vehicles. Performance enthusiasts and tuning shops are seeking ways to enhance the shifting dynamics of these powertrains, creating a secondary market for high-performance transmission components and software upgrades.

As environmental regulations become more stringent, the demand for transmissions that can optimize engine performance while reducing emissions has intensified. This has led to increased research and development efforts in creating more efficient and responsive transmission systems that can work in harmony with engines like the B58 to meet both performance and environmental standards.

In recent years, there has been a significant shift towards more sophisticated transmission systems that can seamlessly integrate with high-performance engines like the B58. The global automotive transmission market, which includes advanced systems compatible with B58 engines, is projected to expand at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is largely attributed to the increasing adoption of automatic and dual-clutch transmissions in premium vehicles.

The B58 engine, known for its robust performance and efficiency, has created a niche market for transmission systems that can effectively harness its power. ZF Friedrichshafen AG, a leading manufacturer of transmission systems, has seen an uptick in demand for their advanced transmissions that pair well with the B58 engine. This demand is not limited to a single automotive brand but spans across multiple premium car manufacturers who utilize the B58 engine in their lineups.

Consumer preferences are also shaping the market demand for seamless shifting dynamics. Drivers are increasingly valuing smooth gear transitions, quick acceleration, and improved fuel economy – all of which can be achieved through the optimal pairing of B58 engines with advanced ZF transmissions. This trend is particularly evident in markets such as North America, Europe, and China, where premium vehicle sales continue to grow.

Furthermore, the push towards electrification and hybrid powertrains has created a new dimension in the market for seamless shifting dynamics. Hybrid vehicles that combine the B58 engine with electric motors require sophisticated transmission systems to manage power distribution effectively. This has opened up new opportunities for innovation in transmission technology, driving further demand for advanced solutions.

The aftermarket sector has also shown significant interest in upgrading transmission systems for B58-equipped vehicles. Performance enthusiasts and tuning shops are seeking ways to enhance the shifting dynamics of these powertrains, creating a secondary market for high-performance transmission components and software upgrades.

As environmental regulations become more stringent, the demand for transmissions that can optimize engine performance while reducing emissions has intensified. This has led to increased research and development efforts in creating more efficient and responsive transmission systems that can work in harmony with engines like the B58 to meet both performance and environmental standards.

Technical Challenges

The integration of the B58 engine with the ZF transmission presents several technical challenges in achieving seamless shifting dynamics. One of the primary obstacles is the synchronization of engine output with transmission gear changes. The B58, known for its rapid power delivery, requires precise timing to match its torque curve with the ZF transmission's shift points, ensuring smooth transitions between gears.

Another significant challenge lies in managing the heat generated during high-performance driving scenarios. The B58's turbocharged configuration can produce substantial heat, which needs to be effectively dissipated to maintain optimal transmission fluid temperatures. Failure to address this issue could lead to premature wear of transmission components and degraded shift quality over time.

The electronic control systems of both the engine and transmission must be harmonized to achieve seamless operation. This involves complex algorithms that predict driver intentions, road conditions, and vehicle dynamics to preemptively adjust shift patterns. The challenge here is to create a responsive yet unobtrusive system that enhances the driving experience without feeling artificial or delayed.

Durability and reliability under various driving conditions pose another set of challenges. The transmission must be capable of handling the B58's power output across a wide range of scenarios, from daily commuting to high-performance track use. This requires advanced materials and manufacturing techniques to ensure longevity without compromising shift quality or efficiency.

Weight distribution and packaging constraints also present technical hurdles. The combination of the B58 engine and ZF transmission must be optimized to maintain ideal weight balance for vehicle dynamics while fitting within the confines of modern vehicle architectures. This often necessitates creative engineering solutions to accommodate both components without compromising performance or interior space.

Fuel efficiency and emissions regulations add another layer of complexity to the integration process. The transmission must be tuned to maximize the B58's efficiency potential, often requiring a delicate balance between performance and economy. This includes implementing advanced features such as coasting modes and intelligent shift strategies that adapt to driving conditions and emissions requirements.

Lastly, the challenge of achieving consistent performance across different vehicle platforms cannot be overlooked. As the B58 and ZF transmission combination may be used in various models, engineers must develop adaptable solutions that can be fine-tuned for specific vehicle characteristics while maintaining core performance attributes. This requires extensive testing and calibration across a diverse range of vehicle types and driving scenarios.

Another significant challenge lies in managing the heat generated during high-performance driving scenarios. The B58's turbocharged configuration can produce substantial heat, which needs to be effectively dissipated to maintain optimal transmission fluid temperatures. Failure to address this issue could lead to premature wear of transmission components and degraded shift quality over time.

The electronic control systems of both the engine and transmission must be harmonized to achieve seamless operation. This involves complex algorithms that predict driver intentions, road conditions, and vehicle dynamics to preemptively adjust shift patterns. The challenge here is to create a responsive yet unobtrusive system that enhances the driving experience without feeling artificial or delayed.

Durability and reliability under various driving conditions pose another set of challenges. The transmission must be capable of handling the B58's power output across a wide range of scenarios, from daily commuting to high-performance track use. This requires advanced materials and manufacturing techniques to ensure longevity without compromising shift quality or efficiency.

Weight distribution and packaging constraints also present technical hurdles. The combination of the B58 engine and ZF transmission must be optimized to maintain ideal weight balance for vehicle dynamics while fitting within the confines of modern vehicle architectures. This often necessitates creative engineering solutions to accommodate both components without compromising performance or interior space.

Fuel efficiency and emissions regulations add another layer of complexity to the integration process. The transmission must be tuned to maximize the B58's efficiency potential, often requiring a delicate balance between performance and economy. This includes implementing advanced features such as coasting modes and intelligent shift strategies that adapt to driving conditions and emissions requirements.

Lastly, the challenge of achieving consistent performance across different vehicle platforms cannot be overlooked. As the B58 and ZF transmission combination may be used in various models, engineers must develop adaptable solutions that can be fine-tuned for specific vehicle characteristics while maintaining core performance attributes. This requires extensive testing and calibration across a diverse range of vehicle types and driving scenarios.

Current Shifting Tech

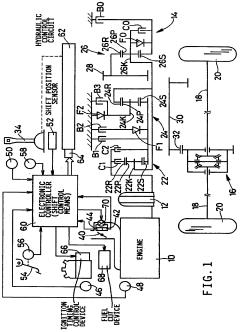

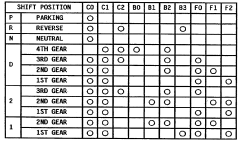

01 Engine and transmission integration

The integration of the B58 engine with ZF transmission involves optimizing the shifting dynamics for improved performance and efficiency. This includes developing control strategies that consider both engine and transmission characteristics to achieve smooth gear changes and optimal power delivery.- Engine and transmission integration for optimal shifting: Integration of the B58 engine with ZF transmission systems to optimize shifting dynamics. This involves coordinating engine output with transmission gear changes for smoother transitions and improved performance. Advanced control algorithms are used to predict and adapt to driving conditions, ensuring optimal gear selection and shift timing.

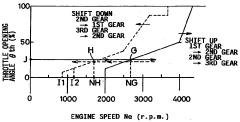

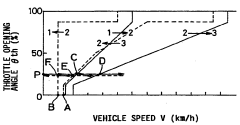

- Adaptive shift strategies for ZF transmissions: Development of adaptive shift strategies specifically for ZF transmissions paired with the B58 engine. These strategies analyze various parameters such as driving style, road conditions, and vehicle load to adjust shift points and characteristics in real-time. This results in improved fuel efficiency, performance, and driver comfort.

- Torque management during gear shifts: Implementation of advanced torque management techniques during gear shifts to enhance the overall driving experience. This involves precise control of engine torque output during shift events to minimize shift shock and improve shift quality. The system may also incorporate features like torque smoothing and torque fill to maintain consistent acceleration during gear changes.

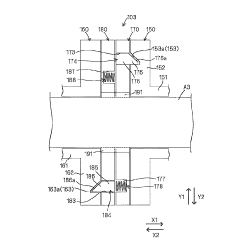

- Multi-clutch technology for faster shifts: Utilization of multi-clutch technology in ZF transmissions to achieve faster and more efficient gear shifts when paired with the B58 engine. This technology allows for pre-selection of the next gear, reducing shift times and improving overall transmission response. The system may also incorporate advanced clutch control strategies to optimize shift smoothness and durability.

- Integration of engine start-stop functionality: Integration of engine start-stop functionality with the B58 engine and ZF transmission combination to improve fuel efficiency in urban driving conditions. This involves developing specialized control strategies to manage the engine restart process and ensure smooth engagement of the transmission. The system may also incorporate predictive algorithms to anticipate when the engine needs to restart based on driver behavior and traffic conditions.

02 Adaptive shift control

Adaptive shift control systems are implemented to adjust shifting patterns based on driving conditions, driver behavior, and vehicle load. These systems continuously learn and adapt to optimize shift points and timing, enhancing the overall driving experience and fuel efficiency.Expand Specific Solutions03 Torque management during gear shifts

Advanced torque management techniques are employed to maintain smooth power delivery during gear shifts. This involves precise control of engine torque output and transmission clutch engagement to minimize shift shock and improve overall drivability.Expand Specific Solutions04 Multi-mode transmission operation

The ZF transmission offers multiple operating modes to cater to different driving scenarios. These modes may include sport, eco, and manual shift options, each with unique shift patterns and response characteristics tailored to the B58 engine's performance profile.Expand Specific Solutions05 Shift quality optimization

Continuous efforts are made to optimize shift quality through advanced control algorithms and mechanical improvements. This includes fine-tuning shift timing, pressure control, and synchronization to achieve seamless gear changes across various driving conditions.Expand Specific Solutions

Key Industry Players

The exploration of seamless shifting dynamics with B58 and ZF transmission is currently in a mature development stage, with significant market potential in the automotive industry. The global transmission market size is substantial, driven by increasing demand for fuel-efficient vehicles. Technologically, this field is well-established, with key players like ZF Friedrichshafen AG, JATCO Ltd., and Aisin Ai Co., Ltd. leading innovation. These companies have extensive experience in developing advanced transmission systems, integrating cutting-edge technologies to enhance performance and efficiency. The competitive landscape is characterized by ongoing research and development efforts to improve shifting dynamics, fuel economy, and overall driving experience.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a new 10-speed automatic transmission that could potentially be adapted for use with engines similar to BMW's B58. This transmission employs a low-friction design and a compact, lightweight architecture[4]. Honda's system utilizes close-ratio gears for the lower gears to enhance acceleration, while higher gears are more widely spaced to improve fuel efficiency at cruising speeds. The transmission also features a new electric oil pump that reduces parasitic losses and improves overall efficiency[5]. Honda has implemented advanced shift logic that uses real-time data from various vehicle sensors to predict and execute optimal shift patterns[6].

Strengths: High number of gears for optimal power delivery and efficiency, advanced shift logic for improved performance. Weaknesses: Increased complexity compared to transmissions with fewer gears, potential for higher production costs.

Zeroshift Ltd.

Technical Solution: Zeroshift Ltd. has developed an innovative transmission technology that could potentially revolutionize the seamless shifting dynamics for engines like the BMW B58. Their patented design eliminates torque interruption during gear changes, providing truly continuous power delivery[13]. The Zeroshift system uses specially designed gear selector mechanisms that allow two gears to be engaged simultaneously during the shift process, ensuring that power is always being transmitted[14]. This technology can be adapted to various transmission types, including manual, automated manual, and dual-clutch transmissions. Zeroshift claims their system can reduce shift times to as low as 60 milliseconds while improving fuel efficiency by up to 5% compared to conventional automatics[15].

Strengths: Eliminates torque interruption, extremely fast shift times, and potential for improved fuel efficiency. Weaknesses: May require significant modifications to existing transmission designs for implementation, potentially increasing complexity and cost.

Core Innovations

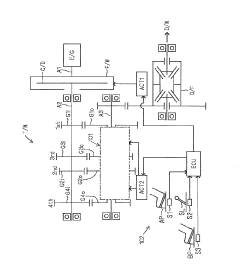

Shift control apparatus for shifting up transmission upon re-acceleration following deceleration of vehicle

PatentInactiveUS5393278A

Innovation

- A shift control apparatus that includes judging means to determine if a predetermined time has elapsed since the low-speed gear position was established during deceleration, detector means to sense the driver's acceleration operation, and shift-up means to transition from the low-speed to high-speed gear position when acceleration is detected, thereby reducing engine racing time. Additionally, idling speed control raises the engine idling speed when additional loads are applied, shifting the shift-down point to prevent prolonged engine racing.

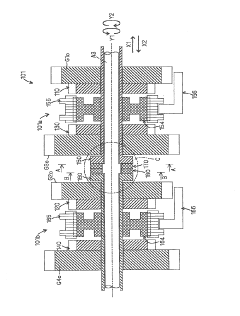

Transmission for vehicle

PatentInactiveJP2014062565A

Innovation

- A vehicle transmission mechanism with a plurality of gear stages, including fixed and idle gears, engaging members, movable members, and a clutch mechanism, allows for seamless shifting by controlling the engagement and disengagement of these components to transition between low-speed, high-speed, and intermediate modes.

Fuel Efficiency Impact

The integration of the B58 engine with the ZF transmission in modern vehicles has significant implications for fuel efficiency. This combination leverages advanced technologies to optimize power delivery and minimize energy losses, resulting in improved overall fuel economy.

The B58 engine, known for its robust performance and efficiency, incorporates several fuel-saving features. Its closed-deck design and precision cooling system allow for higher compression ratios, enhancing thermal efficiency. The engine's direct injection system, coupled with variable valve timing, ensures optimal fuel mixture and combustion across various operating conditions.

When paired with the ZF transmission, particularly the 8-speed automatic variant, the system's efficiency is further amplified. The transmission's wide gear spread enables the engine to operate in its most efficient range more frequently. Lower engine speeds during cruising, facilitated by the transmission's higher gears, contribute to reduced fuel consumption on highways.

The seamless shifting dynamics of this powertrain combination play a crucial role in fuel efficiency. Rapid and smooth gear changes minimize power interruptions, maintaining momentum and reducing the energy required to accelerate back to speed. This is particularly beneficial in urban driving scenarios with frequent stop-start conditions.

Advanced electronic control units in both the engine and transmission continuously optimize their operation based on driving conditions. These systems analyze factors such as throttle position, vehicle speed, and load to select the most efficient gear and engine operating point. This real-time adaptation ensures that the powertrain operates at peak efficiency across various driving scenarios.

The B58 and ZF transmission combination also benefits from weight reduction efforts. The use of lightweight materials in both components helps to decrease overall vehicle mass, which directly translates to improved fuel economy. Additionally, the compact design of the ZF transmission contributes to better weight distribution and reduced parasitic losses.

Regenerative braking systems, often integrated with this powertrain setup, further enhance fuel efficiency by recapturing energy during deceleration. This recovered energy can be used to power vehicle electrical systems, reducing the load on the engine and improving overall efficiency.

In summary, the synergy between the B58 engine and ZF transmission creates a highly efficient powertrain that significantly impacts fuel economy. Through advanced technologies, seamless operation, and intelligent control systems, this combination exemplifies the ongoing efforts in automotive engineering to maximize fuel efficiency without compromising performance.

The B58 engine, known for its robust performance and efficiency, incorporates several fuel-saving features. Its closed-deck design and precision cooling system allow for higher compression ratios, enhancing thermal efficiency. The engine's direct injection system, coupled with variable valve timing, ensures optimal fuel mixture and combustion across various operating conditions.

When paired with the ZF transmission, particularly the 8-speed automatic variant, the system's efficiency is further amplified. The transmission's wide gear spread enables the engine to operate in its most efficient range more frequently. Lower engine speeds during cruising, facilitated by the transmission's higher gears, contribute to reduced fuel consumption on highways.

The seamless shifting dynamics of this powertrain combination play a crucial role in fuel efficiency. Rapid and smooth gear changes minimize power interruptions, maintaining momentum and reducing the energy required to accelerate back to speed. This is particularly beneficial in urban driving scenarios with frequent stop-start conditions.

Advanced electronic control units in both the engine and transmission continuously optimize their operation based on driving conditions. These systems analyze factors such as throttle position, vehicle speed, and load to select the most efficient gear and engine operating point. This real-time adaptation ensures that the powertrain operates at peak efficiency across various driving scenarios.

The B58 and ZF transmission combination also benefits from weight reduction efforts. The use of lightweight materials in both components helps to decrease overall vehicle mass, which directly translates to improved fuel economy. Additionally, the compact design of the ZF transmission contributes to better weight distribution and reduced parasitic losses.

Regenerative braking systems, often integrated with this powertrain setup, further enhance fuel efficiency by recapturing energy during deceleration. This recovered energy can be used to power vehicle electrical systems, reducing the load on the engine and improving overall efficiency.

In summary, the synergy between the B58 engine and ZF transmission creates a highly efficient powertrain that significantly impacts fuel economy. Through advanced technologies, seamless operation, and intelligent control systems, this combination exemplifies the ongoing efforts in automotive engineering to maximize fuel efficiency without compromising performance.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of seamless shifting dynamics for the B58 engine and ZF transmission. As automotive technologies continue to advance, manufacturers must navigate an increasingly complex landscape of regulations and standards to ensure their products meet legal requirements and consumer expectations.

In the context of the B58 engine and ZF transmission, compliance with emissions regulations is of paramount importance. Stringent standards set by various regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards, dictate the acceptable levels of pollutants that can be emitted from vehicles. The seamless shifting technology must be designed and calibrated to optimize fuel efficiency and minimize emissions across all driving conditions.

Safety regulations also significantly impact the development of seamless shifting dynamics. Regulatory bodies like the National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP) establish guidelines for vehicle safety, including aspects related to transmission performance. The seamless shifting system must demonstrate reliability and predictability in various driving scenarios to comply with these safety standards.

Furthermore, noise regulations come into play when considering the acoustic characteristics of the B58 engine and ZF transmission combination. Many jurisdictions have specific limits on vehicle noise levels, and the seamless shifting technology must be engineered to operate within these constraints while still delivering a satisfying driving experience.

Compliance with fuel economy standards is another critical aspect of regulatory considerations. Agencies such as the Corporate Average Fuel Economy (CAFE) in the US set targets for manufacturers' fleet-wide fuel efficiency. The seamless shifting dynamics of the B58 and ZF transmission must contribute to meeting these targets by optimizing gear ratios and shift points for maximum efficiency.

As autonomous driving features become more prevalent, regulatory frameworks are evolving to address the integration of these technologies. The seamless shifting system may need to interface with autonomous driving systems, requiring compliance with emerging regulations governing vehicle automation and connectivity.

Lastly, data privacy and cybersecurity regulations are increasingly relevant as vehicles become more connected. The electronic control units managing the seamless shifting dynamics must be designed with robust security measures to protect against potential cyber threats and comply with data protection laws such as the General Data Protection Regulation (GDPR) in the European Union.

In the context of the B58 engine and ZF transmission, compliance with emissions regulations is of paramount importance. Stringent standards set by various regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards, dictate the acceptable levels of pollutants that can be emitted from vehicles. The seamless shifting technology must be designed and calibrated to optimize fuel efficiency and minimize emissions across all driving conditions.

Safety regulations also significantly impact the development of seamless shifting dynamics. Regulatory bodies like the National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP) establish guidelines for vehicle safety, including aspects related to transmission performance. The seamless shifting system must demonstrate reliability and predictability in various driving scenarios to comply with these safety standards.

Furthermore, noise regulations come into play when considering the acoustic characteristics of the B58 engine and ZF transmission combination. Many jurisdictions have specific limits on vehicle noise levels, and the seamless shifting technology must be engineered to operate within these constraints while still delivering a satisfying driving experience.

Compliance with fuel economy standards is another critical aspect of regulatory considerations. Agencies such as the Corporate Average Fuel Economy (CAFE) in the US set targets for manufacturers' fleet-wide fuel efficiency. The seamless shifting dynamics of the B58 and ZF transmission must contribute to meeting these targets by optimizing gear ratios and shift points for maximum efficiency.

As autonomous driving features become more prevalent, regulatory frameworks are evolving to address the integration of these technologies. The seamless shifting system may need to interface with autonomous driving systems, requiring compliance with emerging regulations governing vehicle automation and connectivity.

Lastly, data privacy and cybersecurity regulations are increasingly relevant as vehicles become more connected. The electronic control units managing the seamless shifting dynamics must be designed with robust security measures to protect against potential cyber threats and comply with data protection laws such as the General Data Protection Regulation (GDPR) in the European Union.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!