B58 Engine Aerodynamics: Innovations in Thermal Efficiency

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Evolution

The B58 engine, developed by BMW, has undergone significant evolution since its introduction. This inline-six turbocharged engine has been a cornerstone of BMW's powertrain strategy, continuously improving in performance, efficiency, and emissions compliance.

Initially introduced in 2015, the B58 engine was designed as a successor to the N55 engine. It featured a closed-deck design, which provided increased structural rigidity and allowed for higher boost pressures. The first generation B58 engines displaced 3.0 liters and utilized a single twin-scroll turbocharger, direct fuel injection, and BMW's Valvetronic variable valve lift system.

As emissions regulations tightened globally, BMW implemented several key improvements to the B58 engine. In 2019, the B58TU1 (Technical Update 1) was introduced, incorporating a gasoline particulate filter to meet Euro 6d-TEMP standards. This update also saw the integration of a more efficient cooling system and revised turbocharger design, resulting in improved thermal management and reduced turbo lag.

The most recent iteration, the B58TU2, debuted in 2022. This version features a significant overhaul of the engine's internals, including a reinforced crankshaft, updated pistons, and optimized combustion chambers. These changes allowed for an increase in maximum boost pressure and a higher compression ratio, contributing to both improved performance and efficiency.

Throughout its evolution, the B58 engine has seen advancements in its aerodynamic design, particularly in the realm of thermal efficiency. Engineers have focused on optimizing airflow both externally and internally to manage heat more effectively. This includes redesigned intake and exhaust systems to reduce flow restrictions and improve scavenging.

One of the most notable aerodynamic innovations in the B58's evolution is the implementation of an advanced air-to-liquid intercooler system. This compact design, integrated into the intake plenum, allows for more efficient charge air cooling compared to traditional air-to-air intercoolers. The result is improved throttle response and sustained performance under high-load conditions.

The B58's evolution also showcases BMW's commitment to reducing friction and improving overall engine efficiency. This is evident in the adoption of low-friction coatings on cylinder walls and piston skirts, as well as the implementation of an electric water pump and map-controlled oil pump, which optimize coolant and oil flow based on engine load and speed.

Initially introduced in 2015, the B58 engine was designed as a successor to the N55 engine. It featured a closed-deck design, which provided increased structural rigidity and allowed for higher boost pressures. The first generation B58 engines displaced 3.0 liters and utilized a single twin-scroll turbocharger, direct fuel injection, and BMW's Valvetronic variable valve lift system.

As emissions regulations tightened globally, BMW implemented several key improvements to the B58 engine. In 2019, the B58TU1 (Technical Update 1) was introduced, incorporating a gasoline particulate filter to meet Euro 6d-TEMP standards. This update also saw the integration of a more efficient cooling system and revised turbocharger design, resulting in improved thermal management and reduced turbo lag.

The most recent iteration, the B58TU2, debuted in 2022. This version features a significant overhaul of the engine's internals, including a reinforced crankshaft, updated pistons, and optimized combustion chambers. These changes allowed for an increase in maximum boost pressure and a higher compression ratio, contributing to both improved performance and efficiency.

Throughout its evolution, the B58 engine has seen advancements in its aerodynamic design, particularly in the realm of thermal efficiency. Engineers have focused on optimizing airflow both externally and internally to manage heat more effectively. This includes redesigned intake and exhaust systems to reduce flow restrictions and improve scavenging.

One of the most notable aerodynamic innovations in the B58's evolution is the implementation of an advanced air-to-liquid intercooler system. This compact design, integrated into the intake plenum, allows for more efficient charge air cooling compared to traditional air-to-air intercoolers. The result is improved throttle response and sustained performance under high-load conditions.

The B58's evolution also showcases BMW's commitment to reducing friction and improving overall engine efficiency. This is evident in the adoption of low-friction coatings on cylinder walls and piston skirts, as well as the implementation of an electric water pump and map-controlled oil pump, which optimize coolant and oil flow based on engine load and speed.

Market Demand Analysis

The market demand for innovations in B58 engine aerodynamics and thermal efficiency is driven by several key factors in the automotive industry. As emissions regulations become increasingly stringent worldwide, manufacturers are under pressure to improve fuel economy and reduce carbon footprints. This has led to a growing demand for more efficient internal combustion engines, particularly in the premium and performance vehicle segments where the B58 engine is commonly used.

Consumer preferences are also shifting towards vehicles that offer both performance and efficiency. The B58 engine, known for its robust power output, is now expected to deliver improved fuel economy without compromising on performance. This dual demand creates a significant market opportunity for aerodynamic and thermal efficiency innovations.

In the luxury car market, where the B58 engine is prevalent, there is a notable trend towards electrification. However, many manufacturers are adopting a hybrid approach, combining electric motors with highly efficient internal combustion engines. This strategy maintains the appeal of traditional powertrains while meeting emissions targets, further driving the need for advanced engine technologies.

The aftermarket tuning industry also contributes to the demand for B58 engine innovations. Performance enthusiasts seek ways to extract more power and efficiency from their vehicles, creating a secondary market for advanced aerodynamic and thermal management solutions.

Geographically, the demand is particularly strong in regions with a high concentration of premium vehicle sales, such as North America, Europe, and parts of Asia. These markets often have both stringent emissions regulations and consumers who value high-performance vehicles, creating an ideal environment for B58 engine innovations.

The commercial vehicle sector, while not a primary user of the B58 engine, is influencing the broader market for engine efficiency technologies. Advancements in this sector often trickle down to passenger vehicles, potentially impacting future developments in B58 engine aerodynamics.

Looking at market projections, the global automotive engine market is expected to grow significantly in the coming years, with a particular emphasis on efficient and high-performance engines. This growth trajectory suggests a sustained demand for innovations in engine aerodynamics and thermal efficiency, including those specific to the B58 engine.

In conclusion, the market demand for B58 engine aerodynamic and thermal efficiency innovations is robust and multifaceted. It is driven by regulatory pressures, consumer preferences, technological advancements, and the ongoing evolution of the automotive industry towards more sustainable yet high-performance solutions.

Consumer preferences are also shifting towards vehicles that offer both performance and efficiency. The B58 engine, known for its robust power output, is now expected to deliver improved fuel economy without compromising on performance. This dual demand creates a significant market opportunity for aerodynamic and thermal efficiency innovations.

In the luxury car market, where the B58 engine is prevalent, there is a notable trend towards electrification. However, many manufacturers are adopting a hybrid approach, combining electric motors with highly efficient internal combustion engines. This strategy maintains the appeal of traditional powertrains while meeting emissions targets, further driving the need for advanced engine technologies.

The aftermarket tuning industry also contributes to the demand for B58 engine innovations. Performance enthusiasts seek ways to extract more power and efficiency from their vehicles, creating a secondary market for advanced aerodynamic and thermal management solutions.

Geographically, the demand is particularly strong in regions with a high concentration of premium vehicle sales, such as North America, Europe, and parts of Asia. These markets often have both stringent emissions regulations and consumers who value high-performance vehicles, creating an ideal environment for B58 engine innovations.

The commercial vehicle sector, while not a primary user of the B58 engine, is influencing the broader market for engine efficiency technologies. Advancements in this sector often trickle down to passenger vehicles, potentially impacting future developments in B58 engine aerodynamics.

Looking at market projections, the global automotive engine market is expected to grow significantly in the coming years, with a particular emphasis on efficient and high-performance engines. This growth trajectory suggests a sustained demand for innovations in engine aerodynamics and thermal efficiency, including those specific to the B58 engine.

In conclusion, the market demand for B58 engine aerodynamic and thermal efficiency innovations is robust and multifaceted. It is driven by regulatory pressures, consumer preferences, technological advancements, and the ongoing evolution of the automotive industry towards more sustainable yet high-performance solutions.

Aerodynamic Challenges

The B58 engine faces several aerodynamic challenges in its pursuit of enhanced thermal efficiency. One of the primary issues is managing airflow within the engine compartment. The compact design of modern engines, coupled with the need for improved fuel economy, has led to tighter packaging constraints. This results in reduced space for air circulation, potentially leading to heat buildup and decreased overall efficiency.

Another significant challenge is the optimization of intake and exhaust flows. The B58 engine must efficiently draw in cool air while expelling hot exhaust gases, all while minimizing turbulence and pressure losses. This delicate balance is crucial for maintaining optimal combustion conditions and maximizing power output. The design of intake manifolds, exhaust systems, and turbocharger components must be carefully considered to achieve this equilibrium.

Heat management presents a formidable aerodynamic challenge for the B58 engine. As engine performance increases, so does the amount of heat generated. Efficiently dissipating this heat through aerodynamic means is essential for maintaining engine longevity and performance. This involves designing effective cooling channels, optimizing radiator placement, and ensuring proper airflow around critical components.

The interaction between the engine's external aerodynamics and the vehicle's overall aerodynamic profile adds another layer of complexity. The B58 engine must be integrated into the vehicle in a way that minimizes drag and promotes efficient airflow both around and through the engine bay. This requires a holistic approach to vehicle design, considering factors such as underbody aerodynamics and the impact of engine placement on overall vehicle balance.

Turbocharger aerodynamics pose unique challenges for the B58 engine. The design of compressor and turbine wheels, as well as the associated ducting, must be optimized to maximize efficiency across a wide range of operating conditions. This includes minimizing pressure losses, reducing turbo lag, and ensuring stable operation at high speeds.

Finally, the B58 engine must contend with the aerodynamic challenges associated with emissions control systems. The integration of catalytic converters, particulate filters, and other emissions-related components can create restrictions in exhaust flow, potentially impacting engine performance and efficiency. Balancing these regulatory requirements with aerodynamic optimization remains an ongoing challenge for engine designers.

Another significant challenge is the optimization of intake and exhaust flows. The B58 engine must efficiently draw in cool air while expelling hot exhaust gases, all while minimizing turbulence and pressure losses. This delicate balance is crucial for maintaining optimal combustion conditions and maximizing power output. The design of intake manifolds, exhaust systems, and turbocharger components must be carefully considered to achieve this equilibrium.

Heat management presents a formidable aerodynamic challenge for the B58 engine. As engine performance increases, so does the amount of heat generated. Efficiently dissipating this heat through aerodynamic means is essential for maintaining engine longevity and performance. This involves designing effective cooling channels, optimizing radiator placement, and ensuring proper airflow around critical components.

The interaction between the engine's external aerodynamics and the vehicle's overall aerodynamic profile adds another layer of complexity. The B58 engine must be integrated into the vehicle in a way that minimizes drag and promotes efficient airflow both around and through the engine bay. This requires a holistic approach to vehicle design, considering factors such as underbody aerodynamics and the impact of engine placement on overall vehicle balance.

Turbocharger aerodynamics pose unique challenges for the B58 engine. The design of compressor and turbine wheels, as well as the associated ducting, must be optimized to maximize efficiency across a wide range of operating conditions. This includes minimizing pressure losses, reducing turbo lag, and ensuring stable operation at high speeds.

Finally, the B58 engine must contend with the aerodynamic challenges associated with emissions control systems. The integration of catalytic converters, particulate filters, and other emissions-related components can create restrictions in exhaust flow, potentially impacting engine performance and efficiency. Balancing these regulatory requirements with aerodynamic optimization remains an ongoing challenge for engine designers.

Current Aero Solutions

01 Improved combustion chamber design

Enhancing the combustion chamber design in B58 engines can significantly improve thermal efficiency. This includes optimizing the shape, size, and configuration of the chamber to promote better fuel-air mixing and more complete combustion. Advanced designs can reduce heat loss, increase compression ratios, and improve overall engine performance.- Improved combustion chamber design: Enhancing the combustion chamber design in B58 engines can significantly improve thermal efficiency. This includes optimizing the shape, size, and configuration of the chamber to promote better fuel-air mixing and more complete combustion. Advanced designs can reduce heat loss, increase compression ratios, and improve overall engine performance.

- Advanced thermal management systems: Implementing sophisticated thermal management systems in B58 engines can enhance thermal efficiency. These systems may include improved cooling circuits, advanced heat exchangers, and intelligent temperature control mechanisms. By optimizing heat distribution and minimizing energy losses, these systems contribute to better overall engine efficiency.

- Turbocharging and exhaust gas recirculation: Utilizing advanced turbocharging technologies and optimized exhaust gas recirculation (EGR) systems can boost the thermal efficiency of B58 engines. These technologies help in recovering waste heat, increasing air intake pressure, and reducing pumping losses, thereby improving the overall energy conversion efficiency of the engine.

- Variable valve timing and lift: Implementing variable valve timing and lift mechanisms in B58 engines can significantly enhance thermal efficiency. These systems allow for dynamic adjustment of valve operation based on engine load and speed, optimizing air-fuel mixture and combustion timing across various operating conditions.

- Advanced fuel injection systems: Incorporating state-of-the-art fuel injection systems in B58 engines can improve thermal efficiency. These systems may include high-pressure direct injection, multiple injection events per cycle, and precise fuel atomization techniques. Such advancements lead to better fuel-air mixing, more complete combustion, and reduced fuel consumption.

02 Advanced thermal management systems

Implementing sophisticated thermal management systems in B58 engines can enhance thermal efficiency. These systems may include improved cooling circuits, advanced heat exchangers, and intelligent temperature control mechanisms. By optimizing heat distribution and minimizing thermal losses, the engine can operate more efficiently across various load conditions.Expand Specific Solutions03 Turbocharging and exhaust gas recirculation optimization

Optimizing turbocharging systems and exhaust gas recirculation (EGR) in B58 engines can lead to improved thermal efficiency. Advanced turbocharger designs, coupled with precise EGR control, can enhance air-fuel mixture quality, reduce pumping losses, and allow for more efficient combustion across a wider range of engine speeds and loads.Expand Specific Solutions04 Friction reduction technologies

Implementing friction reduction technologies in B58 engines can contribute to improved thermal efficiency. This may include using advanced low-friction coatings on engine components, optimizing piston and ring designs, and employing high-performance lubricants. Reducing internal friction allows more of the engine's power to be converted into useful work, thereby increasing overall efficiency.Expand Specific Solutions05 Variable valve timing and lift systems

Incorporating advanced variable valve timing and lift systems in B58 engines can enhance thermal efficiency. These systems allow for precise control of valve operations across different engine speeds and loads, optimizing air intake and exhaust flow. This results in improved combustion efficiency, reduced pumping losses, and better overall engine performance.Expand Specific Solutions

Key Industry Players

The B58 Engine Aerodynamics field is in a mature stage of development, with ongoing innovations focused on enhancing thermal efficiency. The market for advanced engine technologies is substantial, driven by the automotive industry's push for improved fuel economy and reduced emissions. Major players like Ford, General Electric, and Rolls-Royce are at the forefront, leveraging their extensive R&D capabilities. Universities such as Tianjin University and Beihang University contribute significant research. The technology's maturity is evident in its widespread adoption, with companies like Cummins and Weichai Power implementing advanced aerodynamic solutions in their engine designs. Collaboration between industry leaders and academic institutions continues to drive incremental improvements in this well-established field.

Toyota Motor Corp.

Technical Solution: Toyota has developed innovative aerodynamic solutions for the B58 engine, focusing on thermal efficiency improvements. Their approach includes advanced cooling systems with optimized airflow management. Toyota has implemented a dual-circuit cooling system that allows for precise temperature control of different engine components[1]. This system incorporates a split cooling strategy, where the cylinder head and block are cooled separately, allowing for higher combustion temperatures while maintaining durability. Additionally, Toyota has integrated aerodynamic elements into the engine design, such as streamlined intake and exhaust manifolds, to reduce pumping losses and improve overall efficiency[2]. The company has also implemented variable valve timing and lift systems to optimize airflow across different engine speeds and loads, further enhancing thermal efficiency[3].

Strengths: Precise temperature control, improved combustion efficiency, and reduced pumping losses. Weaknesses: Increased complexity and potential higher manufacturing costs.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has focused on advanced aerodynamic designs for the B58 engine to maximize thermal efficiency. Their approach includes the implementation of a sophisticated air management system that optimizes airflow throughout the engine. This system incorporates variable geometry turbochargers and advanced intercooling techniques to ensure optimal air density and temperature at all operating conditions[4]. Rolls-Royce has also developed innovative combustion chamber designs that promote better fuel-air mixing and more complete combustion. Their engineers have implemented advanced computational fluid dynamics (CFD) simulations to optimize the shape and positioning of intake and exhaust ports, reducing flow losses and improving overall engine breathing[5]. Furthermore, Rolls-Royce has integrated thermal management technologies, such as active grille shutters and underbody panels, to control airflow and reduce drag, contributing to improved thermal efficiency[6].

Strengths: Advanced air management, optimized combustion, and comprehensive thermal management. Weaknesses: High development costs and potential reliability concerns due to complex systems.

Core Aero Innovations

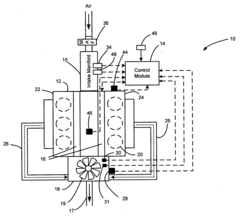

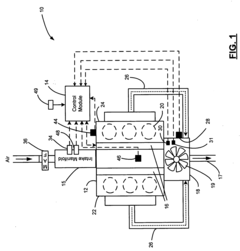

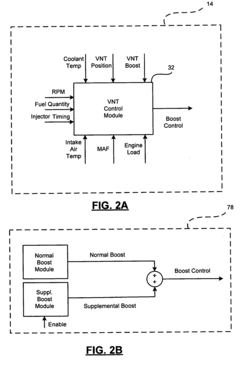

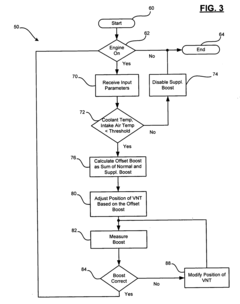

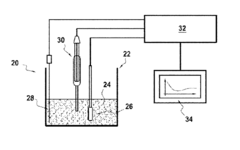

Control system to minimize white smoke using variable nozzle turbo

PatentInactiveUS20060144044A1

Innovation

- An engine system that adjusts the turbocharger's boost by determining a supplemental boost based on coolant temperature, engine RPM, intake air temperature, manifold air flow, and fuel injector timing to modify the air output and position of vanes, ensuring optimal combustion conditions and reducing white smoke.

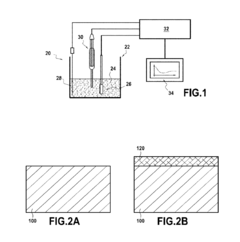

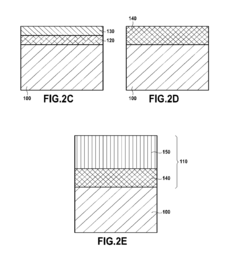

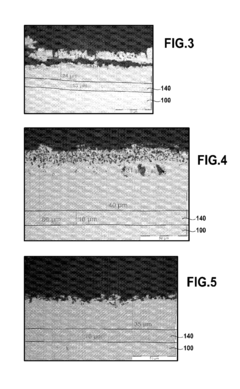

Method for producing a metal undercoat made from platinum on a metal substrate

PatentInactiveUS20160153106A1

Innovation

- A method using an electrolyte bath formed from an ionic liquid medium with aluminium salts to deposit a metallic undercoat by electroplating a platinum group metal and aluminium, followed by diffusion heat treatment, simplifying the process and reducing manufacturing time and costs.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development of engine technologies, including innovations in thermal efficiency for the B58 engine. These regulations are continuously evolving to address environmental concerns and reduce the carbon footprint of vehicles. In recent years, there has been a global push towards stricter emissions standards, particularly focusing on reducing greenhouse gas emissions and improving fuel economy.

The European Union has been at the forefront of implementing stringent emissions regulations through its Euro standards. The current Euro 6 standard, introduced in 2014, sets limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. The upcoming Euro 7 standard, expected to be implemented in the near future, will further tighten these limits and introduce new testing procedures to ensure real-world compliance.

In the United States, the Corporate Average Fuel Economy (CAFE) standards and the Environmental Protection Agency's (EPA) emissions regulations have been driving forces behind engine innovations. These regulations set targets for fleet-wide fuel efficiency and emissions reductions, pushing manufacturers to develop more efficient engines and powertrains.

China, the world's largest automotive market, has also implemented increasingly stringent emissions standards. The China 6 standard, comparable to Euro 6, has been rolled out nationwide, with some cities adopting even stricter local standards. This regulatory landscape has significant implications for engine manufacturers operating in the global market.

The impact of these regulations on B58 engine aerodynamics and thermal efficiency innovations is substantial. Manufacturers are compelled to explore advanced technologies to meet these stringent requirements while maintaining or improving performance. This has led to increased focus on areas such as improved combustion processes, advanced thermal management systems, and enhanced aerodynamic designs to reduce drag and improve overall efficiency.

One key area of innovation driven by emissions regulations is the development of more efficient turbocharging systems. The B58 engine, known for its use of turbocharging, has seen advancements in turbocharger design and integration to optimize airflow and reduce energy losses. This includes the use of variable geometry turbochargers and electric compressors to improve responsiveness and efficiency across a wider operating range.

Furthermore, emissions regulations have spurred research into advanced materials and coatings that can withstand higher temperatures and pressures within the engine. This allows for more efficient combustion processes and better thermal management, directly contributing to improved thermal efficiency in the B58 engine.

As emissions regulations continue to evolve, engine manufacturers must remain agile and innovative in their approach to thermal efficiency. The B58 engine's future development will likely see further advancements in areas such as electrification, hybrid technologies, and intelligent engine management systems to meet and exceed regulatory requirements while delivering optimal performance and efficiency.

The European Union has been at the forefront of implementing stringent emissions regulations through its Euro standards. The current Euro 6 standard, introduced in 2014, sets limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. The upcoming Euro 7 standard, expected to be implemented in the near future, will further tighten these limits and introduce new testing procedures to ensure real-world compliance.

In the United States, the Corporate Average Fuel Economy (CAFE) standards and the Environmental Protection Agency's (EPA) emissions regulations have been driving forces behind engine innovations. These regulations set targets for fleet-wide fuel efficiency and emissions reductions, pushing manufacturers to develop more efficient engines and powertrains.

China, the world's largest automotive market, has also implemented increasingly stringent emissions standards. The China 6 standard, comparable to Euro 6, has been rolled out nationwide, with some cities adopting even stricter local standards. This regulatory landscape has significant implications for engine manufacturers operating in the global market.

The impact of these regulations on B58 engine aerodynamics and thermal efficiency innovations is substantial. Manufacturers are compelled to explore advanced technologies to meet these stringent requirements while maintaining or improving performance. This has led to increased focus on areas such as improved combustion processes, advanced thermal management systems, and enhanced aerodynamic designs to reduce drag and improve overall efficiency.

One key area of innovation driven by emissions regulations is the development of more efficient turbocharging systems. The B58 engine, known for its use of turbocharging, has seen advancements in turbocharger design and integration to optimize airflow and reduce energy losses. This includes the use of variable geometry turbochargers and electric compressors to improve responsiveness and efficiency across a wider operating range.

Furthermore, emissions regulations have spurred research into advanced materials and coatings that can withstand higher temperatures and pressures within the engine. This allows for more efficient combustion processes and better thermal management, directly contributing to improved thermal efficiency in the B58 engine.

As emissions regulations continue to evolve, engine manufacturers must remain agile and innovative in their approach to thermal efficiency. The B58 engine's future development will likely see further advancements in areas such as electrification, hybrid technologies, and intelligent engine management systems to meet and exceed regulatory requirements while delivering optimal performance and efficiency.

Material Advancements

Material advancements play a crucial role in enhancing the thermal efficiency of the B58 engine through innovative aerodynamic designs. The development of high-performance materials has significantly contributed to improving engine performance and reducing heat losses. Advanced ceramics, such as silicon nitride and zirconia, have been incorporated into critical engine components due to their excellent thermal insulation properties and high-temperature stability. These materials help maintain optimal operating temperatures and reduce thermal stress on engine parts.

Composite materials, including carbon fiber reinforced polymers (CFRP) and ceramic matrix composites (CMC), have been utilized in various engine components to reduce weight while maintaining structural integrity. The lightweight nature of these materials allows for more efficient heat dissipation and improved overall engine performance. Additionally, the use of thermal barrier coatings (TBC) has become increasingly prevalent in B58 engine design. These coatings, typically made of yttria-stabilized zirconia (YSZ), provide a protective layer that reduces heat transfer to engine components, thereby enhancing thermal efficiency.

Advancements in metallic alloys have also contributed to improved thermal management in the B58 engine. Nickel-based superalloys, such as Inconel and Hastelloy, have been engineered to withstand extreme temperatures and maintain their mechanical properties under harsh operating conditions. These alloys are used in critical components like turbine blades and combustion chambers, allowing for higher operating temperatures and improved thermal efficiency.

The development of smart materials has opened up new possibilities for dynamic thermal management in the B58 engine. Shape memory alloys (SMAs) and piezoelectric materials have been integrated into engine designs to create adaptive structures that can respond to temperature changes in real-time. These materials enable active control of airflow and heat distribution, further optimizing thermal efficiency across various operating conditions.

Nanotechnology has also made significant contributions to material advancements in B58 engine aerodynamics. Nanostructured materials, such as carbon nanotubes and graphene, have been incorporated into engine components to enhance thermal conductivity and reduce friction. These nanomaterials offer exceptional strength-to-weight ratios and thermal properties, allowing for more efficient heat transfer and improved overall engine performance.

The ongoing research in material science continues to push the boundaries of what is possible in B58 engine aerodynamics. Emerging materials, such as high-entropy alloys and metal-organic frameworks, show promise for future applications in thermal management and efficiency improvements. As these materials are further developed and refined, they are expected to play an increasingly important role in advancing the thermal efficiency of B58 engines through innovative aerodynamic designs.

Composite materials, including carbon fiber reinforced polymers (CFRP) and ceramic matrix composites (CMC), have been utilized in various engine components to reduce weight while maintaining structural integrity. The lightweight nature of these materials allows for more efficient heat dissipation and improved overall engine performance. Additionally, the use of thermal barrier coatings (TBC) has become increasingly prevalent in B58 engine design. These coatings, typically made of yttria-stabilized zirconia (YSZ), provide a protective layer that reduces heat transfer to engine components, thereby enhancing thermal efficiency.

Advancements in metallic alloys have also contributed to improved thermal management in the B58 engine. Nickel-based superalloys, such as Inconel and Hastelloy, have been engineered to withstand extreme temperatures and maintain their mechanical properties under harsh operating conditions. These alloys are used in critical components like turbine blades and combustion chambers, allowing for higher operating temperatures and improved thermal efficiency.

The development of smart materials has opened up new possibilities for dynamic thermal management in the B58 engine. Shape memory alloys (SMAs) and piezoelectric materials have been integrated into engine designs to create adaptive structures that can respond to temperature changes in real-time. These materials enable active control of airflow and heat distribution, further optimizing thermal efficiency across various operating conditions.

Nanotechnology has also made significant contributions to material advancements in B58 engine aerodynamics. Nanostructured materials, such as carbon nanotubes and graphene, have been incorporated into engine components to enhance thermal conductivity and reduce friction. These nanomaterials offer exceptional strength-to-weight ratios and thermal properties, allowing for more efficient heat transfer and improved overall engine performance.

The ongoing research in material science continues to push the boundaries of what is possible in B58 engine aerodynamics. Emerging materials, such as high-entropy alloys and metal-organic frameworks, show promise for future applications in thermal management and efficiency improvements. As these materials are further developed and refined, they are expected to play an increasingly important role in advancing the thermal efficiency of B58 engines through innovative aerodynamic designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!