The Specific Role of EGR Valves in B58 Engine Emissions Management

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 EGR Tech Background

The B58 engine, developed by BMW, represents a significant advancement in automotive engineering, particularly in the realm of emissions management. This turbocharged inline-six engine, first introduced in 2015, has become a cornerstone of BMW's powertrain strategy, finding its way into various models across the BMW Group's portfolio, including some Toyota vehicles.

At the heart of the B58's emissions control system lies the Exhaust Gas Recirculation (EGR) valve, a critical component in modern engine design. The EGR system plays a pivotal role in reducing nitrogen oxide (NOx) emissions, a major pollutant produced during the combustion process, especially at high temperatures and pressures typical of turbocharged engines.

The B58 engine's EGR system is designed to recirculate a portion of the exhaust gases back into the combustion chamber. This process dilutes the oxygen concentration in the incoming air charge, effectively lowering peak combustion temperatures. The reduction in combustion temperature is key to minimizing the formation of NOx, as these compounds are primarily created when nitrogen and oxygen react at high temperatures.

In the B58, the EGR valve is electronically controlled, allowing for precise management of exhaust gas flow based on various engine operating conditions. This level of control enables the engine management system to optimize the EGR rate for different driving scenarios, balancing emissions reduction with performance and fuel efficiency.

The integration of the EGR system in the B58 engine is part of a broader emissions management strategy. It works in conjunction with other technologies such as direct fuel injection, variable valve timing, and advanced turbocharging to achieve a harmonious balance between power output and environmental responsibility. This holistic approach to engine design has enabled BMW to meet increasingly stringent emissions regulations while maintaining the performance characteristics that define the brand.

As emissions standards continue to evolve globally, the role of EGR valves in engines like the B58 becomes increasingly crucial. The technology's ability to significantly reduce NOx emissions without substantially compromising engine performance has made it an indispensable tool in the automotive industry's quest for cleaner, more efficient powertrains.

At the heart of the B58's emissions control system lies the Exhaust Gas Recirculation (EGR) valve, a critical component in modern engine design. The EGR system plays a pivotal role in reducing nitrogen oxide (NOx) emissions, a major pollutant produced during the combustion process, especially at high temperatures and pressures typical of turbocharged engines.

The B58 engine's EGR system is designed to recirculate a portion of the exhaust gases back into the combustion chamber. This process dilutes the oxygen concentration in the incoming air charge, effectively lowering peak combustion temperatures. The reduction in combustion temperature is key to minimizing the formation of NOx, as these compounds are primarily created when nitrogen and oxygen react at high temperatures.

In the B58, the EGR valve is electronically controlled, allowing for precise management of exhaust gas flow based on various engine operating conditions. This level of control enables the engine management system to optimize the EGR rate for different driving scenarios, balancing emissions reduction with performance and fuel efficiency.

The integration of the EGR system in the B58 engine is part of a broader emissions management strategy. It works in conjunction with other technologies such as direct fuel injection, variable valve timing, and advanced turbocharging to achieve a harmonious balance between power output and environmental responsibility. This holistic approach to engine design has enabled BMW to meet increasingly stringent emissions regulations while maintaining the performance characteristics that define the brand.

As emissions standards continue to evolve globally, the role of EGR valves in engines like the B58 becomes increasingly crucial. The technology's ability to significantly reduce NOx emissions without substantially compromising engine performance has made it an indispensable tool in the automotive industry's quest for cleaner, more efficient powertrains.

EGR Market Demand Analysis

The market demand for EGR valves in B58 engine emissions management has been steadily increasing due to stringent emission regulations and the automotive industry's focus on environmental sustainability. As governments worldwide implement stricter emission standards, particularly in Europe, North America, and Asia, the demand for advanced EGR systems has surged.

The B58 engine, primarily used in BMW vehicles, has become a benchmark for performance and efficiency in the premium segment. This has led to a growing market for EGR valves specifically designed for the B58 engine, as manufacturers seek to optimize emissions control without compromising engine performance.

The global EGR valve market is projected to experience significant growth in the coming years, driven by the increasing adoption of turbocharged engines like the B58. The automotive EGR system market is expected to expand at a compound annual growth rate (CAGR) of over 5% between 2021 and 2026, with a substantial portion attributed to premium vehicle segments where the B58 engine is prevalent.

Manufacturers are investing heavily in research and development to improve EGR valve technology for the B58 engine, focusing on enhancing durability, precision, and integration with other engine management systems. This has created a niche market for specialized EGR valves that can withstand the high temperatures and pressures associated with the B58's performance characteristics.

The aftermarket segment for B58 EGR valves is also showing promising growth, as vehicle owners seek replacements and upgrades to maintain optimal engine performance and emissions compliance. This has led to increased competition among aftermarket suppliers to develop high-quality, compatible EGR valves for the B58 engine.

Regional market analysis indicates that Europe currently leads in demand for B58 EGR valves, followed closely by North America and Asia-Pacific. This regional distribution aligns with the primary markets for BMW vehicles equipped with the B58 engine. However, emerging markets in developing countries are showing potential for growth as premium vehicle sales increase and emission regulations tighten.

The market demand is further influenced by the shift towards electrification in the automotive industry. While this trend poses a long-term challenge to the EGR valve market, it has also spurred innovation in hybrid powertrains that incorporate advanced EGR systems, potentially extending the market relevance of EGR technology in B58 and similar engines.

The B58 engine, primarily used in BMW vehicles, has become a benchmark for performance and efficiency in the premium segment. This has led to a growing market for EGR valves specifically designed for the B58 engine, as manufacturers seek to optimize emissions control without compromising engine performance.

The global EGR valve market is projected to experience significant growth in the coming years, driven by the increasing adoption of turbocharged engines like the B58. The automotive EGR system market is expected to expand at a compound annual growth rate (CAGR) of over 5% between 2021 and 2026, with a substantial portion attributed to premium vehicle segments where the B58 engine is prevalent.

Manufacturers are investing heavily in research and development to improve EGR valve technology for the B58 engine, focusing on enhancing durability, precision, and integration with other engine management systems. This has created a niche market for specialized EGR valves that can withstand the high temperatures and pressures associated with the B58's performance characteristics.

The aftermarket segment for B58 EGR valves is also showing promising growth, as vehicle owners seek replacements and upgrades to maintain optimal engine performance and emissions compliance. This has led to increased competition among aftermarket suppliers to develop high-quality, compatible EGR valves for the B58 engine.

Regional market analysis indicates that Europe currently leads in demand for B58 EGR valves, followed closely by North America and Asia-Pacific. This regional distribution aligns with the primary markets for BMW vehicles equipped with the B58 engine. However, emerging markets in developing countries are showing potential for growth as premium vehicle sales increase and emission regulations tighten.

The market demand is further influenced by the shift towards electrification in the automotive industry. While this trend poses a long-term challenge to the EGR valve market, it has also spurred innovation in hybrid powertrains that incorporate advanced EGR systems, potentially extending the market relevance of EGR technology in B58 and similar engines.

EGR Challenges in B58

The B58 engine, developed by BMW, represents a significant advancement in automotive engineering. However, it faces several challenges in its Exhaust Gas Recirculation (EGR) system, which plays a crucial role in emissions management. One of the primary issues is the high operating temperatures of the B58 engine, which can lead to increased thermal stress on the EGR components. This thermal stress can cause premature wear and potential failure of the EGR valves, reducing their effectiveness in controlling emissions over time.

Another challenge is the precise control required for the EGR system in the B58 engine. The engine's high-performance nature demands exact timing and quantity of exhaust gas recirculation to maintain optimal combustion efficiency while simultaneously reducing emissions. Achieving this balance is particularly difficult given the wide range of operating conditions the engine experiences, from idle to full throttle, and across varying environmental conditions.

The B58 engine's compact design, while beneficial for overall vehicle packaging, presents spatial constraints for the EGR system. This limited space can lead to difficulties in implementing larger, more efficient EGR coolers or in positioning EGR components for optimal flow characteristics. The restricted space may also complicate maintenance and replacement procedures, potentially increasing service costs and downtime.

Deposit formation is another significant challenge for the B58's EGR system. The recirculation of exhaust gases can lead to the accumulation of carbon and other particulates within the EGR valves and associated piping. These deposits can restrict gas flow, affecting the system's efficiency and potentially causing sticking or complete failure of the EGR valves. The high-performance nature of the B58 engine may exacerbate this issue due to higher combustion temperatures and pressures.

Furthermore, the B58 engine's use of a twin-scroll turbocharger introduces additional complexities for the EGR system. The interaction between the turbocharger and the EGR system must be carefully managed to ensure optimal performance and emissions control across all engine operating conditions. This requires sophisticated control algorithms and sensors to monitor and adjust the EGR flow in real-time, adding to the system's complexity and potential points of failure.

Lastly, meeting increasingly stringent emissions regulations while maintaining the B58 engine's performance characteristics poses an ongoing challenge. As emission standards become more rigorous, the EGR system must become more efficient and effective, potentially requiring innovative solutions or redesigns to meet future regulatory requirements without compromising the engine's power output and drivability.

Another challenge is the precise control required for the EGR system in the B58 engine. The engine's high-performance nature demands exact timing and quantity of exhaust gas recirculation to maintain optimal combustion efficiency while simultaneously reducing emissions. Achieving this balance is particularly difficult given the wide range of operating conditions the engine experiences, from idle to full throttle, and across varying environmental conditions.

The B58 engine's compact design, while beneficial for overall vehicle packaging, presents spatial constraints for the EGR system. This limited space can lead to difficulties in implementing larger, more efficient EGR coolers or in positioning EGR components for optimal flow characteristics. The restricted space may also complicate maintenance and replacement procedures, potentially increasing service costs and downtime.

Deposit formation is another significant challenge for the B58's EGR system. The recirculation of exhaust gases can lead to the accumulation of carbon and other particulates within the EGR valves and associated piping. These deposits can restrict gas flow, affecting the system's efficiency and potentially causing sticking or complete failure of the EGR valves. The high-performance nature of the B58 engine may exacerbate this issue due to higher combustion temperatures and pressures.

Furthermore, the B58 engine's use of a twin-scroll turbocharger introduces additional complexities for the EGR system. The interaction between the turbocharger and the EGR system must be carefully managed to ensure optimal performance and emissions control across all engine operating conditions. This requires sophisticated control algorithms and sensors to monitor and adjust the EGR flow in real-time, adding to the system's complexity and potential points of failure.

Lastly, meeting increasingly stringent emissions regulations while maintaining the B58 engine's performance characteristics poses an ongoing challenge. As emission standards become more rigorous, the EGR system must become more efficient and effective, potentially requiring innovative solutions or redesigns to meet future regulatory requirements without compromising the engine's power output and drivability.

Current B58 EGR Solutions

01 EGR valve design for emission reduction

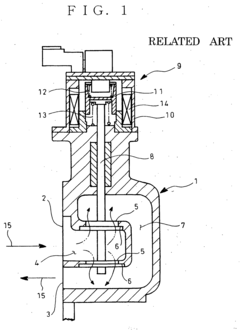

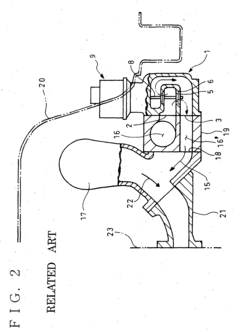

Improved designs of EGR valves to enhance their effectiveness in reducing emissions. These designs focus on optimizing flow control, reducing leakage, and improving durability to ensure consistent performance in exhaust gas recirculation systems.- EGR valve design for emission reduction: Improved designs of EGR valves to enhance their effectiveness in reducing emissions. These designs focus on optimizing flow control, reducing leakage, and improving durability to ensure consistent performance in reducing NOx emissions and improving fuel efficiency.

- EGR system integration with engine control: Integration of EGR systems with advanced engine control strategies to optimize emission reduction. This includes real-time monitoring and adjustment of EGR rates based on engine operating conditions, load, and temperature to achieve the best balance between performance and emissions.

- Cooling and condensation management in EGR systems: Techniques for managing the cooling and condensation in EGR systems to improve emission reduction efficiency. This involves optimizing EGR cooler designs, implementing condensate removal systems, and controlling EGR temperatures to prevent fouling and maintain system effectiveness.

- Low-pressure and high-pressure EGR systems: Development and optimization of both low-pressure and high-pressure EGR systems to address different emission reduction requirements. This includes strategies for combining both systems, controlling the EGR distribution, and adapting the system based on engine operating conditions to maximize emission reduction.

- EGR system diagnostics and fault detection: Implementation of advanced diagnostics and fault detection methods for EGR systems to ensure consistent emission reduction performance. This includes sensors for monitoring EGR flow, temperature, and pressure, as well as algorithms for detecting system malfunctions and triggering maintenance alerts.

02 Control strategies for EGR systems

Advanced control strategies for EGR systems to optimize emission reduction. These strategies involve precise management of EGR flow rates, timing, and temperature based on engine operating conditions and emission targets.Expand Specific Solutions03 Integration of EGR with other emission control technologies

Combining EGR systems with other emission control technologies such as selective catalytic reduction (SCR) or diesel particulate filters (DPF) to achieve synergistic effects in reducing overall emissions from internal combustion engines.Expand Specific Solutions04 EGR cooling techniques

Development of efficient EGR cooling methods to lower the temperature of recirculated exhaust gases. This helps in reducing NOx emissions and improving engine performance by allowing higher EGR rates without compromising combustion efficiency.Expand Specific Solutions05 Diagnostic and monitoring systems for EGR valves

Implementation of advanced diagnostic and monitoring systems to detect EGR valve malfunctions, ensure proper operation, and maintain optimal emission reduction performance over time. These systems can include sensors, predictive algorithms, and real-time feedback mechanisms.Expand Specific Solutions

Key B58 EGR Players

The competitive landscape for EGR valve technology in B58 engine emissions management is characterized by a mature market with established players and ongoing innovation. The industry is in a consolidation phase, with major automotive suppliers like BorgWarner and Cummins leading the way. Market size is substantial, driven by stringent emissions regulations globally. Technological maturity is high, with companies like Wuxi Longsheng, Jacobs Vehicle Systems, and Weichai Power offering advanced EGR solutions. However, there's still room for innovation, particularly in integrating EGR systems with other emissions control technologies. Companies such as Toyota, FCA, and Chery are actively developing proprietary EGR solutions for their engines, while specialized firms like G.W. Lisk and Padmini VNA Mechatronics focus on component manufacturing.

BorgWarner, Inc.

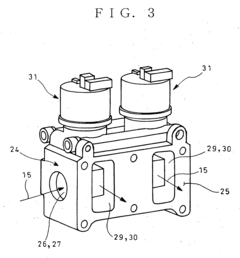

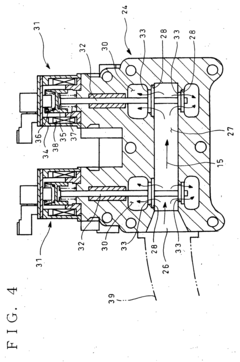

Technical Solution: BorgWarner has developed advanced EGR valve technologies specifically tailored for the B58 engine's emissions management. Their solution incorporates a high-precision electric actuator with integrated position sensing, allowing for precise control of exhaust gas recirculation. The valve design features a low-leak, high-temperature resistant seal to withstand the harsh exhaust environment. BorgWarner's EGR valve for the B58 engine utilizes a dual-cooling system, combining both air and coolant cooling methods to maintain optimal performance across various operating conditions[1]. The company has also implemented advanced flow control algorithms that dynamically adjust EGR rates based on real-time engine parameters, ensuring optimal emissions reduction while maintaining engine efficiency[3].

Strengths: Precise control, durability in harsh conditions, and adaptive flow management. Weaknesses: Potentially higher cost due to advanced features and dual-cooling system.

Cummins, Inc.

Technical Solution: Cummins has engineered a sophisticated EGR valve system for B58 engine emissions management, focusing on robustness and efficiency. Their solution features a high-flow design that allows for increased EGR rates when needed, coupled with a fast-acting actuator for rapid response to changing engine conditions. Cummins' EGR valve incorporates advanced materials such as high-grade stainless steel and specialized coatings to resist corrosion and carbon buildup, extending the valve's operational life[2]. The company has also integrated smart diagnostics into their EGR valve, allowing for real-time monitoring of valve performance and early detection of potential issues. Cummins' system includes a modular design that facilitates easier maintenance and replacement, reducing downtime for B58 engine servicing[5].

Strengths: High durability, smart diagnostics, and ease of maintenance. Weaknesses: Potentially larger size due to high-flow design and diagnostic components.

B58 EGR Core Innovations

Variable reluctance position sensor

PatentInactiveEP1929148A2

Innovation

- Integration of a permanent magnet and Hall-effect device into a single unit with a target that modulates magnetic flux by varying reluctance, allowing for convenient servicing and calibration, and the use of a second target with constant flux modulating property to normalize noise and anomalies.

EGR valve

PatentInactiveEP1342908B1

Innovation

- A compact EGR valve design with a housing having a gas intake pathway and longitudinally spaced gas discharge pathways, eliminating the need for intervening flow-path forming members by increasing the number of openings along the intake pathway, allowing for increased exhaust gas recirculation without lateral protrusion.

B58 Emissions Regulations

The B58 engine, developed by BMW, is subject to stringent emissions regulations that have been evolving rapidly in recent years. These regulations are designed to reduce the environmental impact of automotive emissions and improve air quality in urban areas. The European Union's Euro 6d standard, implemented in 2020, sets strict limits on nitrogen oxide (NOx) emissions, particulate matter, and carbon dioxide (CO2) output for passenger vehicles.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have established similar regulations. The EPA's Tier 3 standards, phased in from 2017 to 2025, require significant reductions in tailpipe and evaporative emissions from passenger cars, light-duty trucks, and some heavy-duty vehicles. CARB's Low-Emission Vehicle III (LEV III) program aligns with the EPA's standards but includes additional requirements for zero-emission vehicles.

China, another major automotive market, has implemented the China 6 emissions standard, which is comparable to Euro 6 in its stringency. This standard places limits on pollutants such as carbon monoxide (CO), hydrocarbons (HC), NOx, and particulate matter.

To comply with these regulations, the B58 engine incorporates various advanced technologies. The Exhaust Gas Recirculation (EGR) system plays a crucial role in managing emissions by recirculating a portion of the exhaust gases back into the combustion chamber. This process helps reduce NOx formation by lowering peak combustion temperatures.

The B58 engine also utilizes a sophisticated engine management system that continuously adjusts fuel injection timing, air-fuel ratios, and boost pressure to optimize combustion efficiency and minimize emissions. Additionally, the engine features a high-pressure direct injection system that improves fuel atomization and combustion, further reducing emissions.

Post-combustion treatment systems are equally important in meeting emissions standards. The B58 engine is equipped with a three-way catalytic converter that effectively reduces CO, HC, and NOx emissions. In diesel variants, a Selective Catalytic Reduction (SCR) system may be employed to further reduce NOx emissions through the use of a urea-based solution.

As emissions regulations continue to tighten globally, manufacturers like BMW must continuously innovate to ensure compliance. Future iterations of the B58 engine may incorporate even more advanced emissions control technologies, such as improved EGR systems, enhanced catalytic converters, and potentially mild hybrid systems to further reduce emissions and fuel consumption.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have established similar regulations. The EPA's Tier 3 standards, phased in from 2017 to 2025, require significant reductions in tailpipe and evaporative emissions from passenger cars, light-duty trucks, and some heavy-duty vehicles. CARB's Low-Emission Vehicle III (LEV III) program aligns with the EPA's standards but includes additional requirements for zero-emission vehicles.

China, another major automotive market, has implemented the China 6 emissions standard, which is comparable to Euro 6 in its stringency. This standard places limits on pollutants such as carbon monoxide (CO), hydrocarbons (HC), NOx, and particulate matter.

To comply with these regulations, the B58 engine incorporates various advanced technologies. The Exhaust Gas Recirculation (EGR) system plays a crucial role in managing emissions by recirculating a portion of the exhaust gases back into the combustion chamber. This process helps reduce NOx formation by lowering peak combustion temperatures.

The B58 engine also utilizes a sophisticated engine management system that continuously adjusts fuel injection timing, air-fuel ratios, and boost pressure to optimize combustion efficiency and minimize emissions. Additionally, the engine features a high-pressure direct injection system that improves fuel atomization and combustion, further reducing emissions.

Post-combustion treatment systems are equally important in meeting emissions standards. The B58 engine is equipped with a three-way catalytic converter that effectively reduces CO, HC, and NOx emissions. In diesel variants, a Selective Catalytic Reduction (SCR) system may be employed to further reduce NOx emissions through the use of a urea-based solution.

As emissions regulations continue to tighten globally, manufacturers like BMW must continuously innovate to ensure compliance. Future iterations of the B58 engine may incorporate even more advanced emissions control technologies, such as improved EGR systems, enhanced catalytic converters, and potentially mild hybrid systems to further reduce emissions and fuel consumption.

EGR Impact on Performance

The implementation of Exhaust Gas Recirculation (EGR) in the B58 engine has a significant impact on its performance characteristics. By recirculating a portion of exhaust gases back into the combustion chamber, EGR affects various aspects of engine operation, both positively and negatively.

One of the primary benefits of EGR on engine performance is the reduction of pumping losses. As the recirculated exhaust gases displace fresh air in the intake, the engine requires less work to draw in the air-fuel mixture during the intake stroke. This reduction in pumping losses contributes to improved fuel efficiency, particularly at part-load conditions where the engine is not operating at full capacity.

However, the introduction of exhaust gases into the combustion chamber also leads to a decrease in the oxygen concentration of the intake charge. This dilution effect results in a slight reduction in power output, especially at high load conditions. The B58 engine's management system must carefully balance the EGR rate to maintain optimal performance across various operating conditions.

EGR implementation also affects the engine's thermal efficiency. The recirculated exhaust gases have a higher specific heat capacity than fresh air, which helps to lower peak combustion temperatures. While this reduction in combustion temperature is beneficial for emissions control, it can slightly decrease the thermal efficiency of the engine if not properly managed.

The B58 engine's turbocharger performance is also influenced by EGR. The recirculation of exhaust gases reduces the amount of exhaust flow available to drive the turbocharger turbine. This can potentially lead to a slight decrease in boost pressure and turbocharger response. However, the B58's advanced engine management system compensates for this effect by adjusting boost control strategies to maintain optimal turbocharger performance.

Another notable impact of EGR on the B58 engine's performance is its effect on combustion stability. The introduction of inert exhaust gases can lead to increased cycle-to-cycle variations in combustion, potentially affecting engine smoothness and drivability. To mitigate this, the engine control unit employs sophisticated algorithms to optimize ignition timing and fuel injection parameters, ensuring stable combustion across various EGR rates and operating conditions.

In terms of long-term performance, the use of EGR in the B58 engine can contribute to reduced carbon deposits on intake valves and pistons. This is particularly beneficial in direct injection engines, where fuel is not sprayed onto the back of the intake valves. The cleaner burning resulting from EGR helps maintain engine efficiency and performance over extended periods of operation.

One of the primary benefits of EGR on engine performance is the reduction of pumping losses. As the recirculated exhaust gases displace fresh air in the intake, the engine requires less work to draw in the air-fuel mixture during the intake stroke. This reduction in pumping losses contributes to improved fuel efficiency, particularly at part-load conditions where the engine is not operating at full capacity.

However, the introduction of exhaust gases into the combustion chamber also leads to a decrease in the oxygen concentration of the intake charge. This dilution effect results in a slight reduction in power output, especially at high load conditions. The B58 engine's management system must carefully balance the EGR rate to maintain optimal performance across various operating conditions.

EGR implementation also affects the engine's thermal efficiency. The recirculated exhaust gases have a higher specific heat capacity than fresh air, which helps to lower peak combustion temperatures. While this reduction in combustion temperature is beneficial for emissions control, it can slightly decrease the thermal efficiency of the engine if not properly managed.

The B58 engine's turbocharger performance is also influenced by EGR. The recirculation of exhaust gases reduces the amount of exhaust flow available to drive the turbocharger turbine. This can potentially lead to a slight decrease in boost pressure and turbocharger response. However, the B58's advanced engine management system compensates for this effect by adjusting boost control strategies to maintain optimal turbocharger performance.

Another notable impact of EGR on the B58 engine's performance is its effect on combustion stability. The introduction of inert exhaust gases can lead to increased cycle-to-cycle variations in combustion, potentially affecting engine smoothness and drivability. To mitigate this, the engine control unit employs sophisticated algorithms to optimize ignition timing and fuel injection parameters, ensuring stable combustion across various EGR rates and operating conditions.

In terms of long-term performance, the use of EGR in the B58 engine can contribute to reduced carbon deposits on intake valves and pistons. This is particularly beneficial in direct injection engines, where fuel is not sprayed onto the back of the intake valves. The cleaner burning resulting from EGR helps maintain engine efficiency and performance over extended periods of operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!