Turbo Lag Elimination Techniques Through E-Boosting Innovations in B58

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

E-Boosting in B58 Engines: Background and Objectives

The B58 engine, developed by BMW, represents a significant advancement in turbocharged inline-six engine technology. As automotive manufacturers strive for improved performance and efficiency, the challenge of turbo lag has become increasingly prominent. Turbo lag, the delay between throttle input and power delivery in turbocharged engines, has long been a concern for both engineers and drivers seeking responsive acceleration.

E-boosting, or electric boosting, has emerged as a promising solution to mitigate turbo lag in modern engines. This technology integrates an electric motor with the turbocharger system to provide instantaneous boost pressure, effectively bridging the gap between throttle input and turbocharger spool-up. The B58 engine, known for its robust performance and versatility, serves as an ideal platform for implementing and refining e-boosting innovations.

The primary objective of e-boosting in B58 engines is to eliminate or significantly reduce turbo lag, thereby enhancing overall engine responsiveness and drivability. This goal aligns with the broader industry trend towards more efficient and responsive powertrains, particularly in the context of increasingly stringent emissions regulations and the shift towards electrification.

E-boosting technology in B58 engines aims to achieve several key objectives. Firstly, it seeks to improve low-end torque delivery, providing immediate power response from low engine speeds. This enhancement is crucial for urban driving scenarios and quick overtaking maneuvers. Secondly, e-boosting targets seamless power delivery across the entire rev range, eliminating the characteristic "boost threshold" often associated with traditional turbocharged engines.

Furthermore, the implementation of e-boosting in B58 engines aims to optimize fuel efficiency by allowing for more precise boost control and potentially enabling downsizing strategies without compromising performance. This aligns with the automotive industry's ongoing efforts to reduce fuel consumption and emissions while maintaining or improving vehicle performance characteristics.

The development of e-boosting technologies for B58 engines also serves as a stepping stone towards more advanced hybrid powertrain systems. By integrating electric components into the boosting system, engineers gain valuable experience and insights that can be applied to future hybrid and electric vehicle platforms, positioning BMW at the forefront of powertrain innovation.

In summary, the background and objectives of e-boosting in B58 engines encompass the elimination of turbo lag, enhancement of overall engine responsiveness, improvement of fuel efficiency, and advancement of hybrid powertrain technologies. This initiative represents a critical step in the evolution of turbocharged engines, addressing long-standing performance challenges while paving the way for future powertrain innovations.

E-boosting, or electric boosting, has emerged as a promising solution to mitigate turbo lag in modern engines. This technology integrates an electric motor with the turbocharger system to provide instantaneous boost pressure, effectively bridging the gap between throttle input and turbocharger spool-up. The B58 engine, known for its robust performance and versatility, serves as an ideal platform for implementing and refining e-boosting innovations.

The primary objective of e-boosting in B58 engines is to eliminate or significantly reduce turbo lag, thereby enhancing overall engine responsiveness and drivability. This goal aligns with the broader industry trend towards more efficient and responsive powertrains, particularly in the context of increasingly stringent emissions regulations and the shift towards electrification.

E-boosting technology in B58 engines aims to achieve several key objectives. Firstly, it seeks to improve low-end torque delivery, providing immediate power response from low engine speeds. This enhancement is crucial for urban driving scenarios and quick overtaking maneuvers. Secondly, e-boosting targets seamless power delivery across the entire rev range, eliminating the characteristic "boost threshold" often associated with traditional turbocharged engines.

Furthermore, the implementation of e-boosting in B58 engines aims to optimize fuel efficiency by allowing for more precise boost control and potentially enabling downsizing strategies without compromising performance. This aligns with the automotive industry's ongoing efforts to reduce fuel consumption and emissions while maintaining or improving vehicle performance characteristics.

The development of e-boosting technologies for B58 engines also serves as a stepping stone towards more advanced hybrid powertrain systems. By integrating electric components into the boosting system, engineers gain valuable experience and insights that can be applied to future hybrid and electric vehicle platforms, positioning BMW at the forefront of powertrain innovation.

In summary, the background and objectives of e-boosting in B58 engines encompass the elimination of turbo lag, enhancement of overall engine responsiveness, improvement of fuel efficiency, and advancement of hybrid powertrain technologies. This initiative represents a critical step in the evolution of turbocharged engines, addressing long-standing performance challenges while paving the way for future powertrain innovations.

Market Demand for Turbo Lag Reduction

The market demand for turbo lag reduction in B58 engines has been steadily increasing, driven by consumer expectations for improved vehicle performance and responsiveness. As automotive technology advances, drivers are becoming more discerning about the driving experience, particularly in high-performance vehicles where the B58 engine is commonly used.

One of the primary factors fueling this demand is the growing popularity of turbocharged engines in the automotive industry. Turbocharging offers significant advantages in terms of power output and fuel efficiency, but the inherent lag in power delivery has been a persistent issue. This lag, often experienced as a delay between pressing the accelerator and feeling the full power of the engine, can detract from the overall driving experience.

In the premium and luxury vehicle segments, where many B58-equipped vehicles are positioned, customers have particularly high expectations for seamless power delivery. The demand for turbo lag reduction is not just about raw performance metrics, but also about the perceived quality and refinement of the driving experience. Manufacturers are under pressure to deliver engines that provide instant throttle response and linear power delivery across all RPM ranges.

The increasing focus on environmental regulations and fuel efficiency standards has also contributed to the demand for turbo lag reduction. As automakers strive to meet stricter emissions targets, they are turning to smaller, turbocharged engines like the B58. However, to maintain customer satisfaction and market competitiveness, these engines must perform comparably to larger, naturally aspirated engines in terms of responsiveness.

Moreover, the rise of electric and hybrid vehicles has set new benchmarks for instant torque delivery. This has further heightened consumer expectations for quick response in traditional internal combustion engines, pushing manufacturers to innovate in areas like e-boosting to bridge the gap.

The aftermarket tuning industry has also played a significant role in driving demand for turbo lag reduction. Performance enthusiasts are constantly seeking ways to enhance their vehicles, and reducing turbo lag is often a top priority. This has created a substantial market for aftermarket solutions and has pushed OEMs to improve their stock offerings to maintain customer loyalty.

In the context of B58 engines specifically, the demand for turbo lag reduction is particularly pronounced due to the engine's widespread use in performance-oriented vehicles. Customers who choose vehicles equipped with B58 engines often have high expectations for dynamic performance, making turbo lag reduction a critical factor in maintaining brand reputation and customer satisfaction.

One of the primary factors fueling this demand is the growing popularity of turbocharged engines in the automotive industry. Turbocharging offers significant advantages in terms of power output and fuel efficiency, but the inherent lag in power delivery has been a persistent issue. This lag, often experienced as a delay between pressing the accelerator and feeling the full power of the engine, can detract from the overall driving experience.

In the premium and luxury vehicle segments, where many B58-equipped vehicles are positioned, customers have particularly high expectations for seamless power delivery. The demand for turbo lag reduction is not just about raw performance metrics, but also about the perceived quality and refinement of the driving experience. Manufacturers are under pressure to deliver engines that provide instant throttle response and linear power delivery across all RPM ranges.

The increasing focus on environmental regulations and fuel efficiency standards has also contributed to the demand for turbo lag reduction. As automakers strive to meet stricter emissions targets, they are turning to smaller, turbocharged engines like the B58. However, to maintain customer satisfaction and market competitiveness, these engines must perform comparably to larger, naturally aspirated engines in terms of responsiveness.

Moreover, the rise of electric and hybrid vehicles has set new benchmarks for instant torque delivery. This has further heightened consumer expectations for quick response in traditional internal combustion engines, pushing manufacturers to innovate in areas like e-boosting to bridge the gap.

The aftermarket tuning industry has also played a significant role in driving demand for turbo lag reduction. Performance enthusiasts are constantly seeking ways to enhance their vehicles, and reducing turbo lag is often a top priority. This has created a substantial market for aftermarket solutions and has pushed OEMs to improve their stock offerings to maintain customer loyalty.

In the context of B58 engines specifically, the demand for turbo lag reduction is particularly pronounced due to the engine's widespread use in performance-oriented vehicles. Customers who choose vehicles equipped with B58 engines often have high expectations for dynamic performance, making turbo lag reduction a critical factor in maintaining brand reputation and customer satisfaction.

Current E-Boosting Technologies and Challenges

E-boosting technologies have emerged as a promising solution to address turbo lag in modern engines, including the BMW B58. These systems utilize electric motors to assist the turbocharger, providing instant boost and improving overall engine responsiveness. Currently, several e-boosting technologies are being implemented or developed for automotive applications.

One of the most prevalent e-boosting solutions is the electric compressor, also known as an e-compressor. This system consists of a small, high-speed electric motor coupled with a compressor wheel, which can be mounted either in series or parallel with the main turbocharger. The e-compressor spools up rapidly, providing immediate boost pressure at low engine speeds or during transient conditions, effectively eliminating turbo lag.

Another innovative approach is the electrically-assisted turbocharger, where an electric motor-generator is integrated directly into the turbocharger shaft. This design allows for both electric assistance during acceleration and energy recovery during deceleration, improving overall efficiency. The system can operate in three modes: motor, generator, and free-wheeling, providing flexibility in boost control and energy management.

Variable geometry turbochargers (VGTs) with electric actuation represent another advancement in e-boosting technology. These systems use electrically controlled vanes to adjust the turbine geometry, optimizing boost pressure across a wide range of engine speeds. The electric actuation allows for faster response times compared to traditional pneumatic systems, further reducing turbo lag.

Despite the promising advancements in e-boosting technologies, several challenges remain. One significant hurdle is the increased complexity and cost associated with integrating electric components into the powertrain. This complexity not only affects manufacturing processes but also impacts long-term reliability and maintenance requirements.

Power management and thermal considerations pose additional challenges. E-boosting systems require substantial electrical power, necessitating robust battery systems and advanced power electronics. Moreover, the high-speed operation of electric motors and compressors generates significant heat, requiring sophisticated cooling solutions to maintain optimal performance and longevity.

Packaging constraints present another obstacle, particularly in compact engine bays. Integrating e-boosting components while maintaining adequate airflow and thermal management can be challenging, often requiring creative engineering solutions and compromises in other areas of engine design.

Lastly, calibration and control strategies for e-boosting systems are complex, requiring sophisticated algorithms to balance performance, efficiency, and emissions across various driving conditions. Developing robust control systems that can seamlessly integrate e-boosting with other powertrain components remains an ongoing challenge for engineers.

One of the most prevalent e-boosting solutions is the electric compressor, also known as an e-compressor. This system consists of a small, high-speed electric motor coupled with a compressor wheel, which can be mounted either in series or parallel with the main turbocharger. The e-compressor spools up rapidly, providing immediate boost pressure at low engine speeds or during transient conditions, effectively eliminating turbo lag.

Another innovative approach is the electrically-assisted turbocharger, where an electric motor-generator is integrated directly into the turbocharger shaft. This design allows for both electric assistance during acceleration and energy recovery during deceleration, improving overall efficiency. The system can operate in three modes: motor, generator, and free-wheeling, providing flexibility in boost control and energy management.

Variable geometry turbochargers (VGTs) with electric actuation represent another advancement in e-boosting technology. These systems use electrically controlled vanes to adjust the turbine geometry, optimizing boost pressure across a wide range of engine speeds. The electric actuation allows for faster response times compared to traditional pneumatic systems, further reducing turbo lag.

Despite the promising advancements in e-boosting technologies, several challenges remain. One significant hurdle is the increased complexity and cost associated with integrating electric components into the powertrain. This complexity not only affects manufacturing processes but also impacts long-term reliability and maintenance requirements.

Power management and thermal considerations pose additional challenges. E-boosting systems require substantial electrical power, necessitating robust battery systems and advanced power electronics. Moreover, the high-speed operation of electric motors and compressors generates significant heat, requiring sophisticated cooling solutions to maintain optimal performance and longevity.

Packaging constraints present another obstacle, particularly in compact engine bays. Integrating e-boosting components while maintaining adequate airflow and thermal management can be challenging, often requiring creative engineering solutions and compromises in other areas of engine design.

Lastly, calibration and control strategies for e-boosting systems are complex, requiring sophisticated algorithms to balance performance, efficiency, and emissions across various driving conditions. Developing robust control systems that can seamlessly integrate e-boosting with other powertrain components remains an ongoing challenge for engineers.

Existing E-Boosting Solutions for B58 Engines

01 Twin-scroll turbocharger design

Implementing a twin-scroll turbocharger design in B58 engines can help reduce turbo lag. This design separates exhaust pulses, allowing for more efficient use of exhaust energy and quicker turbocharger response. The twin-scroll design also helps maintain higher boost pressure at lower engine speeds, improving low-end torque and responsiveness.- Twin-scroll turbocharger design: Implementing a twin-scroll turbocharger design in B58 engines can help reduce turbo lag. This design separates exhaust pulses, allowing for more efficient use of exhaust energy and quicker turbocharger response. The twin-scroll design also helps maintain higher boost pressure at lower engine speeds, improving low-end torque and reducing lag.

- Variable geometry turbocharger: Incorporating a variable geometry turbocharger (VGT) in B58 engines can significantly reduce turbo lag. VGTs use adjustable vanes to optimize exhaust flow across different engine speeds, providing better response and reducing lag. This technology allows for improved low-end torque and faster spooling of the turbocharger.

- Electric supercharger integration: Integrating an electric supercharger alongside the turbocharger in B58 engines can effectively eliminate turbo lag. The electric supercharger can provide instant boost at low engine speeds, filling the gap before the turbocharger spools up. This hybrid forced induction system ensures immediate response and smooth power delivery across the entire rev range.

- Advanced engine management systems: Implementing advanced engine management systems and software optimization can help mitigate turbo lag in B58 engines. These systems can precisely control fuel injection, ignition timing, and boost pressure to maximize engine efficiency and responsiveness. Additionally, they can employ predictive algorithms to anticipate driver inputs and pre-spool the turbocharger.

- Lightweight turbine and compressor wheels: Utilizing lightweight materials and optimized designs for turbine and compressor wheels can reduce turbo lag in B58 engines. Lighter rotating components have lower inertia, allowing for quicker acceleration of the turbocharger. This results in faster boost buildup and improved engine responsiveness, particularly at lower engine speeds.

02 Variable geometry turbocharger

Utilizing a variable geometry turbocharger (VGT) in B58 engines can significantly reduce turbo lag. VGTs feature adjustable vanes that can alter the flow of exhaust gases, optimizing turbocharger performance across a wide range of engine speeds. This technology allows for quicker spooling at low engine speeds while maintaining efficiency at higher speeds.Expand Specific Solutions03 Electric-assisted turbocharger

Incorporating an electric-assisted turbocharger in B58 engines can effectively minimize turbo lag. This system uses an electric motor to quickly spool up the turbocharger, providing instant boost and improving engine responsiveness. The electric assistance can be particularly beneficial during low-speed acceleration and transient conditions.Expand Specific Solutions04 Advanced engine control strategies

Implementing advanced engine control strategies can help mitigate turbo lag in B58 engines. These strategies may include optimized fuel injection timing, variable valve timing, and sophisticated boost control algorithms. By fine-tuning these parameters, the engine management system can improve turbocharger response and overall engine performance.Expand Specific Solutions05 Integrated exhaust manifold design

Adopting an integrated exhaust manifold design in B58 engines can contribute to reducing turbo lag. This design integrates the exhaust manifold directly into the cylinder head, reducing heat loss and improving exhaust gas flow. The compact design also helps in quicker turbocharger spooling and improved overall engine efficiency.Expand Specific Solutions

Key Players in E-Boosting and Engine Innovation

The competitive landscape for "Turbo Lag Elimination Techniques Through E-Boosting Innovations in B58 Engines" is evolving rapidly. The industry is in a growth phase, with increasing market size driven by demand for improved engine performance and fuel efficiency. Technological maturity is advancing, with companies like BMW, Ford, and Toyota leading innovation. Continental Automotive and Robert Bosch are developing advanced e-boosting systems, while Honeywell and BorgWarner focus on turbocharger technologies. Emerging players like SuperTurbo Technologies are introducing novel solutions. The market is characterized by intense competition and rapid technological advancements, with major automotive manufacturers and suppliers investing heavily in research and development to gain a competitive edge.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative e-boosting solution for turbo lag elimination, applicable to engines like the B58. Their system incorporates an electrically-driven compressor (EDC) that works in conjunction with conventional turbochargers. The EDC can spool up to 70,000 rpm in just 250 milliseconds, providing instant boost pressure[2]. Bosch's e-booster is integrated into a 48V electrical system, which allows for efficient energy recovery and distribution. The company has also developed sophisticated control software that optimizes the interaction between the EDC and the traditional turbocharger, ensuring smooth power delivery across the entire rev range[4]. Furthermore, Bosch's system includes advanced thermal management to maintain optimal operating temperatures for both the e-booster and the conventional turbocharger[6].

Strengths: Rapid boost response, seamless integration with existing turbocharger systems, and advanced control algorithms. Weaknesses: Requires integration of 48V electrical system, which may increase overall system cost and complexity.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to eliminating turbo lag in B58 engines involves a sophisticated e-boosting system. This system utilizes an electric compressor working in tandem with the traditional turbocharger. The electric compressor, powered by a 48V electrical system, spools up almost instantaneously, providing boost pressure at low engine speeds where the traditional turbocharger is less effective[1]. This setup allows for immediate throttle response and reduced lag time. BMW has also implemented advanced control algorithms that predict driver behavior and pre-emptively engage the e-booster, further minimizing perceived lag[3]. Additionally, the B58 engine features a twin-scroll turbocharger design, which helps in efficient exhaust gas separation and improves low-end torque[5].

Strengths: Immediate throttle response, improved low-end torque, and seamless power delivery. Weaknesses: Increased system complexity and potential higher costs due to additional electrical components.

Core Innovations in E-Boosting Technology

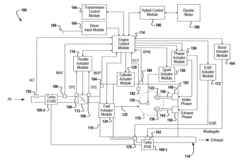

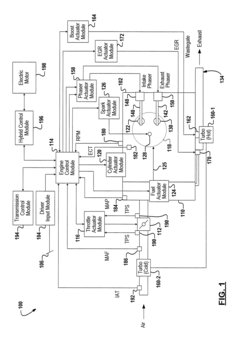

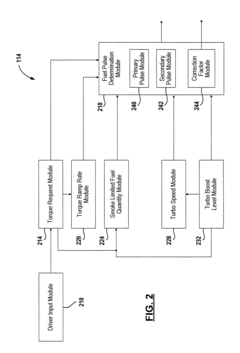

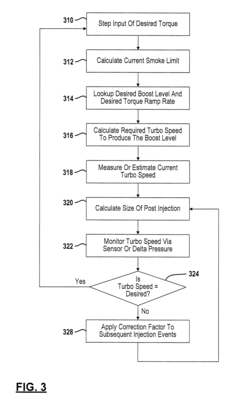

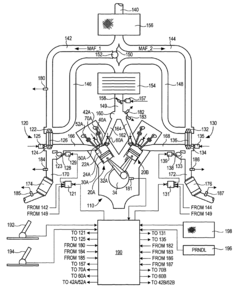

Method and system for reducing turbo lag in an engine

PatentInactiveUS20110257867A1

Innovation

- A system and method that generate a secondary fuel pulse to increase the pressure or temperature of exhaust gases driving the turbocharger turbine, determining primary and secondary fuel injection pulsewidths based on driver-requested torque and desired boost levels to reduce turbo lag.

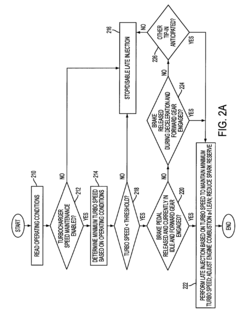

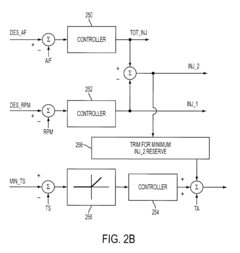

Engine idle speed and turbocharger speed control

PatentInactiveUS8131446B2

Innovation

- A method involving dual fuel injections during a cylinder cycle, where the first injection generates lean combustion and the second injection occurs post-combustion to maintain turbocharger speed responsive to driver input, reducing fuel usage and turbo lag while maintaining rapid tip-in response.

Environmental Impact of E-Boosting Systems

The implementation of e-boosting systems in B58 engines, while aimed at eliminating turbo lag, also has significant environmental implications. These systems, which utilize electric compressors to supplement traditional turbochargers, offer potential benefits in terms of emissions reduction and fuel efficiency. However, they also present challenges related to energy consumption and lifecycle environmental impact.

E-boosting systems can contribute to reduced emissions by enabling more precise control over the air-fuel mixture. This improved combustion efficiency leads to lower levels of harmful pollutants such as carbon monoxide (CO) and nitrogen oxides (NOx). Additionally, the faster response time of e-boosters allows engines to operate more efficiently across a broader range of driving conditions, potentially reducing overall fuel consumption and, consequently, carbon dioxide (CO2) emissions.

The ability of e-boosting systems to support engine downsizing is another environmental advantage. By maintaining performance with smaller displacement engines, manufacturers can reduce the overall weight of vehicles, further improving fuel efficiency and reducing emissions. This aligns with global efforts to meet increasingly stringent environmental regulations and reduce the automotive industry's carbon footprint.

However, the environmental benefits of e-boosting systems must be weighed against the increased electrical energy demand they introduce. The production and disposal of the additional electrical components, including high-performance batteries and power electronics, raise concerns about resource consumption and end-of-life waste management. The manufacturing processes for these components often involve rare earth elements and energy-intensive production methods, which can offset some of the environmental gains achieved during vehicle operation.

The overall environmental impact of e-boosting systems also depends on the source of electricity used to charge vehicle batteries. In regions where electricity is predominantly generated from renewable sources, the net environmental benefit is likely to be more significant. Conversely, in areas heavily reliant on fossil fuels for electricity generation, the indirect emissions associated with e-boosting may partially negate the direct emissions reductions achieved at the vehicle level.

Long-term durability and maintenance requirements of e-boosting systems are additional factors to consider in assessing their environmental impact. If these systems prove to be reliable and long-lasting, they could contribute to extended vehicle lifespans, reducing the frequency of vehicle replacements and associated manufacturing emissions. However, if they require frequent replacements or complex maintenance procedures, the environmental costs could increase.

As the automotive industry continues to evolve towards electrification, the role of e-boosting systems in hybrid and mild-hybrid powertrains may serve as a transitional technology, bridging the gap between traditional internal combustion engines and fully electric vehicles. This transition period could be crucial in reducing overall fleet emissions while battery technology and charging infrastructure continue to develop.

E-boosting systems can contribute to reduced emissions by enabling more precise control over the air-fuel mixture. This improved combustion efficiency leads to lower levels of harmful pollutants such as carbon monoxide (CO) and nitrogen oxides (NOx). Additionally, the faster response time of e-boosters allows engines to operate more efficiently across a broader range of driving conditions, potentially reducing overall fuel consumption and, consequently, carbon dioxide (CO2) emissions.

The ability of e-boosting systems to support engine downsizing is another environmental advantage. By maintaining performance with smaller displacement engines, manufacturers can reduce the overall weight of vehicles, further improving fuel efficiency and reducing emissions. This aligns with global efforts to meet increasingly stringent environmental regulations and reduce the automotive industry's carbon footprint.

However, the environmental benefits of e-boosting systems must be weighed against the increased electrical energy demand they introduce. The production and disposal of the additional electrical components, including high-performance batteries and power electronics, raise concerns about resource consumption and end-of-life waste management. The manufacturing processes for these components often involve rare earth elements and energy-intensive production methods, which can offset some of the environmental gains achieved during vehicle operation.

The overall environmental impact of e-boosting systems also depends on the source of electricity used to charge vehicle batteries. In regions where electricity is predominantly generated from renewable sources, the net environmental benefit is likely to be more significant. Conversely, in areas heavily reliant on fossil fuels for electricity generation, the indirect emissions associated with e-boosting may partially negate the direct emissions reductions achieved at the vehicle level.

Long-term durability and maintenance requirements of e-boosting systems are additional factors to consider in assessing their environmental impact. If these systems prove to be reliable and long-lasting, they could contribute to extended vehicle lifespans, reducing the frequency of vehicle replacements and associated manufacturing emissions. However, if they require frequent replacements or complex maintenance procedures, the environmental costs could increase.

As the automotive industry continues to evolve towards electrification, the role of e-boosting systems in hybrid and mild-hybrid powertrains may serve as a transitional technology, bridging the gap between traditional internal combustion engines and fully electric vehicles. This transition period could be crucial in reducing overall fleet emissions while battery technology and charging infrastructure continue to develop.

Cost-Benefit Analysis of E-Boosting Implementation

The implementation of e-boosting technology in B58 engines presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for e-boosting systems are significant, encompassing the development and integration of electric compressors, power electronics, and control systems. These components demand substantial research and development expenditure, as well as tooling and manufacturing setup costs.

However, the long-term benefits of e-boosting can potentially outweigh these initial expenses. Improved engine performance, particularly in low-end torque and throttle response, can lead to enhanced vehicle drivability and customer satisfaction. This may translate into increased market share and brand value, offsetting the initial investment over time.

Fuel efficiency gains from e-boosting, although modest, accumulate over a vehicle's lifetime. The reduction in turbo lag allows for more efficient engine operation, potentially leading to fuel savings that benefit both consumers and manufacturers in meeting increasingly stringent emissions regulations. This aspect could result in avoided costs related to regulatory compliance and potential fines.

Manufacturing costs may initially increase due to the additional components required for e-boosting. However, economies of scale and learning curve effects are likely to reduce these costs over time as production volumes increase and processes are optimized. The integration of e-boosting may also allow for downsizing of other engine components, potentially offsetting some of the additional costs.

Maintenance considerations must be factored into the cost-benefit analysis. While e-boosting systems may introduce new points of potential failure, they could also reduce wear on traditional turbocharger components, potentially extending overall engine life and reducing warranty claims. The net effect on maintenance costs will depend on the reliability and durability of the e-boosting components.

From a competitive standpoint, being an early adopter of e-boosting technology could provide a significant market advantage. The improved performance characteristics could justify premium pricing, enhancing profit margins. However, this advantage may be temporary as competitors catch up, necessitating ongoing innovation to maintain a technological edge.

In conclusion, while the upfront costs of implementing e-boosting in B58 engines are substantial, the potential long-term benefits in performance, efficiency, and market positioning make it a compelling investment. The success of this technology will ultimately depend on careful engineering, strategic pricing, and effective marketing to ensure that the benefits are fully realized and valued by consumers.

However, the long-term benefits of e-boosting can potentially outweigh these initial expenses. Improved engine performance, particularly in low-end torque and throttle response, can lead to enhanced vehicle drivability and customer satisfaction. This may translate into increased market share and brand value, offsetting the initial investment over time.

Fuel efficiency gains from e-boosting, although modest, accumulate over a vehicle's lifetime. The reduction in turbo lag allows for more efficient engine operation, potentially leading to fuel savings that benefit both consumers and manufacturers in meeting increasingly stringent emissions regulations. This aspect could result in avoided costs related to regulatory compliance and potential fines.

Manufacturing costs may initially increase due to the additional components required for e-boosting. However, economies of scale and learning curve effects are likely to reduce these costs over time as production volumes increase and processes are optimized. The integration of e-boosting may also allow for downsizing of other engine components, potentially offsetting some of the additional costs.

Maintenance considerations must be factored into the cost-benefit analysis. While e-boosting systems may introduce new points of potential failure, they could also reduce wear on traditional turbocharger components, potentially extending overall engine life and reducing warranty claims. The net effect on maintenance costs will depend on the reliability and durability of the e-boosting components.

From a competitive standpoint, being an early adopter of e-boosting technology could provide a significant market advantage. The improved performance characteristics could justify premium pricing, enhancing profit margins. However, this advantage may be temporary as competitors catch up, necessitating ongoing innovation to maintain a technological edge.

In conclusion, while the upfront costs of implementing e-boosting in B58 engines are substantial, the potential long-term benefits in performance, efficiency, and market positioning make it a compelling investment. The success of this technology will ultimately depend on careful engineering, strategic pricing, and effective marketing to ensure that the benefits are fully realized and valued by consumers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!