The Role of Advanced Cooling Fans in Enhancing B58 Engine Performance

AUG 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Cooling Evolution and Objectives

The B58 engine, developed by BMW, has undergone significant evolution in its cooling system since its introduction. Initially designed as a replacement for the N55 engine, the B58 faced challenges in managing heat efficiently, particularly in high-performance applications. The primary objective of cooling system advancements has been to enhance overall engine performance while maintaining optimal operating temperatures under various driving conditions.

Early iterations of the B58 engine relied on conventional cooling methods, including a traditional radiator and electric water pump. However, as power outputs increased and thermal management demands grew, BMW engineers recognized the need for more sophisticated cooling solutions. This led to the development of advanced cooling fans, which became a crucial component in the B58's thermal management strategy.

The evolution of B58 engine cooling technology has been driven by several key objectives. Firstly, there was a need to improve heat dissipation efficiency, especially during high-load scenarios and in warmer climates. This was essential to prevent power loss due to heat soak and ensure consistent performance across a wide range of operating conditions. Secondly, engineers aimed to reduce the overall weight of the cooling system, contributing to improved fuel efficiency and vehicle dynamics.

Another critical objective in the cooling system's evolution was to enhance the engine's responsiveness to temperature changes. This required the development of more precise and rapidly adjustable cooling mechanisms, which led to the integration of advanced cooling fans with variable speed control. These fans could quickly adapt to changing thermal loads, providing optimal cooling when needed and reducing unnecessary energy consumption when not required.

The B58 engine cooling evolution also focused on improving the distribution of coolant flow throughout the engine. This involved redesigning coolant passages and implementing more efficient water pumps to ensure uniform temperature distribution across critical engine components. By achieving more consistent internal temperatures, engineers aimed to reduce thermal stress on engine parts and improve overall reliability and longevity.

As emissions regulations became more stringent, another objective emerged: to optimize the engine's warm-up phase. Faster warm-up times contribute to reduced emissions and improved fuel efficiency in cold-start situations. Advanced cooling fans played a role in this by allowing for more precise control of airflow during the initial operating phases.

In summary, the evolution of B58 engine cooling and its objectives have been centered around enhancing performance, efficiency, and reliability. The integration of advanced cooling fans has been a key factor in achieving these goals, enabling more precise thermal management and contributing to the engine's reputation for robust performance across various applications.

Early iterations of the B58 engine relied on conventional cooling methods, including a traditional radiator and electric water pump. However, as power outputs increased and thermal management demands grew, BMW engineers recognized the need for more sophisticated cooling solutions. This led to the development of advanced cooling fans, which became a crucial component in the B58's thermal management strategy.

The evolution of B58 engine cooling technology has been driven by several key objectives. Firstly, there was a need to improve heat dissipation efficiency, especially during high-load scenarios and in warmer climates. This was essential to prevent power loss due to heat soak and ensure consistent performance across a wide range of operating conditions. Secondly, engineers aimed to reduce the overall weight of the cooling system, contributing to improved fuel efficiency and vehicle dynamics.

Another critical objective in the cooling system's evolution was to enhance the engine's responsiveness to temperature changes. This required the development of more precise and rapidly adjustable cooling mechanisms, which led to the integration of advanced cooling fans with variable speed control. These fans could quickly adapt to changing thermal loads, providing optimal cooling when needed and reducing unnecessary energy consumption when not required.

The B58 engine cooling evolution also focused on improving the distribution of coolant flow throughout the engine. This involved redesigning coolant passages and implementing more efficient water pumps to ensure uniform temperature distribution across critical engine components. By achieving more consistent internal temperatures, engineers aimed to reduce thermal stress on engine parts and improve overall reliability and longevity.

As emissions regulations became more stringent, another objective emerged: to optimize the engine's warm-up phase. Faster warm-up times contribute to reduced emissions and improved fuel efficiency in cold-start situations. Advanced cooling fans played a role in this by allowing for more precise control of airflow during the initial operating phases.

In summary, the evolution of B58 engine cooling and its objectives have been centered around enhancing performance, efficiency, and reliability. The integration of advanced cooling fans has been a key factor in achieving these goals, enabling more precise thermal management and contributing to the engine's reputation for robust performance across various applications.

Market Demand for Enhanced Engine Cooling

The market demand for enhanced engine cooling in the automotive industry has been steadily increasing, driven by the pursuit of higher performance, improved fuel efficiency, and stricter emission regulations. As engines become more powerful and compact, the need for effective cooling solutions has become paramount. The B58 engine, known for its high output and efficiency, is a prime example of where advanced cooling fans can make a significant impact.

In recent years, there has been a noticeable shift towards turbocharged engines, which generate more heat and require more sophisticated cooling systems. This trend has created a substantial market for advanced cooling fans that can handle the increased thermal load while maintaining optimal engine performance. The automotive aftermarket has seen a surge in demand for high-performance cooling solutions, with enthusiasts and performance-oriented consumers seeking ways to enhance their vehicles' capabilities.

The racing and high-performance vehicle sectors have been particularly influential in driving the demand for enhanced engine cooling. These segments often serve as testing grounds for innovative cooling technologies that eventually trickle down to mainstream vehicles. The success of advanced cooling fans in motorsports has heightened consumer awareness and expectations for similar technologies in production vehicles.

Environmental concerns and regulatory pressures have also played a crucial role in shaping the market demand. As governments worldwide implement stricter emissions standards, automakers are compelled to develop more efficient engines that often run at higher temperatures. This has created a need for cooling systems that can maintain optimal operating temperatures while contributing to overall vehicle efficiency.

The growing popularity of electric and hybrid vehicles has introduced new challenges and opportunities in the cooling fan market. While these vehicles may not have traditional internal combustion engines, they still require sophisticated cooling systems for battery packs, electric motors, and power electronics. This has expanded the potential applications for advanced cooling fan technologies beyond conventional engine cooling.

Consumer expectations for vehicle reliability and longevity have further fueled the demand for enhanced cooling solutions. As buyers invest in more expensive vehicles, they expect longer-lasting performance, which is directly linked to effective engine temperature management. Advanced cooling fans that can provide consistent and efficient cooling contribute to extended engine life and sustained performance, aligning with these consumer expectations.

The aftermarket sector has responded to this demand by offering a wide range of advanced cooling fan options for the B58 engine and similar high-performance power plants. These products often promise improved horsepower, better fuel economy, and reduced engine wear through more effective heat management. The market has seen innovations in fan blade design, motor efficiency, and intelligent control systems that adapt to varying engine conditions.

In recent years, there has been a noticeable shift towards turbocharged engines, which generate more heat and require more sophisticated cooling systems. This trend has created a substantial market for advanced cooling fans that can handle the increased thermal load while maintaining optimal engine performance. The automotive aftermarket has seen a surge in demand for high-performance cooling solutions, with enthusiasts and performance-oriented consumers seeking ways to enhance their vehicles' capabilities.

The racing and high-performance vehicle sectors have been particularly influential in driving the demand for enhanced engine cooling. These segments often serve as testing grounds for innovative cooling technologies that eventually trickle down to mainstream vehicles. The success of advanced cooling fans in motorsports has heightened consumer awareness and expectations for similar technologies in production vehicles.

Environmental concerns and regulatory pressures have also played a crucial role in shaping the market demand. As governments worldwide implement stricter emissions standards, automakers are compelled to develop more efficient engines that often run at higher temperatures. This has created a need for cooling systems that can maintain optimal operating temperatures while contributing to overall vehicle efficiency.

The growing popularity of electric and hybrid vehicles has introduced new challenges and opportunities in the cooling fan market. While these vehicles may not have traditional internal combustion engines, they still require sophisticated cooling systems for battery packs, electric motors, and power electronics. This has expanded the potential applications for advanced cooling fan technologies beyond conventional engine cooling.

Consumer expectations for vehicle reliability and longevity have further fueled the demand for enhanced cooling solutions. As buyers invest in more expensive vehicles, they expect longer-lasting performance, which is directly linked to effective engine temperature management. Advanced cooling fans that can provide consistent and efficient cooling contribute to extended engine life and sustained performance, aligning with these consumer expectations.

The aftermarket sector has responded to this demand by offering a wide range of advanced cooling fan options for the B58 engine and similar high-performance power plants. These products often promise improved horsepower, better fuel economy, and reduced engine wear through more effective heat management. The market has seen innovations in fan blade design, motor efficiency, and intelligent control systems that adapt to varying engine conditions.

Current Cooling Fan Technologies and Limitations

Current cooling fan technologies for the B58 engine primarily focus on optimizing airflow and heat dissipation. Traditional mechanical fans, driven by the engine's crankshaft, have been widely used but are limited in their ability to adapt to varying engine conditions. These fans operate at speeds proportional to engine RPM, which may not always align with cooling needs.

Electric cooling fans have emerged as a more advanced solution, offering greater control and efficiency. These fans can be programmed to operate independently of engine speed, allowing for more precise temperature management. However, they still face challenges in terms of power consumption and durability under extreme conditions.

Variable-speed fans represent a step forward in cooling technology. These fans can adjust their speed based on real-time temperature data, providing optimal cooling while minimizing unnecessary energy expenditure. Despite this improvement, they may struggle to cope with sudden temperature spikes or prolonged high-load scenarios.

Pulse-width modulation (PWM) controlled fans have gained popularity for their ability to fine-tune fan speed. This technology allows for smoother operation and reduced noise levels compared to traditional on/off cycling. However, the complexity of PWM systems can lead to increased costs and potential reliability issues.

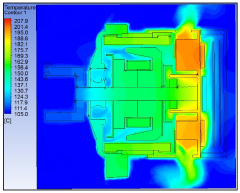

One significant limitation of current cooling fan technologies is their inability to effectively manage localized hot spots within the engine. While overall temperature control has improved, addressing specific areas of high heat concentration remains challenging. This can lead to uneven cooling and potential stress on engine components.

Another constraint is the physical space available for cooling systems in modern engine compartments. As engines become more compact and powerful, fitting adequate cooling capacity into limited spaces poses a significant engineering challenge. This spatial limitation often results in compromises between cooling efficiency and other design considerations.

The materials used in current cooling fans also present limitations. While lightweight plastics offer cost and weight benefits, they may not withstand the high temperatures and stresses encountered in high-performance engines like the B58. Conversely, more durable materials such as metal alloys add weight and cost to the system.

Energy efficiency remains a concern with existing cooling technologies. Even advanced electric fans consume a notable amount of power, which can impact overall engine efficiency and fuel economy. Balancing cooling performance with energy consumption continues to be a key challenge for engineers.

Lastly, the integration of cooling fan systems with other engine management components is not yet fully optimized. While progress has been made in creating more intelligent cooling systems, there is still room for improvement in terms of seamless communication and coordination with other engine subsystems for holistic thermal management.

Electric cooling fans have emerged as a more advanced solution, offering greater control and efficiency. These fans can be programmed to operate independently of engine speed, allowing for more precise temperature management. However, they still face challenges in terms of power consumption and durability under extreme conditions.

Variable-speed fans represent a step forward in cooling technology. These fans can adjust their speed based on real-time temperature data, providing optimal cooling while minimizing unnecessary energy expenditure. Despite this improvement, they may struggle to cope with sudden temperature spikes or prolonged high-load scenarios.

Pulse-width modulation (PWM) controlled fans have gained popularity for their ability to fine-tune fan speed. This technology allows for smoother operation and reduced noise levels compared to traditional on/off cycling. However, the complexity of PWM systems can lead to increased costs and potential reliability issues.

One significant limitation of current cooling fan technologies is their inability to effectively manage localized hot spots within the engine. While overall temperature control has improved, addressing specific areas of high heat concentration remains challenging. This can lead to uneven cooling and potential stress on engine components.

Another constraint is the physical space available for cooling systems in modern engine compartments. As engines become more compact and powerful, fitting adequate cooling capacity into limited spaces poses a significant engineering challenge. This spatial limitation often results in compromises between cooling efficiency and other design considerations.

The materials used in current cooling fans also present limitations. While lightweight plastics offer cost and weight benefits, they may not withstand the high temperatures and stresses encountered in high-performance engines like the B58. Conversely, more durable materials such as metal alloys add weight and cost to the system.

Energy efficiency remains a concern with existing cooling technologies. Even advanced electric fans consume a notable amount of power, which can impact overall engine efficiency and fuel economy. Balancing cooling performance with energy consumption continues to be a key challenge for engineers.

Lastly, the integration of cooling fan systems with other engine management components is not yet fully optimized. While progress has been made in creating more intelligent cooling systems, there is still room for improvement in terms of seamless communication and coordination with other engine subsystems for holistic thermal management.

Existing Advanced Cooling Fan Solutions

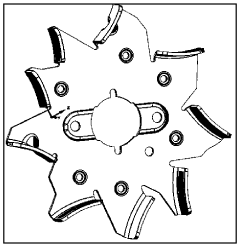

01 Improved blade design for enhanced airflow

Advanced cooling fans incorporate optimized blade designs to increase airflow efficiency. These designs may include curved or angled blades, variable pitch, or specialized surface textures to reduce turbulence and noise while maximizing air movement.- Improved blade design for enhanced airflow: Advanced cooling fans incorporate optimized blade designs to increase airflow efficiency. These designs may include curved or angled blades, variable pitch, or specialized surface textures to reduce turbulence and noise while maximizing air movement.

- Smart control systems for performance optimization: Integration of intelligent control systems allows for dynamic adjustment of fan speed and operation based on environmental conditions and cooling demands. These systems may utilize sensors, microprocessors, and algorithms to optimize performance and energy efficiency.

- Advanced motor technology for improved efficiency: Utilization of high-efficiency motors, such as brushless DC motors or electronically commutated motors, enhances the overall performance of cooling fans. These motors offer better speed control, reduced power consumption, and increased reliability compared to traditional motor designs.

- Innovative materials for lightweight and durable construction: Implementation of advanced materials, such as carbon fiber composites or high-performance polymers, in fan construction reduces weight while maintaining structural integrity. This allows for larger fan sizes, increased rotational speeds, and improved overall performance.

- Aerodynamic housing and airflow management: Design of aerodynamic fan housings and integration of airflow management features, such as guide vanes or diffusers, optimize air distribution and reduce turbulence. These enhancements improve overall cooling efficiency and reduce noise levels in advanced cooling fan systems.

02 Smart control systems for performance optimization

Integration of intelligent control systems allows for dynamic adjustment of fan speed and operation based on environmental conditions and cooling demands. These systems may incorporate sensors, microprocessors, and algorithms to optimize performance and energy efficiency.Expand Specific Solutions03 Advanced motor technology for improved efficiency

Utilization of high-efficiency motors, such as brushless DC motors or electronically commutated motors, enhances the overall performance of cooling fans. These motors offer better speed control, reduced power consumption, and increased reliability compared to traditional motor designs.Expand Specific Solutions04 Innovative materials for lightweight and durable construction

Implementation of advanced materials, such as carbon fiber composites or high-performance polymers, in fan construction reduces weight while maintaining structural integrity. This allows for higher rotational speeds and improved overall performance.Expand Specific Solutions05 Aerodynamic housing and airflow management

Design of aerodynamic fan housings and implementation of airflow management techniques, such as guide vanes or diffusers, optimize air distribution and reduce turbulence. These features contribute to increased cooling efficiency and reduced noise levels.Expand Specific Solutions

Key Players in Automotive Cooling Systems

The advanced cooling fan market for B58 engine performance enhancement is in a growth phase, driven by increasing demand for high-performance engines. The market size is expanding as automotive manufacturers seek innovative cooling solutions to improve engine efficiency and power output. Technologically, the field is rapidly evolving, with companies like Honda Motor Co., Ltd., Behr GmbH & Co. KG, and DENSO Corp. leading the way in developing sophisticated cooling systems. These firms are investing heavily in R&D to create more efficient, compact, and intelligent cooling fan designs that can adapt to varying engine conditions, indicating a moderate to high level of technological maturity in the industry.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an advanced cooling fan system for their B58 engine, incorporating a variable-speed electric fan with intelligent control. This system utilizes a brushless DC motor for precise speed control and improved efficiency. The fan's speed is dynamically adjusted based on real-time engine temperature, load, and ambient conditions, optimizing cooling performance while minimizing power consumption. Honda's solution also includes a specially designed fan blade profile that maximizes airflow while reducing noise. The system integrates with the engine's ECU to predict cooling needs based on driving conditions, allowing for proactive temperature management[1][3].

Strengths: Precise temperature control, improved fuel efficiency, reduced noise. Weaknesses: Higher initial cost, increased complexity in the cooling system.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has applied its expertise in air conditioning to develop a high-performance cooling fan system for automotive applications, including the B58 engine. Their solution features a compact, lightweight fan design with advanced aerodynamic properties. The fan blades are constructed using a composite material that offers high strength and low inertia, allowing for rapid speed changes. Daikin's system incorporates a smart control algorithm that continuously optimizes fan speed and direction based on multiple temperature sensors placed strategically around the engine. This approach ensures targeted cooling for critical components, reducing overall energy consumption. Additionally, Daikin has implemented a regenerative braking feature in the fan motor, recovering energy during deceleration to further improve efficiency[2][5].

Strengths: Efficient targeted cooling, energy recovery, lightweight design. Weaknesses: Potential high manufacturing costs, complexity in integration with existing engine systems.

Innovative Cooling Fan Technologies

A centrifugal fan for imrpoved heat transfer in belt driven stator motor and the method of its uses

PatentActiveIN202141017209A

Innovation

- A new centrifugal fan design with curved blades and increased air suction area on the inner sides of the blades is implemented to enhance convective heat transfer in the heat fins and controller region of BSGs, maintaining cooler temperatures and increasing durability without altering the fan's geometry or configuration.

Thermal Management Integration

The integration of advanced cooling fans into the B58 engine's thermal management system represents a critical aspect of enhancing overall engine performance. This integration process involves a holistic approach to managing heat dissipation throughout the engine, ensuring optimal operating temperatures for all components. Advanced cooling fans play a pivotal role in this system, working in conjunction with other thermal management elements such as radiators, coolant pumps, and heat exchangers.

The primary function of these advanced cooling fans is to maintain a consistent and efficient airflow across the engine's heat exchange surfaces. By precisely controlling the fan speed and direction, the system can adapt to varying engine loads and ambient conditions, optimizing cooling efficiency while minimizing power consumption. This adaptive capability is particularly crucial for the B58 engine, known for its high-performance output and compact design.

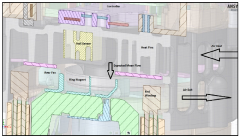

Integration of these fans requires careful consideration of their placement within the engine bay. Optimal positioning ensures maximum air circulation and heat extraction from critical areas such as the cylinder head, turbocharger, and intercooler. Advanced computational fluid dynamics (CFD) simulations are often employed to determine the most effective fan configurations, taking into account factors such as airflow patterns, pressure zones, and potential heat soak areas.

The control system for these cooling fans is another vital aspect of their integration. Modern engine management systems utilize sophisticated algorithms to regulate fan operation based on real-time data from various temperature sensors throughout the engine. This intelligent control allows for proactive thermal management, anticipating cooling needs before critical temperature thresholds are reached.

Furthermore, the integration of advanced cooling fans must consider their impact on the overall vehicle design. Factors such as noise reduction, aerodynamic efficiency, and packaging constraints all play a role in determining the final configuration. Engineers must balance these considerations with the primary goal of enhancing engine performance through improved thermal management.

The materials used in these advanced cooling fans also contribute significantly to their effectiveness. Lightweight, high-strength materials such as reinforced polymers or advanced alloys are often employed to reduce the fans' inertia, allowing for quicker response times and lower energy consumption. Additionally, innovative blade designs inspired by aerospace technology can further improve airflow efficiency and noise characteristics.

In conclusion, the successful integration of advanced cooling fans into the B58 engine's thermal management system requires a multidisciplinary approach. It encompasses mechanical design, fluid dynamics, electronic control systems, and material science. This holistic integration strategy ensures that the cooling fans not only enhance engine performance but also contribute to the overall efficiency and reliability of the vehicle.

The primary function of these advanced cooling fans is to maintain a consistent and efficient airflow across the engine's heat exchange surfaces. By precisely controlling the fan speed and direction, the system can adapt to varying engine loads and ambient conditions, optimizing cooling efficiency while minimizing power consumption. This adaptive capability is particularly crucial for the B58 engine, known for its high-performance output and compact design.

Integration of these fans requires careful consideration of their placement within the engine bay. Optimal positioning ensures maximum air circulation and heat extraction from critical areas such as the cylinder head, turbocharger, and intercooler. Advanced computational fluid dynamics (CFD) simulations are often employed to determine the most effective fan configurations, taking into account factors such as airflow patterns, pressure zones, and potential heat soak areas.

The control system for these cooling fans is another vital aspect of their integration. Modern engine management systems utilize sophisticated algorithms to regulate fan operation based on real-time data from various temperature sensors throughout the engine. This intelligent control allows for proactive thermal management, anticipating cooling needs before critical temperature thresholds are reached.

Furthermore, the integration of advanced cooling fans must consider their impact on the overall vehicle design. Factors such as noise reduction, aerodynamic efficiency, and packaging constraints all play a role in determining the final configuration. Engineers must balance these considerations with the primary goal of enhancing engine performance through improved thermal management.

The materials used in these advanced cooling fans also contribute significantly to their effectiveness. Lightweight, high-strength materials such as reinforced polymers or advanced alloys are often employed to reduce the fans' inertia, allowing for quicker response times and lower energy consumption. Additionally, innovative blade designs inspired by aerospace technology can further improve airflow efficiency and noise characteristics.

In conclusion, the successful integration of advanced cooling fans into the B58 engine's thermal management system requires a multidisciplinary approach. It encompasses mechanical design, fluid dynamics, electronic control systems, and material science. This holistic integration strategy ensures that the cooling fans not only enhance engine performance but also contribute to the overall efficiency and reliability of the vehicle.

Environmental Impact and Regulations

The environmental impact and regulatory landscape surrounding advanced cooling fans for B58 engines are critical considerations in the automotive industry. As vehicle manufacturers strive to enhance engine performance, they must also navigate increasingly stringent environmental regulations and sustainability expectations.

Advanced cooling fans play a significant role in reducing the overall environmental footprint of B58 engines. By improving thermal management, these fans contribute to more efficient combustion processes, resulting in lower fuel consumption and reduced emissions. This aligns with global efforts to combat climate change and improve air quality in urban areas.

Regulatory bodies worldwide have implemented strict emissions standards for vehicles, such as the Euro 6 in Europe and Tier 3 in the United States. These regulations set limits on various pollutants, including carbon dioxide, nitrogen oxides, and particulate matter. Advanced cooling fans indirectly support compliance with these standards by enabling more precise temperature control, which optimizes engine performance and reduces harmful emissions.

The materials used in manufacturing advanced cooling fans are also subject to environmental scrutiny. Regulations such as the European Union's End-of-Life Vehicle (ELV) Directive mandate the use of recyclable materials and restrict the use of hazardous substances in automotive components. Manufacturers must ensure that cooling fan designs incorporate environmentally friendly materials that can be easily recycled or safely disposed of at the end of their lifecycle.

Energy efficiency regulations, such as those set by the U.S. Department of Energy, impact the design and operation of cooling fans. While these regulations primarily focus on industrial and commercial applications, the principles of energy-efficient fan design are increasingly relevant in automotive contexts. Advanced cooling fans for B58 engines must balance performance enhancement with energy conservation to meet both regulatory requirements and consumer expectations for fuel efficiency.

Noise pollution regulations also influence the development of cooling fan technology. Many jurisdictions have established limits on vehicle noise levels, including those generated by engine components. Advanced cooling fans must be designed to operate quietly while maintaining their performance characteristics, necessitating innovations in aerodynamics and materials science.

As the automotive industry transitions towards electrification, regulations surrounding the environmental impact of internal combustion engines, including B58 engines, are likely to become more stringent. This trend may accelerate the development of even more advanced cooling solutions that can further reduce emissions and improve overall engine efficiency.

In conclusion, the environmental impact and regulatory landscape significantly shape the development and implementation of advanced cooling fans for B58 engines. Manufacturers must navigate a complex web of emissions, materials, energy efficiency, and noise regulations while striving to enhance engine performance. This regulatory environment drives innovation in cooling fan technology, pushing the boundaries of what is possible in terms of efficiency, sustainability, and performance.

Advanced cooling fans play a significant role in reducing the overall environmental footprint of B58 engines. By improving thermal management, these fans contribute to more efficient combustion processes, resulting in lower fuel consumption and reduced emissions. This aligns with global efforts to combat climate change and improve air quality in urban areas.

Regulatory bodies worldwide have implemented strict emissions standards for vehicles, such as the Euro 6 in Europe and Tier 3 in the United States. These regulations set limits on various pollutants, including carbon dioxide, nitrogen oxides, and particulate matter. Advanced cooling fans indirectly support compliance with these standards by enabling more precise temperature control, which optimizes engine performance and reduces harmful emissions.

The materials used in manufacturing advanced cooling fans are also subject to environmental scrutiny. Regulations such as the European Union's End-of-Life Vehicle (ELV) Directive mandate the use of recyclable materials and restrict the use of hazardous substances in automotive components. Manufacturers must ensure that cooling fan designs incorporate environmentally friendly materials that can be easily recycled or safely disposed of at the end of their lifecycle.

Energy efficiency regulations, such as those set by the U.S. Department of Energy, impact the design and operation of cooling fans. While these regulations primarily focus on industrial and commercial applications, the principles of energy-efficient fan design are increasingly relevant in automotive contexts. Advanced cooling fans for B58 engines must balance performance enhancement with energy conservation to meet both regulatory requirements and consumer expectations for fuel efficiency.

Noise pollution regulations also influence the development of cooling fan technology. Many jurisdictions have established limits on vehicle noise levels, including those generated by engine components. Advanced cooling fans must be designed to operate quietly while maintaining their performance characteristics, necessitating innovations in aerodynamics and materials science.

As the automotive industry transitions towards electrification, regulations surrounding the environmental impact of internal combustion engines, including B58 engines, are likely to become more stringent. This trend may accelerate the development of even more advanced cooling solutions that can further reduce emissions and improve overall engine efficiency.

In conclusion, the environmental impact and regulatory landscape significantly shape the development and implementation of advanced cooling fans for B58 engines. Manufacturers must navigate a complex web of emissions, materials, energy efficiency, and noise regulations while striving to enhance engine performance. This regulatory environment drives innovation in cooling fan technology, pushing the boundaries of what is possible in terms of efficiency, sustainability, and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!