Ferrofluid Advancements in Automotive Shock Absorption Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Shock Absorption Evolution and Objectives

Ferrofluid technology has emerged as a promising solution in automotive shock absorption systems, revolutionizing the way vehicles handle road irregularities and vibrations. The evolution of this technology can be traced back to the 1960s when NASA first developed ferrofluids for use in space applications. Since then, the automotive industry has recognized its potential for enhancing vehicle performance and comfort.

The primary objective of incorporating ferrofluids in shock absorption systems is to achieve adaptive damping characteristics that can respond in real-time to varying road conditions and driving dynamics. This technology aims to provide a balance between ride comfort and handling performance, addressing the longstanding trade-off between these two aspects in traditional suspension systems.

Over the years, ferrofluid-based shock absorbers have undergone significant advancements. Early iterations focused on basic magnetic field-controlled viscosity changes, while recent developments have explored more sophisticated control algorithms and integration with vehicle sensors and electronic control units (ECUs). The goal is to create a smart suspension system that can anticipate and react to road conditions instantaneously.

One of the key milestones in this evolution was the introduction of magnetorheological (MR) fluids, a type of ferrofluid with enhanced properties suitable for automotive applications. MR fluids exhibit rapid changes in viscosity when exposed to magnetic fields, allowing for precise control of damping forces. This breakthrough has paved the way for more responsive and efficient shock absorption systems.

The current technological trajectory is focused on further refining the control mechanisms and expanding the range of adaptability. Researchers and engineers are working on developing ferrofluids with improved stability and longevity, as well as more efficient electromagnetic actuators to manipulate the fluid properties. Additionally, there is a growing emphasis on integrating these systems with other vehicle technologies, such as active safety systems and autonomous driving capabilities.

Looking ahead, the objectives for ferrofluid-based shock absorption systems include achieving even faster response times, reducing system complexity and cost, and enhancing overall energy efficiency. There is also a push towards developing self-learning systems that can adapt to individual driving styles and preferences over time, providing a personalized driving experience.

As environmental concerns gain prominence, another important goal is to make these systems more sustainable. This involves researching eco-friendly ferrofluid compositions and designing shock absorbers that are easier to recycle or remanufacture at the end of their lifecycle. The automotive industry is also exploring ways to leverage ferrofluid technology to improve the performance and efficiency of electric and hybrid vehicles, aligning with the broader trend of vehicle electrification.

The primary objective of incorporating ferrofluids in shock absorption systems is to achieve adaptive damping characteristics that can respond in real-time to varying road conditions and driving dynamics. This technology aims to provide a balance between ride comfort and handling performance, addressing the longstanding trade-off between these two aspects in traditional suspension systems.

Over the years, ferrofluid-based shock absorbers have undergone significant advancements. Early iterations focused on basic magnetic field-controlled viscosity changes, while recent developments have explored more sophisticated control algorithms and integration with vehicle sensors and electronic control units (ECUs). The goal is to create a smart suspension system that can anticipate and react to road conditions instantaneously.

One of the key milestones in this evolution was the introduction of magnetorheological (MR) fluids, a type of ferrofluid with enhanced properties suitable for automotive applications. MR fluids exhibit rapid changes in viscosity when exposed to magnetic fields, allowing for precise control of damping forces. This breakthrough has paved the way for more responsive and efficient shock absorption systems.

The current technological trajectory is focused on further refining the control mechanisms and expanding the range of adaptability. Researchers and engineers are working on developing ferrofluids with improved stability and longevity, as well as more efficient electromagnetic actuators to manipulate the fluid properties. Additionally, there is a growing emphasis on integrating these systems with other vehicle technologies, such as active safety systems and autonomous driving capabilities.

Looking ahead, the objectives for ferrofluid-based shock absorption systems include achieving even faster response times, reducing system complexity and cost, and enhancing overall energy efficiency. There is also a push towards developing self-learning systems that can adapt to individual driving styles and preferences over time, providing a personalized driving experience.

As environmental concerns gain prominence, another important goal is to make these systems more sustainable. This involves researching eco-friendly ferrofluid compositions and designing shock absorbers that are easier to recycle or remanufacture at the end of their lifecycle. The automotive industry is also exploring ways to leverage ferrofluid technology to improve the performance and efficiency of electric and hybrid vehicles, aligning with the broader trend of vehicle electrification.

Automotive Market Demand for Advanced Suspension Systems

The automotive industry has witnessed a growing demand for advanced suspension systems, driven by consumer expectations for improved ride comfort, handling, and safety. This trend is particularly evident in the luxury and performance vehicle segments, where customers are willing to pay a premium for superior driving experiences. The market for advanced suspension systems is projected to grow significantly over the next decade, with a compound annual growth rate (CAGR) exceeding the overall automotive market growth.

One of the key factors fueling this demand is the increasing focus on vehicle dynamics and performance. As automakers strive to differentiate their products in a competitive market, advanced suspension systems have become a crucial selling point. These systems offer enhanced stability, reduced body roll, and improved traction, all of which contribute to a more refined and controlled driving experience.

Moreover, the rise of electric and autonomous vehicles has created new challenges and opportunities for suspension technology. Electric vehicles, with their heavy battery packs, require innovative suspension solutions to manage weight distribution and maintain ride quality. Similarly, autonomous vehicles demand advanced suspension systems to ensure passenger comfort during various driving modes and road conditions.

The market demand is also influenced by stringent safety regulations and consumer safety expectations. Advanced suspension systems play a critical role in improving vehicle stability, reducing the risk of rollovers, and enhancing overall safety performance. This has led to increased adoption of electronic stability control systems and adaptive suspension technologies across various vehicle segments.

Urbanization and deteriorating road conditions in many regions have further amplified the need for robust and adaptable suspension systems. Consumers are seeking vehicles that can comfortably navigate diverse terrains, from smooth highways to pothole-ridden city streets. This has spurred interest in adjustable and self-leveling suspension systems that can adapt to changing road conditions in real-time.

The aftermarket sector for advanced suspension systems is also experiencing substantial growth. Car enthusiasts and performance-oriented consumers are increasingly investing in upgrades to enhance their vehicles' handling and ride characteristics. This trend has created opportunities for both OEMs and aftermarket suppliers to develop innovative suspension solutions.

As environmental concerns gain prominence, there is a growing demand for suspension systems that contribute to improved fuel efficiency and reduced emissions. Technologies that minimize energy loss through suspension movement and optimize vehicle aerodynamics are gaining traction in the market. This aligns with the broader industry push towards sustainability and eco-friendly vehicle designs.

One of the key factors fueling this demand is the increasing focus on vehicle dynamics and performance. As automakers strive to differentiate their products in a competitive market, advanced suspension systems have become a crucial selling point. These systems offer enhanced stability, reduced body roll, and improved traction, all of which contribute to a more refined and controlled driving experience.

Moreover, the rise of electric and autonomous vehicles has created new challenges and opportunities for suspension technology. Electric vehicles, with their heavy battery packs, require innovative suspension solutions to manage weight distribution and maintain ride quality. Similarly, autonomous vehicles demand advanced suspension systems to ensure passenger comfort during various driving modes and road conditions.

The market demand is also influenced by stringent safety regulations and consumer safety expectations. Advanced suspension systems play a critical role in improving vehicle stability, reducing the risk of rollovers, and enhancing overall safety performance. This has led to increased adoption of electronic stability control systems and adaptive suspension technologies across various vehicle segments.

Urbanization and deteriorating road conditions in many regions have further amplified the need for robust and adaptable suspension systems. Consumers are seeking vehicles that can comfortably navigate diverse terrains, from smooth highways to pothole-ridden city streets. This has spurred interest in adjustable and self-leveling suspension systems that can adapt to changing road conditions in real-time.

The aftermarket sector for advanced suspension systems is also experiencing substantial growth. Car enthusiasts and performance-oriented consumers are increasingly investing in upgrades to enhance their vehicles' handling and ride characteristics. This trend has created opportunities for both OEMs and aftermarket suppliers to develop innovative suspension solutions.

As environmental concerns gain prominence, there is a growing demand for suspension systems that contribute to improved fuel efficiency and reduced emissions. Technologies that minimize energy loss through suspension movement and optimize vehicle aerodynamics are gaining traction in the market. This aligns with the broader industry push towards sustainability and eco-friendly vehicle designs.

Current Ferrofluid Technology in Shock Absorbers

Ferrofluids have emerged as a promising technology in automotive shock absorption systems, offering unique advantages over traditional hydraulic fluids. Current ferrofluid technology in shock absorbers leverages the magnetic properties of these colloidal suspensions to achieve adaptive damping characteristics. The core principle involves the use of magnetorheological fluids, which consist of micron-sized magnetic particles suspended in a carrier fluid.

In modern shock absorber designs, electromagnets are strategically placed around the fluid chamber. When activated, these electromagnets create a magnetic field that alters the viscosity of the ferrofluid, allowing for real-time adjustment of damping forces. This dynamic control enables the shock absorber to respond rapidly to changing road conditions and vehicle dynamics.

One of the primary advantages of ferrofluid-based shock absorbers is their ability to provide a wide range of damping forces without mechanical adjustments. By varying the strength of the magnetic field, the system can instantly switch between soft and firm damping settings. This adaptability contributes to improved ride comfort, handling, and overall vehicle stability.

Current implementations often integrate electronic control units that continuously monitor vehicle parameters such as speed, acceleration, and steering input. These systems use sophisticated algorithms to determine the optimal damping characteristics for any given driving situation, adjusting the magnetic field strength accordingly.

Durability and reliability have been key focus areas in the development of ferrofluid shock absorbers. Advanced sealing technologies and specialized fluid formulations have been employed to prevent particle settling and ensure long-term stability of the magnetic suspension. This has significantly extended the service life of these systems, making them viable for mass-market applications.

Recent advancements have also addressed the challenge of energy efficiency. Some designs incorporate energy harvesting mechanisms that capture the kinetic energy from suspension movement, using it to power the electromagnets or other vehicle systems. This approach not only improves overall vehicle efficiency but also reduces the power demands on the vehicle's electrical system.

Manufacturers are exploring the integration of ferrofluid technology with other advanced vehicle systems. For instance, some prototypes combine ferrofluid shock absorbers with active suspension systems, allowing for even greater control over vehicle dynamics. This synergy enables features such as predictive damping, where the system anticipates road conditions based on GPS data and adjusts the suspension preemptively.

In modern shock absorber designs, electromagnets are strategically placed around the fluid chamber. When activated, these electromagnets create a magnetic field that alters the viscosity of the ferrofluid, allowing for real-time adjustment of damping forces. This dynamic control enables the shock absorber to respond rapidly to changing road conditions and vehicle dynamics.

One of the primary advantages of ferrofluid-based shock absorbers is their ability to provide a wide range of damping forces without mechanical adjustments. By varying the strength of the magnetic field, the system can instantly switch between soft and firm damping settings. This adaptability contributes to improved ride comfort, handling, and overall vehicle stability.

Current implementations often integrate electronic control units that continuously monitor vehicle parameters such as speed, acceleration, and steering input. These systems use sophisticated algorithms to determine the optimal damping characteristics for any given driving situation, adjusting the magnetic field strength accordingly.

Durability and reliability have been key focus areas in the development of ferrofluid shock absorbers. Advanced sealing technologies and specialized fluid formulations have been employed to prevent particle settling and ensure long-term stability of the magnetic suspension. This has significantly extended the service life of these systems, making them viable for mass-market applications.

Recent advancements have also addressed the challenge of energy efficiency. Some designs incorporate energy harvesting mechanisms that capture the kinetic energy from suspension movement, using it to power the electromagnets or other vehicle systems. This approach not only improves overall vehicle efficiency but also reduces the power demands on the vehicle's electrical system.

Manufacturers are exploring the integration of ferrofluid technology with other advanced vehicle systems. For instance, some prototypes combine ferrofluid shock absorbers with active suspension systems, allowing for even greater control over vehicle dynamics. This synergy enables features such as predictive damping, where the system anticipates road conditions based on GPS data and adjusts the suspension preemptively.

Existing Ferrofluid-based Shock Absorption Solutions

01 Ferrofluid-based shock absorbers

Shock absorbers utilizing ferrofluids can provide enhanced damping capabilities. The magnetic properties of ferrofluids allow for adaptive control of damping characteristics, potentially improving shock absorption in various applications such as vehicle suspensions or industrial machinery.- Ferrofluid-based shock absorbers: Shock absorbers utilizing ferrofluids can provide enhanced damping capabilities. The magnetic properties of ferrofluids allow for adaptive control of the damping force, resulting in improved shock absorption across various conditions. These systems can be applied in automotive suspensions, seismic protection, and other vibration control applications.

- Magnetorheological fluid dampers: Magnetorheological fluids, which contain magnetic particles suspended in a carrier fluid, can be used in shock absorption systems. By applying a magnetic field, the viscosity of the fluid can be rapidly and reversibly changed, allowing for real-time adjustments to damping characteristics. This technology is particularly useful in adaptive suspension systems and vibration control devices.

- Nanoparticle-enhanced ferrofluids for shock absorption: The incorporation of nanoparticles into ferrofluids can significantly improve their shock absorption properties. These advanced ferrofluids exhibit enhanced stability, magnetic responsiveness, and damping capabilities. The use of nanoparticles allows for finer control over the fluid's properties and can lead to more efficient energy dissipation in shock absorbers.

- Hybrid ferrofluid-mechanical shock absorption systems: Combining ferrofluid technology with traditional mechanical shock absorption components can create highly effective hybrid systems. These designs may incorporate springs, pneumatic elements, or other mechanical structures alongside ferrofluid chambers to provide a wide range of damping characteristics and improved overall performance in various applications.

- Control systems for ferrofluid-based shock absorbers: Advanced control systems are crucial for optimizing the performance of ferrofluid-based shock absorbers. These systems may employ sensors, microprocessors, and electromagnetic actuators to dynamically adjust the magnetic field strength and fluid properties in response to changing conditions. Such intelligent control can enhance the adaptability and efficiency of ferrofluid shock absorption devices across a wide range of applications.

02 Magnetorheological fluid for vibration control

Magnetorheological fluids, which are similar to ferrofluids but with larger magnetic particles, can be used in shock absorption systems. These fluids change their viscosity in response to magnetic fields, allowing for real-time adjustments to damping properties and improved vibration control.Expand Specific Solutions03 Nanoparticle-enhanced ferrofluids for shock absorption

Incorporating nanoparticles into ferrofluids can enhance their shock absorption properties. These advanced ferrofluids may offer improved stability, magnetic response, and overall performance in shock absorption applications.Expand Specific Solutions04 Ferrofluid-based energy dissipation systems

Energy dissipation systems using ferrofluids can be designed for shock absorption in various structures. These systems may utilize the fluid's magnetic properties to convert kinetic energy into heat, effectively absorbing shocks and vibrations.Expand Specific Solutions05 Adaptive ferrofluid dampers

Adaptive damping systems using ferrofluids can adjust their properties based on external conditions or control inputs. These systems may incorporate sensors and control algorithms to optimize shock absorption performance in real-time, potentially improving safety and comfort in various applications.Expand Specific Solutions

Key Players in Automotive Suspension and Ferrofluid Industry

The ferrofluid advancements in automotive shock absorption systems market is in its growth stage, with increasing adoption across the automotive industry. The market size is expanding as major automotive manufacturers like Ford, Toyota, and Mercedes-Benz explore this technology to enhance vehicle performance and comfort. While the technology is still evolving, companies such as KYB Corp., HL Mando Co., Ltd., and LORD Corp. are at the forefront of developing and refining ferrofluid-based shock absorption systems. The technology's maturity is progressing rapidly, with ongoing research and development efforts by both established automotive suppliers and innovative startups like Carbon Air Ltd.

Tenneco Automotive Operating Co., Inc.

Technical Solution: Tenneco, a leading supplier of ride performance products, has developed an innovative ferrofluid-based shock absorption system called Continuously Variable Semi-Active (CVSA) suspension. This technology utilizes magnetorheological fluids in combination with Tenneco's proprietary valve design. The CVSA system features shock absorbers filled with a ferrofluid that can alter its viscosity within milliseconds when exposed to a magnetic field. Tenneco's implementation includes a sophisticated control unit that processes data from multiple vehicle sensors, including accelerometers and gyroscopes, to determine the optimal damping force for each wheel independently[10]. The system can adjust damping characteristics up to 100 times per second, providing exceptional responsiveness to changing road conditions and driving dynamics[11]. Tenneco has also developed a fail-safe mode that ensures basic damping functionality even in the event of an electrical system failure, enhancing overall reliability.

Strengths: Rapid adaptation to road conditions, independent wheel control for improved handling, and fail-safe functionality. Weaknesses: Reliance on complex electronic systems may increase vulnerability to electrical issues.

Honda Motor Co., Ltd.

Technical Solution: Honda has innovated in ferrofluid shock absorption technology with their Magnetic Ride Control system. This system employs magnetorheological fluids in the shock absorbers, which contain micron-sized magnetic particles. When an electric current is applied, the fluid's viscosity changes instantly, allowing for precise control of the damping force. Honda's implementation includes advanced sensors that monitor road conditions and vehicle movement up to 1000 times per second[2]. The system's ECU processes this data and adjusts the magnetic field strength in real-time, optimizing suspension performance. Honda has also developed a unique sealing technology to prevent fluid degradation, ensuring long-term reliability[4].

Strengths: Extremely fast response to changing road conditions, enhanced vehicle stability, and improved ride quality. Weaknesses: Higher initial cost, potential for increased maintenance complexity due to the sophisticated electronic components.

Core Innovations in Ferrofluid Shock Absorption

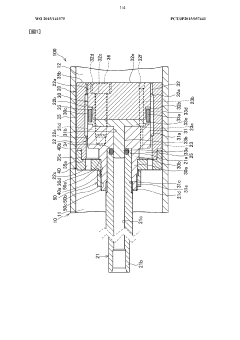

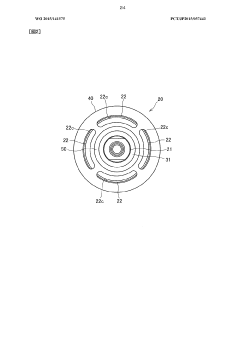

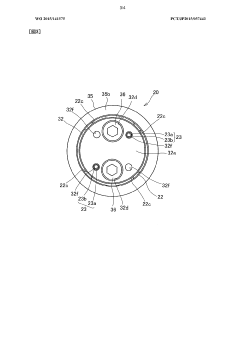

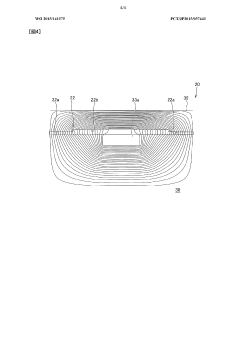

Magnetic viscous damper

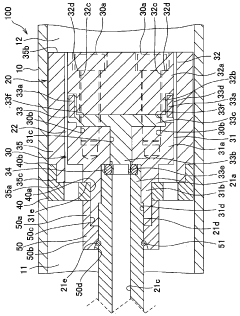

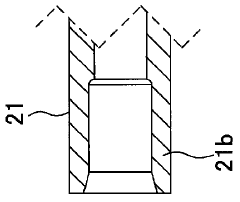

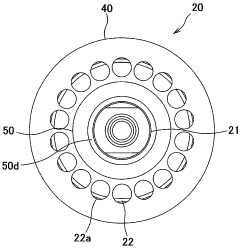

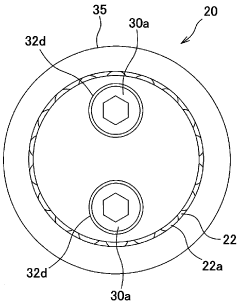

PatentWO2013129162A1

Innovation

- A magnetic viscous fluid shock absorber with a cylinder, piston, and piston rod, featuring a flux ring and annular plate to define the axial position of the piston core, allowing for a shorter overall length by eliminating the need for additional axial components.

Magneto-rheological fluid damper

PatentWO2015141575A1

Innovation

- The shock absorber incorporates a piston with a coil and a flux ring forming a flow path with a first and second flow path portion, where the second flow path portion is larger and longer than the coil, allowing for increased magnetic flux density and adjustable damping force by varying the magnetic field strength.

Environmental Impact of Ferrofluid-based Shock Absorbers

The environmental impact of ferrofluid-based shock absorbers in automotive applications is a critical consideration as the technology advances. These innovative systems offer potential benefits in terms of improved vehicle performance and ride comfort, but their environmental implications must be carefully evaluated throughout their lifecycle.

During the production phase, the manufacturing of ferrofluids involves the use of various chemicals and nanoparticles, which may pose environmental risks if not properly managed. The synthesis of magnetic nanoparticles and the surfactants used to stabilize them can generate hazardous waste and emissions. However, advancements in green chemistry and sustainable manufacturing processes are being developed to mitigate these impacts, focusing on reducing the use of toxic solvents and improving the efficiency of nanoparticle production.

In the operational phase, ferrofluid-based shock absorbers demonstrate potential environmental advantages over conventional systems. Their adaptive nature allows for optimized energy dissipation, potentially leading to improved fuel efficiency in vehicles. This reduction in fuel consumption can contribute to lower greenhouse gas emissions and decreased reliance on fossil fuels. Additionally, the enhanced durability of ferrofluid systems may result in longer service life, reducing the frequency of replacement and associated waste generation.

However, concerns arise regarding the potential release of nanoparticles into the environment during the use and disposal of ferrofluid shock absorbers. While the magnetic properties of these particles allow for easier containment and recovery, the long-term effects of nanoparticle exposure on ecosystems and human health are not yet fully understood. Research is ongoing to assess the potential risks and develop strategies for safe handling and disposal.

End-of-life considerations for ferrofluid-based shock absorbers present both challenges and opportunities. The complex composition of these systems, including magnetic nanoparticles and specialized fluids, necessitates the development of dedicated recycling and disposal protocols. Efforts are underway to design ferrofluid systems with improved recyclability, focusing on the separation and recovery of valuable materials. This approach not only minimizes environmental impact but also aligns with circular economy principles.

As the automotive industry increasingly adopts ferrofluid technology, regulatory frameworks and environmental standards are evolving to address the unique aspects of these systems. Manufacturers are being encouraged to conduct comprehensive life cycle assessments to quantify the environmental footprint of ferrofluid-based shock absorbers compared to traditional alternatives. These assessments consider factors such as resource consumption, energy use, emissions, and waste generation across all stages of the product lifecycle.

In conclusion, while ferrofluid-based shock absorbers offer promising performance benefits, their environmental impact requires careful consideration and ongoing research. Balancing technological advancement with environmental stewardship will be crucial in realizing the full potential of this innovative technology in automotive applications.

During the production phase, the manufacturing of ferrofluids involves the use of various chemicals and nanoparticles, which may pose environmental risks if not properly managed. The synthesis of magnetic nanoparticles and the surfactants used to stabilize them can generate hazardous waste and emissions. However, advancements in green chemistry and sustainable manufacturing processes are being developed to mitigate these impacts, focusing on reducing the use of toxic solvents and improving the efficiency of nanoparticle production.

In the operational phase, ferrofluid-based shock absorbers demonstrate potential environmental advantages over conventional systems. Their adaptive nature allows for optimized energy dissipation, potentially leading to improved fuel efficiency in vehicles. This reduction in fuel consumption can contribute to lower greenhouse gas emissions and decreased reliance on fossil fuels. Additionally, the enhanced durability of ferrofluid systems may result in longer service life, reducing the frequency of replacement and associated waste generation.

However, concerns arise regarding the potential release of nanoparticles into the environment during the use and disposal of ferrofluid shock absorbers. While the magnetic properties of these particles allow for easier containment and recovery, the long-term effects of nanoparticle exposure on ecosystems and human health are not yet fully understood. Research is ongoing to assess the potential risks and develop strategies for safe handling and disposal.

End-of-life considerations for ferrofluid-based shock absorbers present both challenges and opportunities. The complex composition of these systems, including magnetic nanoparticles and specialized fluids, necessitates the development of dedicated recycling and disposal protocols. Efforts are underway to design ferrofluid systems with improved recyclability, focusing on the separation and recovery of valuable materials. This approach not only minimizes environmental impact but also aligns with circular economy principles.

As the automotive industry increasingly adopts ferrofluid technology, regulatory frameworks and environmental standards are evolving to address the unique aspects of these systems. Manufacturers are being encouraged to conduct comprehensive life cycle assessments to quantify the environmental footprint of ferrofluid-based shock absorbers compared to traditional alternatives. These assessments consider factors such as resource consumption, energy use, emissions, and waste generation across all stages of the product lifecycle.

In conclusion, while ferrofluid-based shock absorbers offer promising performance benefits, their environmental impact requires careful consideration and ongoing research. Balancing technological advancement with environmental stewardship will be crucial in realizing the full potential of this innovative technology in automotive applications.

Safety Regulations for Automotive Suspension Systems

Safety regulations for automotive suspension systems play a crucial role in ensuring the reliability and performance of ferrofluid-based shock absorption technologies. As these innovative systems continue to evolve, regulatory bodies must adapt their guidelines to address the unique characteristics and potential risks associated with ferrofluids in automotive applications.

The primary focus of safety regulations in this domain is to establish standards for the containment, stability, and long-term performance of ferrofluid-based shock absorbers. These regulations typically mandate rigorous testing protocols to evaluate the system's response under various environmental conditions, including extreme temperatures, humidity, and vibration. Manufacturers must demonstrate that their ferrofluid shock absorption systems maintain consistent performance and safety levels throughout the vehicle's expected lifespan.

One key aspect of safety regulations is the prevention of ferrofluid leakage. Regulatory bodies require robust sealing mechanisms and containment systems to ensure that the magnetic nanoparticles remain within the designated chambers of the shock absorber. This is critical not only for maintaining system performance but also for preventing potential environmental contamination and health hazards associated with nanoparticle exposure.

Electromagnetic compatibility (EMC) is another significant consideration in safety regulations for ferrofluid-based suspension systems. As these systems often incorporate electromagnetic components for controlling the ferrofluid's behavior, regulations mandate comprehensive EMC testing to ensure that the shock absorbers do not interfere with other vehicle electronics or nearby electronic devices.

Safety regulations also address the fail-safe mechanisms and redundancy requirements for ferrofluid shock absorption systems. Manufacturers must implement backup systems or failover modes that maintain a minimum level of shock absorption capability in the event of a primary system failure. This ensures that vehicle control and stability are not compromised, even if the ferrofluid-based components experience unexpected issues.

The recyclability and end-of-life disposal of ferrofluid shock absorbers are increasingly becoming part of safety regulations. Guidelines are being developed to ensure proper handling and recycling of these components, minimizing the environmental impact of discarded ferrofluids and associated materials.

As the technology advances, regulatory bodies are working closely with automotive manufacturers and research institutions to develop comprehensive safety standards specifically tailored to ferrofluid-based suspension systems. These evolving regulations aim to strike a balance between fostering innovation in automotive shock absorption technology and maintaining the highest levels of vehicle safety and environmental protection.

The primary focus of safety regulations in this domain is to establish standards for the containment, stability, and long-term performance of ferrofluid-based shock absorbers. These regulations typically mandate rigorous testing protocols to evaluate the system's response under various environmental conditions, including extreme temperatures, humidity, and vibration. Manufacturers must demonstrate that their ferrofluid shock absorption systems maintain consistent performance and safety levels throughout the vehicle's expected lifespan.

One key aspect of safety regulations is the prevention of ferrofluid leakage. Regulatory bodies require robust sealing mechanisms and containment systems to ensure that the magnetic nanoparticles remain within the designated chambers of the shock absorber. This is critical not only for maintaining system performance but also for preventing potential environmental contamination and health hazards associated with nanoparticle exposure.

Electromagnetic compatibility (EMC) is another significant consideration in safety regulations for ferrofluid-based suspension systems. As these systems often incorporate electromagnetic components for controlling the ferrofluid's behavior, regulations mandate comprehensive EMC testing to ensure that the shock absorbers do not interfere with other vehicle electronics or nearby electronic devices.

Safety regulations also address the fail-safe mechanisms and redundancy requirements for ferrofluid shock absorption systems. Manufacturers must implement backup systems or failover modes that maintain a minimum level of shock absorption capability in the event of a primary system failure. This ensures that vehicle control and stability are not compromised, even if the ferrofluid-based components experience unexpected issues.

The recyclability and end-of-life disposal of ferrofluid shock absorbers are increasingly becoming part of safety regulations. Guidelines are being developed to ensure proper handling and recycling of these components, minimizing the environmental impact of discarded ferrofluids and associated materials.

As the technology advances, regulatory bodies are working closely with automotive manufacturers and research institutions to develop comprehensive safety standards specifically tailored to ferrofluid-based suspension systems. These evolving regulations aim to strike a balance between fostering innovation in automotive shock absorption technology and maintaining the highest levels of vehicle safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!