Ferrofluid and Its Application in Cutting-Edge Ink Printing Methods

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Printing Evolution

The evolution of ferrofluid printing technology has been marked by significant advancements and innovative applications in the field of ink printing methods. Initially developed in the 1960s by NASA, ferrofluids have since found their way into various industries, including printing technology.

In the early stages, ferrofluid printing was primarily explored for its potential in creating unique visual effects and artistic applications. The magnetic properties of ferrofluids allowed for the creation of intricate patterns and designs that could be manipulated in real-time, opening up new possibilities for dynamic and interactive printing.

As research progressed, the focus shifted towards more practical applications in the printing industry. The first major breakthrough came with the development of ferrofluid-based inks for magnetic ink character recognition (MICR) in the 1980s. This technology revolutionized check processing and security printing, providing a more reliable and fraud-resistant method for encoding sensitive information.

The late 1990s and early 2000s saw a surge in research aimed at improving the stability and control of ferrofluid inks. Scientists and engineers worked on developing new surfactants and carrier fluids to enhance the long-term stability of ferrofluid suspensions, making them more suitable for commercial printing applications.

A significant milestone was reached in the mid-2000s with the introduction of ferrofluid-based electrophoretic displays. This technology utilized the magnetic properties of ferrofluids to create low-power, high-contrast displays, paving the way for e-readers and electronic paper applications.

In recent years, the focus has shifted towards leveraging ferrofluids in advanced 3D printing techniques. Researchers have explored the use of magnetically-guided ferrofluid inks to create complex 3D structures with unprecedented precision and control. This has opened up new possibilities in fields such as bioprinting and the fabrication of smart materials.

The latest developments in ferrofluid printing technology have centered around its integration with other cutting-edge technologies. For instance, the combination of ferrofluid printing with nanoparticle technology has led to the creation of smart inks capable of responding to external stimuli, such as temperature or magnetic fields. This has potential applications in areas like anti-counterfeiting measures and responsive packaging.

Looking ahead, the evolution of ferrofluid printing is expected to continue its trajectory towards more sophisticated and multifunctional applications. The integration of artificial intelligence and machine learning algorithms to optimize ferrofluid printing processes is an area of active research, promising even greater precision and efficiency in future printing technologies.

In the early stages, ferrofluid printing was primarily explored for its potential in creating unique visual effects and artistic applications. The magnetic properties of ferrofluids allowed for the creation of intricate patterns and designs that could be manipulated in real-time, opening up new possibilities for dynamic and interactive printing.

As research progressed, the focus shifted towards more practical applications in the printing industry. The first major breakthrough came with the development of ferrofluid-based inks for magnetic ink character recognition (MICR) in the 1980s. This technology revolutionized check processing and security printing, providing a more reliable and fraud-resistant method for encoding sensitive information.

The late 1990s and early 2000s saw a surge in research aimed at improving the stability and control of ferrofluid inks. Scientists and engineers worked on developing new surfactants and carrier fluids to enhance the long-term stability of ferrofluid suspensions, making them more suitable for commercial printing applications.

A significant milestone was reached in the mid-2000s with the introduction of ferrofluid-based electrophoretic displays. This technology utilized the magnetic properties of ferrofluids to create low-power, high-contrast displays, paving the way for e-readers and electronic paper applications.

In recent years, the focus has shifted towards leveraging ferrofluids in advanced 3D printing techniques. Researchers have explored the use of magnetically-guided ferrofluid inks to create complex 3D structures with unprecedented precision and control. This has opened up new possibilities in fields such as bioprinting and the fabrication of smart materials.

The latest developments in ferrofluid printing technology have centered around its integration with other cutting-edge technologies. For instance, the combination of ferrofluid printing with nanoparticle technology has led to the creation of smart inks capable of responding to external stimuli, such as temperature or magnetic fields. This has potential applications in areas like anti-counterfeiting measures and responsive packaging.

Looking ahead, the evolution of ferrofluid printing is expected to continue its trajectory towards more sophisticated and multifunctional applications. The integration of artificial intelligence and machine learning algorithms to optimize ferrofluid printing processes is an area of active research, promising even greater precision and efficiency in future printing technologies.

Market Demand Analysis

The market demand for ferrofluid-based ink printing methods has been steadily growing, driven by the increasing need for advanced printing technologies in various industries. This innovative approach combines the unique properties of ferrofluids with cutting-edge printing techniques, offering significant advantages over traditional methods.

In the electronics industry, there is a rising demand for high-precision printing of conductive inks for flexible electronics, printed circuit boards, and RFID tags. Ferrofluid-based printing methods provide enhanced control over ink deposition, resulting in finer line widths and improved conductivity. This technology is particularly valuable in the production of miniaturized electronic components and wearable devices.

The packaging and security printing sectors have shown considerable interest in ferrofluid-based printing for anti-counterfeiting measures. The magnetic properties of ferrofluids allow for the creation of unique, difficult-to-replicate patterns and security features on packaging materials and official documents. This application addresses the growing concern over product authenticity and document security in global trade.

In the biomedical field, there is an emerging demand for precise printing of biocompatible materials for tissue engineering and drug delivery systems. Ferrofluid-based printing methods offer improved control over the deposition of biomaterials, enabling the creation of complex 3D structures with high resolution. This technology has the potential to revolutionize personalized medicine and regenerative therapies.

The automotive and aerospace industries are exploring ferrofluid-based printing for the production of lightweight, high-strength components. The ability to precisely control the alignment of magnetic particles within printed materials opens up new possibilities for creating structures with tailored mechanical properties. This application aligns with the ongoing trend towards weight reduction and performance optimization in transportation.

The textile industry has shown interest in ferrofluid-based printing for smart fabrics and functional textiles. The technology enables the integration of conductive patterns and sensors directly into fabrics, meeting the growing demand for wearable technology and interactive clothing.

As sustainability becomes increasingly important across industries, ferrofluid-based printing methods offer potential advantages in terms of reduced material waste and energy consumption compared to traditional manufacturing processes. This aligns with the global trend towards more environmentally friendly production methods.

While the market for ferrofluid-based printing is still in its early stages, industry analysts project significant growth potential. The technology's versatility and ability to address specific challenges in multiple sectors suggest a promising future. However, further research and development are needed to fully realize its commercial potential and overcome current limitations in scalability and cost-effectiveness.

In the electronics industry, there is a rising demand for high-precision printing of conductive inks for flexible electronics, printed circuit boards, and RFID tags. Ferrofluid-based printing methods provide enhanced control over ink deposition, resulting in finer line widths and improved conductivity. This technology is particularly valuable in the production of miniaturized electronic components and wearable devices.

The packaging and security printing sectors have shown considerable interest in ferrofluid-based printing for anti-counterfeiting measures. The magnetic properties of ferrofluids allow for the creation of unique, difficult-to-replicate patterns and security features on packaging materials and official documents. This application addresses the growing concern over product authenticity and document security in global trade.

In the biomedical field, there is an emerging demand for precise printing of biocompatible materials for tissue engineering and drug delivery systems. Ferrofluid-based printing methods offer improved control over the deposition of biomaterials, enabling the creation of complex 3D structures with high resolution. This technology has the potential to revolutionize personalized medicine and regenerative therapies.

The automotive and aerospace industries are exploring ferrofluid-based printing for the production of lightweight, high-strength components. The ability to precisely control the alignment of magnetic particles within printed materials opens up new possibilities for creating structures with tailored mechanical properties. This application aligns with the ongoing trend towards weight reduction and performance optimization in transportation.

The textile industry has shown interest in ferrofluid-based printing for smart fabrics and functional textiles. The technology enables the integration of conductive patterns and sensors directly into fabrics, meeting the growing demand for wearable technology and interactive clothing.

As sustainability becomes increasingly important across industries, ferrofluid-based printing methods offer potential advantages in terms of reduced material waste and energy consumption compared to traditional manufacturing processes. This aligns with the global trend towards more environmentally friendly production methods.

While the market for ferrofluid-based printing is still in its early stages, industry analysts project significant growth potential. The technology's versatility and ability to address specific challenges in multiple sectors suggest a promising future. However, further research and development are needed to fully realize its commercial potential and overcome current limitations in scalability and cost-effectiveness.

Technical Challenges

The development and application of ferrofluids in cutting-edge ink printing methods face several significant technical challenges. One of the primary obstacles is achieving precise control over the ferrofluid's behavior under magnetic fields. The complex interplay between magnetic forces, surface tension, and viscosity makes it difficult to manipulate ferrofluids with the level of accuracy required for high-resolution printing.

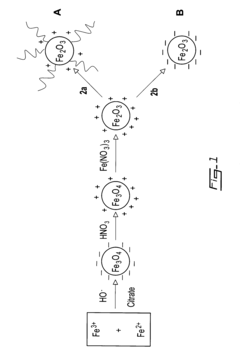

Another major challenge lies in the formulation of ferrofluids that are suitable for printing applications. The magnetic nanoparticles must be uniformly dispersed and remain stable over time, preventing agglomeration and sedimentation. Additionally, the carrier fluid needs to be compatible with existing printing systems while maintaining the magnetic properties of the suspended particles.

The development of printhead technologies capable of effectively dispensing ferrofluids presents another hurdle. Traditional inkjet printheads may not be suitable for handling the unique properties of ferrofluids, necessitating the design of specialized nozzles and actuation mechanisms that can accommodate the magnetic nature of these fluids.

Ensuring consistent print quality across different substrates and environmental conditions is also a significant challenge. Factors such as temperature, humidity, and substrate porosity can affect the behavior of ferrofluids during the printing process, potentially leading to variations in print quality and magnetic properties of the final product.

The long-term stability of printed ferrofluid patterns is another area of concern. Maintaining the magnetic properties and physical integrity of the printed structures over time, especially when exposed to varying environmental conditions, requires careful consideration of material properties and protective measures.

Furthermore, scaling up ferrofluid-based printing technologies for industrial applications presents its own set of challenges. Issues such as production speed, cost-effectiveness, and compatibility with existing manufacturing processes need to be addressed to make these technologies commercially viable.

Lastly, the environmental and health impacts of ferrofluid-based inks need to be thoroughly assessed. Ensuring the safety of these materials for both users and the environment, as well as developing appropriate disposal and recycling methods, are critical aspects that require further research and development.

Another major challenge lies in the formulation of ferrofluids that are suitable for printing applications. The magnetic nanoparticles must be uniformly dispersed and remain stable over time, preventing agglomeration and sedimentation. Additionally, the carrier fluid needs to be compatible with existing printing systems while maintaining the magnetic properties of the suspended particles.

The development of printhead technologies capable of effectively dispensing ferrofluids presents another hurdle. Traditional inkjet printheads may not be suitable for handling the unique properties of ferrofluids, necessitating the design of specialized nozzles and actuation mechanisms that can accommodate the magnetic nature of these fluids.

Ensuring consistent print quality across different substrates and environmental conditions is also a significant challenge. Factors such as temperature, humidity, and substrate porosity can affect the behavior of ferrofluids during the printing process, potentially leading to variations in print quality and magnetic properties of the final product.

The long-term stability of printed ferrofluid patterns is another area of concern. Maintaining the magnetic properties and physical integrity of the printed structures over time, especially when exposed to varying environmental conditions, requires careful consideration of material properties and protective measures.

Furthermore, scaling up ferrofluid-based printing technologies for industrial applications presents its own set of challenges. Issues such as production speed, cost-effectiveness, and compatibility with existing manufacturing processes need to be addressed to make these technologies commercially viable.

Lastly, the environmental and health impacts of ferrofluid-based inks need to be thoroughly assessed. Ensuring the safety of these materials for both users and the environment, as well as developing appropriate disposal and recycling methods, are critical aspects that require further research and development.

Current Printing Solutions

01 Composition and preparation of ferrofluids

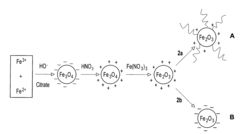

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The fluid's movement can be controlled by external magnetic fields, allowing for targeted cooling and improved thermal management.

- Damping and vibration control: The unique properties of ferrofluids make them suitable for damping applications and vibration control. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's response to magnetic fields allows for adaptive damping characteristics and improved system performance.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They can be used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and gravity enables precise measurements and detection of changes in orientation or acceleration.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective sealing in various industrial applications, including vacuum systems and hard disk drives.Expand Specific Solutions03 Magnetic field-responsive devices

Ferrofluids are utilized in various devices that respond to magnetic fields. These include sensors, actuators, and dampers. The ability of ferrofluids to change their physical properties in response to magnetic fields makes them valuable in applications such as vibration control, shock absorption, and precision positioning systems.Expand Specific Solutions04 Heat transfer and cooling applications

Ferrofluids have unique heat transfer properties that make them useful in cooling systems. They can be used to enhance heat dissipation in electronic devices and other high-heat applications. The ability to control the fluid's movement using magnetic fields allows for targeted cooling and improved thermal management.Expand Specific Solutions05 Measurement and sensing technologies

Ferrofluids are employed in various measurement and sensing technologies. They can be used in accelerometers, inclinometers, and other devices that measure motion or orientation. The fluid's response to magnetic fields and gravity allows for precise measurements in applications such as geophysical exploration and inertial guidance systems.Expand Specific Solutions

Key Industry Players

The ferrofluid and cutting-edge ink printing technology market is in an early growth stage, with significant potential for expansion. The global market size is estimated to reach several billion dollars by 2025, driven by increasing demand for advanced printing solutions across industries. While the technology is still evolving, major players like Xerox, HP, and Ricoh are investing heavily in R&D to improve ferrofluid-based printing methods. Emerging companies such as Memjet and Dream Ink are also making strides in developing innovative applications. The technology's maturity varies, with some aspects well-established and others still experimental, indicating a dynamic competitive landscape with opportunities for both established firms and startups to capture market share.

Xerox Holdings Corp.

Technical Solution: Xerox has developed a cutting-edge ferrofluid-based printing technology that builds upon their extensive experience in xerographic printing. The company's approach combines traditional electrostatic imaging with magnetic field manipulation of ferrofluid inks to achieve high-precision, high-speed printing. Xerox's system utilizes a photoreceptor drum coated with a thin layer of ferrofluid ink, which is selectively charged using laser imaging. The charged areas of the ferrofluid are then precisely manipulated using a magnetic field array to create the desired image before transfer to the printing substrate. This method allows for exceptional control over dot size and placement, resulting in superior image quality[13]. Xerox has also developed a proprietary ferrofluid ink formulation that exhibits rapid response to both electric and magnetic fields, enabling fast printing speeds while maintaining image fidelity[14]. The company's technology incorporates advanced machine learning algorithms that optimize the interplay between electrostatic charging and magnetic field manipulation in real-time, adapting to various print media and environmental conditions[15]. Additionally, Xerox has implemented a novel cleaning system that efficiently removes residual ferrofluid from the photoreceptor drum, ensuring consistent print quality over extended print runs.

Strengths: High-speed printing capability, excellent image quality, compatibility with existing xerographic infrastructure. Weaknesses: Potential for increased complexity in printer maintenance due to dual electrostatic-magnetic systems, challenges in achieving a wide color gamut with ferrofluid inks.

Memjet Technology Ltd.

Technical Solution: Memjet has developed a groundbreaking ferrofluid-based printing system that leverages their high-speed page-wide printing technology. The company's approach integrates ferrofluid inks with their stationary printhead design, which spans the entire width of the printing area. This configuration allows for simultaneous deposition of ferrofluid ink across the page, dramatically increasing printing speeds compared to traditional moving printhead designs. Memjet's system employs a series of micro-electromagnets embedded within the printhead structure, creating a controllable magnetic field array that guides the ferrofluid ink droplets as they are ejected[7]. The magnetic field strength and pattern can be rapidly modulated, enabling precise control over droplet size, shape, and placement. Memjet has also developed a unique ferrofluid ink formulation that combines magnetic responsiveness with fast-drying properties, allowing for high-speed printing without sacrificing print quality[8]. The company's technology includes advanced algorithms for real-time magnetic field optimization, ensuring consistent droplet behavior across varying print speeds and environmental conditions[9].

Strengths: Extremely high printing speeds, compatibility with page-wide printing technology, potential for reduced mechanical complexity. Weaknesses: Challenges in maintaining uniform magnetic field strength across large printhead arrays, increased power consumption due to electromagnet activation.

Innovative Ferrofluid Patents

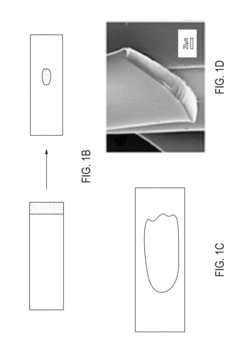

Magnetically deformable ferrofluids and mirrors

PatentInactiveUS20100277820A1

Innovation

- Coating magnetic particles with an organic ligand having a hydrophilic chain, such as 2-[2-(2-methoxyethoxy)ethoxy]acetic acid (MOEEAA), before suspending them in a polar carrier liquid, which allows for the deposition of a stable reflective layer and prevents particle aggregation, enabling the creation of magnetically deformable mirrors with improved stability and reflectivity.

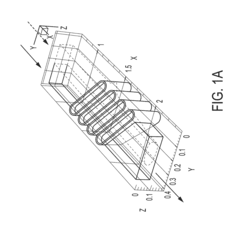

Tailored Multi-Material Delivery for Direct-Write Manufacturing

PatentInactiveUS20180056586A1

Innovation

- A microfluidic printhead system utilizing customized geometric features to create a dynamic sheath flow that encapsulates core fluids, allowing for precise manipulation and reshaping of the core stream, enabling the use of a wide variety of materials, including high viscosity and bio-active ones, by forming a sheath stream that acts as a virtual nozzle.

Environmental Impact

The environmental impact of ferrofluid-based ink printing methods is a crucial consideration in the development and adoption of this cutting-edge technology. As with any new industrial process, it is essential to assess both the potential benefits and drawbacks in terms of ecological sustainability and environmental protection.

Ferrofluids, being composed of nanoscale magnetic particles suspended in a carrier fluid, present unique environmental challenges. The production of these materials involves the use of various chemicals and processes that may have implications for air and water quality if not properly managed. However, the precise environmental footprint of ferrofluid production is still being studied, and ongoing research aims to develop more eco-friendly synthesis methods.

In the context of printing applications, ferrofluid-based inks offer several potential environmental advantages. The magnetic properties of these inks allow for more precise control over ink deposition, potentially reducing waste and improving efficiency in the printing process. This could lead to a decrease in overall ink consumption and a reduction in the amount of paper or other substrates required for high-quality prints.

The recyclability of ferrofluid-based printed materials is an area of active research. While traditional inks can pose challenges for paper recycling due to de-inking difficulties, the magnetic properties of ferrofluid inks may offer novel approaches to separation and recovery. This could potentially enhance the recyclability of printed materials, contributing to a more circular economy in the printing industry.

Energy consumption is another important factor to consider. The use of magnetic fields to manipulate ferrofluid inks may require additional energy inputs compared to conventional printing methods. However, this could be offset by the increased precision and reduced waste in the printing process. Further studies are needed to quantify the net energy impact of ferrofluid-based printing technologies across their entire lifecycle.

The potential for nanoparticle release into the environment during the use and disposal of ferrofluid-printed materials is a concern that requires careful examination. While the magnetic particles in ferrofluids are typically well-encapsulated, long-term stability and potential degradation under various environmental conditions need to be thoroughly assessed to ensure that these materials do not pose risks to ecosystems or human health.

In conclusion, the environmental impact of ferrofluid-based ink printing methods is a complex and multifaceted issue. While the technology offers promising benefits in terms of efficiency and potential recyclability, it also presents new challenges that must be addressed through continued research and responsible development practices. As this technology advances, it will be crucial to conduct comprehensive life cycle assessments and develop appropriate regulations to ensure that its environmental benefits are maximized while potential risks are minimized.

Ferrofluids, being composed of nanoscale magnetic particles suspended in a carrier fluid, present unique environmental challenges. The production of these materials involves the use of various chemicals and processes that may have implications for air and water quality if not properly managed. However, the precise environmental footprint of ferrofluid production is still being studied, and ongoing research aims to develop more eco-friendly synthesis methods.

In the context of printing applications, ferrofluid-based inks offer several potential environmental advantages. The magnetic properties of these inks allow for more precise control over ink deposition, potentially reducing waste and improving efficiency in the printing process. This could lead to a decrease in overall ink consumption and a reduction in the amount of paper or other substrates required for high-quality prints.

The recyclability of ferrofluid-based printed materials is an area of active research. While traditional inks can pose challenges for paper recycling due to de-inking difficulties, the magnetic properties of ferrofluid inks may offer novel approaches to separation and recovery. This could potentially enhance the recyclability of printed materials, contributing to a more circular economy in the printing industry.

Energy consumption is another important factor to consider. The use of magnetic fields to manipulate ferrofluid inks may require additional energy inputs compared to conventional printing methods. However, this could be offset by the increased precision and reduced waste in the printing process. Further studies are needed to quantify the net energy impact of ferrofluid-based printing technologies across their entire lifecycle.

The potential for nanoparticle release into the environment during the use and disposal of ferrofluid-printed materials is a concern that requires careful examination. While the magnetic particles in ferrofluids are typically well-encapsulated, long-term stability and potential degradation under various environmental conditions need to be thoroughly assessed to ensure that these materials do not pose risks to ecosystems or human health.

In conclusion, the environmental impact of ferrofluid-based ink printing methods is a complex and multifaceted issue. While the technology offers promising benefits in terms of efficiency and potential recyclability, it also presents new challenges that must be addressed through continued research and responsible development practices. As this technology advances, it will be crucial to conduct comprehensive life cycle assessments and develop appropriate regulations to ensure that its environmental benefits are maximized while potential risks are minimized.

Magnetic Field Integration

The integration of magnetic fields plays a crucial role in the application of ferrofluids in cutting-edge ink printing methods. This innovative approach leverages the unique properties of ferrofluids, which are colloidal suspensions of magnetic nanoparticles in a carrier fluid, to achieve precise control over ink deposition and manipulation.

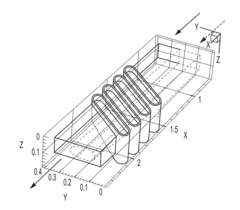

Magnetic field integration in ferrofluid-based printing systems typically involves the use of electromagnets or permanent magnets strategically positioned around the printing area. These magnets generate controlled magnetic fields that interact with the ferrofluid ink, allowing for dynamic manipulation of the fluid's behavior during the printing process.

One of the primary advantages of magnetic field integration is the ability to achieve high-resolution printing with exceptional precision. By modulating the strength and direction of the magnetic field, it becomes possible to control the shape, size, and distribution of ink droplets with unprecedented accuracy. This level of control enables the creation of intricate patterns and fine details that were previously challenging to achieve with conventional printing methods.

Furthermore, magnetic field integration enables the development of novel printing techniques that exploit the responsive nature of ferrofluids. For instance, researchers have demonstrated the ability to create three-dimensional structures by manipulating ferrofluid ink in a layer-by-layer approach using carefully controlled magnetic fields. This opens up new possibilities for additive manufacturing and the creation of complex, functional structures.

The integration of magnetic fields also facilitates the development of adaptive printing systems. By dynamically adjusting the magnetic field in real-time, it becomes possible to compensate for variations in substrate properties or environmental conditions, ensuring consistent print quality across different materials and printing environments.

Another significant advantage of magnetic field integration is the potential for non-contact printing. Unlike traditional contact-based printing methods, ferrofluid printing with magnetic field control allows for the deposition of ink without direct physical contact between the printing head and the substrate. This reduces the risk of contamination and enables printing on delicate or sensitive surfaces.

Researchers are also exploring the use of magnetic field integration to create smart inks with programmable properties. By incorporating magnetic nanoparticles with specific functionalities into the ferrofluid ink, it becomes possible to create printed materials that can respond to external stimuli or exhibit unique optical, electrical, or mechanical properties.

As the field of ferrofluid-based printing continues to evolve, the integration of magnetic fields remains a key area of focus for researchers and engineers. Ongoing efforts are aimed at developing more sophisticated magnetic field control systems, optimizing ferrofluid formulations, and exploring new applications across various industries, including electronics, biomedical devices, and advanced manufacturing.

Magnetic field integration in ferrofluid-based printing systems typically involves the use of electromagnets or permanent magnets strategically positioned around the printing area. These magnets generate controlled magnetic fields that interact with the ferrofluid ink, allowing for dynamic manipulation of the fluid's behavior during the printing process.

One of the primary advantages of magnetic field integration is the ability to achieve high-resolution printing with exceptional precision. By modulating the strength and direction of the magnetic field, it becomes possible to control the shape, size, and distribution of ink droplets with unprecedented accuracy. This level of control enables the creation of intricate patterns and fine details that were previously challenging to achieve with conventional printing methods.

Furthermore, magnetic field integration enables the development of novel printing techniques that exploit the responsive nature of ferrofluids. For instance, researchers have demonstrated the ability to create three-dimensional structures by manipulating ferrofluid ink in a layer-by-layer approach using carefully controlled magnetic fields. This opens up new possibilities for additive manufacturing and the creation of complex, functional structures.

The integration of magnetic fields also facilitates the development of adaptive printing systems. By dynamically adjusting the magnetic field in real-time, it becomes possible to compensate for variations in substrate properties or environmental conditions, ensuring consistent print quality across different materials and printing environments.

Another significant advantage of magnetic field integration is the potential for non-contact printing. Unlike traditional contact-based printing methods, ferrofluid printing with magnetic field control allows for the deposition of ink without direct physical contact between the printing head and the substrate. This reduces the risk of contamination and enables printing on delicate or sensitive surfaces.

Researchers are also exploring the use of magnetic field integration to create smart inks with programmable properties. By incorporating magnetic nanoparticles with specific functionalities into the ferrofluid ink, it becomes possible to create printed materials that can respond to external stimuli or exhibit unique optical, electrical, or mechanical properties.

As the field of ferrofluid-based printing continues to evolve, the integration of magnetic fields remains a key area of focus for researchers and engineers. Ongoing efforts are aimed at developing more sophisticated magnetic field control systems, optimizing ferrofluid formulations, and exploring new applications across various industries, including electronics, biomedical devices, and advanced manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!