Ferrofluid and Its Application in Dynamic Control of Mechanical Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in their composition, properties, and applications. Initially conceived for fuel control in zero-gravity environments, these magnetic liquids have since found diverse uses across various industries. The technology has progressed from simple iron oxide particles suspended in carrier fluids to more sophisticated nanoparticle-based formulations with enhanced stability and magnetic responsiveness.

The evolution of ferrofluid technology has been marked by several key milestones. In the 1970s and 1980s, researchers focused on improving the stability and magnetic properties of ferrofluids, leading to the development of surfactant-coated nanoparticles that prevented agglomeration. The 1990s saw the expansion of ferrofluid applications into fields such as electronics cooling, sealing, and damping. The turn of the millennium brought about advancements in synthesis techniques, allowing for greater control over particle size and distribution, which in turn enhanced the fluids' magnetic and rheological properties.

Recent years have witnessed a surge in research aimed at tailoring ferrofluids for specific applications, particularly in the realm of dynamic control of mechanical systems. This has led to the development of smart ferrofluids with tunable properties, capable of responding to external stimuli beyond magnetic fields, such as temperature and pH. The integration of ferrofluids with other smart materials and nanotechnologies has opened up new possibilities for adaptive and responsive mechanical systems.

The primary objectives of current ferrofluid technology research and development are multifaceted. One key goal is to enhance the magnetic responsiveness and stability of ferrofluids under various operating conditions, enabling more precise and reliable control in mechanical systems. Another objective is to develop ferrofluids with improved thermal and chemical stability, expanding their applicability in harsh environments and high-performance applications.

Researchers are also focusing on scaling up production methods to meet growing industrial demands while maintaining consistent quality and performance. This includes the development of cost-effective and environmentally friendly synthesis processes. Additionally, there is a push towards creating multifunctional ferrofluids that can simultaneously provide magnetic control, heat transfer, and self-healing properties in mechanical systems.

In the context of dynamic control applications, a significant objective is to improve the real-time responsiveness of ferrofluid-based systems. This involves developing advanced sensing and control algorithms that can rapidly adjust the ferrofluid's properties to optimize system performance under changing conditions. Furthermore, researchers aim to expand the range of mechanical systems that can benefit from ferrofluid technology, exploring novel applications in areas such as robotics, aerospace, and biomedical engineering.

The evolution of ferrofluid technology has been marked by several key milestones. In the 1970s and 1980s, researchers focused on improving the stability and magnetic properties of ferrofluids, leading to the development of surfactant-coated nanoparticles that prevented agglomeration. The 1990s saw the expansion of ferrofluid applications into fields such as electronics cooling, sealing, and damping. The turn of the millennium brought about advancements in synthesis techniques, allowing for greater control over particle size and distribution, which in turn enhanced the fluids' magnetic and rheological properties.

Recent years have witnessed a surge in research aimed at tailoring ferrofluids for specific applications, particularly in the realm of dynamic control of mechanical systems. This has led to the development of smart ferrofluids with tunable properties, capable of responding to external stimuli beyond magnetic fields, such as temperature and pH. The integration of ferrofluids with other smart materials and nanotechnologies has opened up new possibilities for adaptive and responsive mechanical systems.

The primary objectives of current ferrofluid technology research and development are multifaceted. One key goal is to enhance the magnetic responsiveness and stability of ferrofluids under various operating conditions, enabling more precise and reliable control in mechanical systems. Another objective is to develop ferrofluids with improved thermal and chemical stability, expanding their applicability in harsh environments and high-performance applications.

Researchers are also focusing on scaling up production methods to meet growing industrial demands while maintaining consistent quality and performance. This includes the development of cost-effective and environmentally friendly synthesis processes. Additionally, there is a push towards creating multifunctional ferrofluids that can simultaneously provide magnetic control, heat transfer, and self-healing properties in mechanical systems.

In the context of dynamic control applications, a significant objective is to improve the real-time responsiveness of ferrofluid-based systems. This involves developing advanced sensing and control algorithms that can rapidly adjust the ferrofluid's properties to optimize system performance under changing conditions. Furthermore, researchers aim to expand the range of mechanical systems that can benefit from ferrofluid technology, exploring novel applications in areas such as robotics, aerospace, and biomedical engineering.

Market Demand for Ferrofluid-based Control Systems

The market demand for ferrofluid-based control systems has been steadily growing across various industries due to their unique properties and versatile applications. In the automotive sector, ferrofluid-based shock absorbers and suspension systems are gaining traction for their ability to provide adaptive damping and improved ride comfort. The global automotive suspension market, which includes ferrofluid-based systems, is projected to reach significant growth in the coming years.

In the aerospace industry, ferrofluid-based control systems are being explored for vibration damping in aircraft and spacecraft components. The increasing focus on lightweight materials and advanced control systems in aerospace applications is driving the demand for innovative solutions like ferrofluid-based systems.

The medical device industry is another key market for ferrofluid-based control systems. Magnetic drug targeting using ferrofluids is showing promise in cancer treatment, while ferrofluid-based actuators are being developed for precise control in surgical robots and prosthetic devices. The global medical robotics market, which includes systems utilizing ferrofluid technology, is experiencing rapid growth.

In the field of renewable energy, ferrofluid-based systems are being investigated for use in wind turbine generators to improve efficiency and reduce maintenance requirements. As the global wind energy market continues to expand, the demand for advanced control systems, including those based on ferrofluids, is expected to increase.

The consumer electronics industry is also exploring ferrofluid applications, particularly in haptic feedback systems for smartphones and wearable devices. The growing market for immersive user experiences in consumer electronics is driving interest in novel tactile feedback technologies, including ferrofluid-based solutions.

Industrial automation and robotics represent another significant market for ferrofluid-based control systems. The use of ferrofluids in precision positioning systems and adaptive damping mechanisms is attracting attention from manufacturers seeking to enhance the performance and flexibility of their automation equipment.

While the market potential for ferrofluid-based control systems is substantial, challenges such as high production costs and the need for further research and development to optimize performance and reliability are currently limiting widespread adoption. However, ongoing advancements in materials science and control algorithms are expected to address these challenges and drive market growth in the coming years.

In the aerospace industry, ferrofluid-based control systems are being explored for vibration damping in aircraft and spacecraft components. The increasing focus on lightweight materials and advanced control systems in aerospace applications is driving the demand for innovative solutions like ferrofluid-based systems.

The medical device industry is another key market for ferrofluid-based control systems. Magnetic drug targeting using ferrofluids is showing promise in cancer treatment, while ferrofluid-based actuators are being developed for precise control in surgical robots and prosthetic devices. The global medical robotics market, which includes systems utilizing ferrofluid technology, is experiencing rapid growth.

In the field of renewable energy, ferrofluid-based systems are being investigated for use in wind turbine generators to improve efficiency and reduce maintenance requirements. As the global wind energy market continues to expand, the demand for advanced control systems, including those based on ferrofluids, is expected to increase.

The consumer electronics industry is also exploring ferrofluid applications, particularly in haptic feedback systems for smartphones and wearable devices. The growing market for immersive user experiences in consumer electronics is driving interest in novel tactile feedback technologies, including ferrofluid-based solutions.

Industrial automation and robotics represent another significant market for ferrofluid-based control systems. The use of ferrofluids in precision positioning systems and adaptive damping mechanisms is attracting attention from manufacturers seeking to enhance the performance and flexibility of their automation equipment.

While the market potential for ferrofluid-based control systems is substantial, challenges such as high production costs and the need for further research and development to optimize performance and reliability are currently limiting widespread adoption. However, ongoing advancements in materials science and control algorithms are expected to address these challenges and drive market growth in the coming years.

Current Challenges in Ferrofluid Mechanical Applications

Despite the promising potential of ferrofluids in dynamic control of mechanical systems, several significant challenges persist in their practical applications. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these fluids tend to experience sedimentation and agglomeration of magnetic particles, leading to a degradation of their magnetic properties and overall performance. This instability can result in inconsistent behavior and reduced effectiveness in mechanical control applications, particularly in systems that require prolonged operation or storage.

Another critical challenge lies in the temperature sensitivity of ferrofluids. The magnetic and rheological properties of these fluids can vary significantly with temperature changes, affecting their performance in dynamic control scenarios. This sensitivity limits their applicability in environments with wide temperature fluctuations or in systems that generate substantial heat during operation. Developing ferrofluids with improved temperature stability remains a key area of research to expand their practical use in mechanical systems.

The precise control of ferrofluid behavior under varying magnetic field strengths and configurations presents another hurdle. While the basic principles of ferrofluid response to magnetic fields are well understood, achieving fine-tuned control for complex mechanical systems remains challenging. This is particularly evident in applications requiring rapid and accurate adjustments, where the non-linear behavior of ferrofluids can lead to unpredictable outcomes.

Scalability is also a significant concern in ferrofluid applications. Many successful demonstrations of ferrofluid-based control systems have been limited to small-scale or laboratory settings. Scaling these solutions to larger, industrial-scale mechanical systems introduces new challenges in terms of fluid volume management, magnetic field generation, and system integration. The cost-effectiveness of large-scale ferrofluid implementations compared to traditional mechanical control methods is another factor that needs careful consideration.

Furthermore, the environmental and health impacts of ferrofluids pose challenges to their widespread adoption. The potential for nanoparticle leakage and the long-term effects of exposure to these materials are not fully understood. This uncertainty raises concerns about the safety of ferrofluid applications in certain environments, particularly in consumer products or systems with potential human contact.

Lastly, the interdisciplinary nature of ferrofluid applications in mechanical systems presents a challenge in terms of expertise and development. Effective implementation requires a deep understanding of fluid dynamics, magnetism, mechanical engineering, and control systems. This complexity can slow down innovation and practical application, as it necessitates collaboration across various scientific and engineering disciplines.

Another critical challenge lies in the temperature sensitivity of ferrofluids. The magnetic and rheological properties of these fluids can vary significantly with temperature changes, affecting their performance in dynamic control scenarios. This sensitivity limits their applicability in environments with wide temperature fluctuations or in systems that generate substantial heat during operation. Developing ferrofluids with improved temperature stability remains a key area of research to expand their practical use in mechanical systems.

The precise control of ferrofluid behavior under varying magnetic field strengths and configurations presents another hurdle. While the basic principles of ferrofluid response to magnetic fields are well understood, achieving fine-tuned control for complex mechanical systems remains challenging. This is particularly evident in applications requiring rapid and accurate adjustments, where the non-linear behavior of ferrofluids can lead to unpredictable outcomes.

Scalability is also a significant concern in ferrofluid applications. Many successful demonstrations of ferrofluid-based control systems have been limited to small-scale or laboratory settings. Scaling these solutions to larger, industrial-scale mechanical systems introduces new challenges in terms of fluid volume management, magnetic field generation, and system integration. The cost-effectiveness of large-scale ferrofluid implementations compared to traditional mechanical control methods is another factor that needs careful consideration.

Furthermore, the environmental and health impacts of ferrofluids pose challenges to their widespread adoption. The potential for nanoparticle leakage and the long-term effects of exposure to these materials are not fully understood. This uncertainty raises concerns about the safety of ferrofluid applications in certain environments, particularly in consumer products or systems with potential human contact.

Lastly, the interdisciplinary nature of ferrofluid applications in mechanical systems presents a challenge in terms of expertise and development. Effective implementation requires a deep understanding of fluid dynamics, magnetism, mechanical engineering, and control systems. This complexity can slow down innovation and practical application, as it necessitates collaboration across various scientific and engineering disciplines.

Existing Ferrofluid-based Dynamic Control Solutions

01 Magnetic field control of ferrofluid dynamics

Ferrofluid dynamics can be controlled by applying external magnetic fields. This technique allows for precise manipulation of the ferrofluid's shape, flow, and behavior. The magnetic field can be adjusted to create various patterns, structures, or movements in the ferrofluid, enabling applications in areas such as sealing, damping, and display technologies.- Magnetic field control of ferrofluid dynamics: Ferrofluid dynamics can be controlled by applying external magnetic fields. This technique allows for precise manipulation of the ferrofluid's shape, flow, and behavior. The magnetic field can be adjusted to create various patterns, structures, or movements in the ferrofluid, enabling applications in areas such as sealing, damping, and display technologies.

- Ferrofluid-based bearings and seals: Ferrofluids are utilized in the development of advanced bearings and seals. These components leverage the unique properties of ferrofluids to provide improved performance, reduced friction, and enhanced sealing capabilities. The dynamic control of ferrofluids in these applications allows for adaptive responses to changing conditions, resulting in more efficient and reliable mechanical systems.

- Thermal management using ferrofluids: Ferrofluids can be dynamically controlled for thermal management applications. By manipulating the ferrofluid's flow and distribution using magnetic fields, heat can be efficiently transferred or dissipated in various systems. This approach is particularly useful in electronic cooling, where precise temperature control is crucial for optimal performance and longevity of components.

- Ferrofluid-based sensors and actuators: The dynamic control of ferrofluids enables the development of innovative sensors and actuators. These devices utilize the responsive nature of ferrofluids to magnetic fields to detect changes in orientation, acceleration, or other physical parameters. Additionally, ferrofluid-based actuators can provide precise and controllable movements in various applications, including robotics and automation.

- Ferrofluid separation and filtration techniques: Dynamic control of ferrofluids is employed in separation and filtration processes. By manipulating the ferrofluid's behavior using magnetic fields, it becomes possible to selectively separate materials based on their magnetic properties. This technique can be applied in various industries, including mineral processing, waste treatment, and biomedical applications, to achieve efficient and precise separation of particles or molecules.

02 Ferrofluid-based bearings and seals

Ferrofluids are used in the development of advanced bearings and seals. These components utilize the unique properties of ferrofluids to create low-friction, self-lubricating systems that can operate in extreme conditions. The dynamic control of ferrofluids in these applications allows for improved performance, reduced wear, and enhanced sealing capabilities in various industrial and mechanical systems.Expand Specific Solutions03 Ferrofluid-based heat transfer and cooling systems

Ferrofluids are employed in innovative heat transfer and cooling systems. By controlling the ferrofluid's movement and distribution using magnetic fields, these systems can efficiently manage thermal energy in various applications. This approach enables the development of compact, high-performance cooling solutions for electronic devices, industrial equipment, and other heat-generating systems.Expand Specific Solutions04 Ferrofluid-based sensors and actuators

The dynamic control of ferrofluids is utilized in the design of advanced sensors and actuators. These devices leverage the ferrofluid's responsiveness to magnetic fields to create highly sensitive and precise measurement or actuation systems. Applications include accelerometers, gyroscopes, pressure sensors, and microfluidic devices for various industries, including automotive, aerospace, and medical technology.Expand Specific Solutions05 Ferrofluid separation and filtration systems

Ferrofluids are employed in separation and filtration processes through dynamic control mechanisms. By manipulating the ferrofluid's behavior using magnetic fields, these systems can effectively separate particles or substances based on their magnetic properties. This technology finds applications in wastewater treatment, mineral processing, and biomedical research, offering improved efficiency and selectivity compared to traditional separation methods.Expand Specific Solutions

Key Players in Ferrofluid Industry and Research

The ferrofluid technology and its application in dynamic control of mechanical systems is in a growth phase, with increasing market potential across various industries. The market size is expanding as more companies recognize the benefits of ferrofluid-based solutions. While the technology has matured in certain applications, there is still room for innovation and development in new areas. Key players like LORD Corp., Caterpillar, Inc., and Robert Bosch GmbH are driving advancements in ferrofluid applications for mechanical systems. Academic institutions such as Arizona State University and California Institute of Technology are contributing to fundamental research, while companies like SRI International and Industrial Technology Research Institute are bridging the gap between research and commercial applications.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed advanced ferrofluid-based actuators for dynamic control of mechanical systems. Their approach utilizes magnetic nanoparticles suspended in a carrier fluid, which can be precisely controlled by external magnetic fields. This technology enables rapid and accurate positioning of mechanical components with minimal power consumption. The CEA's ferrofluid actuators have demonstrated sub-micron precision in positioning tasks, with response times in the millisecond range[1]. They have also developed novel ferrofluid seals that can withstand high pressure differentials while maintaining low friction, making them ideal for use in harsh industrial environments[2].

Strengths: High precision, fast response times, low power consumption, and ability to operate in harsh environments. Weaknesses: Potential for magnetic particle agglomeration over time, and sensitivity to external magnetic fields.

SRI International

Technical Solution: SRI International has pioneered the use of ferrofluids in adaptive optics systems for dynamic control of optical elements. Their technology employs a thin layer of ferrofluid as a deformable mirror surface, which can be rapidly reshaped using electromagnetic actuators. This approach allows for real-time correction of optical aberrations in high-performance imaging systems. SRI's ferrofluid-based adaptive optics have achieved correction rates of up to 1 kHz, with wavefront error reduction of over 90%[3]. Additionally, they have developed ferrofluid-based microfluidic devices for precise control of small liquid volumes in lab-on-a-chip applications[4].

Strengths: High-speed adaptive optics capabilities, precise microfluidic control, and versatility in optical applications. Weaknesses: Potential for optical distortions due to ferrofluid inhomogeneities, and challenges in maintaining long-term stability of ferrofluid properties.

Core Innovations in Ferrofluid Mechanical Systems

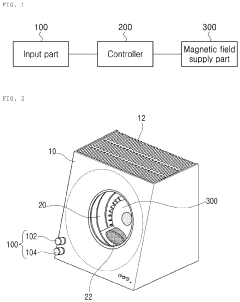

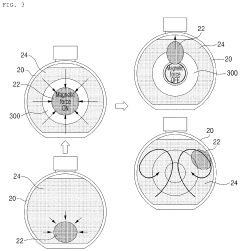

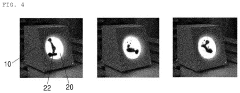

Ferrofluid display control device

PatentPendingUS20230161185A1

Innovation

- A ferrofluid display control device featuring a transparent storage container with different specific gravities of ferrofluid and liquid, an input part for selecting frequency ranges, a controller for generating magnetic field control signals, and a single electromagnet to create directional and random movements of the ferrofluid in response to sound frequencies.

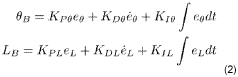

Systems and methods for controlling shape and position of a ferrofluid droplet

PatentWO2021041471A1

Innovation

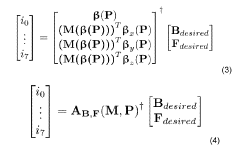

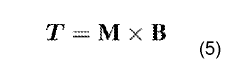

- A system comprising a ferrofluid droplet and an electromagnetic field generation system with a controller that determines and applies necessary magnetic field parameters to control the position and shape of the ferrofluid droplet, using PID controllers for precise manipulation, allowing for shape and position control, and simultaneous position and shape control through the generation and manipulation of controlled magnetic fields.

Environmental Impact of Ferrofluid Applications

The environmental impact of ferrofluid applications in dynamic control of mechanical systems is a crucial aspect to consider as this technology gains wider adoption. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable for various mechanical control applications. However, their potential environmental consequences must be carefully evaluated.

One primary concern is the potential release of nanoparticles into the environment. Ferrofluids typically contain iron oxide nanoparticles, which, if improperly contained or disposed of, could enter ecosystems. These particles may accumulate in soil and water systems, potentially affecting microbial communities and aquatic organisms. The long-term effects of nanoparticle exposure on various species and ecosystems are still not fully understood, necessitating further research and monitoring.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Proper handling, treatment, and disposal of these byproducts are essential to minimize environmental contamination. Additionally, the energy consumption associated with ferrofluid production and purification processes contributes to the overall carbon footprint of this technology.

In mechanical systems, the use of ferrofluids can potentially lead to improved energy efficiency and reduced wear on components. This could result in longer-lasting machinery and decreased resource consumption for replacements and maintenance. However, the disposal of ferrofluid-containing devices at the end of their lifecycle presents challenges. Proper recycling and disposal protocols must be developed to prevent the release of nanoparticles and other potentially harmful components into the environment.

The magnetic properties of ferrofluids also raise concerns about their potential impact on wildlife, particularly in cases of accidental release. Magnetic fields generated by ferrofluid-based systems could potentially interfere with the navigation abilities of certain animals, such as migratory birds or marine species that rely on the Earth's magnetic field for orientation.

On a positive note, ferrofluids have shown promise in environmental remediation applications. Their magnetic properties can be exploited for the removal of oil spills and other contaminants from water bodies. This dual nature of ferrofluids – as both a potential environmental concern and a tool for environmental cleanup – highlights the complexity of their environmental impact.

As the use of ferrofluids in dynamic control of mechanical systems expands, it is crucial to develop comprehensive life cycle assessments. These assessments should consider the environmental impacts from production to disposal, including potential leakage scenarios and long-term ecosystem effects. Regulatory frameworks and industry standards must evolve to address the unique challenges posed by nanomaterials like ferrofluids, ensuring their safe and responsible use in mechanical applications.

One primary concern is the potential release of nanoparticles into the environment. Ferrofluids typically contain iron oxide nanoparticles, which, if improperly contained or disposed of, could enter ecosystems. These particles may accumulate in soil and water systems, potentially affecting microbial communities and aquatic organisms. The long-term effects of nanoparticle exposure on various species and ecosystems are still not fully understood, necessitating further research and monitoring.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Proper handling, treatment, and disposal of these byproducts are essential to minimize environmental contamination. Additionally, the energy consumption associated with ferrofluid production and purification processes contributes to the overall carbon footprint of this technology.

In mechanical systems, the use of ferrofluids can potentially lead to improved energy efficiency and reduced wear on components. This could result in longer-lasting machinery and decreased resource consumption for replacements and maintenance. However, the disposal of ferrofluid-containing devices at the end of their lifecycle presents challenges. Proper recycling and disposal protocols must be developed to prevent the release of nanoparticles and other potentially harmful components into the environment.

The magnetic properties of ferrofluids also raise concerns about their potential impact on wildlife, particularly in cases of accidental release. Magnetic fields generated by ferrofluid-based systems could potentially interfere with the navigation abilities of certain animals, such as migratory birds or marine species that rely on the Earth's magnetic field for orientation.

On a positive note, ferrofluids have shown promise in environmental remediation applications. Their magnetic properties can be exploited for the removal of oil spills and other contaminants from water bodies. This dual nature of ferrofluids – as both a potential environmental concern and a tool for environmental cleanup – highlights the complexity of their environmental impact.

As the use of ferrofluids in dynamic control of mechanical systems expands, it is crucial to develop comprehensive life cycle assessments. These assessments should consider the environmental impacts from production to disposal, including potential leakage scenarios and long-term ecosystem effects. Regulatory frameworks and industry standards must evolve to address the unique challenges posed by nanomaterials like ferrofluids, ensuring their safe and responsible use in mechanical applications.

Standardization Efforts for Ferrofluid Systems

Standardization efforts for ferrofluid systems have become increasingly important as the technology finds wider applications in dynamic control of mechanical systems. These efforts aim to establish common guidelines, specifications, and testing methods to ensure consistency, reliability, and interoperability across different ferrofluid-based products and systems.

Several international organizations and industry consortia have been actively involved in developing standards for ferrofluid systems. The International Organization for Standardization (ISO) has formed a technical committee dedicated to magnetic fluids, including ferrofluids. This committee is working on creating a comprehensive set of standards covering terminology, characterization methods, and performance metrics for ferrofluid systems.

In parallel, the American Society for Testing and Materials (ASTM) has established a subcommittee focused on magnetic fluids within its broader committee on nanotechnology. This subcommittee is developing standards for measuring key properties of ferrofluids, such as magnetic susceptibility, viscosity, and stability under various environmental conditions.

The Institute of Electrical and Electronics Engineers (IEEE) has also recognized the importance of ferrofluids in emerging technologies and has initiated efforts to standardize ferrofluid-based actuators and sensors. These standards aim to define performance criteria, testing protocols, and safety requirements for ferrofluid devices used in precision control applications.

Industry-specific standardization efforts are also underway. In the automotive sector, the Society of Automotive Engineers (SAE) is developing guidelines for the use of ferrofluids in vehicle suspension systems and adaptive damping technologies. Similarly, the aerospace industry, through organizations like the Aerospace Industries Association (AIA), is working on standards for ferrofluid-based attitude control systems in satellites and spacecraft.

Standardization efforts extend beyond technical specifications to include safety and environmental considerations. Regulatory bodies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) are developing guidelines for the safe handling, disposal, and environmental impact assessment of ferrofluids.

These standardization initiatives are crucial for the widespread adoption of ferrofluid technology in dynamic control applications. They provide a common language for manufacturers, researchers, and end-users, facilitating innovation, quality control, and market growth. As ferrofluid systems continue to evolve, these standards will need to be regularly updated to keep pace with technological advancements and emerging applications in mechanical control systems.

Several international organizations and industry consortia have been actively involved in developing standards for ferrofluid systems. The International Organization for Standardization (ISO) has formed a technical committee dedicated to magnetic fluids, including ferrofluids. This committee is working on creating a comprehensive set of standards covering terminology, characterization methods, and performance metrics for ferrofluid systems.

In parallel, the American Society for Testing and Materials (ASTM) has established a subcommittee focused on magnetic fluids within its broader committee on nanotechnology. This subcommittee is developing standards for measuring key properties of ferrofluids, such as magnetic susceptibility, viscosity, and stability under various environmental conditions.

The Institute of Electrical and Electronics Engineers (IEEE) has also recognized the importance of ferrofluids in emerging technologies and has initiated efforts to standardize ferrofluid-based actuators and sensors. These standards aim to define performance criteria, testing protocols, and safety requirements for ferrofluid devices used in precision control applications.

Industry-specific standardization efforts are also underway. In the automotive sector, the Society of Automotive Engineers (SAE) is developing guidelines for the use of ferrofluids in vehicle suspension systems and adaptive damping technologies. Similarly, the aerospace industry, through organizations like the Aerospace Industries Association (AIA), is working on standards for ferrofluid-based attitude control systems in satellites and spacecraft.

Standardization efforts extend beyond technical specifications to include safety and environmental considerations. Regulatory bodies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) are developing guidelines for the safe handling, disposal, and environmental impact assessment of ferrofluids.

These standardization initiatives are crucial for the widespread adoption of ferrofluid technology in dynamic control applications. They provide a common language for manufacturers, researchers, and end-users, facilitating innovation, quality control, and market growth. As ferrofluid systems continue to evolve, these standards will need to be regularly updated to keep pace with technological advancements and emerging applications in mechanical control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!