Ferrofluid Innovations in High-Precision Measurement Tools

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluid technology has undergone significant evolution since its inception in the 1960s, particularly in its application to high-precision measurement tools. The journey began with NASA's development of ferrofluids for controlling liquids in zero gravity, which laid the foundation for future innovations.

In the 1970s and 1980s, researchers explored the unique properties of ferrofluids, such as their responsiveness to magnetic fields and their ability to maintain liquid properties while exhibiting magnetic behavior. This period saw the first attempts to incorporate ferrofluids into measurement devices, primarily in the form of liquid seals and dampers.

The 1990s marked a turning point in ferrofluid technology for precision measurements. Scientists began developing ferrofluid-based accelerometers and gyroscopes, leveraging the fluid's ability to respond to minute changes in orientation and acceleration. These early devices, while promising, faced challenges in terms of stability and accuracy.

The early 2000s witnessed a surge in ferrofluid research for measurement applications. Advances in nanotechnology allowed for the creation of more stable and responsive ferrofluids, with precisely controlled particle sizes and magnetic properties. This led to the development of highly sensitive tilt sensors and improved accelerometers.

From 2010 onwards, ferrofluid technology in measurement tools entered a phase of rapid innovation. Researchers began exploring the use of ferrofluids in microfluidic devices for precise liquid handling and measurement. This period also saw the integration of ferrofluids with MEMS (Micro-Electro-Mechanical Systems) technology, resulting in compact and highly accurate sensors.

Recent years have seen a focus on enhancing the precision and reliability of ferrofluid-based measurement tools. Innovations include the development of temperature-compensated ferrofluids for consistent performance across varying environmental conditions, and the use of advanced magnetic field manipulation techniques to achieve unprecedented levels of sensitivity.

The latest frontier in ferrofluid technology for high-precision measurements involves the integration of smart materials and AI-driven control systems. These advancements allow for real-time adjustment of ferrofluid properties, enabling adaptive measurement tools that can self-calibrate and optimize their performance based on specific measurement requirements.

Looking ahead, the evolution of ferrofluid technology in high-precision measurement tools is expected to continue, with a focus on miniaturization, increased sensitivity, and broader application ranges. Emerging areas of research include quantum sensing applications and the development of bio-compatible ferrofluids for in-vivo measurements in medical diagnostics.

In the 1970s and 1980s, researchers explored the unique properties of ferrofluids, such as their responsiveness to magnetic fields and their ability to maintain liquid properties while exhibiting magnetic behavior. This period saw the first attempts to incorporate ferrofluids into measurement devices, primarily in the form of liquid seals and dampers.

The 1990s marked a turning point in ferrofluid technology for precision measurements. Scientists began developing ferrofluid-based accelerometers and gyroscopes, leveraging the fluid's ability to respond to minute changes in orientation and acceleration. These early devices, while promising, faced challenges in terms of stability and accuracy.

The early 2000s witnessed a surge in ferrofluid research for measurement applications. Advances in nanotechnology allowed for the creation of more stable and responsive ferrofluids, with precisely controlled particle sizes and magnetic properties. This led to the development of highly sensitive tilt sensors and improved accelerometers.

From 2010 onwards, ferrofluid technology in measurement tools entered a phase of rapid innovation. Researchers began exploring the use of ferrofluids in microfluidic devices for precise liquid handling and measurement. This period also saw the integration of ferrofluids with MEMS (Micro-Electro-Mechanical Systems) technology, resulting in compact and highly accurate sensors.

Recent years have seen a focus on enhancing the precision and reliability of ferrofluid-based measurement tools. Innovations include the development of temperature-compensated ferrofluids for consistent performance across varying environmental conditions, and the use of advanced magnetic field manipulation techniques to achieve unprecedented levels of sensitivity.

The latest frontier in ferrofluid technology for high-precision measurements involves the integration of smart materials and AI-driven control systems. These advancements allow for real-time adjustment of ferrofluid properties, enabling adaptive measurement tools that can self-calibrate and optimize their performance based on specific measurement requirements.

Looking ahead, the evolution of ferrofluid technology in high-precision measurement tools is expected to continue, with a focus on miniaturization, increased sensitivity, and broader application ranges. Emerging areas of research include quantum sensing applications and the development of bio-compatible ferrofluids for in-vivo measurements in medical diagnostics.

Precision Measurement Demand

The demand for high-precision measurement tools has been steadily increasing across various industries, driven by the need for enhanced accuracy, reliability, and efficiency in manufacturing processes, scientific research, and quality control. Ferrofluid innovations have emerged as a promising solution to meet these growing demands, offering unique properties that can significantly improve the performance of measurement instruments.

In the manufacturing sector, particularly in industries such as aerospace, automotive, and electronics, there is a critical need for measurement tools capable of detecting minute variations in dimensions, surface quality, and material properties. The ability to measure with nanometer-level precision has become essential for ensuring product quality and maintaining competitive advantage in global markets. Ferrofluid-based sensors and actuators have shown potential in addressing these requirements by providing highly sensitive and responsive measurement capabilities.

The scientific research community has also expressed a strong demand for advanced measurement tools that can push the boundaries of experimental precision. Fields such as quantum physics, nanotechnology, and materials science require instruments that can operate at the atomic and molecular levels. Ferrofluid innovations offer the potential to develop measurement devices with unprecedented sensitivity and resolution, enabling researchers to explore phenomena that were previously beyond the reach of conventional instruments.

In the realm of quality control and inspection, industries are seeking more efficient and reliable methods to detect defects and ensure product consistency. Ferrofluid-based measurement tools have demonstrated the ability to provide rapid, non-destructive testing capabilities, which can significantly improve throughput and reduce waste in production processes. This aligns with the growing emphasis on lean manufacturing and sustainability practices across industries.

The medical and healthcare sectors have also shown increasing interest in high-precision measurement tools for diagnostics, drug development, and personalized medicine. Ferrofluid technologies have the potential to enhance the accuracy of medical imaging, improve the sensitivity of diagnostic tests, and enable more precise drug delivery systems. As healthcare continues to move towards more personalized and targeted treatments, the demand for such advanced measurement capabilities is expected to grow substantially.

Environmental monitoring and climate research represent another area where high-precision measurement tools are in high demand. The need to accurately measure and track changes in atmospheric composition, ocean temperatures, and other environmental parameters has become crucial in understanding and addressing global climate challenges. Ferrofluid-based sensors could potentially offer new ways to collect more precise and comprehensive environmental data.

As industries continue to embrace Industry 4.0 and smart manufacturing concepts, the integration of high-precision measurement tools into automated systems and digital twins has become a key focus. Ferrofluid innovations have the potential to play a significant role in this transformation by providing real-time, high-accuracy measurements that can be seamlessly integrated into digital manufacturing ecosystems.

In the manufacturing sector, particularly in industries such as aerospace, automotive, and electronics, there is a critical need for measurement tools capable of detecting minute variations in dimensions, surface quality, and material properties. The ability to measure with nanometer-level precision has become essential for ensuring product quality and maintaining competitive advantage in global markets. Ferrofluid-based sensors and actuators have shown potential in addressing these requirements by providing highly sensitive and responsive measurement capabilities.

The scientific research community has also expressed a strong demand for advanced measurement tools that can push the boundaries of experimental precision. Fields such as quantum physics, nanotechnology, and materials science require instruments that can operate at the atomic and molecular levels. Ferrofluid innovations offer the potential to develop measurement devices with unprecedented sensitivity and resolution, enabling researchers to explore phenomena that were previously beyond the reach of conventional instruments.

In the realm of quality control and inspection, industries are seeking more efficient and reliable methods to detect defects and ensure product consistency. Ferrofluid-based measurement tools have demonstrated the ability to provide rapid, non-destructive testing capabilities, which can significantly improve throughput and reduce waste in production processes. This aligns with the growing emphasis on lean manufacturing and sustainability practices across industries.

The medical and healthcare sectors have also shown increasing interest in high-precision measurement tools for diagnostics, drug development, and personalized medicine. Ferrofluid technologies have the potential to enhance the accuracy of medical imaging, improve the sensitivity of diagnostic tests, and enable more precise drug delivery systems. As healthcare continues to move towards more personalized and targeted treatments, the demand for such advanced measurement capabilities is expected to grow substantially.

Environmental monitoring and climate research represent another area where high-precision measurement tools are in high demand. The need to accurately measure and track changes in atmospheric composition, ocean temperatures, and other environmental parameters has become crucial in understanding and addressing global climate challenges. Ferrofluid-based sensors could potentially offer new ways to collect more precise and comprehensive environmental data.

As industries continue to embrace Industry 4.0 and smart manufacturing concepts, the integration of high-precision measurement tools into automated systems and digital twins has become a key focus. Ferrofluid innovations have the potential to play a significant role in this transformation by providing real-time, high-accuracy measurements that can be seamlessly integrated into digital manufacturing ecosystems.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in high-precision measurement tools, several significant challenges hinder their widespread adoption and optimal performance. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions tend to degrade over time due to particle agglomeration and oxidation, which can lead to changes in their magnetic properties and overall effectiveness. This instability poses a significant hurdle for applications requiring consistent performance over extended periods.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. The complex interplay between magnetic forces, surface tension, and gravitational effects makes it difficult to predict and manipulate ferrofluid responses accurately. This unpredictability can compromise the reliability and accuracy of measurement tools, especially in applications demanding high precision.

The temperature sensitivity of ferrofluids presents yet another obstacle. Their magnetic and rheological properties can change significantly with temperature fluctuations, affecting the calibration and performance of measurement devices. Developing temperature-compensated systems or ferrofluids with enhanced thermal stability remains a key area of research and development.

Contamination and biocompatibility issues also pose challenges, particularly in biomedical and environmental sensing applications. Ensuring that ferrofluids remain inert and do not interfere with the samples being measured is crucial for maintaining the integrity of results. Additionally, the potential toxicity of some ferrofluid components raises concerns about their use in certain environments.

The manufacturing and quality control of ferrofluids for high-precision applications present their own set of challenges. Achieving consistent particle size distribution, magnetic saturation, and viscosity across batches is essential for reproducible results. However, the complex synthesis processes and the need for specialized equipment can make large-scale production of high-quality ferrofluids difficult and costly.

Lastly, the integration of ferrofluids into existing measurement technologies poses significant engineering challenges. Designing systems that can effectively harness the unique properties of ferrofluids while maintaining compatibility with current instrumentation and standards requires innovative approaches and often necessitates the development of new manufacturing techniques and materials.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. The complex interplay between magnetic forces, surface tension, and gravitational effects makes it difficult to predict and manipulate ferrofluid responses accurately. This unpredictability can compromise the reliability and accuracy of measurement tools, especially in applications demanding high precision.

The temperature sensitivity of ferrofluids presents yet another obstacle. Their magnetic and rheological properties can change significantly with temperature fluctuations, affecting the calibration and performance of measurement devices. Developing temperature-compensated systems or ferrofluids with enhanced thermal stability remains a key area of research and development.

Contamination and biocompatibility issues also pose challenges, particularly in biomedical and environmental sensing applications. Ensuring that ferrofluids remain inert and do not interfere with the samples being measured is crucial for maintaining the integrity of results. Additionally, the potential toxicity of some ferrofluid components raises concerns about their use in certain environments.

The manufacturing and quality control of ferrofluids for high-precision applications present their own set of challenges. Achieving consistent particle size distribution, magnetic saturation, and viscosity across batches is essential for reproducible results. However, the complex synthesis processes and the need for specialized equipment can make large-scale production of high-quality ferrofluids difficult and costly.

Lastly, the integration of ferrofluids into existing measurement technologies poses significant engineering challenges. Designing systems that can effectively harness the unique properties of ferrofluids while maintaining compatibility with current instrumentation and standards requires innovative approaches and often necessitates the development of new manufacturing techniques and materials.

Current Ferrofluid Solutions

01 Precision control of ferrofluid seals

Ferrofluid seals are used in various applications to provide precise control and improved performance. These seals utilize the unique properties of ferrofluids to create dynamic, adjustable barriers that can be manipulated with magnetic fields. This technology allows for enhanced precision in sealing mechanisms, particularly in rotating shaft applications and fluid control systems.- Precision control of ferrofluid seals: Ferrofluid seals are used in various applications to provide precise control and improved performance. These seals utilize the unique properties of ferrofluids to create dynamic, adjustable barriers that can be finely tuned for optimal sealing and reduced friction. The precision control of ferrofluid seals enables enhanced efficiency in mechanical systems and improved reliability in sensitive equipment.

- Ferrofluid-based precision bearings and dampers: Ferrofluids are employed in the development of high-precision bearings and damping systems. These components leverage the magnetic properties of ferrofluids to achieve precise positioning, reduced wear, and improved vibration control. The use of ferrofluids in bearings and dampers allows for enhanced performance in applications requiring high accuracy and stability.

- Ferrofluid-enhanced precision measurement and sensing: Ferrofluids are utilized in various precision measurement and sensing applications. Their unique magnetic properties enable the development of highly sensitive instruments for detecting small changes in magnetic fields, pressure, or acceleration. These ferrofluid-based sensors and measurement devices offer improved accuracy and resolution in scientific and industrial applications.

- Precision manufacturing techniques for ferrofluid devices: Advanced manufacturing techniques are employed to produce high-precision ferrofluid devices. These methods include precise control of ferrofluid composition, nanoparticle size distribution, and surface treatments. The development of specialized manufacturing processes enables the creation of ferrofluid-based components with enhanced performance and reliability for various applications.

- Ferrofluid-based precision cooling and heat transfer: Ferrofluids are employed in precision cooling and heat transfer applications. Their unique properties allow for the development of highly efficient and controllable thermal management systems. These ferrofluid-based cooling solutions offer improved heat dissipation and temperature control in sensitive electronic components and other high-precision equipment.

02 Ferrofluid-based precision bearings and dampers

Ferrofluids are employed in the development of high-precision bearings and damping systems. These components leverage the magnetic properties of ferrofluids to achieve improved stability, reduced friction, and enhanced vibration control. Such applications are particularly valuable in precision instruments, aerospace technology, and advanced manufacturing equipment.Expand Specific Solutions03 Precision measurement and sensing using ferrofluids

Ferrofluids are utilized in various precision measurement and sensing applications. Their unique response to magnetic fields allows for the development of highly sensitive instruments for detecting minute changes in position, pressure, or magnetic field strength. This technology is applied in areas such as accelerometers, pressure sensors, and magnetic field detectors.Expand Specific Solutions04 Ferrofluid-based precision cooling systems

Precision cooling systems incorporating ferrofluids have been developed for applications requiring accurate temperature control. These systems utilize the heat transfer properties of ferrofluids and their ability to be precisely manipulated by magnetic fields. Such cooling solutions are particularly valuable in electronics, medical devices, and scientific instruments where thermal management is critical.Expand Specific Solutions05 Precision manufacturing processes using ferrofluids

Ferrofluids are employed in various precision manufacturing processes to enhance accuracy and control. These applications include precision polishing, surface finishing, and material separation techniques. The ability to manipulate ferrofluids with magnetic fields allows for highly controlled and localized processing, resulting in improved product quality and manufacturing precision.Expand Specific Solutions

Key Ferrofluid Players

The field of ferrofluid innovations in high-precision measurement tools is in a growth phase, with increasing market potential due to advancements in nanotechnology and magnetism. The global market for ferrofluid-based precision instruments is expanding, driven by demand in sectors like aerospace, healthcare, and advanced manufacturing. Technologically, the field is progressing rapidly, with companies like Chongqing University, Yale University, and Azbil Corp. leading research and development efforts. These institutions are focusing on enhancing the stability, sensitivity, and application range of ferrofluid-based measurement tools, pushing the boundaries of precision in various scientific and industrial applications.

The Regents of the University of California

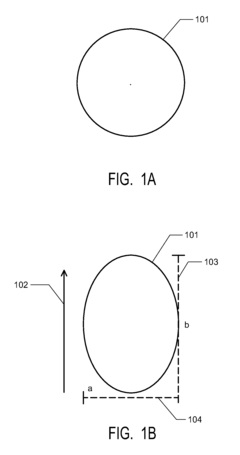

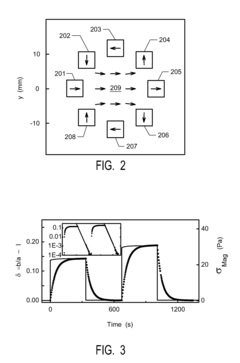

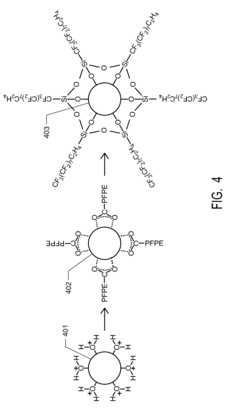

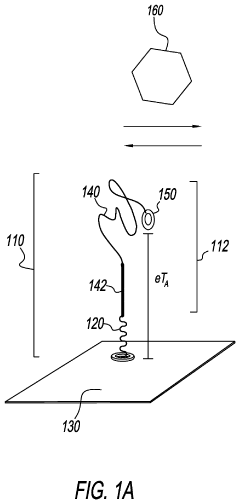

Technical Solution: The University of California has developed innovative ferrofluid-based measurement tools for high-precision applications. Their approach utilizes magnetically responsive nanoparticles suspended in a carrier fluid, which can be precisely controlled and manipulated using external magnetic fields. This technology enables the creation of adaptive and reconfigurable measurement devices with nanometer-scale precision[1]. The university's research has focused on developing ferrofluid-based sensors for various applications, including pressure sensors, accelerometers, and gyroscopes. These sensors exploit the unique properties of ferrofluids, such as their ability to change shape and viscosity in response to magnetic fields, to achieve high sensitivity and accuracy in measurements[3].

Strengths: Nanometer-scale precision, adaptability to various measurement applications, and potential for miniaturization. Weaknesses: Complexity in manufacturing and potential instability of ferrofluids over time.

Endress+Hauser Flowtec AG

Technical Solution: Endress+Hauser Flowtec AG has developed advanced ferrofluid-based flow measurement technologies for high-precision industrial applications. Their innovative approach utilizes ferrofluid-filled sensors that respond to changes in flow rates with high sensitivity. The company's technology leverages the magnetic properties of ferrofluids to create highly accurate and responsive flow meters. These devices use the deformation of the ferrofluid under flow conditions to measure flow rates with exceptional precision, even in challenging industrial environments[2]. Endress+Hauser's ferrofluid flow meters are particularly effective in measuring low flow rates and can operate in a wide range of temperatures and pressures[4].

Strengths: High accuracy in low flow rate measurements, robustness in industrial environments, and wide operating range. Weaknesses: Potential for magnetic interference and higher cost compared to traditional flow meters.

Ferrofluid Core Patents

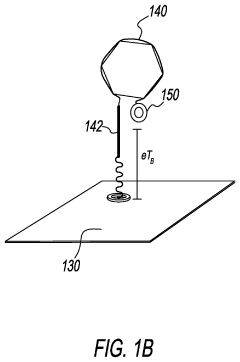

Ferrofluid droplets as in situ mechanical actuators and rheometers in soft materials and biological matter

PatentActiveUS20160116394A1

Innovation

- The use of ferrofluid droplets as mechanical actuators within materials, responsive to controlled magnetic fields, allowing for precise application and measurement of forces across multiple length scales, enabling direct quantification of spatiotemporal mechanical behavior and properties of living and non-living soft materials.

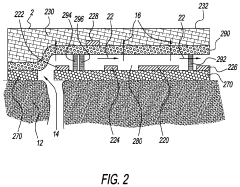

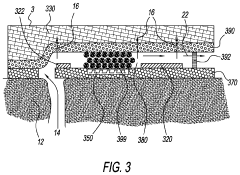

EAB sensing devices with biofluid sample concentration

PatentActiveUS20200155046A1

Innovation

- A biofluid sensing device with a concentration channel, selectively permeable membrane, and EAB sensors on a water-impermeable substrate, which concentrates the biofluid sample using microfluidic components and secondary sensors to enhance detection of low concentration analytes, allowing for both qualitative and quantitative measurements.

Ferrofluid Safety Standards

The development of safety standards for ferrofluids in high-precision measurement tools is crucial to ensure the protection of both users and equipment. These standards address the unique properties and potential risks associated with ferrofluids, which are colloidal liquids containing nanoscale ferromagnetic particles suspended in a carrier fluid.

One of the primary safety concerns is the potential for ferrofluid leakage or spillage. Standards have been established to define containment requirements, including specifications for sealing mechanisms and materials that can withstand the corrosive nature of some ferrofluids. These standards also outline procedures for proper handling and disposal of ferrofluids to prevent environmental contamination.

Electromagnetic compatibility is another critical aspect covered by ferrofluid safety standards. As ferrofluids respond to magnetic fields, guidelines have been developed to ensure that their use in measurement tools does not interfere with other electronic equipment or compromise the accuracy of measurements. These standards specify shielding requirements and acceptable levels of electromagnetic emissions.

Health and safety considerations are paramount in ferrofluid standards. Guidelines have been established for personal protective equipment (PPE) when working with ferrofluids, including recommendations for gloves, eye protection, and respiratory safeguards. Additionally, exposure limits have been defined to minimize potential health risks associated with long-term contact or inhalation of ferrofluid particles.

Stability and degradation of ferrofluids over time are addressed in safety standards, with protocols for regular testing and replacement to maintain optimal performance and safety. These standards also provide guidance on storage conditions, including temperature and humidity controls, to prevent degradation or changes in ferrofluid properties that could affect measurement accuracy or safety.

Calibration and quality control procedures specific to ferrofluid-based measurement tools are outlined in the safety standards. These ensure that the ferrofluid's magnetic properties remain consistent and that the tools maintain their high precision over time. Regular maintenance schedules and performance checks are prescribed to detect any deviations that could compromise safety or accuracy.

In the event of accidents or emergencies, ferrofluid safety standards include detailed response protocols. These cover procedures for containment of spills, decontamination of affected areas, and proper reporting of incidents. Training requirements for personnel working with ferrofluid-based tools are also specified to ensure competence in handling these specialized materials safely.

As the field of ferrofluid applications in measurement tools continues to evolve, safety standards are regularly reviewed and updated. This ongoing process involves collaboration between industry experts, regulatory bodies, and research institutions to incorporate new findings and address emerging safety concerns, ensuring that the standards remain relevant and effective in protecting users and maintaining the integrity of high-precision measurements.

One of the primary safety concerns is the potential for ferrofluid leakage or spillage. Standards have been established to define containment requirements, including specifications for sealing mechanisms and materials that can withstand the corrosive nature of some ferrofluids. These standards also outline procedures for proper handling and disposal of ferrofluids to prevent environmental contamination.

Electromagnetic compatibility is another critical aspect covered by ferrofluid safety standards. As ferrofluids respond to magnetic fields, guidelines have been developed to ensure that their use in measurement tools does not interfere with other electronic equipment or compromise the accuracy of measurements. These standards specify shielding requirements and acceptable levels of electromagnetic emissions.

Health and safety considerations are paramount in ferrofluid standards. Guidelines have been established for personal protective equipment (PPE) when working with ferrofluids, including recommendations for gloves, eye protection, and respiratory safeguards. Additionally, exposure limits have been defined to minimize potential health risks associated with long-term contact or inhalation of ferrofluid particles.

Stability and degradation of ferrofluids over time are addressed in safety standards, with protocols for regular testing and replacement to maintain optimal performance and safety. These standards also provide guidance on storage conditions, including temperature and humidity controls, to prevent degradation or changes in ferrofluid properties that could affect measurement accuracy or safety.

Calibration and quality control procedures specific to ferrofluid-based measurement tools are outlined in the safety standards. These ensure that the ferrofluid's magnetic properties remain consistent and that the tools maintain their high precision over time. Regular maintenance schedules and performance checks are prescribed to detect any deviations that could compromise safety or accuracy.

In the event of accidents or emergencies, ferrofluid safety standards include detailed response protocols. These cover procedures for containment of spills, decontamination of affected areas, and proper reporting of incidents. Training requirements for personnel working with ferrofluid-based tools are also specified to ensure competence in handling these specialized materials safely.

As the field of ferrofluid applications in measurement tools continues to evolve, safety standards are regularly reviewed and updated. This ongoing process involves collaboration between industry experts, regulatory bodies, and research institutions to incorporate new findings and address emerging safety concerns, ensuring that the standards remain relevant and effective in protecting users and maintaining the integrity of high-precision measurements.

Nanoparticle Regulations

The regulation of nanoparticles, including those used in ferrofluids for high-precision measurement tools, is a complex and evolving field. As these particles become increasingly prevalent in various industries, regulatory bodies worldwide are working to establish comprehensive frameworks to ensure their safe development, production, and application.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating nanoparticles under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new nanomaterials, allowing the agency to assess potential risks and implement necessary controls. Additionally, the Food and Drug Administration (FDA) oversees nanoparticles in food, drugs, and medical devices, while the Occupational Safety and Health Administration (OSHA) addresses workplace safety concerns related to nanoparticle exposure.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to nanomaterials. REACH mandates that companies register substances manufactured or imported in quantities over one tonne per year, including detailed safety information. The EU has also introduced specific provisions for nanomaterials in various product-specific regulations, such as those governing cosmetics and food additives.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for nanomaterials. Japan's approach focuses on voluntary reporting and risk assessment, while South Korea has implemented mandatory registration requirements for nanomaterials through its Act on Registration and Evaluation of Chemical Substances.

International organizations, such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO), are working to harmonize nanoparticle regulations and develop standardized testing methods. These efforts aim to facilitate global trade while ensuring consistent safety standards across borders.

For ferrofluids used in high-precision measurement tools, specific regulations may apply depending on the intended application and industry. Manufacturers must consider not only general nanoparticle regulations but also sector-specific requirements, such as those for scientific instruments or industrial equipment. Compliance with these regulations often involves extensive testing, documentation, and ongoing monitoring to ensure the safety and efficacy of ferrofluid-based measurement tools.

As nanotechnology continues to advance, regulatory frameworks are expected to evolve. Policymakers and scientists are collaborating to address emerging challenges, such as the long-term environmental impacts of nanoparticles and potential health risks associated with prolonged exposure. This ongoing dialogue between industry, academia, and regulatory bodies is crucial for developing balanced regulations that promote innovation while safeguarding public health and the environment.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating nanoparticles under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new nanomaterials, allowing the agency to assess potential risks and implement necessary controls. Additionally, the Food and Drug Administration (FDA) oversees nanoparticles in food, drugs, and medical devices, while the Occupational Safety and Health Administration (OSHA) addresses workplace safety concerns related to nanoparticle exposure.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to nanomaterials. REACH mandates that companies register substances manufactured or imported in quantities over one tonne per year, including detailed safety information. The EU has also introduced specific provisions for nanomaterials in various product-specific regulations, such as those governing cosmetics and food additives.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for nanomaterials. Japan's approach focuses on voluntary reporting and risk assessment, while South Korea has implemented mandatory registration requirements for nanomaterials through its Act on Registration and Evaluation of Chemical Substances.

International organizations, such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO), are working to harmonize nanoparticle regulations and develop standardized testing methods. These efforts aim to facilitate global trade while ensuring consistent safety standards across borders.

For ferrofluids used in high-precision measurement tools, specific regulations may apply depending on the intended application and industry. Manufacturers must consider not only general nanoparticle regulations but also sector-specific requirements, such as those for scientific instruments or industrial equipment. Compliance with these regulations often involves extensive testing, documentation, and ongoing monitoring to ensure the safety and efficacy of ferrofluid-based measurement tools.

As nanotechnology continues to advance, regulatory frameworks are expected to evolve. Policymakers and scientists are collaborating to address emerging challenges, such as the long-term environmental impacts of nanoparticles and potential health risks associated with prolonged exposure. This ongoing dialogue between industry, academia, and regulatory bodies is crucial for developing balanced regulations that promote innovation while safeguarding public health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!