Ferrofluid's Contribution to Revolutionary Signal Processing Techniques

Ferrofluid Technology Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in their applications and technological advancements. Initially conceived for fuel control in zero-gravity environments, these magnetic liquids have since found their way into various fields, including signal processing. The journey of ferrofluid technology in signal processing began in the late 1980s when researchers started exploring their unique properties for enhancing sensor capabilities and signal transmission.

The primary objective of ferrofluid technology in signal processing is to leverage its magnetic and fluid properties to improve signal quality, sensitivity, and reliability in various applications. This includes enhancing the performance of acoustic transducers, developing novel magnetic field sensors, and creating adaptive optical systems. The technology aims to overcome limitations in traditional signal processing methods by introducing a dynamic, responsive medium that can be precisely controlled through external magnetic fields.

Over the past decades, ferrofluid technology has evolved from basic magnetic fluid dynamics to more sophisticated applications in signal processing. Key milestones include the development of ferrofluid-based acoustic devices in the 1990s, the introduction of ferrofluid-enhanced magnetic field sensors in the early 2000s, and the recent advancements in adaptive optics using ferrofluids for wavefront correction.

The current technological landscape sees ferrofluids contributing to revolutionary signal processing techniques in several ways. In acoustics, ferrofluids are used to create adaptive damping systems that can dynamically adjust to different frequency ranges, significantly improving sound quality and reducing distortion. In magnetic field sensing, ferrofluid-based sensors offer higher sensitivity and faster response times compared to traditional solid-state sensors, enabling more precise measurements in applications such as geomagnetic surveys and non-destructive testing.

Looking forward, the objectives for ferrofluid technology in signal processing are multifaceted. Researchers aim to develop more stable and responsive ferrofluid formulations that can operate under a wider range of environmental conditions. There is also a push towards miniaturization, with the goal of integrating ferrofluid-based components into microelectromechanical systems (MEMS) for advanced signal processing in compact devices. Additionally, efforts are being made to combine ferrofluids with other emerging technologies, such as metamaterials and nanostructures, to create hybrid systems with unprecedented signal processing capabilities.

Signal Processing Market Demand Analysis

The signal processing market has experienced significant growth in recent years, driven by the increasing demand for advanced data analysis and manipulation techniques across various industries. The integration of ferrofluid technology into signal processing applications has opened up new possibilities, further expanding the market potential.

In the telecommunications sector, the demand for improved signal processing techniques has surged due to the rapid adoption of 5G networks and the ongoing development of 6G technology. Ferrofluid-based signal processing solutions offer enhanced performance in noise reduction, signal amplification, and frequency filtering, making them particularly attractive for next-generation wireless communication systems.

The automotive industry has also shown a growing interest in advanced signal processing technologies, especially in the context of autonomous vehicles and advanced driver assistance systems (ADAS). Ferrofluid-based sensors and signal processing units can provide more accurate and reliable data for vehicle navigation, obstacle detection, and environmental perception, contributing to safer and more efficient autonomous driving systems.

In the healthcare sector, there is an increasing demand for sophisticated signal processing techniques in medical imaging and diagnostic equipment. Ferrofluid-enhanced MRI machines, for instance, can offer higher resolution images and improved contrast, enabling more accurate diagnoses and treatment planning. This application has the potential to revolutionize medical imaging and create a substantial market opportunity for ferrofluid-based signal processing solutions.

The aerospace and defense industries have also recognized the potential of ferrofluid technology in signal processing applications. From radar systems to satellite communications, ferrofluid-based solutions can enhance signal quality, improve target detection capabilities, and increase the overall efficiency of communication systems in challenging environments.

Consumer electronics represent another significant market segment for ferrofluid-based signal processing technologies. As smartphones, wearables, and smart home devices become increasingly sophisticated, there is a growing need for more efficient and accurate signal processing capabilities. Ferrofluid technology can contribute to improved audio quality, enhanced haptic feedback, and more precise motion sensing in these devices.

The industrial automation sector is experiencing a surge in demand for advanced signal processing techniques as part of the Industry 4.0 revolution. Ferrofluid-based sensors and signal processing units can enhance the performance of industrial control systems, predictive maintenance solutions, and quality control processes, leading to increased productivity and reduced downtime in manufacturing environments.

As the Internet of Things (IoT) continues to expand, the demand for efficient signal processing in edge computing applications is growing rapidly. Ferrofluid technology can enable more compact and energy-efficient signal processing units, making it ideal for deployment in IoT devices and edge computing nodes.

Ferrofluid Challenges in Signal Processing

Ferrofluids present several challenges in signal processing applications, primarily due to their unique physical properties and the complexities of their behavior under various conditions. One of the main obstacles is the nonlinear response of ferrofluids to external magnetic fields, which can introduce distortions and uncertainties in signal processing systems. This nonlinearity complicates the development of accurate models and algorithms for signal analysis and interpretation.

Another significant challenge lies in the dynamic nature of ferrofluids. Their magnetic properties can change rapidly in response to external stimuli, making it difficult to maintain consistent signal processing performance across different operational conditions. This variability necessitates the development of adaptive algorithms capable of adjusting to changing ferrofluid characteristics in real-time.

The multiphase nature of ferrofluids, consisting of magnetic nanoparticles suspended in a carrier fluid, introduces additional complexities in signal processing. The interaction between these phases can lead to complex rheological behaviors, affecting the propagation and manipulation of signals within ferrofluid-based systems. Accurately accounting for these interactions in signal processing models remains a significant challenge.

Thermal effects pose another hurdle in ferrofluid-based signal processing. Temperature fluctuations can alter the magnetic properties and viscosity of ferrofluids, potentially leading to signal drift and degradation of system performance. Developing temperature-compensated signal processing techniques is crucial for ensuring reliable operation across a wide range of environmental conditions.

The integration of ferrofluids with conventional electronic components and systems presents additional challenges. Electromagnetic interference and potential leakage of ferrofluids can impact the performance and reliability of surrounding electronic circuits. Designing effective shielding and containment solutions while maintaining optimal signal processing capabilities is a complex engineering task.

Scalability is another concern in ferrofluid-based signal processing applications. As systems become more miniaturized, maintaining the desired magnetic and fluid properties of ferrofluids at smaller scales becomes increasingly challenging. This scaling issue can limit the applicability of ferrofluid-based signal processing techniques in certain domains, such as microfluidics or nanoelectronics.

Lastly, the long-term stability and reliability of ferrofluids in signal processing systems remain areas of ongoing research. Factors such as nanoparticle agglomeration, oxidation, and degradation of carrier fluids can lead to changes in ferrofluid properties over time, potentially affecting the consistency and accuracy of signal processing operations. Developing strategies to mitigate these long-term effects is crucial for the widespread adoption of ferrofluid-based signal processing technologies in practical applications.

Current Ferrofluid Signal Processing Solutions

01 Ferrofluid-based signal processing in sensors

Ferrofluids are utilized in various sensing applications for signal processing. These magnetic fluids can be manipulated by external magnetic fields, allowing for precise control and measurement of physical parameters. The unique properties of ferrofluids enable the development of sensitive and accurate sensors for applications such as motion detection, pressure sensing, and vibration analysis.- Ferrofluid-based signal processing in sensors: Ferrofluids are utilized in various sensing applications for signal processing. These magnetic fluids can be manipulated by external magnetic fields, allowing for precise control and measurement of physical parameters. The unique properties of ferrofluids enable the development of sensitive and accurate sensors for applications such as position sensing, pressure measurement, and vibration detection.

- Magnetic field manipulation for data processing: Ferrofluids can be used in conjunction with magnetic fields to process and manipulate data signals. By controlling the magnetic properties of the ferrofluid, it is possible to modulate, amplify, or filter signals. This approach can be applied in various fields, including telecommunications, data storage, and signal encryption.

- Ferrofluid-based optical signal processing: Ferrofluids can be employed in optical signal processing applications. By manipulating the ferrofluid with magnetic fields, it is possible to control the transmission, reflection, or refraction of light. This property can be utilized in optical switches, variable attenuators, and adaptive optics systems for signal processing and communication.

- Ferrofluid damping for vibration signal processing: Ferrofluids can be used in damping systems to process and attenuate vibration signals. The magnetic properties of ferrofluids allow for adaptive damping characteristics, which can be tuned to specific frequencies or amplitudes. This technology can be applied in various fields, including automotive, aerospace, and industrial machinery, to improve signal-to-noise ratios and enhance overall system performance.

- Ferrofluid-based signal amplification and modulation: Ferrofluids can be utilized to amplify and modulate signals in various applications. By leveraging the magnetic properties of ferrofluids, it is possible to enhance weak signals or modify signal characteristics. This approach can be applied in areas such as medical imaging, geophysical exploration, and communication systems to improve signal quality and information transfer.

02 Magnetic field manipulation for data processing

Ferrofluids can be used in conjunction with magnetic fields to process and manipulate data signals. By applying controlled magnetic fields to ferrofluid systems, it is possible to modulate, filter, or amplify signals. This technique can be applied in various fields, including telecommunications, data storage, and signal encryption.Expand Specific Solutions03 Ferrofluid-based optical signal processing

Ferrofluids can be employed in optical signal processing applications. By manipulating the ferrofluid with magnetic fields, it is possible to create tunable optical elements such as lenses, filters, or switches. This technology can be used in fiber optic communications, adaptive optics, and optical computing systems.Expand Specific Solutions04 Ferrofluid damping systems for vibration control

Ferrofluids can be used in damping systems to control vibrations and process mechanical signals. The magnetic properties of ferrofluids allow for adaptive damping characteristics, which can be tuned in real-time to respond to changing vibration conditions. This technology has applications in automotive suspension systems, aerospace structures, and precision machinery.Expand Specific Solutions05 Ferrofluid-based microfluidic devices for signal processing

Ferrofluids can be integrated into microfluidic devices for signal processing at the microscale. By manipulating ferrofluid droplets or streams using magnetic fields, it is possible to perform operations such as mixing, separation, and detection of chemical or biological signals. This technology has potential applications in lab-on-a-chip devices, biomedical diagnostics, and environmental monitoring.Expand Specific Solutions

Key Players in Ferrofluid Signal Processing

The ferrofluid signal processing technology market is in an early growth stage, with increasing research interest but limited commercial applications. The market size is relatively small but expanding as potential uses in sensors, actuators, and biomedical devices emerge. Technologically, ferrofluids for signal processing are still developing, with ongoing research to improve performance and reliability. Key players like LG Electronics, Yale University, and MIT are advancing the fundamental science, while companies such as Nokia Technologies and Siemens Medical Solutions are exploring practical applications. Universities and research institutes, including Chongqing University and Japan Science & Technology Agency, are also contributing significantly to the field's development through collaborative research efforts.

LG Electronics, Inc.

Massachusetts Institute of Technology

Innovative Ferrofluid Signal Processing Patents

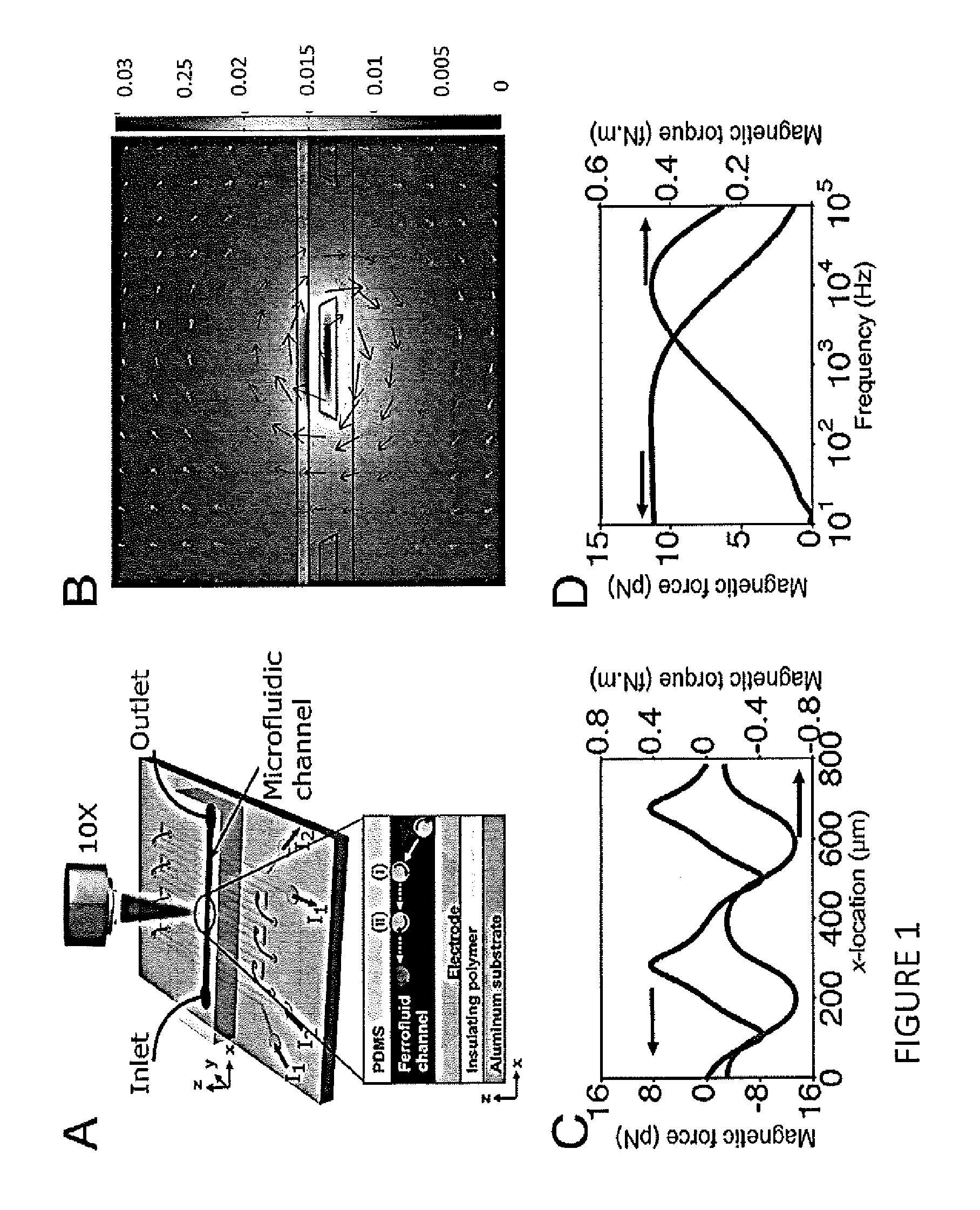

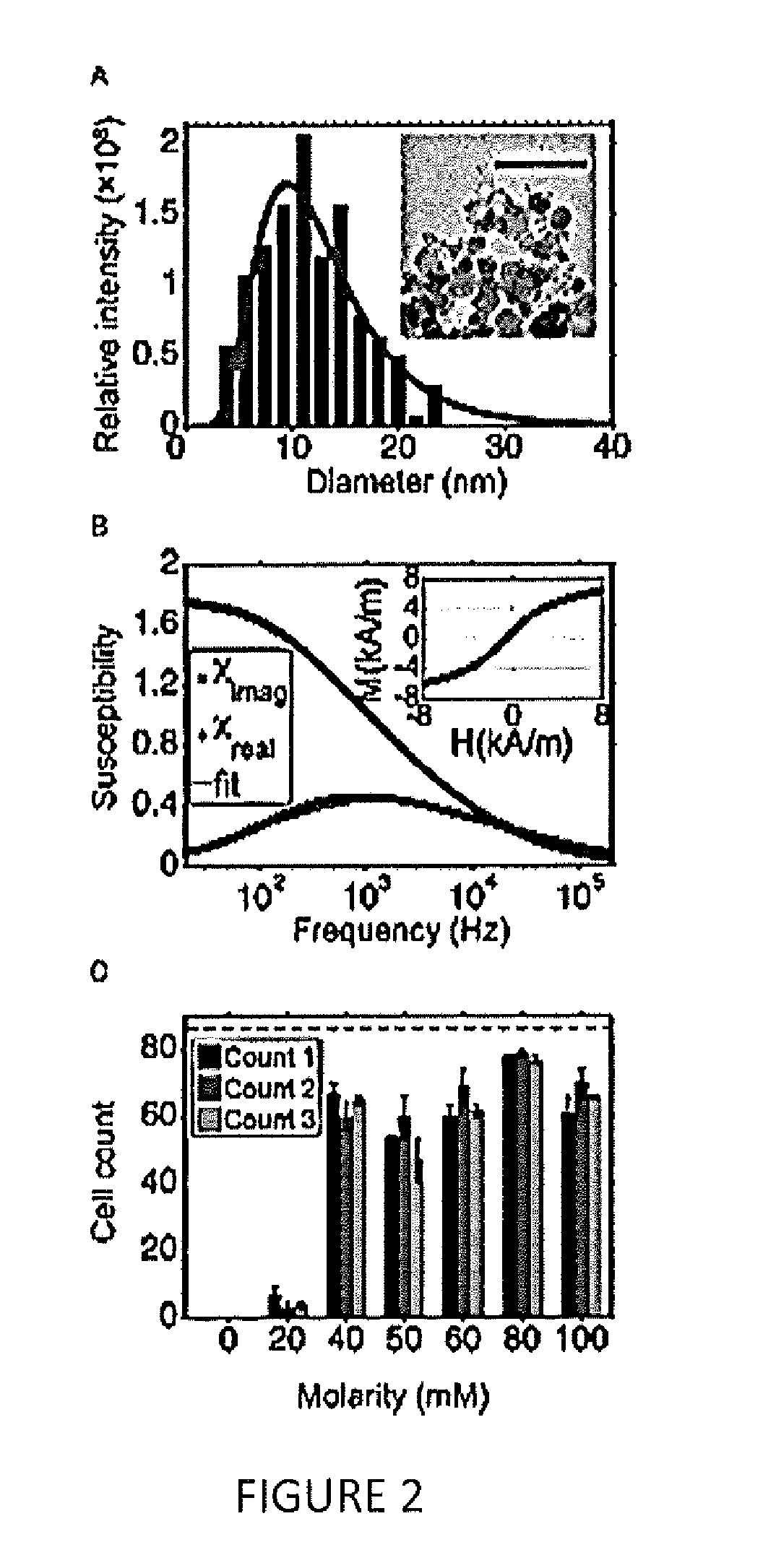

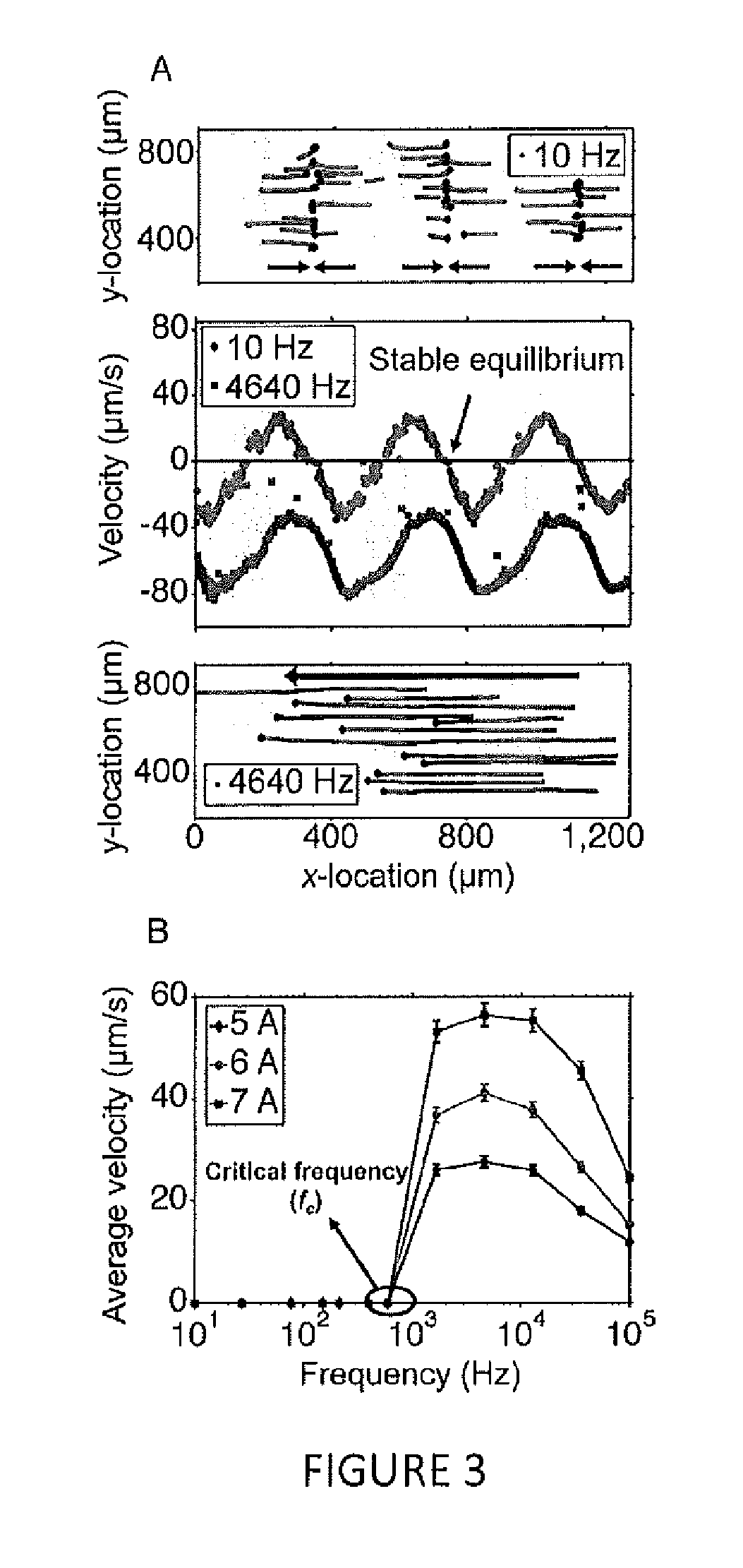

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

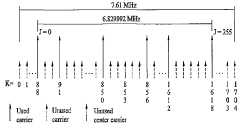

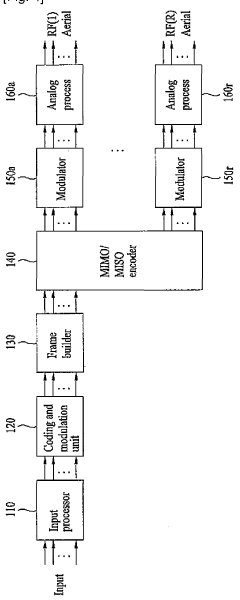

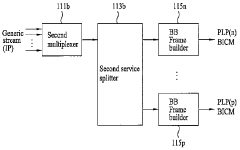

- The implementation of an Orthogonal Frequency Division Multiplexing (OFDM) system using Time Frequency Slicing (TFS) frames, which includes a tuner, frequency deinterleaver, parser, demapper, and Low Density Parity Check (LDPC) decoder, along with a Bose-Chaudhuri-Hocquenghem (BCH) decoder, to enhance data transmission efficiency and error correction.

Ferrofluid Environmental Impact Assessment

The environmental impact of ferrofluids in signal processing applications is a critical consideration as these materials gain prominence in advanced technologies. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable for signal processing but also raise concerns about their potential effects on ecosystems.

One primary environmental concern is the potential release of nanoparticles into water systems or soil. If not properly contained or disposed of, these particles could accumulate in the environment, potentially affecting aquatic life and soil microorganisms. The long-term effects of such accumulation are not yet fully understood, necessitating further research into the bioaccumulation and toxicity of ferrofluid nanoparticles in various ecosystems.

The production process of ferrofluids also warrants attention from an environmental perspective. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Ensuring proper waste management and exploring greener synthesis methods are crucial steps in mitigating the environmental footprint of ferrofluid production.

Energy consumption is another factor to consider. While ferrofluids can enhance the efficiency of certain signal processing techniques, potentially reducing overall energy requirements, the production and maintenance of ferrofluid-based systems may have their own energy demands. A comprehensive life cycle assessment would be necessary to determine the net energy impact of incorporating ferrofluids into signal processing applications.

On a positive note, the use of ferrofluids in signal processing could lead to more compact and efficient devices, potentially reducing electronic waste in the long term. Additionally, the improved performance of ferrofluid-based systems might extend the lifespan of certain electronic components, further contributing to waste reduction.

The recyclability and end-of-life management of ferrofluid-containing devices are also important considerations. Developing effective methods for separating and recycling ferrofluids from decommissioned equipment could significantly reduce their environmental impact and promote a more circular economy in the electronics industry.

As research in this field progresses, it is crucial to establish guidelines and best practices for the safe handling, use, and disposal of ferrofluids in signal processing applications. This includes developing containment strategies to prevent leaks or spills, as well as creating protocols for the proper disposal or recycling of ferrofluid-containing components.

Ferrofluid Signal Processing Applications

Ferrofluid signal processing applications have emerged as a groundbreaking field, offering innovative solutions to complex signal processing challenges. These applications leverage the unique properties of ferrofluids, which are colloidal liquids containing magnetic nanoparticles suspended in a carrier fluid.

One of the primary applications of ferrofluids in signal processing is in the development of adaptive filters. These filters utilize the magnetic properties of ferrofluids to dynamically adjust their frequency response based on the input signal characteristics. This adaptability allows for more efficient noise reduction and signal enhancement in various communication systems, particularly in environments with rapidly changing noise profiles.

Ferrofluid-based sensors have also shown promise in signal acquisition and processing. These sensors exploit the magnetic field-dependent properties of ferrofluids to detect and measure various physical parameters, such as pressure, acceleration, and magnetic field strength. The high sensitivity and fast response times of ferrofluid sensors make them ideal for applications in aerospace, automotive, and industrial monitoring systems.

In the realm of acoustic signal processing, ferrofluids have been employed to create tunable acoustic metamaterials. These materials can manipulate sound waves in ways not possible with conventional materials, enabling advanced noise cancellation, sound focusing, and acoustic cloaking applications. The ability to control the acoustic properties of these metamaterials using external magnetic fields opens up new possibilities for adaptive acoustic signal processing.

Ferrofluids have also found applications in microwave and radio frequency (RF) signal processing. Researchers have developed ferrofluid-based phase shifters and tunable filters that can be controlled with external magnetic fields. These devices offer advantages such as fast response times, low power consumption, and continuous tunability, making them attractive for use in phased array antennas and reconfigurable RF systems.

In the field of optical signal processing, ferrofluids have been utilized to create tunable optical devices. Magnetically controlled ferrofluid lenses and gratings have been demonstrated, allowing for dynamic manipulation of optical signals. These devices have potential applications in adaptive optics, optical switching, and tunable laser systems.

The integration of ferrofluids with microfluidic systems has led to the development of novel lab-on-a-chip devices for biosignal processing. These devices can manipulate and analyze biological samples using magnetic fields, enabling rapid and sensitive detection of biomarkers and pathogens. The ability to precisely control fluid flow and particle manipulation at the microscale offers new possibilities for point-of-care diagnostics and personalized medicine.