Ferrofluid's Potential in Improving Biomedical Device Accuracy

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Biomedical Applications and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have emerged as a promising technology in the biomedical field, particularly in enhancing the accuracy and functionality of medical devices. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit remarkable responsiveness to external magnetic fields, making them ideal for various biomedical applications.

The development of ferrofluids can be traced back to the 1960s, initially conceived for NASA space missions. However, their potential in biomedicine has only recently been fully recognized. The evolution of nanotechnology and materials science has significantly contributed to refining ferrofluid compositions and properties, making them more suitable for medical use.

In the context of biomedical devices, ferrofluids offer unique advantages due to their ability to be precisely controlled and manipulated using external magnetic fields. This characteristic opens up new possibilities for improving the accuracy, sensitivity, and overall performance of diagnostic and therapeutic devices.

One of the primary objectives in utilizing ferrofluids for biomedical applications is to enhance the precision of medical imaging techniques. By incorporating ferrofluids as contrast agents, researchers aim to improve the resolution and clarity of magnetic resonance imaging (MRI) scans, potentially leading to earlier and more accurate disease detection.

Another crucial goal is to develop targeted drug delivery systems using ferrofluids as carriers. The ability to guide these magnetic nanoparticles to specific locations within the body using external magnetic fields could revolutionize cancer treatment and other localized therapies, minimizing side effects and improving treatment efficacy.

In the realm of biosensors and diagnostic devices, ferrofluids show promise in increasing sensitivity and reducing detection limits. Researchers are exploring their use in developing highly accurate point-of-care diagnostic tools for rapid disease detection and monitoring.

The integration of ferrofluids in microfluidic devices is another area of intense research. The objective here is to create more efficient and precise lab-on-a-chip systems for various biomedical applications, including cell sorting, DNA analysis, and protein detection.

As the field progresses, a key technological trend is the development of biocompatible and biodegradable ferrofluids. This advancement aims to address safety concerns and expand the range of in vivo applications, particularly for long-term therapeutic interventions.

The ongoing research in this field is driven by the overarching goal of creating more accurate, efficient, and minimally invasive medical technologies. As ferrofluid technology continues to evolve, it holds the potential to significantly impact various aspects of healthcare, from diagnostics to treatment, ultimately improving patient outcomes and quality of care.

The development of ferrofluids can be traced back to the 1960s, initially conceived for NASA space missions. However, their potential in biomedicine has only recently been fully recognized. The evolution of nanotechnology and materials science has significantly contributed to refining ferrofluid compositions and properties, making them more suitable for medical use.

In the context of biomedical devices, ferrofluids offer unique advantages due to their ability to be precisely controlled and manipulated using external magnetic fields. This characteristic opens up new possibilities for improving the accuracy, sensitivity, and overall performance of diagnostic and therapeutic devices.

One of the primary objectives in utilizing ferrofluids for biomedical applications is to enhance the precision of medical imaging techniques. By incorporating ferrofluids as contrast agents, researchers aim to improve the resolution and clarity of magnetic resonance imaging (MRI) scans, potentially leading to earlier and more accurate disease detection.

Another crucial goal is to develop targeted drug delivery systems using ferrofluids as carriers. The ability to guide these magnetic nanoparticles to specific locations within the body using external magnetic fields could revolutionize cancer treatment and other localized therapies, minimizing side effects and improving treatment efficacy.

In the realm of biosensors and diagnostic devices, ferrofluids show promise in increasing sensitivity and reducing detection limits. Researchers are exploring their use in developing highly accurate point-of-care diagnostic tools for rapid disease detection and monitoring.

The integration of ferrofluids in microfluidic devices is another area of intense research. The objective here is to create more efficient and precise lab-on-a-chip systems for various biomedical applications, including cell sorting, DNA analysis, and protein detection.

As the field progresses, a key technological trend is the development of biocompatible and biodegradable ferrofluids. This advancement aims to address safety concerns and expand the range of in vivo applications, particularly for long-term therapeutic interventions.

The ongoing research in this field is driven by the overarching goal of creating more accurate, efficient, and minimally invasive medical technologies. As ferrofluid technology continues to evolve, it holds the potential to significantly impact various aspects of healthcare, from diagnostics to treatment, ultimately improving patient outcomes and quality of care.

Market Analysis for Precision Biomedical Devices

The precision biomedical device market is experiencing significant growth, driven by increasing demand for accurate diagnostic and therapeutic tools. This market segment encompasses a wide range of devices, including imaging systems, surgical robots, and advanced monitoring equipment. The global precision medicine market, which heavily relies on these devices, is projected to reach $141.7 billion by 2026, with a compound annual growth rate (CAGR) of 11.5% from 2021 to 2026.

Key factors fueling this market growth include the rising prevalence of chronic diseases, advancements in genomics and personalized medicine, and the increasing adoption of point-of-care diagnostics. The aging population in many developed countries is also contributing to the demand for more precise and less invasive medical interventions.

In the context of ferrofluid technology, its potential applications in improving biomedical device accuracy are particularly relevant to several high-growth segments. These include magnetic resonance imaging (MRI) contrast agents, targeted drug delivery systems, and biosensors for rapid and sensitive diagnostics.

The MRI contrast agent market, where ferrofluids show promise, is expected to reach $2.13 billion by 2025, growing at a CAGR of 3.5%. This growth is driven by the increasing number of MRI procedures and the need for enhanced image quality for accurate diagnoses.

In the field of targeted drug delivery, where ferrofluids can potentially improve precision, the market is forecasted to reach $230 billion by 2026, with a CAGR of 12.8%. This rapid growth is attributed to the rising demand for more effective and less toxic cancer treatments.

The biosensor market, another area where ferrofluids could enhance accuracy, is projected to reach $36.7 billion by 2027, growing at a CAGR of 8.3%. This growth is fueled by the increasing need for rapid, point-of-care diagnostic tools in both clinical and research settings.

Geographically, North America currently dominates the precision biomedical device market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by improving healthcare infrastructure and increasing healthcare expenditure in countries like China and India.

The market for precision biomedical devices is highly competitive, with key players including Medtronic, Siemens Healthineers, Abbott Laboratories, and Stryker Corporation. These companies are investing heavily in research and development to maintain their competitive edge and capitalize on emerging technologies like ferrofluids.

Key factors fueling this market growth include the rising prevalence of chronic diseases, advancements in genomics and personalized medicine, and the increasing adoption of point-of-care diagnostics. The aging population in many developed countries is also contributing to the demand for more precise and less invasive medical interventions.

In the context of ferrofluid technology, its potential applications in improving biomedical device accuracy are particularly relevant to several high-growth segments. These include magnetic resonance imaging (MRI) contrast agents, targeted drug delivery systems, and biosensors for rapid and sensitive diagnostics.

The MRI contrast agent market, where ferrofluids show promise, is expected to reach $2.13 billion by 2025, growing at a CAGR of 3.5%. This growth is driven by the increasing number of MRI procedures and the need for enhanced image quality for accurate diagnoses.

In the field of targeted drug delivery, where ferrofluids can potentially improve precision, the market is forecasted to reach $230 billion by 2026, with a CAGR of 12.8%. This rapid growth is attributed to the rising demand for more effective and less toxic cancer treatments.

The biosensor market, another area where ferrofluids could enhance accuracy, is projected to reach $36.7 billion by 2027, growing at a CAGR of 8.3%. This growth is fueled by the increasing need for rapid, point-of-care diagnostic tools in both clinical and research settings.

Geographically, North America currently dominates the precision biomedical device market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by improving healthcare infrastructure and increasing healthcare expenditure in countries like China and India.

The market for precision biomedical devices is highly competitive, with key players including Medtronic, Siemens Healthineers, Abbott Laboratories, and Stryker Corporation. These companies are investing heavily in research and development to maintain their competitive edge and capitalize on emerging technologies like ferrofluids.

Current Challenges in Biomedical Device Accuracy

Biomedical devices play a crucial role in modern healthcare, providing essential diagnostic and therapeutic capabilities. However, these devices face several challenges in maintaining high levels of accuracy, which is paramount for patient safety and effective treatment. One of the primary issues is the inherent variability in biological systems, making it difficult to achieve consistent and precise measurements across different patients and conditions.

Environmental factors, such as temperature fluctuations, electromagnetic interference, and mechanical vibrations, can significantly impact the performance of biomedical devices. These external influences can lead to measurement errors, calibration drift, and reduced reliability, particularly in sensitive instruments like MRI machines or implantable sensors.

Another significant challenge is the miniaturization of biomedical devices, which aims to make them less invasive and more portable. While this trend offers numerous benefits, it also introduces complexities in maintaining accuracy within smaller form factors. Reduced size often means compromising on sensor sensitivity or signal-to-noise ratios, potentially affecting the overall precision of the device.

The integration of multiple sensing modalities in modern biomedical devices, while advantageous for comprehensive diagnostics, presents challenges in data fusion and interpretation. Ensuring that various sensors work harmoniously and provide accurate, combined results requires sophisticated algorithms and calibration techniques.

Biological fouling and tissue response to implanted devices pose ongoing challenges to long-term accuracy. The accumulation of proteins, cells, or other biological materials on device surfaces can interfere with sensor function and lead to degradation of performance over time. This is particularly problematic for implantable devices intended for continuous monitoring or long-term therapy.

The dynamic nature of physiological parameters adds another layer of complexity. Biomedical devices must be capable of adapting to rapid changes in the body while maintaining accuracy across a wide range of conditions. This requires advanced signal processing and adaptive algorithms, which can be challenging to implement effectively.

Regulatory requirements and the need for extensive clinical validation further complicate the development of highly accurate biomedical devices. Stringent standards for safety and efficacy necessitate rigorous testing and validation processes, which can be time-consuming and costly, potentially slowing the adoption of new technologies that could improve accuracy.

Human Resource: Now, please generate the content for the section "Technology Evolution Path" based on the technical problem "Ferrofluid's Potential in Improving Biomedical Device Accuracy".

Environmental factors, such as temperature fluctuations, electromagnetic interference, and mechanical vibrations, can significantly impact the performance of biomedical devices. These external influences can lead to measurement errors, calibration drift, and reduced reliability, particularly in sensitive instruments like MRI machines or implantable sensors.

Another significant challenge is the miniaturization of biomedical devices, which aims to make them less invasive and more portable. While this trend offers numerous benefits, it also introduces complexities in maintaining accuracy within smaller form factors. Reduced size often means compromising on sensor sensitivity or signal-to-noise ratios, potentially affecting the overall precision of the device.

The integration of multiple sensing modalities in modern biomedical devices, while advantageous for comprehensive diagnostics, presents challenges in data fusion and interpretation. Ensuring that various sensors work harmoniously and provide accurate, combined results requires sophisticated algorithms and calibration techniques.

Biological fouling and tissue response to implanted devices pose ongoing challenges to long-term accuracy. The accumulation of proteins, cells, or other biological materials on device surfaces can interfere with sensor function and lead to degradation of performance over time. This is particularly problematic for implantable devices intended for continuous monitoring or long-term therapy.

The dynamic nature of physiological parameters adds another layer of complexity. Biomedical devices must be capable of adapting to rapid changes in the body while maintaining accuracy across a wide range of conditions. This requires advanced signal processing and adaptive algorithms, which can be challenging to implement effectively.

Regulatory requirements and the need for extensive clinical validation further complicate the development of highly accurate biomedical devices. Stringent standards for safety and efficacy necessitate rigorous testing and validation processes, which can be time-consuming and costly, potentially slowing the adoption of new technologies that could improve accuracy.

Human Resource: Now, please generate the content for the section "Technology Evolution Path" based on the technical problem "Ferrofluid's Potential in Improving Biomedical Device Accuracy".

Existing Ferrofluid-Based Accuracy Enhancement Solutions

01 Ferrofluid sealing systems

Ferrofluid seals are used to improve accuracy and precision in various mechanical systems. These seals utilize the unique properties of ferrofluids to create a barrier that prevents contamination and reduces friction, thereby enhancing the overall performance and accuracy of the system.- Ferrofluid sealing systems: Ferrofluid seals are used to improve accuracy and precision in various mechanical systems. These seals utilize the unique properties of ferrofluids to create a barrier that prevents contamination and reduces friction, thereby enhancing the overall performance and accuracy of the system.

- Ferrofluid-based sensors and measurement devices: Ferrofluids are employed in sensors and measurement devices to increase accuracy. The magnetic properties of ferrofluids allow for precise detection and measurement of various parameters, such as position, pressure, and acceleration, leading to improved accuracy in scientific and industrial applications.

- Ferrofluid-enhanced bearings and damping systems: Ferrofluids are used to improve the accuracy and stability of bearings and damping systems. By incorporating ferrofluids into these components, vibration and friction can be reduced, resulting in more precise and accurate mechanical operations.

- Ferrofluid-based heat transfer systems: Ferrofluids are utilized in heat transfer systems to enhance thermal management and improve overall system accuracy. The magnetic properties of ferrofluids allow for better control of heat distribution, leading to more stable and accurate operation of sensitive equipment.

- Ferrofluid applications in optical systems: Ferrofluids are employed in optical systems to improve accuracy and precision. By utilizing the unique properties of ferrofluids, such as their ability to form precise shapes under magnetic fields, optical components can be more accurately aligned and controlled, resulting in enhanced performance.

02 Ferrofluid-based sensors and measurement devices

Ferrofluids are employed in sensors and measurement devices to increase accuracy. The magnetic properties of ferrofluids allow for precise detection and measurement of various parameters, such as position, pressure, and acceleration, leading to improved accuracy in scientific and industrial applications.Expand Specific Solutions03 Ferrofluid-enhanced bearings and lubrication

Ferrofluids are used to enhance the performance of bearings and lubrication systems. By incorporating ferrofluids into these components, friction is reduced, and stability is improved, resulting in increased accuracy and precision in rotational and linear motion systems.Expand Specific Solutions04 Ferrofluid-based damping and vibration control

Ferrofluids are utilized in damping systems and vibration control applications to improve accuracy in sensitive equipment. The magnetic properties of ferrofluids allow for adaptive damping and precise control of vibrations, enhancing the stability and accuracy of various instruments and machines.Expand Specific Solutions05 Ferrofluid-enhanced optical systems

Ferrofluids are employed in optical systems to improve accuracy and performance. By utilizing the unique properties of ferrofluids, such as their ability to change shape in response to magnetic fields, optical systems can achieve better focusing, alignment, and overall accuracy in various applications.Expand Specific Solutions

Key Players in Ferrofluid and Biomedical Industries

The ferrofluid technology for improving biomedical device accuracy is in an early development stage, with significant potential for growth. The market size is expanding as healthcare demands more precise diagnostic and therapeutic tools. While the technology shows promise, it is still maturing, with varying levels of advancement among key players. Academic institutions like Yale University, Peking University, and Nanyang Technological University are driving fundamental research. Companies such as Koninklijke Philips NV and Samsung Electronics Co., Ltd. are exploring practical applications, leveraging their expertise in medical devices. Specialized firms like Precision Biosensor, Inc. and Nano4Imaging GmbH are focusing on niche applications, potentially accelerating commercialization in specific areas.

Yale University

Technical Solution: Yale University has developed a novel approach using ferrofluids to enhance the accuracy of biomedical devices. Their research focuses on creating magnetically-controlled microfluidic systems that utilize ferrofluids for precise manipulation of biological samples. The team has engineered nanoparticle-based ferrofluids with tailored magnetic properties, allowing for controlled movement and positioning of fluids within microchannels[1]. This technology enables more accurate sample handling, mixing, and separation in diagnostic devices. Yale researchers have also explored the use of ferrofluid-based actuators for improved control in minimally invasive surgical tools, potentially increasing the precision of procedures[2].

Strengths: Cutting-edge research in ferrofluid applications for biomedical devices, potential for high-precision sample manipulation. Weaknesses: May require further development for commercial applications, potential challenges in scaling up production.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has made significant strides in utilizing ferrofluids to enhance biomedical device accuracy. Their approach involves developing magneto-responsive hydrogels incorporating ferrofluid nanoparticles for controlled drug delivery systems. These smart materials can change shape or release drugs in response to external magnetic fields, allowing for precise spatial and temporal control of therapeutic agents[3]. CNRS researchers have also explored ferrofluid-based biosensors that leverage the unique magnetic properties of these fluids to detect biomolecules with high sensitivity. Their work includes the development of ferrofluid-enhanced microfluidic devices for cell sorting and analysis, potentially improving the accuracy of diagnostic tests[4].

Strengths: Strong fundamental research capabilities, innovative applications in drug delivery and biosensing. Weaknesses: May face challenges in translating research findings into clinical applications, potential regulatory hurdles.

Core Innovations in Ferrofluid for Biomedical Applications

Systems and methods for controlling shape and position of a ferrofluid droplet

PatentWO2021041471A1

Innovation

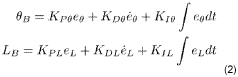

- A system comprising a ferrofluid droplet and an electromagnetic field generation system with a controller that determines and applies necessary magnetic field parameters to control the position and shape of the ferrofluid droplet, using PID controllers for precise manipulation, allowing for shape and position control, and simultaneous position and shape control through the generation and manipulation of controlled magnetic fields.

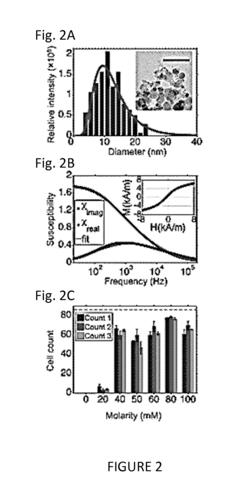

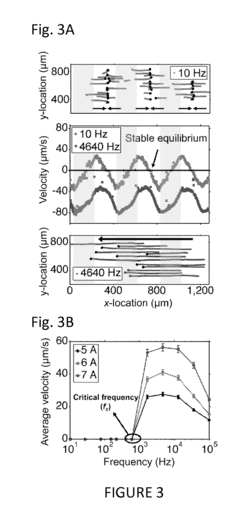

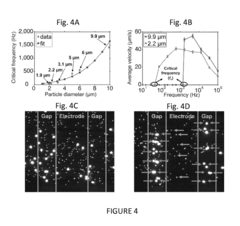

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

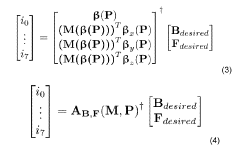

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Regulatory Framework for Ferrofluid in Medical Devices

The regulatory framework for ferrofluid in medical devices is a complex and evolving landscape that requires careful navigation. As ferrofluids gain traction in biomedical applications, particularly in improving device accuracy, regulatory bodies worldwide are adapting their guidelines to ensure patient safety and product efficacy.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating medical devices incorporating ferrofluids. These devices typically fall under Class II or Class III classifications, depending on their intended use and potential risks. The FDA's premarket approval (PMA) process is often required for novel ferrofluid-based devices, necessitating extensive clinical trials and safety data.

The European Union's regulatory approach is governed by the Medical Device Regulation (MDR), which came into full effect in May 2021. Under the MDR, ferrofluid-containing devices are subject to rigorous conformity assessments and must bear the CE mark before market entry. The regulation emphasizes post-market surveillance and the need for ongoing risk management throughout the device lifecycle.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the approval process for ferrofluid-based medical devices. The Japanese regulatory framework places significant emphasis on quality management systems and often requires local clinical data to supplement international studies.

Globally, the International Organization for Standardization (ISO) provides crucial standards that influence regulatory decisions. ISO 13485, which specifies requirements for quality management systems in medical devices, is particularly relevant for manufacturers incorporating ferrofluids into their products.

As the technology advances, regulatory bodies are increasingly focusing on the long-term effects of ferrofluids in the human body. This has led to the development of specific guidelines for biocompatibility testing and risk assessment of nanoparticle-based materials used in medical devices.

Manufacturers must also consider environmental regulations, as the production and disposal of ferrofluids may have ecological implications. Many jurisdictions require comprehensive environmental impact assessments as part of the regulatory approval process.

The regulatory landscape is further complicated by the rapid pace of technological innovation in ferrofluid applications. Regulatory agencies are striving to balance the need for thorough safety evaluations with the desire to facilitate timely access to potentially life-saving technologies. This has resulted in the emergence of adaptive licensing pathways and accelerated approval programs for promising ferrofluid-based medical devices.

As the field continues to evolve, international harmonization efforts, such as the Medical Device Single Audit Program (MDSAP), are gaining importance. These initiatives aim to streamline regulatory processes across different countries, potentially reducing the time and cost associated with bringing ferrofluid-enhanced medical devices to global markets.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating medical devices incorporating ferrofluids. These devices typically fall under Class II or Class III classifications, depending on their intended use and potential risks. The FDA's premarket approval (PMA) process is often required for novel ferrofluid-based devices, necessitating extensive clinical trials and safety data.

The European Union's regulatory approach is governed by the Medical Device Regulation (MDR), which came into full effect in May 2021. Under the MDR, ferrofluid-containing devices are subject to rigorous conformity assessments and must bear the CE mark before market entry. The regulation emphasizes post-market surveillance and the need for ongoing risk management throughout the device lifecycle.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the approval process for ferrofluid-based medical devices. The Japanese regulatory framework places significant emphasis on quality management systems and often requires local clinical data to supplement international studies.

Globally, the International Organization for Standardization (ISO) provides crucial standards that influence regulatory decisions. ISO 13485, which specifies requirements for quality management systems in medical devices, is particularly relevant for manufacturers incorporating ferrofluids into their products.

As the technology advances, regulatory bodies are increasingly focusing on the long-term effects of ferrofluids in the human body. This has led to the development of specific guidelines for biocompatibility testing and risk assessment of nanoparticle-based materials used in medical devices.

Manufacturers must also consider environmental regulations, as the production and disposal of ferrofluids may have ecological implications. Many jurisdictions require comprehensive environmental impact assessments as part of the regulatory approval process.

The regulatory landscape is further complicated by the rapid pace of technological innovation in ferrofluid applications. Regulatory agencies are striving to balance the need for thorough safety evaluations with the desire to facilitate timely access to potentially life-saving technologies. This has resulted in the emergence of adaptive licensing pathways and accelerated approval programs for promising ferrofluid-based medical devices.

As the field continues to evolve, international harmonization efforts, such as the Medical Device Single Audit Program (MDSAP), are gaining importance. These initiatives aim to streamline regulatory processes across different countries, potentially reducing the time and cost associated with bringing ferrofluid-enhanced medical devices to global markets.

Biocompatibility and Safety Considerations of Ferrofluids

The biocompatibility and safety of ferrofluids are critical considerations for their application in biomedical devices. Ferrofluids, composed of magnetic nanoparticles suspended in a carrier fluid, must be carefully evaluated to ensure they do not cause adverse effects when introduced into biological systems.

One of the primary concerns is the potential toxicity of the nanoparticles. The size, shape, and surface properties of these particles can significantly influence their interactions with cells and tissues. Smaller particles may be more easily internalized by cells, potentially leading to cellular dysfunction or damage. Therefore, extensive in vitro and in vivo studies are necessary to assess the cytotoxicity and genotoxicity of ferrofluids under various conditions.

The stability of ferrofluids in physiological environments is another crucial factor. The nanoparticles must remain dispersed and not aggregate, as this could lead to blockages in blood vessels or impair the function of the biomedical device. Surface modifications, such as coating the particles with biocompatible polymers, can enhance stability and reduce the risk of aggregation.

Immunogenicity is also a significant concern. The introduction of foreign materials into the body can trigger immune responses, potentially leading to inflammation or rejection of the device. Researchers must carefully design the ferrofluid components to minimize immunogenic reactions and conduct thorough immunological studies to assess their safety.

Long-term effects of ferrofluids on biological systems require extensive investigation. Chronic exposure studies are essential to understand potential accumulation in organs, clearance mechanisms, and any long-term toxicological effects. This is particularly important for applications where the ferrofluid may remain in the body for extended periods.

The biodegradability and excretion pathways of ferrofluids must be thoroughly examined. Ideally, the nanoparticles should be metabolized or excreted from the body without causing harm. Understanding these processes is crucial for predicting the long-term safety profile of ferrofluid-based biomedical devices.

Regulatory considerations play a vital role in the development and approval of ferrofluid-containing medical devices. Stringent safety standards set by regulatory bodies such as the FDA and EMA must be met, requiring extensive preclinical and clinical testing to demonstrate the biocompatibility and safety of these materials.

In conclusion, while ferrofluids show great potential for improving biomedical device accuracy, their biocompatibility and safety must be rigorously evaluated. A multidisciplinary approach involving materials science, biology, and toxicology is essential to address these challenges and ensure the safe application of ferrofluids in medical technologies.

One of the primary concerns is the potential toxicity of the nanoparticles. The size, shape, and surface properties of these particles can significantly influence their interactions with cells and tissues. Smaller particles may be more easily internalized by cells, potentially leading to cellular dysfunction or damage. Therefore, extensive in vitro and in vivo studies are necessary to assess the cytotoxicity and genotoxicity of ferrofluids under various conditions.

The stability of ferrofluids in physiological environments is another crucial factor. The nanoparticles must remain dispersed and not aggregate, as this could lead to blockages in blood vessels or impair the function of the biomedical device. Surface modifications, such as coating the particles with biocompatible polymers, can enhance stability and reduce the risk of aggregation.

Immunogenicity is also a significant concern. The introduction of foreign materials into the body can trigger immune responses, potentially leading to inflammation or rejection of the device. Researchers must carefully design the ferrofluid components to minimize immunogenic reactions and conduct thorough immunological studies to assess their safety.

Long-term effects of ferrofluids on biological systems require extensive investigation. Chronic exposure studies are essential to understand potential accumulation in organs, clearance mechanisms, and any long-term toxicological effects. This is particularly important for applications where the ferrofluid may remain in the body for extended periods.

The biodegradability and excretion pathways of ferrofluids must be thoroughly examined. Ideally, the nanoparticles should be metabolized or excreted from the body without causing harm. Understanding these processes is crucial for predicting the long-term safety profile of ferrofluid-based biomedical devices.

Regulatory considerations play a vital role in the development and approval of ferrofluid-containing medical devices. Stringent safety standards set by regulatory bodies such as the FDA and EMA must be met, requiring extensive preclinical and clinical testing to demonstrate the biocompatibility and safety of these materials.

In conclusion, while ferrofluids show great potential for improving biomedical device accuracy, their biocompatibility and safety must be rigorously evaluated. A multidisciplinary approach involving materials science, biology, and toxicology is essential to address these challenges and ensure the safe application of ferrofluids in medical technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!