Field Monitoring Systems For Second-Life BESS Performance

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life BESS Field Monitoring Background & Objectives

Battery Energy Storage Systems (BESS) have emerged as a critical component in the global transition towards renewable energy integration and grid stabilization. As the first generation of lithium-ion batteries from electric vehicles (EVs) reaches the end of their primary life cycle, a significant opportunity has emerged to repurpose these batteries for second-life applications in stationary storage systems. This repurposing not only extends the useful life of these valuable resources but also provides a more cost-effective solution for grid-scale energy storage.

The evolution of second-life BESS technology has accelerated over the past decade, driven by the increasing volume of retired EV batteries and the growing demand for affordable energy storage solutions. Initially, these systems faced significant technical barriers including battery degradation assessment, pack heterogeneity, and safety concerns. However, recent advancements in battery management systems (BMS) and diagnostic tools have substantially improved the viability of these solutions.

Field monitoring systems represent the next frontier in second-life BESS development, serving as the critical infrastructure needed to validate performance, ensure safety, and optimize operational efficiency in real-world deployments. These monitoring systems must address unique challenges not present in new BESS installations, including the variable degradation states of repurposed cells, potentially incomplete battery history data, and the need for more sophisticated state-of-health algorithms.

The primary objectives of field monitoring for second-life BESS include establishing reliable performance benchmarks across diverse operating conditions, developing early warning systems for potential failure modes specific to aged cells, and creating standardized protocols for data collection and analysis. Additionally, these systems aim to provide valuable feedback loops to improve battery selection criteria and repurposing methodologies.

Current field monitoring approaches range from basic voltage, current, and temperature measurements to more advanced techniques incorporating electrochemical impedance spectroscopy, ultrasonic testing, and machine learning algorithms for predictive analytics. The integration of these monitoring technologies with cloud-based platforms enables remote diagnostics and performance optimization, critical for widespread deployment of second-life systems.

The technical trajectory for field monitoring systems is moving toward non-invasive sensing technologies, distributed intelligence at the module level, and self-learning algorithms that can adapt to the unique characteristics of each repurposed battery pack. These advancements are essential to overcome the inherent variability in second-life batteries and to establish the performance reliability necessary for market acceptance and regulatory approval.

As the industry matures, standardization of monitoring protocols and performance metrics will become increasingly important to facilitate comparison across different second-life BESS implementations and to build confidence among potential adopters and investors in this emerging technology sector.

The evolution of second-life BESS technology has accelerated over the past decade, driven by the increasing volume of retired EV batteries and the growing demand for affordable energy storage solutions. Initially, these systems faced significant technical barriers including battery degradation assessment, pack heterogeneity, and safety concerns. However, recent advancements in battery management systems (BMS) and diagnostic tools have substantially improved the viability of these solutions.

Field monitoring systems represent the next frontier in second-life BESS development, serving as the critical infrastructure needed to validate performance, ensure safety, and optimize operational efficiency in real-world deployments. These monitoring systems must address unique challenges not present in new BESS installations, including the variable degradation states of repurposed cells, potentially incomplete battery history data, and the need for more sophisticated state-of-health algorithms.

The primary objectives of field monitoring for second-life BESS include establishing reliable performance benchmarks across diverse operating conditions, developing early warning systems for potential failure modes specific to aged cells, and creating standardized protocols for data collection and analysis. Additionally, these systems aim to provide valuable feedback loops to improve battery selection criteria and repurposing methodologies.

Current field monitoring approaches range from basic voltage, current, and temperature measurements to more advanced techniques incorporating electrochemical impedance spectroscopy, ultrasonic testing, and machine learning algorithms for predictive analytics. The integration of these monitoring technologies with cloud-based platforms enables remote diagnostics and performance optimization, critical for widespread deployment of second-life systems.

The technical trajectory for field monitoring systems is moving toward non-invasive sensing technologies, distributed intelligence at the module level, and self-learning algorithms that can adapt to the unique characteristics of each repurposed battery pack. These advancements are essential to overcome the inherent variability in second-life batteries and to establish the performance reliability necessary for market acceptance and regulatory approval.

As the industry matures, standardization of monitoring protocols and performance metrics will become increasingly important to facilitate comparison across different second-life BESS implementations and to build confidence among potential adopters and investors in this emerging technology sector.

Market Analysis for Second-Life Battery Storage Solutions

The second-life battery energy storage system (BESS) market is experiencing significant growth as sustainability initiatives and circular economy principles gain traction globally. The market for repurposed electric vehicle (EV) batteries is projected to reach $7.8 billion by 2030, growing at a CAGR of 23.1% from 2023. This growth is primarily driven by the increasing volume of retired EV batteries that retain 70-80% of their original capacity, making them suitable for stationary storage applications.

The demand for second-life battery storage solutions is particularly strong in grid support services, renewable energy integration, and commercial/industrial applications. Utility companies are increasingly deploying these systems for peak shaving, frequency regulation, and grid stabilization, which can extend the useful life of batteries by 5-10 years beyond their automotive use.

Regional market analysis reveals that Asia Pacific currently dominates the second-life BESS market, with China and South Korea leading in implementation. Europe follows closely, driven by stringent sustainability regulations and ambitious renewable energy targets. The North American market is gaining momentum as states like California implement aggressive energy storage mandates.

Cost considerations remain a primary market driver, with second-life battery systems offering 30-40% cost savings compared to new battery installations. This economic advantage is particularly appealing for applications where energy density and performance requirements are less stringent than in automotive uses.

Market challenges include the lack of standardization in battery management systems, which complicates the integration of second-life batteries from different manufacturers. Additionally, concerns about long-term reliability and performance degradation create market hesitation, highlighting the critical need for robust field monitoring systems.

The competitive landscape features both established energy storage providers expanding into second-life applications and specialized startups focused exclusively on battery repurposing. Automotive manufacturers are also entering this space, creating closed-loop systems for their EV batteries.

Market segmentation shows distinct customer groups: utilities seeking large-scale storage solutions, commercial entities looking for behind-the-meter applications, and renewable energy developers requiring storage to enhance project economics. Each segment has unique requirements for monitoring systems and performance guarantees.

Future market growth will be significantly influenced by regulatory developments, particularly around battery recycling mandates, extended producer responsibility, and carbon pricing mechanisms that favor circular economy solutions.

The demand for second-life battery storage solutions is particularly strong in grid support services, renewable energy integration, and commercial/industrial applications. Utility companies are increasingly deploying these systems for peak shaving, frequency regulation, and grid stabilization, which can extend the useful life of batteries by 5-10 years beyond their automotive use.

Regional market analysis reveals that Asia Pacific currently dominates the second-life BESS market, with China and South Korea leading in implementation. Europe follows closely, driven by stringent sustainability regulations and ambitious renewable energy targets. The North American market is gaining momentum as states like California implement aggressive energy storage mandates.

Cost considerations remain a primary market driver, with second-life battery systems offering 30-40% cost savings compared to new battery installations. This economic advantage is particularly appealing for applications where energy density and performance requirements are less stringent than in automotive uses.

Market challenges include the lack of standardization in battery management systems, which complicates the integration of second-life batteries from different manufacturers. Additionally, concerns about long-term reliability and performance degradation create market hesitation, highlighting the critical need for robust field monitoring systems.

The competitive landscape features both established energy storage providers expanding into second-life applications and specialized startups focused exclusively on battery repurposing. Automotive manufacturers are also entering this space, creating closed-loop systems for their EV batteries.

Market segmentation shows distinct customer groups: utilities seeking large-scale storage solutions, commercial entities looking for behind-the-meter applications, and renewable energy developers requiring storage to enhance project economics. Each segment has unique requirements for monitoring systems and performance guarantees.

Future market growth will be significantly influenced by regulatory developments, particularly around battery recycling mandates, extended producer responsibility, and carbon pricing mechanisms that favor circular economy solutions.

Technical Challenges in Second-Life BESS Monitoring

Second-life battery energy storage systems (BESS) face significant monitoring challenges that differ from new battery installations. The repurposing of electric vehicle (EV) batteries introduces inherent complexities due to their varied usage histories, degradation patterns, and original manufacturing specifications. These batteries have already undergone substantial cycling and aging, making their performance characteristics less predictable and more heterogeneous compared to new batteries.

A primary technical challenge lies in the accurate assessment of the state of health (SOH) for second-life batteries. Traditional methods developed for new batteries often fail to account for the unique degradation profiles of used cells. The monitoring systems must adapt to detect subtle changes in performance that may indicate accelerated degradation or potential failure modes specific to second-life applications.

Data integration presents another significant hurdle. Second-life BESS typically comprise batteries from different manufacturers, production batches, and vehicle models. Each may have proprietary battery management systems (BMS) with varying communication protocols and data formats. Developing monitoring systems capable of harmonizing these diverse data streams requires sophisticated interface solutions and standardization efforts that the industry has yet to fully establish.

The detection of anomalies in second-life batteries demands more sophisticated algorithms than those used for new systems. Historical performance data from the battery's first life is often incomplete or inaccessible, creating blind spots in predictive modeling. Monitoring systems must therefore employ advanced machine learning techniques that can function effectively with limited historical context while still providing reliable early warning of potential issues.

Environmental factors introduce additional complexity. Second-life batteries may exhibit heightened sensitivity to temperature variations, charging rates, and depth of discharge compared to new batteries. Monitoring systems must track these parameters with greater precision and correlate them with performance metrics to prevent accelerated degradation.

Safety monitoring represents perhaps the most critical challenge. Used batteries may develop internal defects not present in new cells, increasing the risk of thermal runaway events. Conventional safety systems may not adequately detect the subtle precursors to failure in second-life applications, necessitating more sophisticated thermal monitoring, gas detection, and electrochemical impedance spectroscopy capabilities.

Longevity prediction for second-life BESS remains highly uncertain. Field monitoring systems must continuously refine lifetime models based on operational data, accounting for the unique aging characteristics of repurposed batteries. This requires adaptive algorithms that can evolve their predictive capabilities as more performance data becomes available from the growing installed base of second-life systems.

A primary technical challenge lies in the accurate assessment of the state of health (SOH) for second-life batteries. Traditional methods developed for new batteries often fail to account for the unique degradation profiles of used cells. The monitoring systems must adapt to detect subtle changes in performance that may indicate accelerated degradation or potential failure modes specific to second-life applications.

Data integration presents another significant hurdle. Second-life BESS typically comprise batteries from different manufacturers, production batches, and vehicle models. Each may have proprietary battery management systems (BMS) with varying communication protocols and data formats. Developing monitoring systems capable of harmonizing these diverse data streams requires sophisticated interface solutions and standardization efforts that the industry has yet to fully establish.

The detection of anomalies in second-life batteries demands more sophisticated algorithms than those used for new systems. Historical performance data from the battery's first life is often incomplete or inaccessible, creating blind spots in predictive modeling. Monitoring systems must therefore employ advanced machine learning techniques that can function effectively with limited historical context while still providing reliable early warning of potential issues.

Environmental factors introduce additional complexity. Second-life batteries may exhibit heightened sensitivity to temperature variations, charging rates, and depth of discharge compared to new batteries. Monitoring systems must track these parameters with greater precision and correlate them with performance metrics to prevent accelerated degradation.

Safety monitoring represents perhaps the most critical challenge. Used batteries may develop internal defects not present in new cells, increasing the risk of thermal runaway events. Conventional safety systems may not adequately detect the subtle precursors to failure in second-life applications, necessitating more sophisticated thermal monitoring, gas detection, and electrochemical impedance spectroscopy capabilities.

Longevity prediction for second-life BESS remains highly uncertain. Field monitoring systems must continuously refine lifetime models based on operational data, accounting for the unique aging characteristics of repurposed batteries. This requires adaptive algorithms that can evolve their predictive capabilities as more performance data becomes available from the growing installed base of second-life systems.

Current Monitoring Solutions for Second-Life BESS

01 Remote monitoring and performance analysis systems

Remote monitoring systems enable real-time tracking and analysis of field equipment performance. These systems collect data from distributed field devices and transmit it to central monitoring stations for analysis. The technology allows for continuous performance evaluation, early detection of issues, and optimization of field operations without requiring physical presence at the monitored sites.- Network Performance Monitoring Systems: Systems designed to monitor and analyze network performance metrics in real-time. These systems collect data on network traffic, bandwidth utilization, latency, and packet loss to identify bottlenecks and performance issues. They provide visualization tools and dashboards for network administrators to quickly assess network health and troubleshoot problems before they impact users. Advanced implementations include predictive analytics to anticipate potential network failures.

- Remote Field Monitoring and Diagnostics: Technologies for remotely monitoring field equipment and systems across distributed locations. These solutions enable real-time data collection from sensors and devices in the field, allowing for continuous monitoring of operational parameters. They support remote diagnostics capabilities to identify equipment malfunctions without requiring on-site visits. The systems typically include alert mechanisms that notify technicians when measurements fall outside acceptable ranges, enabling proactive maintenance.

- Performance Analytics and Visualization Tools: Software solutions that process monitoring data to provide actionable insights through advanced analytics and visualization. These tools transform complex performance data into intuitive dashboards and reports that highlight trends, anomalies, and potential issues. They incorporate data visualization techniques to represent system performance metrics in ways that facilitate quick understanding and decision-making. Many implementations include customizable reporting features to meet specific organizational needs.

- Automated Fault Detection and Recovery Systems: Intelligent systems that automatically detect performance degradation or failures and initiate recovery procedures. These systems employ machine learning algorithms to establish normal performance baselines and identify deviations that may indicate problems. They can automatically implement predefined recovery protocols when issues are detected, minimizing downtime. Advanced implementations include self-healing capabilities that can reconfigure system parameters to maintain optimal performance without human intervention.

- Scalable Monitoring Infrastructure for Large Deployments: Architectures designed to monitor performance across large-scale field deployments with thousands of devices or sensors. These systems employ distributed monitoring agents that collect and aggregate data from multiple sources while minimizing network overhead. They include hierarchical data processing capabilities to handle the volume of information generated by extensive deployments. The infrastructure typically supports dynamic scaling to accommodate growing numbers of monitored devices without performance degradation.

02 Network performance monitoring and management

Systems designed to monitor and manage network performance in field deployments. These solutions track network metrics, bandwidth utilization, and communication efficiency between field devices. They include tools for visualizing network status, identifying bottlenecks, and implementing automated responses to maintain optimal connectivity for field monitoring applications.Expand Specific Solutions03 Fault detection and diagnostic systems

Advanced systems that identify, diagnose, and predict failures in field monitoring equipment. These solutions employ algorithms to detect anomalies in operational data, classify potential issues, and recommend corrective actions. They help minimize downtime by enabling proactive maintenance and rapid troubleshooting of field monitoring infrastructure.Expand Specific Solutions04 User interface and visualization tools for field monitoring

Specialized interfaces and visualization tools that present complex field monitoring data in accessible formats. These systems provide dashboards, interactive displays, and reporting capabilities that enable operators to quickly assess system performance, identify trends, and make informed decisions. The tools support customization to meet specific monitoring requirements across different field applications.Expand Specific Solutions05 Sensor integration and data acquisition systems

Technologies that focus on integrating diverse sensor types and optimizing data collection from field monitoring equipment. These systems address challenges in sensor calibration, data synchronization, and efficient transmission of field measurements. They include hardware and software solutions that ensure accurate, reliable data acquisition under varying environmental conditions.Expand Specific Solutions

Key Industry Players in Second-Life BESS Market

The field of Second-Life Battery Energy Storage Systems (BESS) performance monitoring is currently in its growth phase, with increasing market adoption driven by sustainability initiatives and economic benefits of repurposing EV batteries. The global market is projected to expand significantly as more first-life batteries reach end-of-life status in EVs. Technologically, the field shows varying maturity levels across players. Companies like LG Energy Solution and SK On lead with advanced monitoring systems for their batteries, while Tesla and State Grid Corp. of China are developing comprehensive field monitoring solutions. Newer entrants like Eco Stor are specializing specifically in second-life applications, bringing innovative approaches to performance tracking. Traditional energy companies such as ABB, Siemens, and Hitachi are leveraging their grid expertise to develop integrated monitoring platforms that connect BESS performance with broader energy management systems.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a specialized Field Monitoring System for Second-Life BESS that builds upon their extensive battery manufacturing expertise. Their system employs a dual-approach monitoring strategy that combines physical sensors with virtual battery models to create digital twins of each battery module. This allows for more accurate performance prediction even with heterogeneous second-life batteries. LG's solution features their Battery Monitoring Unit (BMU) technology that has been adapted to account for the increased variability in second-life applications[5]. The system continuously tracks electrochemical impedance spectroscopy (EIS) measurements to detect internal resistance changes that often precede performance degradation. LG's monitoring platform incorporates adaptive algorithms that automatically adjust performance parameters based on observed degradation patterns, extending useful life while maintaining safety margins. Their system includes specialized diagnostics for identifying capacity imbalances between repurposed modules, which is a common challenge in second-life applications[6].

Strengths: Deep expertise in battery cell chemistry and manufacturing; sophisticated battery modeling capabilities; extensive experience with various battery degradation mechanisms. Weaknesses: System optimization primarily focused on LG's own battery technologies; requires significant computational resources for digital twin modeling; limited field validation data specifically for second-life applications.

Hitachi Ltd.

Technical Solution: Hitachi has developed an integrated Field Monitoring System for Second-Life BESS that leverages their expertise in both energy storage and industrial IoT. Their solution combines physical monitoring hardware with advanced analytics software to provide comprehensive performance tracking of repurposed batteries. Hitachi's system employs their Lumada IoT platform to collect and analyze battery performance data, enabling predictive maintenance and optimized operation[7]. The monitoring solution features adaptive reference models that account for the unique degradation patterns of second-life batteries, allowing for more accurate state of health estimation. Hitachi's approach includes non-invasive monitoring techniques such as ultrasonic and thermal imaging to detect physical changes within battery cells that might indicate potential failure modes. Their system incorporates machine learning algorithms that continuously refine performance models based on operational data, improving prediction accuracy over time. Hitachi's monitoring platform also includes grid integration features that optimize battery performance based on grid conditions and energy market signals[8].

Strengths: Strong integration with broader industrial IoT ecosystems; extensive experience with grid-scale energy storage systems; sophisticated data analytics capabilities. Weaknesses: Complex implementation requiring significant technical expertise; higher initial cost compared to simpler monitoring solutions; potential challenges with monitoring non-standardized second-life battery configurations.

Critical Technologies for BESS Performance Assessment

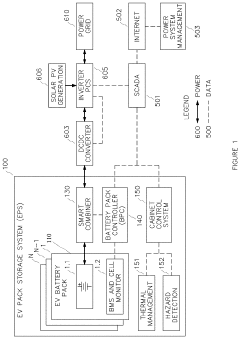

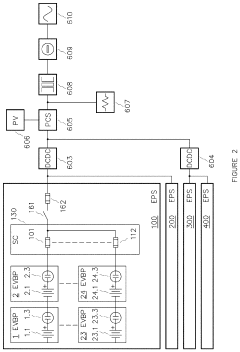

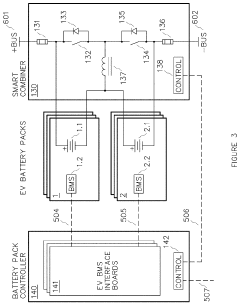

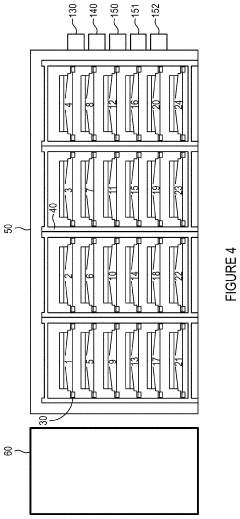

Energy storage system and method employing second-life electric vehicle batteries

PatentActiveUS20220209546A1

Innovation

- An integrated battery energy storage system that aggregates multiple electric vehicle battery packs in a series/parallel arrangement, using a computer system to manage and balance the batteries, ensuring efficient charge and discharge cycles, and utilizing a battery pack controller and smart combiner for active or passive balancing.

Battery energy storage (BES) asset management to facilitate transition from battery first life to second life using physics-based modeling

PatentWO2024263623A1

Innovation

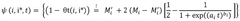

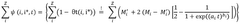

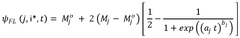

- A method utilizing physics-based modeling to analyze historical aging data, predict second-life aging, and select suitable second-life uses for batteries based on their State of Health (SOH) and operating conditions, employing sigmoidal rate expressions and computational tools like CellSage to simulate and diagnose aging processes, thereby optimizing battery life and facilitating materials recycling.

Safety and Risk Management Frameworks

Safety and risk management frameworks for second-life Battery Energy Storage Systems (BESS) require comprehensive approaches that address the unique challenges posed by repurposed batteries. These frameworks must account for the degraded nature of second-life batteries and their varied operational histories, which introduce additional complexity to risk assessment protocols.

The foundation of effective safety management for second-life BESS begins with thorough battery characterization and classification systems. Batteries must undergo rigorous testing to determine their state of health, remaining capacity, and potential failure modes. This initial assessment forms the basis for risk categorization, which determines the appropriate monitoring parameters and safety thresholds for field deployment.

Real-time monitoring systems play a crucial role in these frameworks, continuously tracking critical parameters such as cell voltage, temperature distribution, and internal resistance. Advanced Battery Management Systems (BMS) specifically designed for second-life applications incorporate adaptive algorithms that account for accelerated degradation patterns and can detect early warning signs of potential failures that might not be present in new battery systems.

Thermal management considerations are particularly important for second-life BESS safety frameworks. Repurposed batteries often exhibit increased thermal sensitivity and less predictable heat generation patterns. Monitoring systems must therefore incorporate enhanced thermal sensors with greater spatial resolution and faster response times to detect hotspots before they can trigger thermal runaway events.

Regulatory compliance represents another critical dimension of these frameworks. While standards for new BESS installations are well-established, second-life applications often operate in regulatory gray areas. Progressive safety frameworks incorporate emerging standards such as IEC 63330 (under development for second-life applications) and adapt existing protocols like UL 1973 and IEC 62619 to address the unique characteristics of repurposed batteries.

Emergency response protocols within these frameworks must account for the potentially unpredictable behavior of aged cells under failure conditions. This includes enhanced fire suppression systems, specialized ventilation requirements, and detailed decommissioning procedures that address the environmental and safety concerns specific to degraded battery materials.

Data-driven risk assessment models form the analytical backbone of modern safety frameworks. These models leverage operational data from field monitoring systems to continuously refine risk profiles and safety thresholds. Machine learning algorithms can identify subtle patterns in performance data that might indicate developing safety issues, enabling preventive maintenance before critical failures occur.

The foundation of effective safety management for second-life BESS begins with thorough battery characterization and classification systems. Batteries must undergo rigorous testing to determine their state of health, remaining capacity, and potential failure modes. This initial assessment forms the basis for risk categorization, which determines the appropriate monitoring parameters and safety thresholds for field deployment.

Real-time monitoring systems play a crucial role in these frameworks, continuously tracking critical parameters such as cell voltage, temperature distribution, and internal resistance. Advanced Battery Management Systems (BMS) specifically designed for second-life applications incorporate adaptive algorithms that account for accelerated degradation patterns and can detect early warning signs of potential failures that might not be present in new battery systems.

Thermal management considerations are particularly important for second-life BESS safety frameworks. Repurposed batteries often exhibit increased thermal sensitivity and less predictable heat generation patterns. Monitoring systems must therefore incorporate enhanced thermal sensors with greater spatial resolution and faster response times to detect hotspots before they can trigger thermal runaway events.

Regulatory compliance represents another critical dimension of these frameworks. While standards for new BESS installations are well-established, second-life applications often operate in regulatory gray areas. Progressive safety frameworks incorporate emerging standards such as IEC 63330 (under development for second-life applications) and adapt existing protocols like UL 1973 and IEC 62619 to address the unique characteristics of repurposed batteries.

Emergency response protocols within these frameworks must account for the potentially unpredictable behavior of aged cells under failure conditions. This includes enhanced fire suppression systems, specialized ventilation requirements, and detailed decommissioning procedures that address the environmental and safety concerns specific to degraded battery materials.

Data-driven risk assessment models form the analytical backbone of modern safety frameworks. These models leverage operational data from field monitoring systems to continuously refine risk profiles and safety thresholds. Machine learning algorithms can identify subtle patterns in performance data that might indicate developing safety issues, enabling preventive maintenance before critical failures occur.

Environmental Impact and Sustainability Metrics

The environmental impact assessment of second-life Battery Energy Storage Systems (BESS) requires comprehensive monitoring frameworks that quantify sustainability metrics throughout the extended lifecycle. Field monitoring systems play a crucial role in measuring and validating the environmental benefits claimed by second-life battery deployments, providing data-driven evidence for sustainability reporting and regulatory compliance.

Carbon footprint reduction represents a primary environmental metric for second-life BESS implementations. Advanced monitoring systems now incorporate lifecycle carbon accounting capabilities that track emissions avoided through battery reuse compared to manufacturing new storage systems. These systems typically measure the operational efficiency of repurposed batteries and calculate the associated carbon offset, with current field data suggesting that second-life applications can reduce carbon emissions by 25-40% compared to new battery production.

Resource conservation metrics form another critical dimension of environmental monitoring. Field systems track material recovery rates and resource efficiency by monitoring the percentage of original battery components successfully repurposed. Leading monitoring platforms now incorporate material passport functionality that documents the complete material composition and tracks the conservation of critical raw materials such as lithium, cobalt, and nickel throughout the second-life application.

Waste reduction performance represents a third key sustainability metric. Monitoring systems quantify diverted landfill volume and extended product lifespans, with current field data indicating that effective second-life applications can extend overall battery utility by 5-10 years beyond automotive use. These metrics directly support circular economy objectives and provide tangible evidence of waste management improvements.

Energy efficiency degradation patterns constitute an essential environmental performance indicator. Field monitoring systems track the comparative efficiency of second-life systems against new batteries, measuring energy losses during charge-discharge cycles and identifying optimization opportunities. This data helps operators maintain optimal environmental performance despite the natural degradation processes in repurposed batteries.

Toxicity prevention metrics have emerged as increasingly important monitoring parameters. Advanced field systems now incorporate leakage detection and containment verification to prevent potential environmental contamination from aging battery components. These systems employ sensors that can detect minute quantities of electrolyte or heavy metal release, triggering automated containment protocols before environmental damage occurs.

The integration of these environmental metrics into comprehensive field monitoring systems enables operators to validate the sustainability claims of second-life BESS deployments with empirical evidence. This data-driven approach not only supports environmental compliance but also provides valuable insights for continuous improvement of second-life battery applications from a sustainability perspective.

Carbon footprint reduction represents a primary environmental metric for second-life BESS implementations. Advanced monitoring systems now incorporate lifecycle carbon accounting capabilities that track emissions avoided through battery reuse compared to manufacturing new storage systems. These systems typically measure the operational efficiency of repurposed batteries and calculate the associated carbon offset, with current field data suggesting that second-life applications can reduce carbon emissions by 25-40% compared to new battery production.

Resource conservation metrics form another critical dimension of environmental monitoring. Field systems track material recovery rates and resource efficiency by monitoring the percentage of original battery components successfully repurposed. Leading monitoring platforms now incorporate material passport functionality that documents the complete material composition and tracks the conservation of critical raw materials such as lithium, cobalt, and nickel throughout the second-life application.

Waste reduction performance represents a third key sustainability metric. Monitoring systems quantify diverted landfill volume and extended product lifespans, with current field data indicating that effective second-life applications can extend overall battery utility by 5-10 years beyond automotive use. These metrics directly support circular economy objectives and provide tangible evidence of waste management improvements.

Energy efficiency degradation patterns constitute an essential environmental performance indicator. Field monitoring systems track the comparative efficiency of second-life systems against new batteries, measuring energy losses during charge-discharge cycles and identifying optimization opportunities. This data helps operators maintain optimal environmental performance despite the natural degradation processes in repurposed batteries.

Toxicity prevention metrics have emerged as increasingly important monitoring parameters. Advanced field systems now incorporate leakage detection and containment verification to prevent potential environmental contamination from aging battery components. These systems employ sensors that can detect minute quantities of electrolyte or heavy metal release, triggering automated containment protocols before environmental damage occurs.

The integration of these environmental metrics into comprehensive field monitoring systems enables operators to validate the sustainability claims of second-life BESS deployments with empirical evidence. This data-driven approach not only supports environmental compliance but also provides valuable insights for continuous improvement of second-life battery applications from a sustainability perspective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!