Hybrid Systems: Combining New And Second-Life Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Battery Systems Background and Objectives

The concept of hybrid battery systems combining new and second-life cells has emerged as a promising solution to address the growing energy storage demands while promoting sustainability. This technological approach has evolved significantly over the past decade, driven by the rapid expansion of electric vehicles (EVs) and renewable energy systems, which has created both challenges and opportunities in battery lifecycle management.

Battery technology has historically followed a linear lifecycle model where cells are manufactured, used until performance degrades below acceptable thresholds, and then disposed of or recycled. However, this approach fails to maximize the potential value of these energy storage assets. Second-life batteries—those removed from their primary applications like EVs when capacity falls below 70-80%—still retain significant functionality that can be harnessed in less demanding applications.

The evolution of hybrid battery systems can be traced through several key technological milestones. Early experiments in the 2010s demonstrated the feasibility of repurposing EV batteries for stationary storage. By 2015, several automakers had launched pilot programs to evaluate second-life applications. The technological breakthrough came around 2018-2020 when advanced battery management systems (BMS) capable of effectively managing cells with different degradation profiles were developed.

Current hybrid battery system technology aims to optimize the integration of new and used cells to create cost-effective, sustainable energy storage solutions. The primary technical objectives include developing sophisticated algorithms for state-of-health estimation, creating adaptive management systems that can accommodate heterogeneous cell characteristics, and designing scalable architectures suitable for various applications from residential to utility-scale storage.

Market projections indicate that by 2030, over 200 GWh of second-life batteries could be available globally, creating a significant opportunity for hybrid systems. This growth is further supported by regulatory frameworks promoting circular economy principles and extended producer responsibility in major markets.

The technological trajectory is now focused on overcoming key challenges such as accurate degradation modeling, standardization of battery modules across manufacturers, and development of predictive maintenance protocols. Research is increasingly concentrated on artificial intelligence and machine learning approaches to optimize the performance and lifespan of these heterogeneous systems.

The ultimate goal of hybrid battery system technology is to create a sustainable battery ecosystem that maximizes resource utilization while providing reliable, cost-effective energy storage solutions across multiple application domains.

Battery technology has historically followed a linear lifecycle model where cells are manufactured, used until performance degrades below acceptable thresholds, and then disposed of or recycled. However, this approach fails to maximize the potential value of these energy storage assets. Second-life batteries—those removed from their primary applications like EVs when capacity falls below 70-80%—still retain significant functionality that can be harnessed in less demanding applications.

The evolution of hybrid battery systems can be traced through several key technological milestones. Early experiments in the 2010s demonstrated the feasibility of repurposing EV batteries for stationary storage. By 2015, several automakers had launched pilot programs to evaluate second-life applications. The technological breakthrough came around 2018-2020 when advanced battery management systems (BMS) capable of effectively managing cells with different degradation profiles were developed.

Current hybrid battery system technology aims to optimize the integration of new and used cells to create cost-effective, sustainable energy storage solutions. The primary technical objectives include developing sophisticated algorithms for state-of-health estimation, creating adaptive management systems that can accommodate heterogeneous cell characteristics, and designing scalable architectures suitable for various applications from residential to utility-scale storage.

Market projections indicate that by 2030, over 200 GWh of second-life batteries could be available globally, creating a significant opportunity for hybrid systems. This growth is further supported by regulatory frameworks promoting circular economy principles and extended producer responsibility in major markets.

The technological trajectory is now focused on overcoming key challenges such as accurate degradation modeling, standardization of battery modules across manufacturers, and development of predictive maintenance protocols. Research is increasingly concentrated on artificial intelligence and machine learning approaches to optimize the performance and lifespan of these heterogeneous systems.

The ultimate goal of hybrid battery system technology is to create a sustainable battery ecosystem that maximizes resource utilization while providing reliable, cost-effective energy storage solutions across multiple application domains.

Market Analysis for Second-Life Battery Applications

The second-life battery market has experienced significant growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and the subsequent need for sustainable battery lifecycle management. By 2030, the global second-life battery market is projected to reach $4.2 billion, with a compound annual growth rate of approximately 30% between 2023 and 2030. This growth is primarily fueled by the expanding EV market, which is expected to generate a substantial volume of retired batteries that retain 70-80% of their original capacity.

The utility sector represents the largest application segment for second-life batteries, accounting for nearly 40% of the market share. Energy storage systems for grid stabilization, peak shaving, and renewable energy integration constitute the primary use cases. The commercial and industrial sectors follow closely, utilizing second-life batteries for backup power, demand charge reduction, and energy cost optimization.

Regionally, Asia Pacific dominates the second-life battery market, with China and South Korea leading in implementation and technology development. Europe follows as the second-largest market, driven by stringent environmental regulations and ambitious renewable energy targets. North America shows promising growth potential, particularly in California and other states with advanced energy storage incentive programs.

From an economic perspective, second-life battery applications offer compelling value propositions. The cost of repurposed EV batteries ranges from $50-150 per kWh, significantly lower than new battery costs of $200-300 per kWh. This price differential creates substantial market opportunities, especially in price-sensitive applications where energy density and cycle life requirements are less demanding than in automotive applications.

Key market drivers include increasing environmental regulations mandating battery recycling, growing renewable energy integration requiring flexible storage solutions, and the economic benefits of extending battery lifecycle value. The circular economy principles are gaining traction among both battery manufacturers and energy storage developers, creating new business models centered around battery reuse.

Market challenges persist, including the lack of standardization in battery designs, uncertainty regarding long-term performance reliability, and competition from declining new battery prices. Additionally, the fragmented nature of the supply chain, involving multiple stakeholders from EV manufacturers to recycling facilities, creates logistical and coordination challenges.

Customer segments show varying adoption patterns, with utilities and commercial-scale operations showing the strongest interest due to their ability to manage larger installations and absorb the technical risks associated with second-life batteries. Residential applications remain limited but are expected to grow as standardized solutions and performance guarantees become more widely available.

The utility sector represents the largest application segment for second-life batteries, accounting for nearly 40% of the market share. Energy storage systems for grid stabilization, peak shaving, and renewable energy integration constitute the primary use cases. The commercial and industrial sectors follow closely, utilizing second-life batteries for backup power, demand charge reduction, and energy cost optimization.

Regionally, Asia Pacific dominates the second-life battery market, with China and South Korea leading in implementation and technology development. Europe follows as the second-largest market, driven by stringent environmental regulations and ambitious renewable energy targets. North America shows promising growth potential, particularly in California and other states with advanced energy storage incentive programs.

From an economic perspective, second-life battery applications offer compelling value propositions. The cost of repurposed EV batteries ranges from $50-150 per kWh, significantly lower than new battery costs of $200-300 per kWh. This price differential creates substantial market opportunities, especially in price-sensitive applications where energy density and cycle life requirements are less demanding than in automotive applications.

Key market drivers include increasing environmental regulations mandating battery recycling, growing renewable energy integration requiring flexible storage solutions, and the economic benefits of extending battery lifecycle value. The circular economy principles are gaining traction among both battery manufacturers and energy storage developers, creating new business models centered around battery reuse.

Market challenges persist, including the lack of standardization in battery designs, uncertainty regarding long-term performance reliability, and competition from declining new battery prices. Additionally, the fragmented nature of the supply chain, involving multiple stakeholders from EV manufacturers to recycling facilities, creates logistical and coordination challenges.

Customer segments show varying adoption patterns, with utilities and commercial-scale operations showing the strongest interest due to their ability to manage larger installations and absorb the technical risks associated with second-life batteries. Residential applications remain limited but are expected to grow as standardized solutions and performance guarantees become more widely available.

Technical Challenges in Hybrid Cell Integration

The integration of new and second-life cells into hybrid battery systems presents significant technical challenges that require innovative solutions. One of the primary obstacles is the inherent voltage mismatch between new and used cells. New cells typically operate at higher voltage levels and maintain more stable discharge curves compared to second-life cells, which have experienced capacity degradation and voltage depression. This mismatch creates complex power management issues when cells are connected in series or parallel configurations.

Cell degradation heterogeneity compounds these challenges further. Even within batches of second-life cells recovered from the same application, individual cells often exhibit vastly different degradation patterns based on their unique usage history, thermal exposure, and manufacturing variations. This heterogeneity makes it difficult to predict performance and requires sophisticated battery management systems (BMS) capable of handling cells with divergent characteristics.

Thermal management represents another critical challenge in hybrid systems. The different internal resistance profiles between new and aged cells lead to uneven heat generation during charge and discharge cycles. Second-life cells typically generate more heat due to increased internal resistance, creating thermal gradients within the battery pack that can accelerate degradation of neighboring cells and potentially create safety hazards if not properly managed.

State of health (SOH) and state of charge (SOC) estimation becomes particularly complex in hybrid configurations. Traditional BMS algorithms are calibrated for homogeneous cell populations and often fail to accurately assess the condition of mixed cell types. This limitation can lead to suboptimal utilization of available capacity and potentially dangerous operating conditions if cells are pushed beyond their safe operating windows.

Safety concerns are heightened in hybrid systems due to the unpredictable nature of aged cells. Second-life cells may have developed internal structural weaknesses or chemical changes that are not immediately detectable but could lead to thermal runaway under certain conditions. The combination with new cells can create unexpected electrical stresses that might trigger failure modes not typically seen in homogeneous battery packs.

Communication protocols between battery management subsystems present additional integration challenges. Different generations of cells may utilize varying communication standards or require different monitoring parameters, necessitating complex translation layers within the BMS architecture. This communication complexity increases system overhead and introduces potential points of failure.

Lifecycle management strategies must also be reconsidered for hybrid systems. The replacement and maintenance schedules become more complicated when components have different remaining useful lifetimes. Determining optimal replacement timing and strategies for gradual system upgrades requires new predictive models that can account for the complex interactions between new and aged cells.

Cell degradation heterogeneity compounds these challenges further. Even within batches of second-life cells recovered from the same application, individual cells often exhibit vastly different degradation patterns based on their unique usage history, thermal exposure, and manufacturing variations. This heterogeneity makes it difficult to predict performance and requires sophisticated battery management systems (BMS) capable of handling cells with divergent characteristics.

Thermal management represents another critical challenge in hybrid systems. The different internal resistance profiles between new and aged cells lead to uneven heat generation during charge and discharge cycles. Second-life cells typically generate more heat due to increased internal resistance, creating thermal gradients within the battery pack that can accelerate degradation of neighboring cells and potentially create safety hazards if not properly managed.

State of health (SOH) and state of charge (SOC) estimation becomes particularly complex in hybrid configurations. Traditional BMS algorithms are calibrated for homogeneous cell populations and often fail to accurately assess the condition of mixed cell types. This limitation can lead to suboptimal utilization of available capacity and potentially dangerous operating conditions if cells are pushed beyond their safe operating windows.

Safety concerns are heightened in hybrid systems due to the unpredictable nature of aged cells. Second-life cells may have developed internal structural weaknesses or chemical changes that are not immediately detectable but could lead to thermal runaway under certain conditions. The combination with new cells can create unexpected electrical stresses that might trigger failure modes not typically seen in homogeneous battery packs.

Communication protocols between battery management subsystems present additional integration challenges. Different generations of cells may utilize varying communication standards or require different monitoring parameters, necessitating complex translation layers within the BMS architecture. This communication complexity increases system overhead and introduces potential points of failure.

Lifecycle management strategies must also be reconsidered for hybrid systems. The replacement and maintenance schedules become more complicated when components have different remaining useful lifetimes. Determining optimal replacement timing and strategies for gradual system upgrades requires new predictive models that can account for the complex interactions between new and aged cells.

Current Hybrid Battery Integration Solutions

01 Battery Management Systems for Hybrid Configurations

Advanced battery management systems (BMS) are essential for optimizing the performance of hybrid battery systems. These systems monitor and control various parameters such as state of charge, temperature, and voltage across different battery types within the hybrid configuration. The integration of sophisticated BMS enables efficient energy distribution, extends battery life, and ensures safe operation by preventing overcharging or deep discharging conditions. These management systems also facilitate seamless switching between different energy sources based on demand and availability.- Battery management systems for hybrid configurations: Advanced battery management systems are essential for optimizing the performance of hybrid battery configurations. These systems monitor and control various parameters such as state of charge, temperature, and power distribution across different battery types. By intelligently managing the energy flow between batteries with different chemistries or capacities, these systems can maximize overall efficiency, extend battery life, and ensure stable operation under varying load conditions.

- Integration of multiple battery technologies: Hybrid battery systems combine different battery technologies to leverage their complementary characteristics. For example, integrating high-energy density batteries with high-power density batteries allows systems to handle both sustained energy needs and power surges. This approach enables better performance across diverse operating conditions while mitigating the limitations of individual battery types. The integration may involve lithium-ion batteries paired with supercapacitors or different lithium chemistries optimized for specific performance attributes.

- Thermal management for hybrid battery systems: Effective thermal management is crucial for maintaining optimal performance in hybrid battery systems. These systems employ various cooling and heating mechanisms to keep different battery components within their ideal temperature ranges. Advanced thermal management solutions include liquid cooling circuits, phase-change materials, and intelligent temperature control algorithms. By preventing overheating and maintaining uniform temperature distribution, these systems enhance battery efficiency, longevity, and safety during high-power operations.

- Vehicle applications of hybrid battery systems: Hybrid battery systems are particularly valuable in vehicle applications, where they can significantly improve performance and efficiency. In electric and hybrid vehicles, these systems can provide both high power for acceleration and sufficient energy for extended range. The integration of different battery types allows for regenerative braking optimization, reduced weight compared to single-chemistry solutions, and better adaptation to varying driving conditions. These systems often incorporate sophisticated power electronics to manage the different voltage levels and charging requirements.

- Control algorithms and power electronics for hybrid batteries: Sophisticated control algorithms and specialized power electronics are essential for optimizing hybrid battery system performance. These algorithms dynamically allocate power demands between different battery types based on their current state, operational efficiency, and performance characteristics. Advanced power electronics, including DC-DC converters and intelligent switching systems, enable seamless energy flow between battery components with different voltage levels. Machine learning approaches can further enhance system performance by adapting to usage patterns and predicting optimal power distribution strategies.

02 Integration of Multiple Battery Technologies

Hybrid battery systems combine different battery technologies (such as lithium-ion, lead-acid, and supercapacitors) to leverage the advantages of each type while mitigating their individual limitations. This integration approach allows for optimized performance characteristics including improved power density, energy density, cycle life, and temperature tolerance. The strategic combination of fast-charging capabilities with high energy storage capacity creates systems that can respond to both peak power demands and sustained energy requirements, making them suitable for diverse applications from electric vehicles to renewable energy storage.Expand Specific Solutions03 Thermal Management and Performance Optimization

Effective thermal management is crucial for maintaining optimal performance in hybrid battery systems. Advanced cooling and heating mechanisms ensure that different battery components operate within their ideal temperature ranges, preventing thermal runaway and extending operational life. These systems incorporate temperature sensors, cooling circuits, and heat dissipation technologies to maintain balanced thermal conditions across various battery modules. Optimized thermal management contributes significantly to overall system efficiency, reliability, and safety while enabling consistent performance under varying load conditions.Expand Specific Solutions04 Energy Distribution and Power Electronics

Sophisticated power electronics and energy distribution systems are fundamental to hybrid battery performance integration. These components include DC-DC converters, inverters, and intelligent power routing systems that efficiently manage energy flow between different battery types and the load. Advanced algorithms determine optimal power distribution pathways based on real-time demand, battery conditions, and system efficiency parameters. These systems enable seamless transitions between power sources, minimize conversion losses, and maximize overall energy utilization while maintaining stable output characteristics.Expand Specific Solutions05 Vehicle Integration and Regenerative Systems

Integration of hybrid battery systems in vehicles requires specialized approaches to accommodate regenerative braking, variable load demands, and space constraints. These systems capture and store energy during deceleration through regenerative braking, significantly improving overall efficiency. The integration architecture must balance weight distribution, thermal considerations, and safety requirements while providing sufficient power for acceleration and range for distance travel. Advanced control systems coordinate between the hybrid battery system and vehicle powertrain to optimize performance across various driving conditions and usage patterns.Expand Specific Solutions

Key Industry Players in Hybrid Battery Systems

The hybrid energy storage market, combining new and second-life cells, is currently in its early growth phase with increasing market adoption. This sector is projected to expand significantly as circular economy principles gain traction in the energy storage industry. Leading technology developers include Samsung SDI, LG Energy Solution, and Toyota, who are advancing commercial solutions by leveraging their expertise in battery manufacturing and lifecycle management. Academic institutions like MIT and University of California are contributing fundamental research on cell integration and performance optimization. Companies like Huawei and Hitachi are developing sophisticated battery management systems essential for hybrid configurations. The technology is approaching commercial maturity for stationary applications, though challenges remain in standardization and performance prediction of second-life cells.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced hybrid battery system that integrates new lithium-ion cells with second-life cells recovered from electric vehicles. Their proprietary Battery Management System (BMS) employs adaptive algorithms to optimize performance across cells with varying degradation levels. The system incorporates cell-level monitoring with temperature and voltage sensors for each cell group, enabling real-time performance tracking. Samsung's hybrid architecture uses new cells for high-power demands while second-life cells handle base load operations, extending overall system lifespan. Their thermal management system addresses the different cooling requirements of new and aged cells, maintaining optimal operating temperatures across the hybrid array. Samsung has implemented this technology in grid-scale energy storage installations, demonstrating up to 30% cost reduction compared to all-new battery systems while maintaining 85-90% of new system performance.

Strengths: Cost-effective solution leveraging existing battery resources; sophisticated BMS optimizes performance across varied cell conditions; proven implementation in commercial grid storage applications. Weaknesses: System complexity increases maintenance requirements; performance limitations compared to all-new systems; requires careful cell matching and selection process.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a hybrid battery system called "RE:NEW" that strategically combines fresh lithium-ion cells with repurposed cells from automotive applications. Their approach features a modular design where second-life modules can be hot-swapped as their capacity degrades further, extending system utility. LG's proprietary Battery Intelligence Platform analyzes cell characteristics to create optimally balanced hybrid arrays, using machine learning algorithms to predict performance and degradation patterns. The system employs parallel-series configurations that isolate new and second-life cell groups while maintaining electrical balance. For grid storage applications, LG has developed specialized power conversion systems that accommodate the different voltage and current characteristics of mixed-age cells. Their hybrid systems have been deployed in commercial microgrids, demonstrating 25-40% cost savings while maintaining reliability comparable to conventional systems through sophisticated fault detection and isolation mechanisms.

Strengths: Modular architecture allows for easy maintenance and gradual upgrades; advanced analytics optimize cell grouping and performance; proven cost savings in commercial deployments. Weaknesses: Requires sophisticated management systems adding complexity; performance variability between different batches of second-life cells; higher initial engineering costs compared to homogeneous systems.

Core Technologies for Cell Balancing and Management

Hybrid cell system

PatentWO2014199942A1

Innovation

- A hybrid battery system comprising a first battery with medium energy density and high power density, and a second battery with high energy density and low power density, utilizing a conductive polymer positive electrode and a control unit to dynamically switch between batteries based on current output needs, eliminating the need for a cooling system and reducing costs by using general-purpose Li-ion batteries.

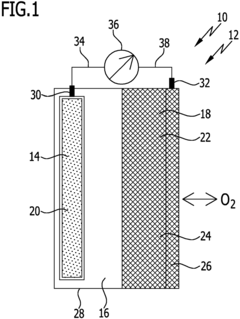

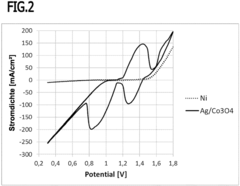

Secondary cell, battery comprising one or more secondary cells and a method for loading and discharging

PatentActiveEP3331073A1

Innovation

- A zinc-air battery with a cathode designed as a gas diffusion electrode containing a mixture of silver and/or silver oxide, along with catalysts like cobalt oxide, manganese oxides, and ruthenium oxide, which enhances catalytic activity and conductivity, eliminating the need for carbon and improving corrosion resistance.

Environmental Impact and Sustainability Assessment

The integration of new and second-life battery cells in hybrid systems represents a significant advancement in sustainable energy storage solutions. From an environmental perspective, these hybrid systems substantially reduce the ecological footprint associated with battery production and disposal. By extending the useful life of battery cells beyond their primary applications, these systems effectively decrease the demand for raw materials extraction, particularly critical minerals like lithium, cobalt, and nickel, which often involve environmentally destructive mining practices.

Life cycle assessment (LCA) studies indicate that repurposing second-life batteries can reduce carbon emissions by 15-70% compared to manufacturing new batteries, depending on the application and system configuration. This reduction stems primarily from avoiding the energy-intensive processes of material extraction and battery manufacturing. Additionally, hybrid systems optimize resource utilization by matching performance requirements with appropriate battery types, further enhancing sustainability metrics.

Water conservation represents another critical environmental benefit of hybrid battery systems. Traditional battery manufacturing consumes substantial water resources—approximately 7,000 liters per kWh of battery capacity. By incorporating second-life cells, hybrid systems can reduce freshwater consumption by up to 40% across the entire battery lifecycle, contributing significantly to water conservation efforts in water-stressed regions.

Waste reduction constitutes a fundamental environmental advantage of hybrid battery systems. The battery industry currently faces significant challenges regarding end-of-life management, with global battery waste projected to reach 11 million tonnes annually by 2030. Hybrid systems directly address this challenge by creating a structured pathway for battery reuse, potentially diverting 25-35% of batteries from immediate recycling or disposal channels.

From a circular economy perspective, hybrid systems represent an intermediate step between primary use and recycling, maximizing value extraction from manufactured batteries. This approach aligns with sustainable development principles by creating additional value cycles before material recovery through recycling. Furthermore, these systems support the development of localized battery refurbishment industries, reducing transportation emissions associated with global battery supply chains.

Regulatory frameworks increasingly recognize the environmental benefits of battery reuse strategies. The European Battery Directive revision and similar policies worldwide are establishing sustainability requirements that favor second-life applications. Companies implementing hybrid battery systems may gain competitive advantages through improved environmental compliance scores and reduced exposure to raw material supply risks.

Life cycle assessment (LCA) studies indicate that repurposing second-life batteries can reduce carbon emissions by 15-70% compared to manufacturing new batteries, depending on the application and system configuration. This reduction stems primarily from avoiding the energy-intensive processes of material extraction and battery manufacturing. Additionally, hybrid systems optimize resource utilization by matching performance requirements with appropriate battery types, further enhancing sustainability metrics.

Water conservation represents another critical environmental benefit of hybrid battery systems. Traditional battery manufacturing consumes substantial water resources—approximately 7,000 liters per kWh of battery capacity. By incorporating second-life cells, hybrid systems can reduce freshwater consumption by up to 40% across the entire battery lifecycle, contributing significantly to water conservation efforts in water-stressed regions.

Waste reduction constitutes a fundamental environmental advantage of hybrid battery systems. The battery industry currently faces significant challenges regarding end-of-life management, with global battery waste projected to reach 11 million tonnes annually by 2030. Hybrid systems directly address this challenge by creating a structured pathway for battery reuse, potentially diverting 25-35% of batteries from immediate recycling or disposal channels.

From a circular economy perspective, hybrid systems represent an intermediate step between primary use and recycling, maximizing value extraction from manufactured batteries. This approach aligns with sustainable development principles by creating additional value cycles before material recovery through recycling. Furthermore, these systems support the development of localized battery refurbishment industries, reducing transportation emissions associated with global battery supply chains.

Regulatory frameworks increasingly recognize the environmental benefits of battery reuse strategies. The European Battery Directive revision and similar policies worldwide are establishing sustainability requirements that favor second-life applications. Companies implementing hybrid battery systems may gain competitive advantages through improved environmental compliance scores and reduced exposure to raw material supply risks.

Regulatory Framework for Second-Life Battery Usage

The regulatory landscape for second-life battery usage remains fragmented globally, presenting significant challenges for hybrid system implementation. In the European Union, the Battery Directive (2006/66/EC) and its 2022 update establish comprehensive frameworks for battery waste management but lack specific provisions for second-life applications. This regulatory gap creates uncertainty for manufacturers integrating new and repurposed cells in hybrid systems.

The United States currently operates without federal-level regulations specifically addressing second-life battery usage. Instead, a patchwork of state regulations exists, with California leading through its Advanced Clean Cars Program and battery recycling initiatives. The EPA's Resource Conservation and Recovery Act (RCRA) governs battery disposal but provides limited guidance on repurposing, creating compliance challenges for hybrid system developers.

In Asia, China has implemented the "New Energy Vehicle Industry Development Plan (2021-2035)" which includes provisions for battery reuse, establishing traceability systems and technical standards for second-life applications. Japan's Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment contains battery management provisions but requires updating to address hybrid system configurations specifically.

Safety certification represents another critical regulatory hurdle. UL 1974 in the United States and IEC 63330 internationally provide testing standards for repurposed batteries, but certification processes remain costly and time-consuming. These standards must evolve to address the unique characteristics of hybrid systems where new and second-life cells operate in tandem.

Liability frameworks present additional complexity, as responsibility allocation throughout the battery lifecycle remains unclear. Questions persist regarding whether original manufacturers, repurposers, or system integrators bear ultimate responsibility for safety incidents involving hybrid systems. Insurance providers have responded cautiously, offering limited coverage options with high premiums due to perceived risks.

Transportation regulations add further complications, with the UN Model Regulations for Dangerous Goods classifying lithium batteries as Class 9 hazardous materials. Second-life batteries face additional scrutiny during cross-border shipping, often requiring extensive documentation and safety testing that increases logistical costs for hybrid system deployment.

Moving forward, regulatory harmonization is essential. Industry stakeholders are advocating for standardized testing protocols, clear liability frameworks, and streamlined certification processes specifically designed for hybrid battery systems. The development of these regulatory frameworks will significantly influence the economic viability and market adoption of hybrid systems combining new and second-life cells.

The United States currently operates without federal-level regulations specifically addressing second-life battery usage. Instead, a patchwork of state regulations exists, with California leading through its Advanced Clean Cars Program and battery recycling initiatives. The EPA's Resource Conservation and Recovery Act (RCRA) governs battery disposal but provides limited guidance on repurposing, creating compliance challenges for hybrid system developers.

In Asia, China has implemented the "New Energy Vehicle Industry Development Plan (2021-2035)" which includes provisions for battery reuse, establishing traceability systems and technical standards for second-life applications. Japan's Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment contains battery management provisions but requires updating to address hybrid system configurations specifically.

Safety certification represents another critical regulatory hurdle. UL 1974 in the United States and IEC 63330 internationally provide testing standards for repurposed batteries, but certification processes remain costly and time-consuming. These standards must evolve to address the unique characteristics of hybrid systems where new and second-life cells operate in tandem.

Liability frameworks present additional complexity, as responsibility allocation throughout the battery lifecycle remains unclear. Questions persist regarding whether original manufacturers, repurposers, or system integrators bear ultimate responsibility for safety incidents involving hybrid systems. Insurance providers have responded cautiously, offering limited coverage options with high premiums due to perceived risks.

Transportation regulations add further complications, with the UN Model Regulations for Dangerous Goods classifying lithium batteries as Class 9 hazardous materials. Second-life batteries face additional scrutiny during cross-border shipping, often requiring extensive documentation and safety testing that increases logistical costs for hybrid system deployment.

Moving forward, regulatory harmonization is essential. Industry stakeholders are advocating for standardized testing protocols, clear liability frameworks, and streamlined certification processes specifically designed for hybrid battery systems. The development of these regulatory frameworks will significantly influence the economic viability and market adoption of hybrid systems combining new and second-life cells.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!