Quality Control Checklists For Second-Life Module Assembly

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Second-Life Technology Background and Objectives

The concept of battery second-life technology emerged in the early 2000s as electric vehicles (EVs) began gaining market traction. Initially, these batteries were primarily discarded after reaching 70-80% of their original capacity, deemed insufficient for automotive applications. However, this practice represented significant waste of valuable resources and untapped potential, as these "degraded" batteries still retained substantial capacity suitable for less demanding applications.

The evolution of second-life battery technology has accelerated dramatically over the past decade, driven by the exponential growth in EV adoption and the corresponding increase in batteries reaching end-of-automotive life. Industry projections indicate that by 2030, over 2 million metric tons of EV batteries will reach their end-of-vehicle life annually, creating both an environmental challenge and a technological opportunity.

Quality control in second-life battery module assembly has become increasingly critical as the market matures. Early repurposing efforts often lacked standardized assessment protocols, resulting in inconsistent performance and reliability issues. The industry has gradually moved from rudimentary visual inspections and basic capacity tests toward sophisticated diagnostic systems that can accurately determine the state of health, remaining useful life, and safety parameters of used battery modules.

The primary technical objective in second-life battery quality control is to develop comprehensive, efficient, and reliable assessment methodologies that can accurately classify and grade used battery modules for appropriate second-life applications. This includes standardized testing protocols that can identify potential failure modes, assess degradation patterns, and predict future performance under various operating conditions.

Another key objective is the development of automated assembly processes with integrated quality control checkpoints that can efficiently disassemble, test, sort, and reassemble battery modules at scale. This requires advanced sensing technologies, data analytics capabilities, and adaptive manufacturing systems that can handle the inherent variability in used battery conditions.

The industry also aims to establish universal standards and certification frameworks for second-life batteries, ensuring safety, reliability, and performance across different applications ranging from stationary energy storage to backup power systems. These standards must address the unique challenges of repurposed batteries, including variable degradation states, diverse chemistries, and different original manufacturing specifications.

Ultimately, the technological trajectory is moving toward creating a circular economy for lithium-ion batteries, where end-of-automotive-life does not represent disposal but rather a transition to new applications, maximizing the total lifetime value of these energy storage assets while minimizing environmental impact.

The evolution of second-life battery technology has accelerated dramatically over the past decade, driven by the exponential growth in EV adoption and the corresponding increase in batteries reaching end-of-automotive life. Industry projections indicate that by 2030, over 2 million metric tons of EV batteries will reach their end-of-vehicle life annually, creating both an environmental challenge and a technological opportunity.

Quality control in second-life battery module assembly has become increasingly critical as the market matures. Early repurposing efforts often lacked standardized assessment protocols, resulting in inconsistent performance and reliability issues. The industry has gradually moved from rudimentary visual inspections and basic capacity tests toward sophisticated diagnostic systems that can accurately determine the state of health, remaining useful life, and safety parameters of used battery modules.

The primary technical objective in second-life battery quality control is to develop comprehensive, efficient, and reliable assessment methodologies that can accurately classify and grade used battery modules for appropriate second-life applications. This includes standardized testing protocols that can identify potential failure modes, assess degradation patterns, and predict future performance under various operating conditions.

Another key objective is the development of automated assembly processes with integrated quality control checkpoints that can efficiently disassemble, test, sort, and reassemble battery modules at scale. This requires advanced sensing technologies, data analytics capabilities, and adaptive manufacturing systems that can handle the inherent variability in used battery conditions.

The industry also aims to establish universal standards and certification frameworks for second-life batteries, ensuring safety, reliability, and performance across different applications ranging from stationary energy storage to backup power systems. These standards must address the unique challenges of repurposed batteries, including variable degradation states, diverse chemistries, and different original manufacturing specifications.

Ultimately, the technological trajectory is moving toward creating a circular economy for lithium-ion batteries, where end-of-automotive-life does not represent disposal but rather a transition to new applications, maximizing the total lifetime value of these energy storage assets while minimizing environmental impact.

Market Analysis for Second-Life Battery Applications

The second-life battery market has experienced significant growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and the subsequent need for sustainable battery lifecycle management. As EV batteries typically retain 70-80% of their original capacity after their automotive life cycle, they present substantial value for repurposing in less demanding applications. The global second-life battery market was valued at approximately $1.6 billion in 2022 and is projected to reach $7.9 billion by 2030, representing a compound annual growth rate of 22.3%.

Energy storage systems constitute the largest application segment for second-life batteries, accounting for nearly 45% of the market share. These systems are increasingly deployed for grid stabilization, peak shaving, and renewable energy integration. The residential energy storage sector is particularly promising, with homeowners seeking cost-effective solutions to pair with rooftop solar installations.

Commercial and industrial applications represent another significant market segment, where second-life batteries are utilized for backup power, demand charge reduction, and energy cost optimization. This segment is expected to grow at 25% annually through 2028, driven by rising electricity costs and increasing focus on business continuity.

Regional analysis indicates that Asia Pacific currently dominates the second-life battery market, with China, Japan, and South Korea leading in both supply and demand. Europe follows closely, supported by stringent environmental regulations and ambitious renewable energy targets. The North American market is gaining momentum, particularly in California and other states with favorable energy storage policies.

Market dynamics are influenced by several factors, including decreasing costs of new batteries, which puts pressure on second-life battery pricing. However, this is counterbalanced by increasing environmental regulations mandating responsible battery disposal and recycling, creating opportunities for second-life applications as an intermediate step before recycling.

Customer segments show varying requirements for second-life batteries. Utilities prioritize reliability and long-term performance guarantees, while commercial customers focus on return on investment and system integration capabilities. Residential customers value cost savings, ease of installation, and safety assurances.

The competitive landscape features both established energy storage providers expanding into second-life solutions and specialized startups focused exclusively on battery repurposing. Automotive manufacturers are increasingly entering this space, establishing dedicated second-life battery divisions to capture additional value from their EV battery supply chains.

Energy storage systems constitute the largest application segment for second-life batteries, accounting for nearly 45% of the market share. These systems are increasingly deployed for grid stabilization, peak shaving, and renewable energy integration. The residential energy storage sector is particularly promising, with homeowners seeking cost-effective solutions to pair with rooftop solar installations.

Commercial and industrial applications represent another significant market segment, where second-life batteries are utilized for backup power, demand charge reduction, and energy cost optimization. This segment is expected to grow at 25% annually through 2028, driven by rising electricity costs and increasing focus on business continuity.

Regional analysis indicates that Asia Pacific currently dominates the second-life battery market, with China, Japan, and South Korea leading in both supply and demand. Europe follows closely, supported by stringent environmental regulations and ambitious renewable energy targets. The North American market is gaining momentum, particularly in California and other states with favorable energy storage policies.

Market dynamics are influenced by several factors, including decreasing costs of new batteries, which puts pressure on second-life battery pricing. However, this is counterbalanced by increasing environmental regulations mandating responsible battery disposal and recycling, creating opportunities for second-life applications as an intermediate step before recycling.

Customer segments show varying requirements for second-life batteries. Utilities prioritize reliability and long-term performance guarantees, while commercial customers focus on return on investment and system integration capabilities. Residential customers value cost savings, ease of installation, and safety assurances.

The competitive landscape features both established energy storage providers expanding into second-life solutions and specialized startups focused exclusively on battery repurposing. Automotive manufacturers are increasingly entering this space, establishing dedicated second-life battery divisions to capture additional value from their EV battery supply chains.

Technical Challenges in Second-Life Module Assembly

Second-life battery module assembly presents significant technical challenges that must be addressed to ensure safety, reliability, and performance. The variability in incoming used battery modules creates fundamental difficulties in standardization, as these modules arrive with diverse degradation patterns, physical damage, and remaining capacity levels. This heterogeneity complicates the development of universal assembly protocols and quality standards.

Material compatibility issues arise when integrating cells from different manufacturers, chemistries, or production batches. These differences can lead to electrical imbalances, thermal management complications, and potential safety hazards if not properly addressed during the assembly process. The battery management system (BMS) must be reconfigured to accommodate these variations, requiring sophisticated algorithms and adaptive control systems.

Diagnostic limitations represent another major challenge. Current testing methodologies often fail to accurately assess the true state of health of used cells, particularly when evaluating internal resistance changes, capacity fade patterns, and potential for thermal runaway. Non-destructive testing techniques remain limited in their ability to detect microscopic defects that could lead to catastrophic failures in second-life applications.

Safety concerns are paramount in second-life module assembly. The risk of thermal events increases with cell age and previous usage patterns. Detecting potential failure modes becomes more complex as cells may exhibit unpredictable behavior after their first life cycle. Assembly processes must incorporate enhanced safety protocols beyond those used in new battery manufacturing.

Automation challenges persist throughout the assembly process. While first-life battery production benefits from highly automated assembly lines with standardized components, second-life module assembly requires more adaptive systems capable of handling variability. Current automation solutions lack the flexibility and intelligence to efficiently process diverse incoming materials.

Regulatory compliance presents additional hurdles, as standards for second-life batteries remain in development across many jurisdictions. Assembly processes must anticipate evolving requirements while ensuring traceability of components throughout the battery's extended lifecycle.

Economic viability remains a technical challenge as assembly processes must balance quality control with cost-effectiveness. Excessive testing and sorting can render second-life applications financially unviable, while insufficient quality control introduces unacceptable risks. Finding this balance requires innovative approaches to streamlined yet thorough assembly protocols.

Knowledge gaps in long-term performance prediction further complicate assembly decisions. Limited historical data exists on how various assembly techniques affect the extended performance of second-life batteries, making it difficult to optimize processes for specific applications and desired lifespans.

Material compatibility issues arise when integrating cells from different manufacturers, chemistries, or production batches. These differences can lead to electrical imbalances, thermal management complications, and potential safety hazards if not properly addressed during the assembly process. The battery management system (BMS) must be reconfigured to accommodate these variations, requiring sophisticated algorithms and adaptive control systems.

Diagnostic limitations represent another major challenge. Current testing methodologies often fail to accurately assess the true state of health of used cells, particularly when evaluating internal resistance changes, capacity fade patterns, and potential for thermal runaway. Non-destructive testing techniques remain limited in their ability to detect microscopic defects that could lead to catastrophic failures in second-life applications.

Safety concerns are paramount in second-life module assembly. The risk of thermal events increases with cell age and previous usage patterns. Detecting potential failure modes becomes more complex as cells may exhibit unpredictable behavior after their first life cycle. Assembly processes must incorporate enhanced safety protocols beyond those used in new battery manufacturing.

Automation challenges persist throughout the assembly process. While first-life battery production benefits from highly automated assembly lines with standardized components, second-life module assembly requires more adaptive systems capable of handling variability. Current automation solutions lack the flexibility and intelligence to efficiently process diverse incoming materials.

Regulatory compliance presents additional hurdles, as standards for second-life batteries remain in development across many jurisdictions. Assembly processes must anticipate evolving requirements while ensuring traceability of components throughout the battery's extended lifecycle.

Economic viability remains a technical challenge as assembly processes must balance quality control with cost-effectiveness. Excessive testing and sorting can render second-life applications financially unviable, while insufficient quality control introduces unacceptable risks. Finding this balance requires innovative approaches to streamlined yet thorough assembly protocols.

Knowledge gaps in long-term performance prediction further complicate assembly decisions. Limited historical data exists on how various assembly techniques affect the extended performance of second-life batteries, making it difficult to optimize processes for specific applications and desired lifespans.

Current Quality Control Methodologies for Battery Modules

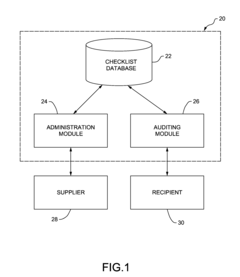

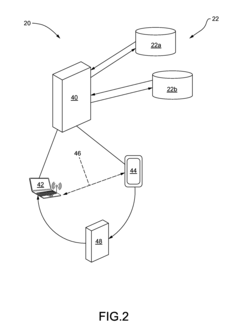

01 Digital quality control checklist systems

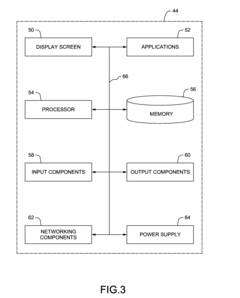

Digital systems have been developed to replace traditional paper-based quality control checklists. These systems allow for real-time data collection, automated validation, and immediate feedback. They can be implemented on various devices including tablets and smartphones, enabling quality inspectors to perform checks more efficiently. The digital format also facilitates integration with other enterprise systems and provides better traceability of quality control activities.- Automated quality control checklist systems: Automated systems for quality control checklists enhance efficiency and accuracy in quality management processes. These systems can automatically generate, update, and track checklists based on predefined criteria, reducing manual effort and human error. They often include features for real-time monitoring, data collection, and analysis to ensure compliance with quality standards across various industries.

- Software-based quality control management: Software solutions specifically designed for quality control management provide comprehensive tools for creating, implementing, and monitoring quality control checklists. These platforms often include document management capabilities, workflow automation, and integration with other enterprise systems. They enable organizations to standardize quality control processes, maintain audit trails, and facilitate collaboration among quality control teams.

- Manufacturing quality control checklist implementations: Quality control checklists tailored for manufacturing environments focus on production line monitoring, product inspection, and process verification. These checklists incorporate industry-specific requirements and standards to ensure consistent product quality. They may include visual inspection criteria, measurement parameters, and acceptance thresholds that help identify defects and maintain quality throughout the manufacturing process.

- Data analytics for quality control improvement: Advanced data analytics techniques applied to quality control processes enable organizations to identify patterns, predict potential quality issues, and continuously improve their quality management systems. These solutions analyze historical quality control data to establish benchmarks, detect anomalies, and recommend corrective actions. By leveraging machine learning and statistical analysis, organizations can enhance the effectiveness of their quality control checklists and reduce defect rates.

- Mobile and cloud-based quality control checklist solutions: Mobile and cloud-based platforms for quality control checklists provide flexibility and accessibility for quality inspectors and managers. These solutions enable real-time data collection, photo documentation, and instant reporting from any location. They facilitate immediate communication of quality issues, allowing for faster resolution and improved collaboration. Cloud storage ensures that quality control data is securely maintained and easily accessible for analysis and compliance purposes.

02 Automated quality control verification methods

Automated methods for quality control verification involve systems that can automatically check products or processes against predefined quality standards. These methods often incorporate machine learning algorithms to detect defects or anomalies without human intervention. They can analyze large volumes of data quickly, identify patterns, and flag issues that might be missed in manual inspections, thereby increasing the reliability and consistency of quality control processes.Expand Specific Solutions03 Software-based quality management systems

Software solutions specifically designed for quality management enable organizations to create, implement, and monitor quality control checklists across various operational areas. These systems often include features for checklist creation, workflow management, compliance tracking, and reporting. They provide centralized platforms where quality standards can be documented, distributed, and updated, ensuring that all stakeholders have access to the most current quality control requirements.Expand Specific Solutions04 Integration of quality control with manufacturing processes

Integration approaches focus on embedding quality control checkpoints directly within manufacturing or production processes. This integration ensures that quality checks are performed at critical stages rather than only at the end of production. Such systems often incorporate real-time monitoring, automated alerts for deviations, and process controls that can adjust operations based on quality measurements. This approach helps prevent defects rather than simply detecting them after they occur.Expand Specific Solutions05 Customizable quality control frameworks

Customizable frameworks allow organizations to tailor quality control checklists to their specific needs while maintaining compliance with industry standards. These frameworks provide templates and building blocks that can be adapted for different products, processes, or regulatory environments. They often include risk assessment tools to help prioritize quality control efforts and ensure that the most critical aspects receive appropriate attention. The flexibility of these frameworks makes them suitable for diverse industries and operational contexts.Expand Specific Solutions

Key Industry Players in Second-Life Battery Market

The second-life battery module assembly market is currently in a growth phase, with increasing demand driven by sustainability initiatives and circular economy principles. The market size is projected to expand significantly as electric vehicle adoption accelerates, creating a substantial supply of used batteries for repurposing. Technologically, the field is maturing rapidly with key players establishing quality control frameworks. Leading companies like LG Energy Solution, CATL, and Toyota are pioneering standardized testing protocols, while Samsung SDI, Northvolt, and LG Chem are developing automated inspection systems. Vehicle Energy Japan and Hitachi are focusing on specialized diagnostic tools for second-life applications. The competitive landscape features both established battery manufacturers and new entrants developing proprietary quality assurance methodologies to address the unique challenges of repurposed battery modules.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive quality control system specifically for second-life battery module assembly that incorporates multi-stage inspection protocols. Their approach begins with an AI-powered diagnostic system that evaluates each battery cell's state of health (SOH) and remaining useful life before integration into second-life modules. The company employs a standardized testing framework that includes capacity measurement, internal resistance testing, and voltage stability analysis to ensure consistent performance across repurposed modules. Their assembly line features automated optical inspection (AOI) systems that detect physical defects and connection issues with 99.7% accuracy. LG Energy Solution's quality control checklists include thermal runaway prevention protocols, with each module undergoing stress testing in environmental chambers that simulate extreme operating conditions. The company has also implemented blockchain-based traceability systems that maintain complete lifecycle data for each battery component, enabling precise quality verification throughout the second-life assembly process.

Strengths: Industry-leading diagnostic algorithms provide highly accurate cell evaluation, reducing failure rates in assembled modules. Their integrated traceability system enables complete battery history tracking from first to second life applications. Weaknesses: The extensive testing protocols increase production time and costs compared to competitors, potentially limiting scalability for mass market applications.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a systematic approach to second-life battery module assembly quality control through their "Toyota Production System" principles adapted specifically for battery reuse. Their methodology centers on a three-tier inspection framework that evaluates batteries at the cell, module, and system levels. Toyota's quality control checklists incorporate non-destructive testing techniques including ultrasonic scanning and thermographic imaging to identify internal defects without compromising battery integrity. Their process begins with automated sorting systems that categorize used batteries based on capacity retention, internal resistance, and self-discharge rates, ensuring only suitable candidates enter the remanufacturing stream. Toyota has developed specialized jigs and fixtures that standardize the reassembly process, with digital torque verification systems that ensure proper connection force for every electrical contact point. Their quality control system includes mandatory rest periods between testing phases to detect potential voltage recovery issues that might otherwise go unnoticed in rapid testing protocols. Toyota also implements accelerated aging tests on sample modules from each batch to predict long-term performance reliability in second-life applications.

Strengths: Exceptional consistency in quality outcomes due to standardized processes and specialized assembly tools. Their multi-level testing approach identifies potential failure modes that single-stage testing might miss. Weaknesses: Higher labor costs associated with their meticulous inspection protocols compared to more automated competitors. Their system requires significant technical expertise, limiting deployment in regions with workforce skill gaps.

Critical Technical Standards for Second-Life Batteries

Quality Control Checklist Systems and Methods

PatentInactiveUS20160371624A1

Innovation

- A system and method utilizing a quality control server with a checklist database to store, transmit, and update inspection checklists on portable electronic devices, allowing for auditing results and annotations, which generates and stores completed checklists, enabling efficient and standardized quality control processes.

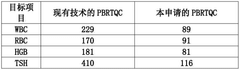

Method and system for performing real-time quality control on basis of patient sample, and method for constructing quality control model

PatentWO2024245224A1

Innovation

- Using real-time quality monitoring technology based on patient samples and neural networks, by quantifying patient information and inputting pre-trained machine learning models, monitoring indicators are obtained to determine whether the detection instrument is out of control, and to reduce the quality control performance of factors such as disease, age, and gender. Influence, reduce the number of samples required for error detection.

Safety Compliance Framework for Repurposed Batteries

The Safety Compliance Framework for repurposed batteries represents a critical infrastructure for ensuring that second-life battery modules meet stringent safety standards before deployment. This framework encompasses multiple layers of regulatory requirements, industry standards, and best practices specifically tailored to address the unique challenges posed by previously used battery systems.

At its foundation, the framework integrates international safety standards including IEC 62619 for secondary lithium cells and batteries for industrial applications, UL 1973 for batteries used in light electric rail and stationary applications, and UN 38.3 for transportation safety. These standards must be adapted to account for the degraded nature of second-life batteries, requiring more conservative safety margins than those applied to new battery systems.

The compliance structure is organized into four primary domains: electrical safety, thermal management, mechanical integrity, and chemical containment. Each domain features specific testing protocols and acceptance criteria that must be documented in the quality control checklists for second-life module assembly. For electrical safety, this includes isolation resistance verification, voltage tolerance testing, and BMS communication validation with enhanced focus on detecting internal short circuits that may have developed during the battery's first life cycle.

Risk assessment methodologies form another crucial component, with FMEA (Failure Mode and Effects Analysis) specifically modified for second-life applications. These assessments must account for the unknown stress history of the battery modules and incorporate accelerated aging test results to predict potential failure modes unique to repurposed systems.

Documentation requirements within the framework mandate comprehensive traceability records that track each module from its original application through the refurbishment process. This includes detailed performance degradation metrics, disassembly inspection reports, and component replacement records that become integral parts of the module's safety certification package.

The framework also establishes verification procedures that must be integrated into the assembly process, including staged testing at multiple points: post-disassembly, post-refurbishment, and final assembly. These verification steps must be reflected in the quality control checklists with clear pass/fail criteria and remediation protocols for modules that exhibit borderline performance characteristics.

Emergency response protocols constitute the final element of the framework, requiring that each repurposed battery system be accompanied by specific handling instructions, fire suppression recommendations, and decommissioning procedures that account for the unique characteristics of aged cells and potentially modified battery architectures.

At its foundation, the framework integrates international safety standards including IEC 62619 for secondary lithium cells and batteries for industrial applications, UL 1973 for batteries used in light electric rail and stationary applications, and UN 38.3 for transportation safety. These standards must be adapted to account for the degraded nature of second-life batteries, requiring more conservative safety margins than those applied to new battery systems.

The compliance structure is organized into four primary domains: electrical safety, thermal management, mechanical integrity, and chemical containment. Each domain features specific testing protocols and acceptance criteria that must be documented in the quality control checklists for second-life module assembly. For electrical safety, this includes isolation resistance verification, voltage tolerance testing, and BMS communication validation with enhanced focus on detecting internal short circuits that may have developed during the battery's first life cycle.

Risk assessment methodologies form another crucial component, with FMEA (Failure Mode and Effects Analysis) specifically modified for second-life applications. These assessments must account for the unknown stress history of the battery modules and incorporate accelerated aging test results to predict potential failure modes unique to repurposed systems.

Documentation requirements within the framework mandate comprehensive traceability records that track each module from its original application through the refurbishment process. This includes detailed performance degradation metrics, disassembly inspection reports, and component replacement records that become integral parts of the module's safety certification package.

The framework also establishes verification procedures that must be integrated into the assembly process, including staged testing at multiple points: post-disassembly, post-refurbishment, and final assembly. These verification steps must be reflected in the quality control checklists with clear pass/fail criteria and remediation protocols for modules that exhibit borderline performance characteristics.

Emergency response protocols constitute the final element of the framework, requiring that each repurposed battery system be accompanied by specific handling instructions, fire suppression recommendations, and decommissioning procedures that account for the unique characteristics of aged cells and potentially modified battery architectures.

Environmental Impact Assessment of Battery Reuse

The environmental impact assessment of battery reuse represents a critical component in evaluating the sustainability of second-life battery applications. When batteries reach approximately 70-80% of their original capacity, they become unsuitable for their primary applications but retain significant utility for less demanding secondary applications. This repurposing process delivers substantial environmental benefits compared to immediate recycling or disposal.

Battery reuse significantly extends the useful life of energy storage systems, effectively doubling the environmental value extracted from the original manufacturing inputs. Life cycle assessment (LCA) studies indicate that repurposing electric vehicle batteries for stationary storage applications can reduce carbon emissions by 15-70% compared to manufacturing new batteries, depending on the application scenario and energy mix used during operation.

The environmental benefits extend beyond carbon reduction. Reusing batteries delays the need for raw material extraction, particularly for critical minerals like lithium, cobalt, and nickel. This conservation effect is especially significant given that mining operations for these materials often create substantial ecological disruption, water pollution, and habitat destruction in resource-rich regions.

Water conservation represents another important environmental advantage. Battery manufacturing is water-intensive, requiring approximately 7,000-11,000 liters of water per kWh of battery capacity produced. By extending battery life through second-use applications, the water footprint per unit of energy storage is effectively reduced by 40-60% over the combined life cycles.

The assessment must also consider potential environmental risks associated with battery reuse. These include the possibility of improper handling during disassembly and reconfiguration, which could lead to electrolyte leakage or thermal events. Comprehensive quality control protocols during second-life module assembly are therefore essential to mitigate these risks and ensure environmental protection throughout the extended lifecycle.

Energy consumption during the refurbishment process must be factored into the overall environmental impact calculation. Current best practices indicate that the energy required for testing, reconfiguration, and module assembly represents only 2-5% of the embedded energy in the original battery manufacturing, creating a strongly positive environmental balance.

Regional factors significantly influence the environmental impact profile of battery reuse operations. In regions with carbon-intensive electricity grids, the benefits of battery reuse are somewhat diminished, while areas with high renewable energy penetration maximize the environmental advantages of second-life applications.

Battery reuse significantly extends the useful life of energy storage systems, effectively doubling the environmental value extracted from the original manufacturing inputs. Life cycle assessment (LCA) studies indicate that repurposing electric vehicle batteries for stationary storage applications can reduce carbon emissions by 15-70% compared to manufacturing new batteries, depending on the application scenario and energy mix used during operation.

The environmental benefits extend beyond carbon reduction. Reusing batteries delays the need for raw material extraction, particularly for critical minerals like lithium, cobalt, and nickel. This conservation effect is especially significant given that mining operations for these materials often create substantial ecological disruption, water pollution, and habitat destruction in resource-rich regions.

Water conservation represents another important environmental advantage. Battery manufacturing is water-intensive, requiring approximately 7,000-11,000 liters of water per kWh of battery capacity produced. By extending battery life through second-use applications, the water footprint per unit of energy storage is effectively reduced by 40-60% over the combined life cycles.

The assessment must also consider potential environmental risks associated with battery reuse. These include the possibility of improper handling during disassembly and reconfiguration, which could lead to electrolyte leakage or thermal events. Comprehensive quality control protocols during second-life module assembly are therefore essential to mitigate these risks and ensure environmental protection throughout the extended lifecycle.

Energy consumption during the refurbishment process must be factored into the overall environmental impact calculation. Current best practices indicate that the energy required for testing, reconfiguration, and module assembly represents only 2-5% of the embedded energy in the original battery manufacturing, creating a strongly positive environmental balance.

Regional factors significantly influence the environmental impact profile of battery reuse operations. In regions with carbon-intensive electricity grids, the benefits of battery reuse are somewhat diminished, while areas with high renewable energy penetration maximize the environmental advantages of second-life applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!