Predictive Degradation Models For Used EV Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Degradation Background and Objectives

Electric vehicle (EV) battery technology has evolved significantly over the past two decades, transitioning from early nickel-metal hydride batteries to the now-dominant lithium-ion chemistry. This evolution has been driven by the need for higher energy density, longer lifespan, and reduced costs to make EVs commercially viable alternatives to internal combustion engine vehicles. Despite these advancements, battery degradation remains one of the most critical challenges facing widespread EV adoption, with implications for vehicle range, resale value, and sustainability.

Battery degradation in EVs occurs through multiple mechanisms, including calendar aging, cycle aging, and environmental stress factors. Calendar aging refers to the degradation that occurs over time regardless of use, while cycle aging relates to capacity loss due to charge-discharge cycles. Environmental factors such as temperature extremes, charging rates, and depth of discharge significantly accelerate these degradation processes. Understanding these mechanisms is essential for developing accurate predictive models.

The objective of predictive degradation modeling for used EV cells is to accurately forecast remaining useful life and performance characteristics of batteries that have already undergone partial degradation in real-world conditions. This differs significantly from modeling new batteries, as used cells have unique degradation signatures based on their individual usage histories. Effective models must account for this heterogeneity while maintaining predictive accuracy.

Current industry standards typically estimate EV battery end-of-life at 70-80% of original capacity, but this threshold varies based on application requirements. For second-life applications such as stationary energy storage, batteries may remain useful well below this threshold. Predictive models aim to provide more nuanced assessments of battery health beyond simple capacity measurements, incorporating metrics such as internal resistance increase, power capability, and thermal behavior.

The development of these models serves multiple strategic goals: enabling more accurate valuation of used EVs, optimizing battery management systems for aging cells, facilitating effective battery refurbishment strategies, and supporting the emerging second-life battery market. Additionally, these models contribute to sustainability efforts by maximizing battery utilization before recycling becomes necessary.

Recent technological advances in sensing, data collection, and machine learning have created new opportunities for more sophisticated degradation modeling approaches. The integration of onboard diagnostics, cloud computing, and advanced analytics now allows for continuous monitoring and updating of degradation predictions throughout a battery's lifecycle, representing a significant advancement over traditional laboratory-based testing methods.

Battery degradation in EVs occurs through multiple mechanisms, including calendar aging, cycle aging, and environmental stress factors. Calendar aging refers to the degradation that occurs over time regardless of use, while cycle aging relates to capacity loss due to charge-discharge cycles. Environmental factors such as temperature extremes, charging rates, and depth of discharge significantly accelerate these degradation processes. Understanding these mechanisms is essential for developing accurate predictive models.

The objective of predictive degradation modeling for used EV cells is to accurately forecast remaining useful life and performance characteristics of batteries that have already undergone partial degradation in real-world conditions. This differs significantly from modeling new batteries, as used cells have unique degradation signatures based on their individual usage histories. Effective models must account for this heterogeneity while maintaining predictive accuracy.

Current industry standards typically estimate EV battery end-of-life at 70-80% of original capacity, but this threshold varies based on application requirements. For second-life applications such as stationary energy storage, batteries may remain useful well below this threshold. Predictive models aim to provide more nuanced assessments of battery health beyond simple capacity measurements, incorporating metrics such as internal resistance increase, power capability, and thermal behavior.

The development of these models serves multiple strategic goals: enabling more accurate valuation of used EVs, optimizing battery management systems for aging cells, facilitating effective battery refurbishment strategies, and supporting the emerging second-life battery market. Additionally, these models contribute to sustainability efforts by maximizing battery utilization before recycling becomes necessary.

Recent technological advances in sensing, data collection, and machine learning have created new opportunities for more sophisticated degradation modeling approaches. The integration of onboard diagnostics, cloud computing, and advanced analytics now allows for continuous monitoring and updating of degradation predictions throughout a battery's lifecycle, representing a significant advancement over traditional laboratory-based testing methods.

Market Analysis for Second-Life EV Battery Applications

The second-life EV battery market is experiencing significant growth as the first generation of electric vehicles reaches end-of-life status. Current market valuations estimate the global second-life battery market at approximately $2.3 billion in 2023, with projections indicating growth to $7.8 billion by 2030, representing a compound annual growth rate of 19.4%. This growth is driven by increasing EV adoption rates worldwide, creating a substantial future supply of used batteries.

Key market segments for second-life applications include stationary energy storage systems, which currently dominate with 65% market share. These applications range from residential backup power to grid-scale energy storage. The telecommunications sector represents 15% of the market, utilizing repurposed batteries for base station backup power. Other emerging applications include EV charging infrastructure support (10%), industrial equipment (7%), and miscellaneous applications (3%).

Regional analysis reveals Asia-Pacific as the leading market for second-life batteries, accounting for 48% of global demand. This dominance stems from the region's early EV adoption, particularly in China, Japan, and South Korea. Europe follows at 32%, with North America at 18%, and other regions comprising the remaining 2%. European growth is accelerated by stringent regulations promoting circular economy principles.

Market drivers include significant cost advantages, with second-life batteries typically priced 40-60% lower than new batteries while still retaining 70-80% of original capacity. Environmental regulations increasingly mandate battery recycling and reuse, creating regulatory tailwinds. Additionally, grid modernization initiatives worldwide are creating demand for flexible energy storage solutions.

Challenges facing market growth include standardization issues across different battery chemistries and form factors, creating technical barriers to scalable repurposing. Warranty and liability concerns remain unresolved in many markets, with unclear responsibility chains for repurposed products. Competition from declining new battery prices threatens the value proposition, with lithium-ion battery prices falling approximately 13% annually over the past five years.

The market demonstrates strong correlation with predictive degradation modeling capabilities. Advanced degradation models enable more accurate valuation of used batteries, potentially increasing second-life market value by 25-30% through improved sorting, application matching, and performance guarantees.

Key market segments for second-life applications include stationary energy storage systems, which currently dominate with 65% market share. These applications range from residential backup power to grid-scale energy storage. The telecommunications sector represents 15% of the market, utilizing repurposed batteries for base station backup power. Other emerging applications include EV charging infrastructure support (10%), industrial equipment (7%), and miscellaneous applications (3%).

Regional analysis reveals Asia-Pacific as the leading market for second-life batteries, accounting for 48% of global demand. This dominance stems from the region's early EV adoption, particularly in China, Japan, and South Korea. Europe follows at 32%, with North America at 18%, and other regions comprising the remaining 2%. European growth is accelerated by stringent regulations promoting circular economy principles.

Market drivers include significant cost advantages, with second-life batteries typically priced 40-60% lower than new batteries while still retaining 70-80% of original capacity. Environmental regulations increasingly mandate battery recycling and reuse, creating regulatory tailwinds. Additionally, grid modernization initiatives worldwide are creating demand for flexible energy storage solutions.

Challenges facing market growth include standardization issues across different battery chemistries and form factors, creating technical barriers to scalable repurposing. Warranty and liability concerns remain unresolved in many markets, with unclear responsibility chains for repurposed products. Competition from declining new battery prices threatens the value proposition, with lithium-ion battery prices falling approximately 13% annually over the past five years.

The market demonstrates strong correlation with predictive degradation modeling capabilities. Advanced degradation models enable more accurate valuation of used batteries, potentially increasing second-life market value by 25-30% through improved sorting, application matching, and performance guarantees.

Current Challenges in Used EV Cell Assessment

The assessment of used EV cells presents significant technical challenges that impede accurate evaluation of their remaining useful life and potential for second-life applications. Current diagnostic methods often rely on simplified models that fail to capture the complex degradation mechanisms occurring within lithium-ion batteries throughout their operational lifetime. These mechanisms include SEI layer growth, lithium plating, electrode particle cracking, and electrolyte decomposition, all of which progress non-linearly and interdependently.

One major challenge is the lack of standardized testing protocols for used EV cells. Different manufacturers employ proprietary battery management systems (BMS) that record varying parameters, making it difficult to establish universal assessment criteria. Additionally, the historical usage data necessary for accurate degradation modeling is often incomplete or inaccessible, particularly for cells from older EV models or those with multiple ownership transfers.

The heterogeneity of degradation patterns across cells within the same battery pack further complicates assessment efforts. Even cells manufactured in the same batch and subjected to seemingly identical conditions can exhibit divergent aging behaviors due to thermal gradients, manufacturing variations, and localized stress factors. This cell-to-cell variation necessitates individual assessment approaches rather than pack-level generalizations.

Current non-invasive diagnostic techniques such as electrochemical impedance spectroscopy (EIS) and incremental capacity analysis (ICA) provide valuable insights but remain time-consuming and require specialized equipment. These methods often struggle to differentiate between overlapping degradation mechanisms, leading to ambiguous interpretations of cell health. Moreover, the translation of these laboratory-based diagnostics to field applications presents significant practical challenges.

The development of predictive degradation models is further hindered by the scarcity of comprehensive end-of-life data from real-world EV applications. Most existing models are trained on accelerated aging tests that may not accurately represent actual usage conditions, leading to potential discrepancies between predicted and actual degradation trajectories.

Computational limitations also pose challenges for implementing complex physics-based models in real-time applications. While detailed electrochemical models offer greater accuracy, their computational intensity makes them impractical for on-board diagnostics or rapid screening of large battery inventories. Conversely, empirical and semi-empirical models that are computationally efficient often sacrifice accuracy and adaptability across different cell chemistries and designs.

The integration of multiple data sources—including BMS data, diagnostic measurements, and manufacturing information—into cohesive predictive models remains an unresolved challenge, requiring advanced data fusion techniques and machine learning approaches that can handle heterogeneous and incomplete datasets.

One major challenge is the lack of standardized testing protocols for used EV cells. Different manufacturers employ proprietary battery management systems (BMS) that record varying parameters, making it difficult to establish universal assessment criteria. Additionally, the historical usage data necessary for accurate degradation modeling is often incomplete or inaccessible, particularly for cells from older EV models or those with multiple ownership transfers.

The heterogeneity of degradation patterns across cells within the same battery pack further complicates assessment efforts. Even cells manufactured in the same batch and subjected to seemingly identical conditions can exhibit divergent aging behaviors due to thermal gradients, manufacturing variations, and localized stress factors. This cell-to-cell variation necessitates individual assessment approaches rather than pack-level generalizations.

Current non-invasive diagnostic techniques such as electrochemical impedance spectroscopy (EIS) and incremental capacity analysis (ICA) provide valuable insights but remain time-consuming and require specialized equipment. These methods often struggle to differentiate between overlapping degradation mechanisms, leading to ambiguous interpretations of cell health. Moreover, the translation of these laboratory-based diagnostics to field applications presents significant practical challenges.

The development of predictive degradation models is further hindered by the scarcity of comprehensive end-of-life data from real-world EV applications. Most existing models are trained on accelerated aging tests that may not accurately represent actual usage conditions, leading to potential discrepancies between predicted and actual degradation trajectories.

Computational limitations also pose challenges for implementing complex physics-based models in real-time applications. While detailed electrochemical models offer greater accuracy, their computational intensity makes them impractical for on-board diagnostics or rapid screening of large battery inventories. Conversely, empirical and semi-empirical models that are computationally efficient often sacrifice accuracy and adaptability across different cell chemistries and designs.

The integration of multiple data sources—including BMS data, diagnostic measurements, and manufacturing information—into cohesive predictive models remains an unresolved challenge, requiring advanced data fusion techniques and machine learning approaches that can handle heterogeneous and incomplete datasets.

Existing Predictive Models for Battery Health Estimation

01 Predictive models for material degradation

Advanced computational models are developed to predict the degradation behavior of various materials over time. These models incorporate factors such as environmental conditions, stress levels, and material properties to forecast when and how materials will degrade. By analyzing historical data and applying machine learning algorithms, these predictive models can accurately estimate the remaining useful life of components and materials, enabling proactive maintenance and replacement strategies.- Predictive models for material degradation: Predictive models can be developed to forecast the degradation of materials over time. These models utilize various parameters such as environmental conditions, stress factors, and material properties to predict how materials will degrade. By analyzing historical data and applying mathematical algorithms, these models can help in estimating the remaining useful life of materials and components, enabling proactive maintenance and replacement strategies before critical failure occurs.

- Machine learning approaches for degradation prediction: Machine learning techniques are increasingly being applied to develop more accurate degradation prediction models. These approaches can process large datasets to identify patterns and correlations that might not be apparent through traditional analytical methods. Neural networks, support vector machines, and other machine learning algorithms can be trained on historical degradation data to predict future degradation trajectories, improving the accuracy and reliability of degradation forecasts.

- Real-time monitoring systems for degradation assessment: Real-time monitoring systems can continuously collect data on the condition of materials and components to assess degradation. These systems utilize sensors and IoT devices to measure parameters such as temperature, pressure, vibration, and chemical composition. The collected data is then processed through degradation models to provide up-to-date assessments of component health and predict potential failures, allowing for timely interventions.

- Degradation models for specific industries and applications: Specialized degradation models have been developed for specific industries and applications, taking into account the unique degradation mechanisms and environmental conditions relevant to each context. These models may focus on particular materials, components, or systems, such as batteries, semiconductors, mechanical parts, or biological samples. By tailoring the models to specific applications, more accurate predictions of degradation behavior can be achieved.

- Integration of degradation models with maintenance planning systems: Degradation models can be integrated with maintenance planning systems to optimize maintenance schedules and resource allocation. By predicting when components are likely to fail or reach a critical degradation threshold, maintenance activities can be planned proactively rather than reactively. This integration enables condition-based maintenance strategies, reducing downtime, extending component lifespans, and minimizing maintenance costs through more efficient scheduling of inspections and replacements.

02 Machine learning approaches for degradation prediction

Machine learning techniques are increasingly applied to develop more accurate degradation prediction models. These approaches utilize neural networks, support vector machines, and other algorithms to identify patterns in degradation data that might not be apparent through traditional statistical methods. By training on extensive datasets of historical degradation information, these systems can learn to recognize early indicators of potential failure and predict future degradation trajectories with greater precision.Expand Specific Solutions03 Real-time monitoring systems for degradation assessment

Systems that continuously monitor equipment and materials for signs of degradation provide data for predictive models. These monitoring systems employ sensors to track various parameters such as temperature, vibration, pressure, and chemical composition changes that might indicate ongoing degradation processes. The real-time data collected enables dynamic updating of degradation models, allowing for more accurate predictions and timely interventions before critical failure occurs.Expand Specific Solutions04 Biological and pharmaceutical degradation prediction

Specialized predictive models are developed for biological materials and pharmaceutical products to forecast their stability and shelf life. These models account for factors such as temperature fluctuations, humidity, light exposure, and chemical interactions that can accelerate degradation in these sensitive materials. By accurately predicting degradation rates, these models help in optimizing storage conditions, formulation adjustments, and establishing appropriate expiration dates for biological and pharmaceutical products.Expand Specific Solutions05 Digital twin technology for degradation simulation

Digital twin technology creates virtual replicas of physical assets to simulate and predict degradation processes. These digital models are continuously updated with real-world data from the physical counterpart, allowing for accurate simulation of current conditions and prediction of future degradation. By running various scenarios on the digital twin, engineers can evaluate different operating conditions and maintenance strategies to minimize degradation and extend asset life without risking the actual physical asset.Expand Specific Solutions

Leading Players in EV Battery Lifecycle Management

The electric vehicle (EV) battery degradation prediction market is currently in a growth phase, with increasing demand driven by sustainability concerns and the expanding EV sector. The global market for predictive battery analytics is estimated to reach $2-3 billion by 2025. Major automotive manufacturers like Toyota, GM, Ford, and Stellantis are competing with specialized battery producers such as LG Energy Solution and Panasonic. Technology maturity varies significantly across players, with companies like Bosch, Siemens, and Toyota demonstrating advanced capabilities through extensive patent portfolios and commercial implementations. Academic institutions including MIT, Beihang University, and Zhejiang University are contributing significant research advancements, particularly in machine learning applications for degradation modeling, creating a competitive ecosystem balancing established industrial players and emerging specialized solutions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive predictive degradation model for used EV cells that combines electrochemical impedance spectroscopy (EIS) and machine learning algorithms. Their approach utilizes real-time monitoring systems that track multiple parameters including voltage fluctuations, temperature variations, and internal resistance changes across charge-discharge cycles. The company employs a dual-layer prediction framework where the first layer analyzes physical degradation mechanisms (SEI growth, lithium plating, electrode particle cracking) while the second layer implements adaptive machine learning models that continuously refine predictions based on accumulated usage data[1]. Their system can predict remaining useful life (RUL) with claimed accuracy rates exceeding 90% after calibration periods, enabling precise second-life applications sorting and valuation. LG's model also incorporates accelerated aging test data correlated with real-world usage patterns to improve prediction reliability across various operating conditions and battery chemistries.

Strengths: Industry-leading data collection infrastructure across millions of deployed cells provides exceptional training datasets for machine learning models. Their integrated Battery Management System allows for continuous model refinement through over-the-air updates. Weaknesses: The model requires significant computational resources for real-time implementation and shows reduced accuracy for cells exposed to extreme operating conditions or those with manufacturing variations.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a multi-physics predictive degradation model for used EV cells that integrates electrochemical, thermal, and mechanical degradation mechanisms. Their approach combines first-principles modeling with data-driven techniques to create a comprehensive digital twin of battery aging processes. Toyota's system employs a hierarchical framework that operates at multiple time scales - from microsecond electrochemical reactions to years-long degradation patterns. The model incorporates both calendar aging and cycle aging components, with particular emphasis on solid-electrolyte interphase (SEI) growth dynamics and active material loss[2]. A distinguishing feature is their implementation of Gaussian Process Regression algorithms that quantify uncertainty in predictions, allowing for risk-based decision making in second-life applications. Toyota has validated their model using an extensive database of field data collected from their hybrid and electric vehicle fleets, demonstrating prediction accuracy within 5-8% of actual capacity fade over extended periods (5+ years) across various operating environments[3]. The system also incorporates adaptive parameters that account for different cell chemistries, including their latest solid-state battery technology.

Strengths: Exceptional integration with vehicle telemetry systems provides continuous real-world validation data. Their uncertainty quantification approach enables risk-informed decisions for second-life applications. Weaknesses: Model complexity requires significant computational resources and specialized expertise for implementation and maintenance. The system shows reduced accuracy for cells with manufacturing defects or those subjected to abuse conditions.

Key Technologies in Battery Degradation Prediction

Device and Method for Predicting Defective Rate of Battery

PatentPendingUS20250053697A1

Innovation

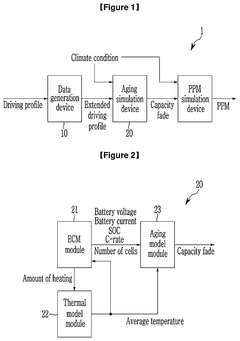

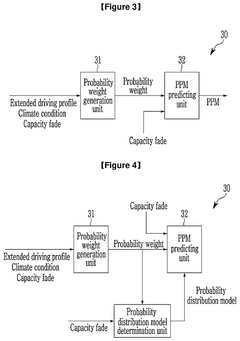

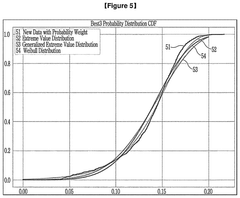

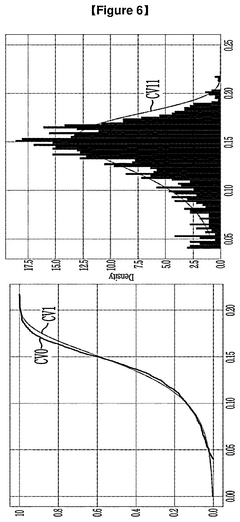

- An apparatus and method that utilize aging simulation to predict battery capacity fade, combining extended driving profiles and climate conditions to generate probability weights, and calculate a parts per million (PPM) value based on these simulations.

Battery prognosis method and system

PatentPendingUS20250180650A1

Innovation

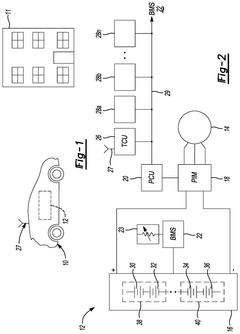

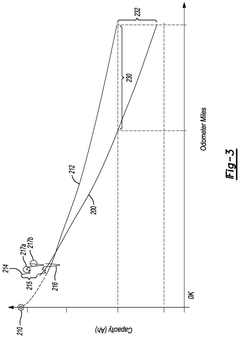

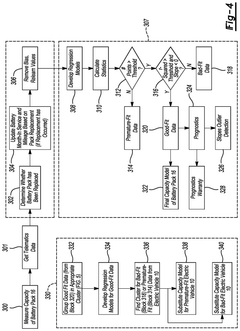

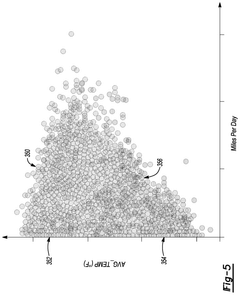

- An electric vehicle system that includes controllers programmed to measure battery data, create models of storage capacity versus distance driven or time in service, assess model reliability, and perform battery prognosis using either the primary model or a substitute model based on similar vehicles if the primary model is unreliable.

Environmental Impact and Sustainability Considerations

The development of predictive degradation models for used EV cells carries significant environmental implications that extend beyond technical performance metrics. Battery lifecycle management represents a critical sustainability challenge as global EV adoption accelerates. Current estimates suggest that by 2030, over 11 million metric tons of EV batteries will reach end-of-life status, creating an unprecedented waste management challenge if not properly addressed.

Accurate predictive degradation models enable more efficient second-life applications, substantially extending the useful lifespan of battery components before recycling becomes necessary. Research indicates that repurposed EV batteries can retain 70-80% of their original capacity, making them viable for stationary energy storage applications for an additional 5-10 years. This extension significantly improves the overall carbon footprint of battery production by amortizing manufacturing emissions across a longer operational period.

Environmental impact assessments of battery lifecycle management demonstrate that effective second-life deployment can reduce greenhouse gas emissions by 15-25% compared to scenarios where batteries proceed directly to recycling after vehicle use. Furthermore, predictive models that accurately identify optimal repurposing candidates minimize unnecessary processing and transportation, further reducing associated carbon emissions.

From a resource conservation perspective, predictive degradation models contribute to circular economy principles by maximizing material utilization efficiency. The lithium, cobalt, nickel, and other critical materials contained in EV batteries represent significant environmental extraction costs. Each year of extended battery use through accurate degradation prediction translates to proportional reductions in new material mining requirements.

Regulatory frameworks worldwide are increasingly incorporating battery sustainability metrics, with the European Union's proposed Battery Regulation establishing mandatory carbon footprint declarations and recycled content requirements. Predictive degradation models will become essential compliance tools as these regulations mature, helping manufacturers demonstrate extended product lifecycles and improved sustainability performance.

Water conservation represents another environmental benefit, as battery manufacturing typically requires 7-15 cubic meters of water per kWh of battery capacity produced. By extending useful battery life through accurate degradation prediction, the water intensity per kWh delivered over the battery's complete lifecycle is substantially reduced, contributing to more sustainable water resource management in regions where battery production occurs.

Accurate predictive degradation models enable more efficient second-life applications, substantially extending the useful lifespan of battery components before recycling becomes necessary. Research indicates that repurposed EV batteries can retain 70-80% of their original capacity, making them viable for stationary energy storage applications for an additional 5-10 years. This extension significantly improves the overall carbon footprint of battery production by amortizing manufacturing emissions across a longer operational period.

Environmental impact assessments of battery lifecycle management demonstrate that effective second-life deployment can reduce greenhouse gas emissions by 15-25% compared to scenarios where batteries proceed directly to recycling after vehicle use. Furthermore, predictive models that accurately identify optimal repurposing candidates minimize unnecessary processing and transportation, further reducing associated carbon emissions.

From a resource conservation perspective, predictive degradation models contribute to circular economy principles by maximizing material utilization efficiency. The lithium, cobalt, nickel, and other critical materials contained in EV batteries represent significant environmental extraction costs. Each year of extended battery use through accurate degradation prediction translates to proportional reductions in new material mining requirements.

Regulatory frameworks worldwide are increasingly incorporating battery sustainability metrics, with the European Union's proposed Battery Regulation establishing mandatory carbon footprint declarations and recycled content requirements. Predictive degradation models will become essential compliance tools as these regulations mature, helping manufacturers demonstrate extended product lifecycles and improved sustainability performance.

Water conservation represents another environmental benefit, as battery manufacturing typically requires 7-15 cubic meters of water per kWh of battery capacity produced. By extending useful battery life through accurate degradation prediction, the water intensity per kWh delivered over the battery's complete lifecycle is substantially reduced, contributing to more sustainable water resource management in regions where battery production occurs.

Standardization and Testing Protocols for Used Cells

The standardization of testing protocols for used EV cells represents a critical foundation for developing reliable predictive degradation models. Currently, the industry faces significant challenges due to the lack of universally accepted testing methodologies specifically designed for second-life battery assessment. This inconsistency creates barriers to accurate comparison of research findings and hinders the development of robust predictive models.

Several international organizations, including ISO, IEC, and SAE, have begun developing standards for used EV cell testing, though these efforts remain fragmented. The emerging consensus suggests that standardized protocols should include calendar aging tests, cycle life tests under various depth-of-discharge conditions, and thermal stress tests that simulate real-world operating environments. These protocols must account for the unique characteristics of previously used cells, which differ significantly from new cell testing requirements.

A comprehensive testing protocol for used cells should incorporate both non-destructive and destructive testing methods. Non-destructive techniques include electrochemical impedance spectroscopy (EIS), pulse testing, and capacity measurement, which provide valuable data without compromising cell integrity. Destructive methods, such as post-mortem analysis, offer deeper insights into degradation mechanisms but require specialized equipment and expertise.

Data collection standardization represents another crucial aspect of testing protocols. Minimum requirements should include voltage and current measurements at specified sampling rates, temperature monitoring at multiple points, and internal resistance measurements. Advanced protocols may incorporate acoustic emission monitoring and thermal imaging to detect early signs of degradation not captured by conventional measurements.

The validation of testing protocols across different cell chemistries presents additional challenges. While NMC and LFP cells dominate the current EV market, emerging chemistries like solid-state batteries will require adapted testing methodologies. Testing protocols must therefore be flexible enough to accommodate technological evolution while maintaining comparability of results.

Accelerated aging tests present particular standardization challenges, as the correlation between accelerated test results and real-world degradation remains imperfect. Research indicates that combining multiple stress factors (temperature, C-rate, DOD) provides more realistic predictions than single-factor acceleration, though standardizing these multi-factor approaches requires further development.

Implementation of round-robin testing across multiple laboratories would significantly enhance protocol reliability and facilitate wider adoption of standardized approaches. Such collaborative validation efforts would help establish confidence in testing methodologies and accelerate the development of accurate predictive degradation models for used EV cells.

Several international organizations, including ISO, IEC, and SAE, have begun developing standards for used EV cell testing, though these efforts remain fragmented. The emerging consensus suggests that standardized protocols should include calendar aging tests, cycle life tests under various depth-of-discharge conditions, and thermal stress tests that simulate real-world operating environments. These protocols must account for the unique characteristics of previously used cells, which differ significantly from new cell testing requirements.

A comprehensive testing protocol for used cells should incorporate both non-destructive and destructive testing methods. Non-destructive techniques include electrochemical impedance spectroscopy (EIS), pulse testing, and capacity measurement, which provide valuable data without compromising cell integrity. Destructive methods, such as post-mortem analysis, offer deeper insights into degradation mechanisms but require specialized equipment and expertise.

Data collection standardization represents another crucial aspect of testing protocols. Minimum requirements should include voltage and current measurements at specified sampling rates, temperature monitoring at multiple points, and internal resistance measurements. Advanced protocols may incorporate acoustic emission monitoring and thermal imaging to detect early signs of degradation not captured by conventional measurements.

The validation of testing protocols across different cell chemistries presents additional challenges. While NMC and LFP cells dominate the current EV market, emerging chemistries like solid-state batteries will require adapted testing methodologies. Testing protocols must therefore be flexible enough to accommodate technological evolution while maintaining comparability of results.

Accelerated aging tests present particular standardization challenges, as the correlation between accelerated test results and real-world degradation remains imperfect. Research indicates that combining multiple stress factors (temperature, C-rate, DOD) provides more realistic predictions than single-factor acceleration, though standardizing these multi-factor approaches requires further development.

Implementation of round-robin testing across multiple laboratories would significantly enhance protocol reliability and facilitate wider adoption of standardized approaches. Such collaborative validation efforts would help establish confidence in testing methodologies and accelerate the development of accurate predictive degradation models for used EV cells.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!