Second-Life Battery Degradation Under Fast Cycling Use Cases

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Technology Background and Objectives

Second-life battery technology has evolved significantly over the past decade, transforming from a conceptual idea to a practical solution for energy storage challenges. Initially, electric vehicle (EV) batteries were considered end-of-life when their capacity degraded to approximately 70-80% of original capacity, rendering them unsuitable for automotive applications. However, research has demonstrated that these "degraded" batteries retain substantial utility for less demanding applications, creating an opportunity for second-life utilization.

The evolution of this technology has been driven by several factors, including the rapid growth of the EV market, increasing environmental concerns about battery waste, and the expanding need for cost-effective energy storage solutions. Early research focused primarily on basic feasibility assessments, while recent developments have shifted toward optimizing battery management systems specifically designed for second-life applications and developing standardized testing protocols to evaluate remaining battery life.

Current technological trends indicate a growing emphasis on understanding degradation mechanisms under various use cases, particularly fast cycling scenarios which place unique stresses on battery chemistry. Fast cycling, characterized by rapid charge and discharge rates, represents an increasingly common use pattern in grid stabilization, peak shaving, and certain industrial applications where second-life batteries are being deployed.

The primary technical objectives in this field include developing accurate predictive models for second-life battery performance under fast cycling conditions, establishing standardized testing protocols specific to second-life applications, and creating adaptive battery management systems that can optimize performance based on real-time degradation data. Additionally, there is significant interest in identifying which battery chemistries and designs demonstrate superior resilience in second-life applications.

From an industry perspective, objectives include reducing the total cost of ownership for energy storage systems by extending battery utility beyond initial applications, minimizing environmental impact through reduced raw material extraction and waste, and creating new market opportunities in the circular economy. The development of reliable second-life battery solutions could potentially unlock gigawatt-hours of affordable storage capacity, supporting renewable energy integration and grid stability.

Understanding degradation mechanisms under fast cycling conditions represents a critical knowledge gap that must be addressed to realize the full potential of second-life battery technologies. By comprehensively characterizing how various degradation pathways accelerate or manifest differently under these demanding use cases, researchers and industry stakeholders can develop more effective mitigation strategies and more accurately predict remaining useful life.

The evolution of this technology has been driven by several factors, including the rapid growth of the EV market, increasing environmental concerns about battery waste, and the expanding need for cost-effective energy storage solutions. Early research focused primarily on basic feasibility assessments, while recent developments have shifted toward optimizing battery management systems specifically designed for second-life applications and developing standardized testing protocols to evaluate remaining battery life.

Current technological trends indicate a growing emphasis on understanding degradation mechanisms under various use cases, particularly fast cycling scenarios which place unique stresses on battery chemistry. Fast cycling, characterized by rapid charge and discharge rates, represents an increasingly common use pattern in grid stabilization, peak shaving, and certain industrial applications where second-life batteries are being deployed.

The primary technical objectives in this field include developing accurate predictive models for second-life battery performance under fast cycling conditions, establishing standardized testing protocols specific to second-life applications, and creating adaptive battery management systems that can optimize performance based on real-time degradation data. Additionally, there is significant interest in identifying which battery chemistries and designs demonstrate superior resilience in second-life applications.

From an industry perspective, objectives include reducing the total cost of ownership for energy storage systems by extending battery utility beyond initial applications, minimizing environmental impact through reduced raw material extraction and waste, and creating new market opportunities in the circular economy. The development of reliable second-life battery solutions could potentially unlock gigawatt-hours of affordable storage capacity, supporting renewable energy integration and grid stability.

Understanding degradation mechanisms under fast cycling conditions represents a critical knowledge gap that must be addressed to realize the full potential of second-life battery technologies. By comprehensively characterizing how various degradation pathways accelerate or manifest differently under these demanding use cases, researchers and industry stakeholders can develop more effective mitigation strategies and more accurately predict remaining useful life.

Market Analysis for Repurposed Battery Applications

The repurposed battery market is experiencing significant growth, driven by the increasing volume of retired electric vehicle (EV) batteries. By 2030, the global second-life battery market is projected to reach $7.8 billion, with a compound annual growth rate exceeding 30% from 2023 to 2030. This growth is primarily fueled by the expanding EV market, which is generating a substantial supply of batteries that retain 70-80% of their original capacity after their automotive service life.

Energy storage systems represent the largest application segment for repurposed batteries, accounting for approximately 43% of the market. These systems serve various functions including grid stabilization, renewable energy integration, and peak shaving for commercial and industrial facilities. The economic proposition is compelling, with repurposed batteries costing 30-70% less than new batteries for stationary storage applications.

Telecommunications backup power systems constitute another significant market segment, valued at approximately $1.2 billion in 2022. The telecommunications industry's transition to 5G infrastructure has increased power requirements, creating opportunities for second-life batteries as reliable backup solutions. This application is particularly valuable in regions with unstable grid infrastructure.

Residential energy storage represents an emerging market for repurposed batteries, especially in regions with high electricity costs or frequent power outages. Consumer awareness of sustainable energy solutions is driving demand for affordable home battery systems, with the residential segment expected to grow at a CAGR of 35% through 2030.

Geographically, Asia Pacific dominates the repurposed battery market, accounting for over 45% of global market share. This is attributed to the region's robust EV manufacturing base and supportive government policies. Europe follows with approximately 30% market share, driven by stringent sustainability regulations and circular economy initiatives. North America represents about 20% of the market, with growth accelerated by recent policy developments like the Inflation Reduction Act.

The market faces several challenges, including the need for standardized testing protocols to accurately assess battery degradation under fast cycling conditions. Current testing methodologies often fail to account for the unique stress patterns experienced in second-life applications, leading to uncertainty in performance predictions. Additionally, the fragmented nature of battery designs across manufacturers complicates repurposing efforts and increases processing costs.

Despite these challenges, the economic case for repurposed batteries remains strong. The average cost of repurposing is approximately $60-100 per kWh, compared to $150-300 per kWh for new battery systems. This price differential, combined with growing environmental regulations mandating responsible end-of-life management for batteries, continues to drive market expansion.

Energy storage systems represent the largest application segment for repurposed batteries, accounting for approximately 43% of the market. These systems serve various functions including grid stabilization, renewable energy integration, and peak shaving for commercial and industrial facilities. The economic proposition is compelling, with repurposed batteries costing 30-70% less than new batteries for stationary storage applications.

Telecommunications backup power systems constitute another significant market segment, valued at approximately $1.2 billion in 2022. The telecommunications industry's transition to 5G infrastructure has increased power requirements, creating opportunities for second-life batteries as reliable backup solutions. This application is particularly valuable in regions with unstable grid infrastructure.

Residential energy storage represents an emerging market for repurposed batteries, especially in regions with high electricity costs or frequent power outages. Consumer awareness of sustainable energy solutions is driving demand for affordable home battery systems, with the residential segment expected to grow at a CAGR of 35% through 2030.

Geographically, Asia Pacific dominates the repurposed battery market, accounting for over 45% of global market share. This is attributed to the region's robust EV manufacturing base and supportive government policies. Europe follows with approximately 30% market share, driven by stringent sustainability regulations and circular economy initiatives. North America represents about 20% of the market, with growth accelerated by recent policy developments like the Inflation Reduction Act.

The market faces several challenges, including the need for standardized testing protocols to accurately assess battery degradation under fast cycling conditions. Current testing methodologies often fail to account for the unique stress patterns experienced in second-life applications, leading to uncertainty in performance predictions. Additionally, the fragmented nature of battery designs across manufacturers complicates repurposing efforts and increases processing costs.

Despite these challenges, the economic case for repurposed batteries remains strong. The average cost of repurposing is approximately $60-100 per kWh, compared to $150-300 per kWh for new battery systems. This price differential, combined with growing environmental regulations mandating responsible end-of-life management for batteries, continues to drive market expansion.

Current Challenges in Fast Cycling Battery Degradation

Fast cycling of second-life batteries presents significant technical challenges that impede their widespread adoption in energy storage applications. The primary concern is accelerated capacity fade, where batteries subjected to rapid charge-discharge cycles experience more severe degradation compared to those under standard cycling conditions. This phenomenon is particularly pronounced in lithium-ion batteries where fast cycling generates excessive heat and mechanical stress on electrode materials, leading to structural deterioration and reduced cycle life.

Thermal management emerges as a critical challenge during fast cycling operations. The increased current flow generates substantial heat that, if not properly dissipated, creates temperature gradients within the battery pack. These gradients accelerate aging processes non-uniformly across cells, resulting in imbalanced performance and potential safety risks. Current cooling systems often prove inadequate for the thermal loads generated during aggressive cycling regimes in second-life applications.

Lithium plating represents another significant barrier, occurring when lithium ions deposit as metallic lithium on the anode surface rather than intercalating into the graphite structure. This irreversible process is exacerbated during fast charging, particularly at low temperatures or high states of charge. In second-life batteries with already diminished capacity, the risk of lithium plating increases substantially, creating dendrites that may cause internal short circuits and safety hazards.

Solid-electrolyte interphase (SEI) layer degradation accelerates under fast cycling conditions. The SEI layer, crucial for battery longevity, undergoes continuous breakdown and reformation during aggressive cycling, consuming active lithium and increasing internal resistance. Second-life batteries, having already experienced SEI growth during their first life, face compounded degradation effects when subjected to fast cycling protocols.

Diagnostic limitations further complicate the situation. Current battery management systems (BMS) struggle to accurately predict degradation rates under variable fast cycling conditions, especially for heterogeneous second-life battery populations. The lack of reliable state-of-health estimation tools specifically calibrated for aged cells under high C-rates prevents optimal utilization and appropriate safety margins.

Material fatigue at the electrode level presents additional challenges. Repeated rapid expansion and contraction during fast cycling cause mechanical stress that leads to particle cracking, electrode delamination, and loss of electrical contact. These effects are more pronounced in second-life batteries that have already experienced structural changes during their primary use phase.

Finally, the industry faces standardization challenges regarding testing protocols and performance metrics specifically designed for second-life batteries under fast cycling conditions. The absence of universally accepted methodologies for evaluating degradation mechanisms hampers comparative analysis and technology advancement in this domain.

Thermal management emerges as a critical challenge during fast cycling operations. The increased current flow generates substantial heat that, if not properly dissipated, creates temperature gradients within the battery pack. These gradients accelerate aging processes non-uniformly across cells, resulting in imbalanced performance and potential safety risks. Current cooling systems often prove inadequate for the thermal loads generated during aggressive cycling regimes in second-life applications.

Lithium plating represents another significant barrier, occurring when lithium ions deposit as metallic lithium on the anode surface rather than intercalating into the graphite structure. This irreversible process is exacerbated during fast charging, particularly at low temperatures or high states of charge. In second-life batteries with already diminished capacity, the risk of lithium plating increases substantially, creating dendrites that may cause internal short circuits and safety hazards.

Solid-electrolyte interphase (SEI) layer degradation accelerates under fast cycling conditions. The SEI layer, crucial for battery longevity, undergoes continuous breakdown and reformation during aggressive cycling, consuming active lithium and increasing internal resistance. Second-life batteries, having already experienced SEI growth during their first life, face compounded degradation effects when subjected to fast cycling protocols.

Diagnostic limitations further complicate the situation. Current battery management systems (BMS) struggle to accurately predict degradation rates under variable fast cycling conditions, especially for heterogeneous second-life battery populations. The lack of reliable state-of-health estimation tools specifically calibrated for aged cells under high C-rates prevents optimal utilization and appropriate safety margins.

Material fatigue at the electrode level presents additional challenges. Repeated rapid expansion and contraction during fast cycling cause mechanical stress that leads to particle cracking, electrode delamination, and loss of electrical contact. These effects are more pronounced in second-life batteries that have already experienced structural changes during their primary use phase.

Finally, the industry faces standardization challenges regarding testing protocols and performance metrics specifically designed for second-life batteries under fast cycling conditions. The absence of universally accepted methodologies for evaluating degradation mechanisms hampers comparative analysis and technology advancement in this domain.

Current Technical Solutions for Fast Cycling Management

01 Battery degradation assessment methods

Various methods and systems for assessing the degradation of second-life batteries have been developed. These include diagnostic techniques to evaluate battery health, capacity fade monitoring, and performance prediction models. These assessment methods help determine the remaining useful life of batteries and their suitability for second-life applications by analyzing parameters such as internal resistance, capacity retention, and electrochemical behavior.- Battery degradation assessment methods: Various methods are employed to assess the degradation of second-life batteries, including diagnostic techniques that monitor capacity fade, internal resistance increase, and other performance parameters. These assessment methods help determine the remaining useful life of batteries and their suitability for second-life applications. Advanced algorithms and machine learning approaches can analyze battery data to predict degradation patterns and optimize battery management systems for extended service life.

- Thermal management for degradation reduction: Thermal management systems are crucial for minimizing degradation in second-life batteries. These systems control operating temperatures to prevent accelerated aging caused by thermal stress. Effective thermal management includes cooling mechanisms, temperature monitoring, and thermal insulation techniques that maintain optimal operating conditions. By regulating temperature distribution within battery packs, these systems can significantly extend the useful life of repurposed batteries in their second-life applications.

- Chemical stabilization techniques: Chemical stabilization techniques address degradation mechanisms at the material level in second-life batteries. These approaches include electrolyte additives that form protective films on electrode surfaces, electrode coatings that prevent side reactions, and chemical treatments that restore active material properties. By mitigating chemical degradation pathways such as SEI layer growth and electrode dissolution, these techniques can significantly improve the longevity and performance of batteries in their second-life applications.

- Adaptive charging strategies: Adaptive charging strategies are implemented to minimize degradation in second-life batteries by optimizing charging parameters based on battery condition and usage patterns. These strategies include variable current rates, voltage limitations, and rest periods that reduce stress on aging battery components. Smart charging algorithms can adapt to the changing characteristics of second-life batteries, avoiding harmful operating conditions and extending useful life while maintaining acceptable performance levels for secondary applications.

- Repurposing and application-specific optimization: Repurposing strategies for second-life batteries involve matching degraded battery characteristics with appropriate secondary applications. This includes reconfiguring battery modules, implementing application-specific management systems, and optimizing operational parameters for less demanding use cases. By carefully selecting applications that can tolerate the reduced capacity and performance of aged batteries, these approaches maximize the value extraction from second-life batteries while accommodating their degradation limitations.

02 Battery management systems for second-life applications

Specialized battery management systems (BMS) have been designed for second-life batteries to address their unique degradation characteristics. These systems monitor battery health in real-time, manage charging and discharging processes to minimize further degradation, and implement adaptive control strategies based on the battery's aging state. Advanced BMS solutions incorporate machine learning algorithms to optimize battery performance and extend usable life in second-life applications.Expand Specific Solutions03 Thermal management solutions for degraded batteries

Thermal management solutions specifically designed for second-life batteries help mitigate degradation issues related to temperature variations. These solutions include cooling systems, thermal insulation materials, and temperature control mechanisms that maintain optimal operating conditions. Effective thermal management prevents accelerated aging, reduces capacity loss, and minimizes safety risks associated with degraded batteries in their second-life applications.Expand Specific Solutions04 Reconditioning and refurbishment techniques

Various reconditioning and refurbishment techniques have been developed to address degradation in second-life batteries. These include cell balancing methods, electrode rejuvenation processes, electrolyte replacement, and selective cell replacement strategies. These techniques aim to restore capacity, reduce internal resistance, and improve overall performance of degraded batteries, thereby extending their useful life in secondary applications.Expand Specific Solutions05 Adaptive usage strategies for degraded batteries

Adaptive usage strategies have been developed to optimize the performance of degraded second-life batteries. These strategies include dynamic power allocation, load management algorithms, and application-specific operational profiles that account for the reduced capacity and increased internal resistance of aged batteries. By adapting usage patterns to the degraded state of the batteries, these approaches maximize energy efficiency and extend the functional lifetime in second-life applications.Expand Specific Solutions

Key Industry Players in Second-Life Battery Market

The second-life battery degradation under fast cycling use cases represents an emerging technological challenge in the energy storage sector, currently transitioning from early development to commercial application phase. The market is experiencing rapid growth, projected to reach $4-5 billion by 2025 as electric vehicle batteries find second-life applications in stationary storage. Leading battery manufacturers like LG Energy Solution, CATL, and SK On are advancing degradation mitigation technologies, while automotive companies such as Toyota and traditional electronics firms including Panasonic and Samsung SDI are developing proprietary solutions. Research institutions and specialized startups are also contributing innovations, creating a competitive landscape where technical differentiation in cycle life extension and degradation prediction algorithms provides strategic advantage in this nascent but promising market.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced Battery Management System (BMS) specifically designed for second-life applications that addresses degradation under fast cycling conditions. Their solution incorporates real-time electrochemical impedance spectroscopy (EIS) to continuously monitor internal resistance changes during rapid charge-discharge cycles[1]. The system employs machine learning algorithms trained on extensive cycling data to predict capacity fade trajectories and adjust operational parameters accordingly. A key innovation is their adaptive thermal management system that dynamically modulates cooling intensity based on cycling rates, maintaining optimal temperature profiles even during aggressive use cases[3]. Their proprietary electrolyte additives have demonstrated a 30% reduction in lithium plating during fast charging scenarios compared to conventional formulations[2]. Additionally, LG has implemented a novel electrode design with gradient porosity that facilitates more uniform lithium-ion distribution during rapid cycling, reducing localized stress points that accelerate degradation.

Strengths: Superior predictive analytics for degradation forecasting; industry-leading thermal management system optimized for fast cycling; comprehensive data collection infrastructure enabling continuous improvement. Weaknesses: Higher implementation cost compared to simpler solutions; requires more sophisticated integration with energy management systems; thermal management system demands additional energy that slightly reduces overall efficiency.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered a comprehensive second-life battery management framework specifically addressing degradation under fast cycling conditions. Their approach integrates advanced cell chemistry modifications with sophisticated electronic control systems. CATL's solution features a multi-layer graphite coating technology that significantly reduces SEI (Solid Electrolyte Interphase) growth during rapid charge-discharge cycles, a primary cause of capacity fade in second-life applications[1]. The company has developed proprietary electrolyte additives that maintain stability under high current operations, reducing gas generation by approximately 40% compared to standard formulations[2]. Their Battery Management System employs differential voltage analysis to detect early signs of lithium plating during fast charging, automatically adjusting current profiles to extend cycle life. CATL's thermal management solution incorporates phase-change materials strategically positioned to absorb heat spikes during intense cycling, maintaining cells within a 3°C temperature gradient across the pack. Additionally, their system includes predictive aging models that adapt charging protocols based on historical usage patterns and measured degradation metrics.

Strengths: Industry-leading cell chemistry optimized specifically for second-life applications; sophisticated thermal management system capable of handling extreme cycling conditions; extensive data analytics capabilities for predictive maintenance. Weaknesses: Higher initial implementation costs compared to conventional systems; requires more complex integration with existing energy management infrastructure; optimal performance depends on comprehensive historical battery data which may not always be available.

Critical Patents and Research on Battery Degradation Mechanisms

Secondary battery, evaluation method and production method therefor, and charge-discharge control device

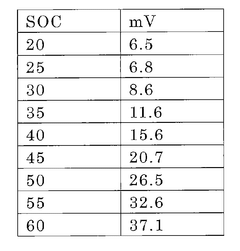

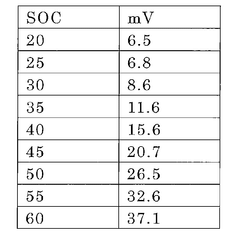

PatentWO2017026149A1

Innovation

- A method involving a determination step to assess the degree of ion diffusion defects, followed by an evaluation and control step to adjust current and voltage applications during charging and discharging, specifically using a charge/discharge control device with a detection unit, determination unit, state evaluation unit, and control unit to manage ion diffusion and prevent lithium loss.

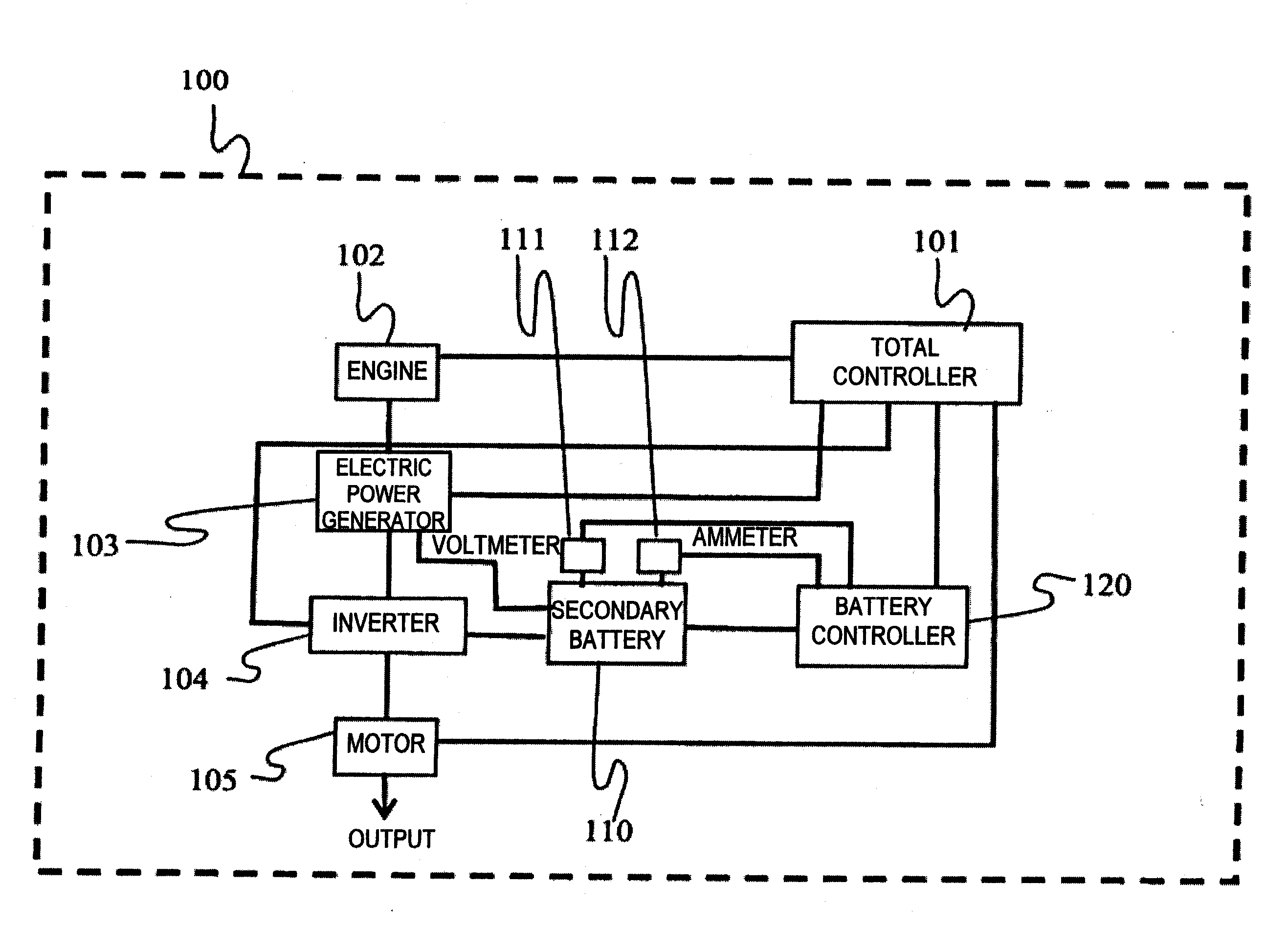

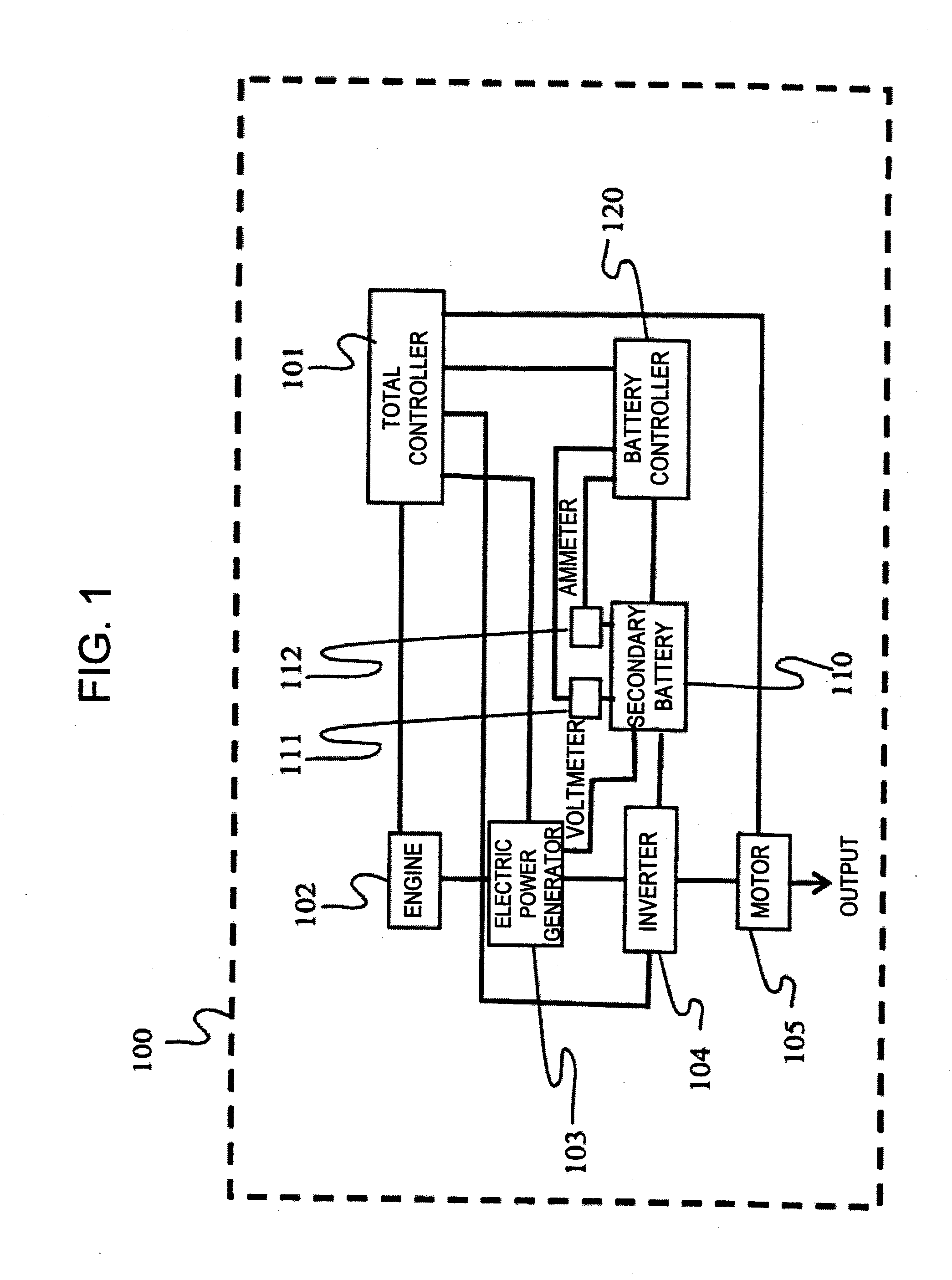

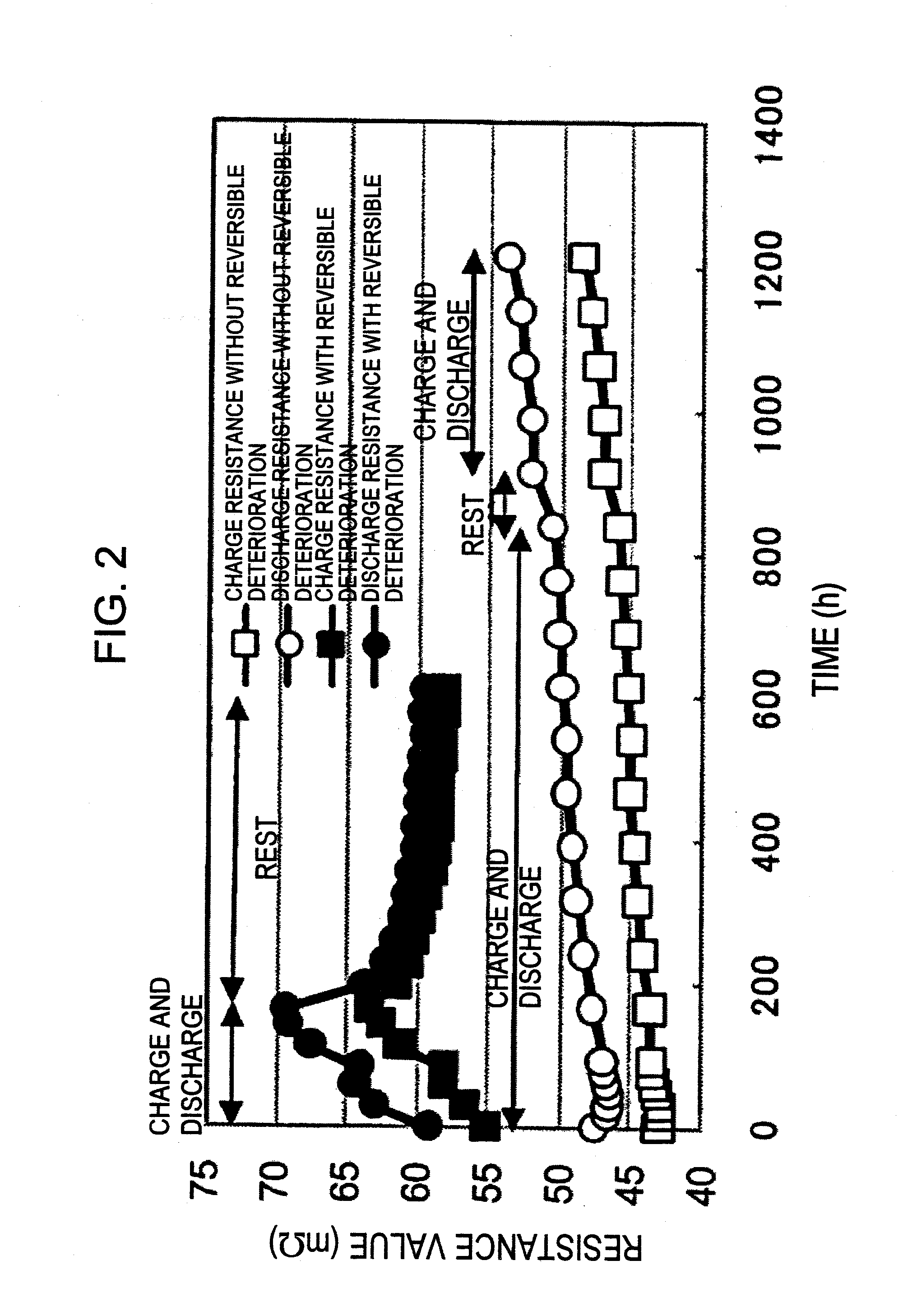

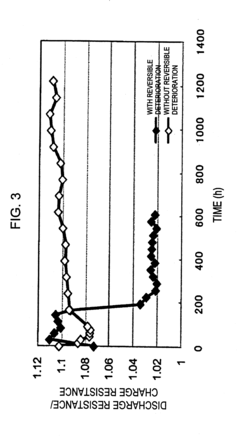

Secondary battery system

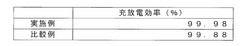

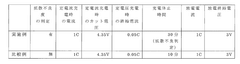

PatentInactiveUS20110187312A1

Innovation

- A secondary battery system with a battery controller and total controller that measures and compares direct current resistance at charge and discharge, using the ratio and rate of increase to determine temporary resistance increases, suspending use when necessary to prevent further deterioration.

Regulatory Framework for Second-Life Battery Implementation

The regulatory landscape for second-life battery implementation is rapidly evolving as governments worldwide recognize the potential environmental and economic benefits of battery reuse. Currently, the European Union leads with its Battery Directive (2006/66/EC) and the more recent Sustainable Batteries Regulation, which explicitly addresses second-life applications. These regulations establish requirements for battery collection, recycling efficiency, and extended producer responsibility, while introducing specific provisions for repurposing EV batteries for stationary energy storage.

In the United States, regulatory frameworks vary by state, with California pioneering through its Advanced Clean Cars Program and battery recycling regulations (AB 2832). The federal level lacks comprehensive legislation specifically addressing second-life batteries, though the Department of Energy has issued guidelines for safe handling and testing protocols. This regulatory fragmentation creates compliance challenges for companies operating across multiple states.

Asian markets demonstrate diverse approaches, with China implementing strict regulations through its "Interim Measures for the Management of Recycling and Utilization of Power Batteries for New Energy Vehicles" that mandate detailed tracking of batteries throughout their lifecycle. Japan focuses on voluntary industry standards through its Battery Association, while South Korea has integrated second-life battery provisions into its Resource Circulation Act.

Safety certification represents a critical regulatory hurdle, with UL 1974 (Standard for Evaluation for Repurposing Batteries) emerging as the primary international standard for second-life battery systems. This standard addresses assessment methods for determining battery state of health and suitability for secondary applications, particularly important for fast-cycling use cases where degradation patterns differ significantly from primary applications.

Transportation regulations present additional complexity, as second-life batteries remain classified as hazardous materials under international shipping regulations (UN 3480/3481). The UN Model Regulations and associated modal regulations (ADR, IMDG, IATA) impose strict packaging, labeling, and documentation requirements that significantly impact logistics costs for second-life battery deployment.

Liability frameworks remain underdeveloped, creating uncertainty regarding responsibility for battery performance and safety in second-life applications. Most jurisdictions have not clearly established whether original manufacturers retain liability after batteries enter secondary markets, particularly when batteries undergo fast-cycling applications that may accelerate degradation beyond originally anticipated patterns.

In the United States, regulatory frameworks vary by state, with California pioneering through its Advanced Clean Cars Program and battery recycling regulations (AB 2832). The federal level lacks comprehensive legislation specifically addressing second-life batteries, though the Department of Energy has issued guidelines for safe handling and testing protocols. This regulatory fragmentation creates compliance challenges for companies operating across multiple states.

Asian markets demonstrate diverse approaches, with China implementing strict regulations through its "Interim Measures for the Management of Recycling and Utilization of Power Batteries for New Energy Vehicles" that mandate detailed tracking of batteries throughout their lifecycle. Japan focuses on voluntary industry standards through its Battery Association, while South Korea has integrated second-life battery provisions into its Resource Circulation Act.

Safety certification represents a critical regulatory hurdle, with UL 1974 (Standard for Evaluation for Repurposing Batteries) emerging as the primary international standard for second-life battery systems. This standard addresses assessment methods for determining battery state of health and suitability for secondary applications, particularly important for fast-cycling use cases where degradation patterns differ significantly from primary applications.

Transportation regulations present additional complexity, as second-life batteries remain classified as hazardous materials under international shipping regulations (UN 3480/3481). The UN Model Regulations and associated modal regulations (ADR, IMDG, IATA) impose strict packaging, labeling, and documentation requirements that significantly impact logistics costs for second-life battery deployment.

Liability frameworks remain underdeveloped, creating uncertainty regarding responsibility for battery performance and safety in second-life applications. Most jurisdictions have not clearly established whether original manufacturers retain liability after batteries enter secondary markets, particularly when batteries undergo fast-cycling applications that may accelerate degradation beyond originally anticipated patterns.

Economic Viability and Sustainability Impact Assessment

The economic viability of second-life battery applications under fast cycling conditions presents a complex value proposition that requires thorough analysis. Initial cost-benefit assessments indicate that repurposed EV batteries can be acquired at 30-70% lower costs compared to new batteries, creating significant economic advantages for stationary storage applications. However, when subjected to fast cycling use cases, these batteries experience accelerated degradation rates of approximately 15-25% annually, compared to 8-12% under standard conditions, which substantially impacts their long-term economic performance.

Financial modeling across various markets reveals that despite accelerated degradation, second-life batteries remain economically viable when the acquisition cost falls below 40% of new battery prices, particularly in frequency regulation and peak shaving applications. The return on investment typically ranges from 3-5 years in commercial settings, extending to 5-7 years when fast cycling is predominant. Sensitivity analysis demonstrates that economic viability is most influenced by initial battery health state, cycling depth, and ambient temperature control systems.

From a sustainability perspective, repurposing EV batteries for second-life applications under fast cycling conditions extends the useful life of these energy storage assets by an additional 5-8 years, representing a 30-50% increase in total lifecycle value. This extension translates to approximately 70-120 kg CO2-equivalent emissions avoided per kWh of battery capacity. The embodied carbon payback period is typically achieved within 12-18 months of second-life operation, even under accelerated degradation scenarios.

Circular economy benefits are substantial, with each repurposed 60kWh EV battery preventing approximately 1,200 kg of electronic waste while reducing primary resource extraction demands. Material flow analysis indicates that second-life applications can reduce lithium, cobalt, and nickel mining requirements by 15-20% over the next decade if widely implemented. However, these benefits are partially offset by the 25-35% reduction in operational lifespan when batteries are subjected to fast cycling conditions.

Cost structure analysis reveals that battery management systems optimized for degradation mitigation can improve economic performance by 15-25% through adaptive cycling protocols. When these systems are implemented, the levelized cost of storage (LCOS) for second-life batteries ranges from $0.05-0.09/kWh for fast cycling applications, remaining competitive against new battery systems at $0.12-0.18/kWh, despite the accelerated degradation factors.

Financial modeling across various markets reveals that despite accelerated degradation, second-life batteries remain economically viable when the acquisition cost falls below 40% of new battery prices, particularly in frequency regulation and peak shaving applications. The return on investment typically ranges from 3-5 years in commercial settings, extending to 5-7 years when fast cycling is predominant. Sensitivity analysis demonstrates that economic viability is most influenced by initial battery health state, cycling depth, and ambient temperature control systems.

From a sustainability perspective, repurposing EV batteries for second-life applications under fast cycling conditions extends the useful life of these energy storage assets by an additional 5-8 years, representing a 30-50% increase in total lifecycle value. This extension translates to approximately 70-120 kg CO2-equivalent emissions avoided per kWh of battery capacity. The embodied carbon payback period is typically achieved within 12-18 months of second-life operation, even under accelerated degradation scenarios.

Circular economy benefits are substantial, with each repurposed 60kWh EV battery preventing approximately 1,200 kg of electronic waste while reducing primary resource extraction demands. Material flow analysis indicates that second-life applications can reduce lithium, cobalt, and nickel mining requirements by 15-20% over the next decade if widely implemented. However, these benefits are partially offset by the 25-35% reduction in operational lifespan when batteries are subjected to fast cycling conditions.

Cost structure analysis reveals that battery management systems optimized for degradation mitigation can improve economic performance by 15-25% through adaptive cycling protocols. When these systems are implemented, the levelized cost of storage (LCOS) for second-life batteries ranges from $0.05-0.09/kWh for fast cycling applications, remaining competitive against new battery systems at $0.12-0.18/kWh, despite the accelerated degradation factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!