Power Electronics Interfaces For Heterogeneous SLB Packs

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Electronics Interface Technology Background and Objectives

Power electronics interfaces for Second Life Battery (SLB) packs have emerged as a critical technology in the sustainable energy ecosystem. The evolution of this technology can be traced back to the early 2010s when electric vehicle (EV) adoption began to accelerate, creating a subsequent need for battery repurposing solutions. Initially, these interfaces were rudimentary, focusing primarily on basic voltage conversion without sophisticated management capabilities. As the volume of retired EV batteries grew, the technology evolved to address the inherent challenges of heterogeneous battery characteristics.

The technological trajectory has been shaped by several key factors, including the increasing diversity of battery chemistries, form factors, and degradation states in the secondary market. Early systems typically handled homogeneous battery packs from a single manufacturer, but current interfaces must accommodate multiple battery types with varying states of health, capacities, and discharge characteristics. This heterogeneity presents unique engineering challenges that have driven innovation in power electronics design.

Recent advancements have focused on developing adaptive power conversion architectures that can dynamically adjust to the changing characteristics of SLB packs. These systems incorporate sophisticated sensing, control algorithms, and modular designs to optimize energy extraction while ensuring safe operation. The integration of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has enabled higher efficiency and power density in these interfaces.

The primary technical objectives in this field include maximizing the usable capacity of heterogeneous battery packs, extending their operational lifetime, and ensuring safe integration with various energy systems. This requires developing interfaces that can accurately assess individual battery module conditions, balance energy flow, and provide robust protection mechanisms. Additionally, these interfaces must be cost-effective to maintain the economic viability of SLB solutions compared to new battery alternatives.

Another critical objective is standardization of communication protocols and electrical interfaces to facilitate broader adoption across different battery types and applications. Current efforts are focused on creating flexible architectures that can adapt to various battery management systems while maintaining compatibility with grid requirements and energy management systems.

Looking forward, the technology is expected to evolve toward more intelligent systems incorporating machine learning algorithms for predictive health management and adaptive control. These advanced interfaces will likely feature enhanced connectivity for remote monitoring and management, supporting the growing ecosystem of distributed energy resources. The ultimate goal is to develop seamless integration solutions that can effectively incorporate heterogeneous SLB packs into renewable energy systems, microgrids, and grid-scale storage applications, thereby maximizing the value extraction from retired EV batteries.

The technological trajectory has been shaped by several key factors, including the increasing diversity of battery chemistries, form factors, and degradation states in the secondary market. Early systems typically handled homogeneous battery packs from a single manufacturer, but current interfaces must accommodate multiple battery types with varying states of health, capacities, and discharge characteristics. This heterogeneity presents unique engineering challenges that have driven innovation in power electronics design.

Recent advancements have focused on developing adaptive power conversion architectures that can dynamically adjust to the changing characteristics of SLB packs. These systems incorporate sophisticated sensing, control algorithms, and modular designs to optimize energy extraction while ensuring safe operation. The integration of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has enabled higher efficiency and power density in these interfaces.

The primary technical objectives in this field include maximizing the usable capacity of heterogeneous battery packs, extending their operational lifetime, and ensuring safe integration with various energy systems. This requires developing interfaces that can accurately assess individual battery module conditions, balance energy flow, and provide robust protection mechanisms. Additionally, these interfaces must be cost-effective to maintain the economic viability of SLB solutions compared to new battery alternatives.

Another critical objective is standardization of communication protocols and electrical interfaces to facilitate broader adoption across different battery types and applications. Current efforts are focused on creating flexible architectures that can adapt to various battery management systems while maintaining compatibility with grid requirements and energy management systems.

Looking forward, the technology is expected to evolve toward more intelligent systems incorporating machine learning algorithms for predictive health management and adaptive control. These advanced interfaces will likely feature enhanced connectivity for remote monitoring and management, supporting the growing ecosystem of distributed energy resources. The ultimate goal is to develop seamless integration solutions that can effectively incorporate heterogeneous SLB packs into renewable energy systems, microgrids, and grid-scale storage applications, thereby maximizing the value extraction from retired EV batteries.

Market Analysis for Heterogeneous SLB Pack Solutions

The global market for Second Life Battery (SLB) solutions is experiencing robust growth, driven primarily by the increasing adoption of electric vehicles (EVs) and the subsequent need for battery repurposing. The market value for heterogeneous SLB pack solutions is projected to reach $7.8 billion by 2030, growing at a compound annual growth rate of 23.4% from 2023 to 2030. This significant growth trajectory reflects the expanding opportunities in energy storage applications utilizing retired EV batteries.

Consumer demand for sustainable energy solutions has created a favorable environment for SLB technologies. Energy storage systems utilizing heterogeneous battery packs are gaining traction in residential, commercial, and utility-scale applications. The residential segment currently holds the largest market share at 42%, followed by commercial applications at 35% and utility-scale implementations at 23%. This distribution highlights the versatility of heterogeneous SLB solutions across different market segments.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. These countries benefit from mature EV markets and supportive government policies promoting battery recycling and repurposing. Europe follows with 30% market share, where stringent environmental regulations and sustainability goals drive adoption. North America accounts for 20% of the market, with the remaining 5% distributed across other regions.

Key market drivers include the growing gap between battery supply and demand, increasing focus on circular economy principles, and favorable regulatory frameworks promoting battery reuse. The cost advantage of repurposed batteries, typically 40-60% lower than new batteries, presents a compelling value proposition for energy storage applications. Additionally, the environmental benefits of extending battery life cycles align with corporate sustainability goals and regulatory requirements.

Market challenges include technical complexities in integrating heterogeneous battery cells, quality concerns regarding used batteries, and evolving regulatory standards. The lack of standardized testing protocols for second-life batteries creates uncertainty regarding performance guarantees and warranty terms. These challenges present opportunities for companies developing advanced power electronics interfaces capable of efficiently managing heterogeneous battery packs.

Customer segments show varying needs and adoption patterns. Utilities seek large-scale solutions with predictable performance metrics, commercial entities prioritize return on investment and space efficiency, while residential customers value ease of installation and integration with existing renewable energy systems. This segmentation necessitates tailored power electronics interfaces to address specific requirements across different applications.

Consumer demand for sustainable energy solutions has created a favorable environment for SLB technologies. Energy storage systems utilizing heterogeneous battery packs are gaining traction in residential, commercial, and utility-scale applications. The residential segment currently holds the largest market share at 42%, followed by commercial applications at 35% and utility-scale implementations at 23%. This distribution highlights the versatility of heterogeneous SLB solutions across different market segments.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. These countries benefit from mature EV markets and supportive government policies promoting battery recycling and repurposing. Europe follows with 30% market share, where stringent environmental regulations and sustainability goals drive adoption. North America accounts for 20% of the market, with the remaining 5% distributed across other regions.

Key market drivers include the growing gap between battery supply and demand, increasing focus on circular economy principles, and favorable regulatory frameworks promoting battery reuse. The cost advantage of repurposed batteries, typically 40-60% lower than new batteries, presents a compelling value proposition for energy storage applications. Additionally, the environmental benefits of extending battery life cycles align with corporate sustainability goals and regulatory requirements.

Market challenges include technical complexities in integrating heterogeneous battery cells, quality concerns regarding used batteries, and evolving regulatory standards. The lack of standardized testing protocols for second-life batteries creates uncertainty regarding performance guarantees and warranty terms. These challenges present opportunities for companies developing advanced power electronics interfaces capable of efficiently managing heterogeneous battery packs.

Customer segments show varying needs and adoption patterns. Utilities seek large-scale solutions with predictable performance metrics, commercial entities prioritize return on investment and space efficiency, while residential customers value ease of installation and integration with existing renewable energy systems. This segmentation necessitates tailored power electronics interfaces to address specific requirements across different applications.

Technical Challenges in SLB Pack Integration

The integration of heterogeneous Second Life Battery (SLB) packs presents significant technical challenges due to the inherent variability in battery characteristics. One primary challenge is the management of different voltage levels across various battery types and states of health. Power electronic interfaces must accommodate these voltage disparities through sophisticated DC-DC conversion techniques, requiring advanced control algorithms that can dynamically adjust to changing battery conditions.

Thermal management represents another critical challenge in heterogeneous SLB pack integration. Different battery chemistries and aging profiles lead to varied thermal behaviors, creating hotspots and thermal gradients that can accelerate degradation. Power electronics must incorporate thermal monitoring and management systems capable of addressing these disparities, often necessitating complex cooling solutions and thermal modeling approaches.

State estimation accuracy poses a substantial technical hurdle. Heterogeneous packs contain batteries with different degradation histories and performance characteristics, making traditional state-of-charge and state-of-health estimation methods inadequate. Advanced algorithms incorporating machine learning and adaptive models are required to accurately predict the behavior of diverse battery elements within a unified system.

Protection mechanisms for heterogeneous SLB packs must account for varying failure modes across different battery types. This requires sophisticated fault detection systems capable of identifying chemistry-specific failure signatures and implementing appropriate mitigation strategies. The power electronics interface must incorporate redundant protection layers to prevent cascading failures that could propagate through the interconnected system.

Communication protocols present interoperability challenges when integrating batteries from different manufacturers and generations. Power electronic interfaces must support multiple Battery Management System (BMS) communication standards and provide translation layers between proprietary protocols. This often requires gateway solutions that can harmonize data formats and control signals across the heterogeneous system.

Efficiency optimization across varied operating conditions represents a significant design challenge. Power converters must maintain high efficiency across wide operating ranges to accommodate the diverse voltage, current, and impedance characteristics of heterogeneous batteries. This often necessitates advanced semiconductor technologies and innovative converter topologies that can adapt to changing battery parameters.

Scalability and modularity requirements further complicate the design of power electronic interfaces. Systems must accommodate the addition or replacement of battery modules with minimal reconfiguration, requiring hot-swappable interfaces and self-configuring control systems that can automatically detect and adapt to changes in the battery ecosystem.

Thermal management represents another critical challenge in heterogeneous SLB pack integration. Different battery chemistries and aging profiles lead to varied thermal behaviors, creating hotspots and thermal gradients that can accelerate degradation. Power electronics must incorporate thermal monitoring and management systems capable of addressing these disparities, often necessitating complex cooling solutions and thermal modeling approaches.

State estimation accuracy poses a substantial technical hurdle. Heterogeneous packs contain batteries with different degradation histories and performance characteristics, making traditional state-of-charge and state-of-health estimation methods inadequate. Advanced algorithms incorporating machine learning and adaptive models are required to accurately predict the behavior of diverse battery elements within a unified system.

Protection mechanisms for heterogeneous SLB packs must account for varying failure modes across different battery types. This requires sophisticated fault detection systems capable of identifying chemistry-specific failure signatures and implementing appropriate mitigation strategies. The power electronics interface must incorporate redundant protection layers to prevent cascading failures that could propagate through the interconnected system.

Communication protocols present interoperability challenges when integrating batteries from different manufacturers and generations. Power electronic interfaces must support multiple Battery Management System (BMS) communication standards and provide translation layers between proprietary protocols. This often requires gateway solutions that can harmonize data formats and control signals across the heterogeneous system.

Efficiency optimization across varied operating conditions represents a significant design challenge. Power converters must maintain high efficiency across wide operating ranges to accommodate the diverse voltage, current, and impedance characteristics of heterogeneous batteries. This often necessitates advanced semiconductor technologies and innovative converter topologies that can adapt to changing battery parameters.

Scalability and modularity requirements further complicate the design of power electronic interfaces. Systems must accommodate the addition or replacement of battery modules with minimal reconfiguration, requiring hot-swappable interfaces and self-configuring control systems that can automatically detect and adapt to changes in the battery ecosystem.

Current Interface Solutions for Heterogeneous SLB Packs

01 Advanced Power Conversion Architectures

Modern power electronics interfaces employ advanced conversion architectures to improve integration efficiency. These include multi-level converters, matrix converters, and resonant topologies that reduce switching losses and improve power density. Such architectures enable higher frequency operation, smaller passive components, and better thermal management, resulting in more compact and efficient power electronic systems for various applications including renewable energy integration and electric vehicle charging.- Advanced Power Conversion Architectures: Modern power electronics interfaces employ advanced conversion architectures to improve integration efficiency. These include multi-level converters, matrix converters, and resonant topologies that reduce switching losses and improve power density. Such architectures enable higher frequency operation, smaller passive components, and better thermal management, resulting in more compact and efficient power electronic systems.

- Semiconductor Device Optimization: Integration efficiency in power electronics interfaces is enhanced through optimization of semiconductor devices. This includes the use of wide bandgap semiconductors like SiC and GaN, advanced packaging techniques, and improved thermal management solutions. These optimizations allow for higher switching frequencies, reduced losses, and better power density, leading to more efficient and compact power electronic systems.

- Control and Communication Systems: Sophisticated control and communication systems are implemented in power electronics interfaces to enhance integration efficiency. These include digital control algorithms, real-time monitoring systems, and network communication protocols that enable seamless integration with other systems. Advanced control strategies optimize power flow, reduce harmonics, and improve dynamic response, resulting in higher overall system efficiency.

- Grid Integration and Energy Management: Power electronics interfaces are designed with features that facilitate efficient grid integration and energy management. These include bidirectional power flow capabilities, grid synchronization techniques, and adaptive control strategies that respond to changing grid conditions. Such features enable efficient integration of renewable energy sources, energy storage systems, and smart grid applications.

- Modular and Scalable Designs: Modular and scalable design approaches are employed in power electronics interfaces to improve integration efficiency. These designs feature standardized components, plug-and-play functionality, and reconfigurable architectures that can be adapted to different applications. Modular designs facilitate easier maintenance, upgrades, and system expansion while maintaining high efficiency across various power levels and applications.

02 Thermal Management and Packaging Innovations

Efficient thermal management and advanced packaging techniques are crucial for power electronics interface integration. Innovations include direct liquid cooling, phase-change materials, and 3D packaging technologies that allow for higher power density while maintaining operational temperatures. These approaches enable better heat dissipation from semiconductor devices, reducing thermal resistance and allowing for higher current densities and more compact designs without compromising reliability or performance.Expand Specific Solutions03 Wide Bandgap Semiconductor Integration

Integration of wide bandgap semiconductors such as Silicon Carbide (SiC) and Gallium Nitride (GaN) significantly enhances power electronics efficiency. These materials enable higher switching frequencies, higher temperature operation, and lower conduction losses compared to traditional silicon-based devices. Their implementation in power converters results in smaller passive components, reduced cooling requirements, and overall system size reduction while improving energy conversion efficiency across various voltage and power ranges.Expand Specific Solutions04 Digital Control and Smart Power Management

Advanced digital control strategies and smart power management systems optimize the operation of power electronic interfaces. These include adaptive control algorithms, predictive techniques, and real-time optimization that respond to changing load conditions and system requirements. Implementation of digital signal processors and field-programmable gate arrays enables sophisticated control schemes that maximize efficiency, improve dynamic response, and enhance reliability through features like fault detection and self-diagnosis.Expand Specific Solutions05 Grid Integration and Energy Storage Solutions

Power electronics interfaces for grid integration and energy storage systems focus on bidirectional power flow capabilities and seamless mode transitions. These interfaces incorporate synchronization techniques, active and reactive power control, and harmonics mitigation to ensure grid code compliance. Advanced topologies enable efficient energy transfer between different voltage levels and frequencies, supporting renewable energy integration, microgrid operation, and energy storage systems while maintaining power quality and system stability.Expand Specific Solutions

Key Industry Players in SLB Power Electronics

The power electronics interfaces for heterogeneous Second Life Battery (SLB) packs market is in its growth phase, characterized by increasing adoption as renewable energy storage solutions gain traction. The market is projected to expand significantly due to sustainability initiatives and the circular economy approach to battery reuse. Technologically, the field is advancing rapidly with varying maturity levels among key players. LG Energy Solution and Samsung SDI lead with comprehensive battery management systems, while companies like Infineon Technologies, Wolfspeed, and Navitas Semiconductor are developing specialized power semiconductor solutions. Academic institutions including South China University of Technology and Zhejiang University contribute significant research. Traditional electronics giants such as Intel, Siemens, and ABB are leveraging their expertise to enter this emerging market, focusing on integration capabilities for diverse battery chemistries and voltage levels.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced power electronics interfaces specifically designed for heterogeneous second-life battery (SLB) packs. Their technology employs a multi-level modular converter architecture that accommodates batteries with varying states of health, capacities, and chemistries. The system features adaptive control algorithms that dynamically adjust power distribution based on real-time battery parameters. LG's solution incorporates cell-level monitoring with distributed battery management systems (BMS) that communicate through a hierarchical network, enabling precise state estimation and thermal management across heterogeneous cells. Their power electronics interface includes bidirectional DC-DC converters with wide input voltage ranges (100-800V) to handle the diverse voltage characteristics of different battery modules, while maintaining high conversion efficiency (>95%) across various operating conditions.

Strengths: Superior integration with existing energy storage infrastructure, highly scalable architecture allowing for easy expansion, and advanced diagnostic capabilities for predictive maintenance. Weaknesses: Higher initial implementation cost compared to simpler solutions, and requires sophisticated control systems that may increase complexity in field deployment.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered a comprehensive power electronics interface solution for heterogeneous second-life battery (SLB) packs that builds upon their extensive experience in battery manufacturing and energy storage systems. Their technology employs a hierarchical control architecture with distributed power electronics modules that can individually manage battery modules with varying chemistries, capacities, and degradation levels. Samsung's system features adaptive DC-DC converters with wide input voltage ranges (50-1000V) and dynamic current limiting capabilities to accommodate batteries at different states of health. The interface incorporates their proprietary Battery Management Unit (BMU) with advanced algorithms for state estimation and predictive analytics that can accurately assess the remaining useful life of heterogeneous battery modules. Samsung's solution also includes intelligent thermal management systems with phase-change materials and variable-speed cooling that can address the uneven heat generation patterns typical in mixed battery assemblies. Their power electronics interface achieves high efficiency (96%+) across a wide operating range while maintaining compatibility with various grid-tie inverters and energy management systems.

Strengths: Seamless integration with Samsung's ecosystem of energy storage products, extensive battery expertise informing power electronics design, and sophisticated battery health monitoring capabilities. Weaknesses: Proprietary communication protocols may limit compatibility with third-party systems, and solution is optimized primarily for Samsung's own battery modules.

Core Technologies for Power Electronics Interfaces

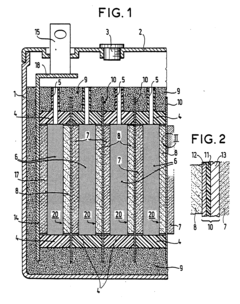

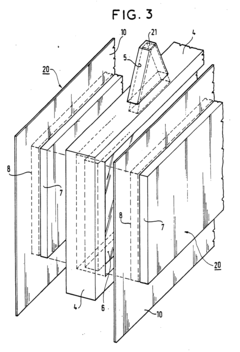

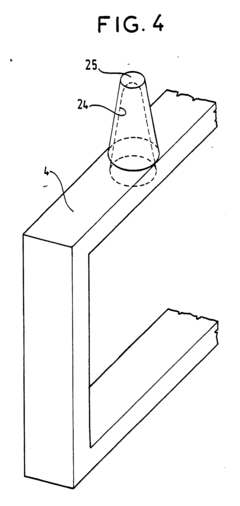

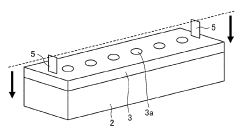

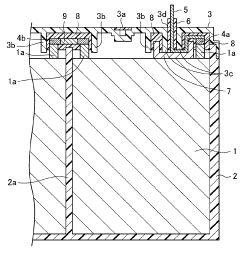

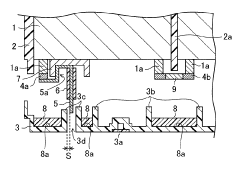

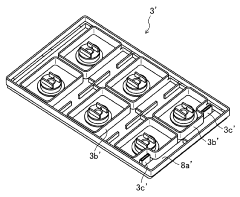

Sealed lead accumulator battery with bipolar electrodes

PatentInactiveEP0402265A1

Innovation

- A sealed lead acid battery design featuring a stack of bipolar electrodes with interposed separators and current collectors made of conductive plastic materials, embedded in a sulfuric acid-resistant plastic foam for sealing, and a method of assembly that includes injecting electrolyte through tubes in the frames, ensuring a secure seal and efficient current transfer.

sealed lead acid battery

PatentInactiveJPWO2012164831A1

Innovation

- A configuration where the terminal is bent multiple times and covered with an elastic member made of resin, which is then sealed with a thermosetting resin adhesive, ensuring the adhesive does not leak and simplifying the manufacturing process.

Thermal Management Considerations

Thermal management represents a critical challenge in the design and operation of power electronics interfaces for heterogeneous second-life battery (SLB) packs. The varying thermal characteristics of repurposed batteries with different degradation levels, chemistries, and form factors create complex heat distribution patterns that must be carefully managed to ensure system reliability and longevity.

Temperature gradients within heterogeneous SLB packs can significantly impact the performance of power electronic components, particularly semiconductor devices such as MOSFETs, IGBTs, and diodes. These components exhibit temperature-dependent electrical characteristics, with increased resistance and switching losses at elevated temperatures. For SLB applications, this thermal sensitivity is particularly problematic as it can create feedback loops where localized heating further degrades battery performance, increasing internal resistance and generating additional heat.

Advanced cooling strategies must be implemented to address these challenges. Liquid cooling systems offer superior thermal conductivity compared to air cooling, making them increasingly popular for high-power SLB applications. These systems can be designed with multiple cooling zones to accommodate the varying thermal needs of different battery modules within a heterogeneous pack. Computational fluid dynamics (CFD) modeling has become essential in optimizing coolant flow paths and heat exchanger designs for these complex thermal environments.

Thermal interface materials (TIMs) play a crucial role in establishing efficient thermal pathways between power electronic components and cooling systems. Recent developments in phase-change materials and metal-matrix composites have yielded TIMs with thermal conductivities exceeding 25 W/m·K, significantly improving heat transfer efficiency in SLB power interfaces. These advanced materials help mitigate the thermal resistance at component junctions, which often represents a major bottleneck in overall system cooling.

Active thermal management systems incorporating temperature sensors and microcontroller-based regulation are increasingly being deployed in sophisticated SLB installations. These systems can dynamically adjust cooling parameters based on real-time temperature measurements, preventing thermal runaway conditions while optimizing energy consumption. Some cutting-edge designs incorporate predictive thermal models that anticipate temperature changes based on load profiles, enabling proactive cooling adjustments.

The integration of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), in power electronic interfaces has shown promising results for SLB applications. These materials can operate at significantly higher temperatures than traditional silicon-based components, reducing cooling requirements and allowing for more compact designs. However, their implementation in heterogeneous SLB systems requires careful thermal design to ensure that temperature variations across the pack do not compromise the performance advantages of these advanced semiconductors.

Temperature gradients within heterogeneous SLB packs can significantly impact the performance of power electronic components, particularly semiconductor devices such as MOSFETs, IGBTs, and diodes. These components exhibit temperature-dependent electrical characteristics, with increased resistance and switching losses at elevated temperatures. For SLB applications, this thermal sensitivity is particularly problematic as it can create feedback loops where localized heating further degrades battery performance, increasing internal resistance and generating additional heat.

Advanced cooling strategies must be implemented to address these challenges. Liquid cooling systems offer superior thermal conductivity compared to air cooling, making them increasingly popular for high-power SLB applications. These systems can be designed with multiple cooling zones to accommodate the varying thermal needs of different battery modules within a heterogeneous pack. Computational fluid dynamics (CFD) modeling has become essential in optimizing coolant flow paths and heat exchanger designs for these complex thermal environments.

Thermal interface materials (TIMs) play a crucial role in establishing efficient thermal pathways between power electronic components and cooling systems. Recent developments in phase-change materials and metal-matrix composites have yielded TIMs with thermal conductivities exceeding 25 W/m·K, significantly improving heat transfer efficiency in SLB power interfaces. These advanced materials help mitigate the thermal resistance at component junctions, which often represents a major bottleneck in overall system cooling.

Active thermal management systems incorporating temperature sensors and microcontroller-based regulation are increasingly being deployed in sophisticated SLB installations. These systems can dynamically adjust cooling parameters based on real-time temperature measurements, preventing thermal runaway conditions while optimizing energy consumption. Some cutting-edge designs incorporate predictive thermal models that anticipate temperature changes based on load profiles, enabling proactive cooling adjustments.

The integration of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), in power electronic interfaces has shown promising results for SLB applications. These materials can operate at significantly higher temperatures than traditional silicon-based components, reducing cooling requirements and allowing for more compact designs. However, their implementation in heterogeneous SLB systems requires careful thermal design to ensure that temperature variations across the pack do not compromise the performance advantages of these advanced semiconductors.

Standardization and Interoperability Requirements

The standardization of power electronics interfaces for heterogeneous Second Life Battery (SLB) packs represents a critical challenge in the evolving energy storage ecosystem. Currently, the market faces significant fragmentation due to proprietary designs from various manufacturers, creating barriers to widespread adoption and efficient integration. Industry stakeholders must establish comprehensive standards addressing electrical parameters, communication protocols, physical connections, and safety mechanisms to ensure seamless interoperability across different battery systems.

Key standardization requirements include voltage and current specifications that accommodate diverse battery chemistries and configurations. These standards must define acceptable ranges for operating parameters while ensuring compatibility with existing grid infrastructure and energy management systems. Additionally, thermal management interfaces require standardization to prevent catastrophic failures and optimize performance across varying environmental conditions.

Communication protocol standardization emerges as particularly crucial for heterogeneous SLB integration. The industry needs unified data exchange frameworks that enable real-time monitoring, state estimation, and control across multi-vendor battery systems. Protocols must support secure authentication mechanisms while maintaining backward compatibility with legacy systems. Organizations such as IEEE, IEC, and ISO are actively developing standards like IEEE 2030.2.1 and IEC 62619, though gaps remain in addressing the specific challenges of repurposed batteries.

Physical interface standardization encompasses connector designs, mounting provisions, and cooling interfaces. These standards must balance the need for universality with the practical constraints of different form factors and applications. The automotive industry's progress with CCS and CHAdeMO standards offers valuable precedents, though SLB applications present unique challenges requiring tailored approaches.

Safety certification requirements constitute another critical dimension of standardization efforts. Clear guidelines for fault detection, isolation mechanisms, and emergency shutdown procedures are essential for market acceptance and regulatory compliance. These standards must address the unique risk profiles of repurposed batteries with varying degradation histories and remaining useful life.

Interoperability testing methodologies represent the final piece of the standardization puzzle. The industry requires consensus on validation procedures, compliance testing, and certification processes to verify that different components can function together reliably. Test beds and reference implementations will play vital roles in accelerating adoption and ensuring consistent performance across heterogeneous systems.

Key standardization requirements include voltage and current specifications that accommodate diverse battery chemistries and configurations. These standards must define acceptable ranges for operating parameters while ensuring compatibility with existing grid infrastructure and energy management systems. Additionally, thermal management interfaces require standardization to prevent catastrophic failures and optimize performance across varying environmental conditions.

Communication protocol standardization emerges as particularly crucial for heterogeneous SLB integration. The industry needs unified data exchange frameworks that enable real-time monitoring, state estimation, and control across multi-vendor battery systems. Protocols must support secure authentication mechanisms while maintaining backward compatibility with legacy systems. Organizations such as IEEE, IEC, and ISO are actively developing standards like IEEE 2030.2.1 and IEC 62619, though gaps remain in addressing the specific challenges of repurposed batteries.

Physical interface standardization encompasses connector designs, mounting provisions, and cooling interfaces. These standards must balance the need for universality with the practical constraints of different form factors and applications. The automotive industry's progress with CCS and CHAdeMO standards offers valuable precedents, though SLB applications present unique challenges requiring tailored approaches.

Safety certification requirements constitute another critical dimension of standardization efforts. Clear guidelines for fault detection, isolation mechanisms, and emergency shutdown procedures are essential for market acceptance and regulatory compliance. These standards must address the unique risk profiles of repurposed batteries with varying degradation histories and remaining useful life.

Interoperability testing methodologies represent the final piece of the standardization puzzle. The industry requires consensus on validation procedures, compliance testing, and certification processes to verify that different components can function together reliably. Test beds and reference implementations will play vital roles in accelerating adoption and ensuring consistent performance across heterogeneous systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!