Testing For Thermal Runaway Risk In Reconditioned Packs

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Thermal runaway in lithium-ion batteries represents one of the most critical safety concerns in energy storage systems. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and the release of toxic gases. The evolution of battery technology has been marked by continuous efforts to balance increased energy density with safety considerations, with thermal runaway remaining a persistent challenge throughout this development.

The reconditioned battery market has grown significantly in recent years, driven by sustainability initiatives and economic factors. These second-life batteries, often repurposed from electric vehicles for stationary storage applications, present unique thermal runaway risks due to their usage history, potential internal damage, and varied degradation patterns across cells. Unlike new batteries with consistent manufacturing quality, reconditioned packs may contain cells with different aging profiles and hidden defects that traditional testing methods might not detect.

Historical incidents involving thermal runaway in battery systems have highlighted the devastating consequences of inadequate safety measures. Notable cases include electric vehicle fires, energy storage system explosions, and consumer electronics incidents that have resulted in property damage, injuries, and even fatalities. These events have prompted regulatory bodies worldwide to implement increasingly stringent safety standards for battery systems, though specific guidelines for reconditioned batteries remain less developed.

The technical objective of this research is to develop comprehensive, reliable, and economically viable testing methodologies specifically designed to assess thermal runaway risks in reconditioned battery packs. These methods must account for the unique characteristics and challenges presented by previously used cells, including detecting latent defects, evaluating cell imbalance risks, and predicting potential failure cascades within repurposed packs.

Current testing approaches for new batteries typically involve accelerated aging tests, nail penetration tests, thermal abuse tests, and electrical abuse tests. However, these standardized methods may not adequately address the specific risk factors in reconditioned batteries. The goal is to establish testing protocols that can effectively identify cells prone to thermal runaway within reconditioned packs before deployment, thereby ensuring safety without imposing prohibitive costs that would undermine the economic viability of battery reconditioning.

The advancement of non-destructive testing techniques, coupled with machine learning algorithms for pattern recognition in battery behavior, presents promising avenues for achieving these objectives. By developing specialized testing methodologies for reconditioned batteries, this research aims to support the growing circular economy for energy storage while maintaining the highest safety standards.

The reconditioned battery market has grown significantly in recent years, driven by sustainability initiatives and economic factors. These second-life batteries, often repurposed from electric vehicles for stationary storage applications, present unique thermal runaway risks due to their usage history, potential internal damage, and varied degradation patterns across cells. Unlike new batteries with consistent manufacturing quality, reconditioned packs may contain cells with different aging profiles and hidden defects that traditional testing methods might not detect.

Historical incidents involving thermal runaway in battery systems have highlighted the devastating consequences of inadequate safety measures. Notable cases include electric vehicle fires, energy storage system explosions, and consumer electronics incidents that have resulted in property damage, injuries, and even fatalities. These events have prompted regulatory bodies worldwide to implement increasingly stringent safety standards for battery systems, though specific guidelines for reconditioned batteries remain less developed.

The technical objective of this research is to develop comprehensive, reliable, and economically viable testing methodologies specifically designed to assess thermal runaway risks in reconditioned battery packs. These methods must account for the unique characteristics and challenges presented by previously used cells, including detecting latent defects, evaluating cell imbalance risks, and predicting potential failure cascades within repurposed packs.

Current testing approaches for new batteries typically involve accelerated aging tests, nail penetration tests, thermal abuse tests, and electrical abuse tests. However, these standardized methods may not adequately address the specific risk factors in reconditioned batteries. The goal is to establish testing protocols that can effectively identify cells prone to thermal runaway within reconditioned packs before deployment, thereby ensuring safety without imposing prohibitive costs that would undermine the economic viability of battery reconditioning.

The advancement of non-destructive testing techniques, coupled with machine learning algorithms for pattern recognition in battery behavior, presents promising avenues for achieving these objectives. By developing specialized testing methodologies for reconditioned batteries, this research aims to support the growing circular economy for energy storage while maintaining the highest safety standards.

Market Analysis for Reconditioned Battery Testing Solutions

The global market for reconditioned battery testing solutions is experiencing significant growth, driven by the expanding electric vehicle (EV) sector and increasing focus on sustainable energy storage solutions. Current market valuations indicate that the battery recycling market is projected to reach approximately $24 billion by 2030, with testing solutions for reconditioned batteries representing a crucial segment within this ecosystem.

The demand for reliable thermal runaway testing equipment has intensified as battery second-life applications gain traction across multiple industries. Energy storage systems utilizing reconditioned EV batteries have emerged as a particularly promising market segment, with grid storage applications showing annual growth rates exceeding 30% in regions with advanced renewable energy infrastructure.

Regional analysis reveals distinct market characteristics across different territories. North America currently leads in terms of technological sophistication, with stringent safety regulations driving adoption of comprehensive testing protocols. The European market demonstrates the highest growth rate, propelled by aggressive carbon neutrality targets and circular economy initiatives. Meanwhile, the Asia-Pacific region represents the largest market by volume, with China dominating both battery production and reconditioning activities.

Customer segmentation within this market reveals three primary buyer categories: battery refurbishment facilities requiring high-throughput testing solutions; research institutions seeking precision diagnostic equipment; and end-users of reconditioned batteries (utilities, commercial facilities, etc.) demanding certification and quality assurance tools.

Price sensitivity varies significantly across these segments, with enterprise-level solutions commanding premium prices between $50,000-$250,000 depending on testing capabilities, while smaller-scale verification systems typically range from $10,000-$30,000. The market demonstrates a clear willingness to invest in solutions that effectively mitigate thermal runaway risks, as the financial and reputational consequences of battery failures far outweigh testing costs.

Distribution channels are evolving rapidly, with direct sales dominating for high-end systems while e-commerce platforms increasingly serve the market for standardized testing equipment. Strategic partnerships between testing equipment manufacturers and battery reconditioning facilities represent a growing trend, creating integrated service offerings that enhance market penetration.

Market barriers include regulatory uncertainty regarding certification standards for reconditioned batteries, technical challenges in developing testing protocols that accurately predict real-world performance, and price competition from low-cost but less reliable testing alternatives emerging from new market entrants.

The demand for reliable thermal runaway testing equipment has intensified as battery second-life applications gain traction across multiple industries. Energy storage systems utilizing reconditioned EV batteries have emerged as a particularly promising market segment, with grid storage applications showing annual growth rates exceeding 30% in regions with advanced renewable energy infrastructure.

Regional analysis reveals distinct market characteristics across different territories. North America currently leads in terms of technological sophistication, with stringent safety regulations driving adoption of comprehensive testing protocols. The European market demonstrates the highest growth rate, propelled by aggressive carbon neutrality targets and circular economy initiatives. Meanwhile, the Asia-Pacific region represents the largest market by volume, with China dominating both battery production and reconditioning activities.

Customer segmentation within this market reveals three primary buyer categories: battery refurbishment facilities requiring high-throughput testing solutions; research institutions seeking precision diagnostic equipment; and end-users of reconditioned batteries (utilities, commercial facilities, etc.) demanding certification and quality assurance tools.

Price sensitivity varies significantly across these segments, with enterprise-level solutions commanding premium prices between $50,000-$250,000 depending on testing capabilities, while smaller-scale verification systems typically range from $10,000-$30,000. The market demonstrates a clear willingness to invest in solutions that effectively mitigate thermal runaway risks, as the financial and reputational consequences of battery failures far outweigh testing costs.

Distribution channels are evolving rapidly, with direct sales dominating for high-end systems while e-commerce platforms increasingly serve the market for standardized testing equipment. Strategic partnerships between testing equipment manufacturers and battery reconditioning facilities represent a growing trend, creating integrated service offerings that enhance market penetration.

Market barriers include regulatory uncertainty regarding certification standards for reconditioned batteries, technical challenges in developing testing protocols that accurately predict real-world performance, and price competition from low-cost but less reliable testing alternatives emerging from new market entrants.

Current Challenges in Thermal Runaway Detection

Despite significant advancements in battery safety technologies, thermal runaway detection in reconditioned battery packs presents several persistent challenges that impede reliable early warning systems. The heterogeneous nature of reconditioned cells creates inconsistent baseline parameters, making it difficult to establish uniform detection thresholds across packs assembled from diverse sources with varying degradation histories.

Current detection methods predominantly rely on temperature monitoring using thermocouples or thermistors strategically placed within battery packs. However, these sensors often provide localized readings that may not accurately represent the thermal conditions across the entire pack. The thermal propagation between cells can occur rapidly, leaving insufficient time between detection and catastrophic failure, particularly in densely packed configurations where heat dissipation is limited.

Voltage fluctuation monitoring presents another challenge, as the correlation between voltage anomalies and thermal events remains inconsistent in reconditioned cells. The electrical signatures preceding thermal runaway vary significantly based on cell chemistry, age, and previous usage patterns, complicating the development of universal detection algorithms.

Gas sensing technologies, while promising for detecting early-stage decomposition products, face implementation hurdles in sealed battery systems. The integration of effective venting mechanisms without compromising structural integrity represents a significant engineering challenge, especially in retrofitted or reconditioned packs not originally designed with these features.

Data processing limitations further complicate real-time detection efforts. Current battery management systems (BMS) often lack the computational capacity to run sophisticated detection algorithms that can differentiate between normal operational fluctuations and genuine thermal runaway precursors. This is particularly problematic for reconditioned packs where operational parameters exhibit greater variability.

Cost constraints represent a significant barrier to implementing comprehensive detection systems in reconditioned battery applications. The economic viability of reconditioning often depends on minimizing additional components, creating a tension between safety requirements and commercial feasibility.

Validation and standardization pose additional challenges, as testing protocols for thermal runaway detection in reconditioned batteries remain underdeveloped. The absence of industry-wide standards specifically addressing reconditioned cells creates uncertainty regarding minimum safety requirements and testing methodologies, hampering the development and adoption of effective detection solutions.

Environmental factors introduce further complications, as temperature extremes, humidity, and vibration can affect both battery behavior and sensor performance. Detection systems must maintain reliability across diverse operating conditions while accommodating the wider performance variability inherent to reconditioned cells.

Current detection methods predominantly rely on temperature monitoring using thermocouples or thermistors strategically placed within battery packs. However, these sensors often provide localized readings that may not accurately represent the thermal conditions across the entire pack. The thermal propagation between cells can occur rapidly, leaving insufficient time between detection and catastrophic failure, particularly in densely packed configurations where heat dissipation is limited.

Voltage fluctuation monitoring presents another challenge, as the correlation between voltage anomalies and thermal events remains inconsistent in reconditioned cells. The electrical signatures preceding thermal runaway vary significantly based on cell chemistry, age, and previous usage patterns, complicating the development of universal detection algorithms.

Gas sensing technologies, while promising for detecting early-stage decomposition products, face implementation hurdles in sealed battery systems. The integration of effective venting mechanisms without compromising structural integrity represents a significant engineering challenge, especially in retrofitted or reconditioned packs not originally designed with these features.

Data processing limitations further complicate real-time detection efforts. Current battery management systems (BMS) often lack the computational capacity to run sophisticated detection algorithms that can differentiate between normal operational fluctuations and genuine thermal runaway precursors. This is particularly problematic for reconditioned packs where operational parameters exhibit greater variability.

Cost constraints represent a significant barrier to implementing comprehensive detection systems in reconditioned battery applications. The economic viability of reconditioning often depends on minimizing additional components, creating a tension between safety requirements and commercial feasibility.

Validation and standardization pose additional challenges, as testing protocols for thermal runaway detection in reconditioned batteries remain underdeveloped. The absence of industry-wide standards specifically addressing reconditioned cells creates uncertainty regarding minimum safety requirements and testing methodologies, hampering the development and adoption of effective detection solutions.

Environmental factors introduce further complications, as temperature extremes, humidity, and vibration can affect both battery behavior and sensor performance. Detection systems must maintain reliability across diverse operating conditions while accommodating the wider performance variability inherent to reconditioned cells.

Existing Thermal Runaway Testing Protocols

01 Thermal management systems for reconditioned battery packs

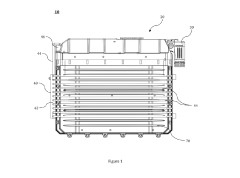

Effective thermal management systems are crucial for preventing thermal runaway in reconditioned battery packs. These systems include cooling mechanisms, temperature monitoring, and heat dissipation technologies that help maintain optimal operating temperatures. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling systems to efficiently remove excess heat from battery cells, reducing the risk of thermal events in second-life applications.- Thermal management systems for reconditioned battery packs: Thermal management systems are crucial for preventing thermal runaway in reconditioned battery packs. These systems include cooling mechanisms, temperature monitoring sensors, and heat dissipation structures that help maintain optimal operating temperatures. Advanced thermal management solutions can detect temperature anomalies early and activate cooling systems to prevent cascading thermal events in refurbished battery modules.

- Battery cell isolation and protection mechanisms: Implementing physical isolation barriers between cells in reconditioned battery packs can prevent thermal runaway propagation. These protection mechanisms include flame-retardant separators, thermal fuses, and compartmentalized designs that contain potential failures to individual cells. Such isolation strategies are particularly important for reconditioned batteries where cell conditions may vary more than in new battery packs.

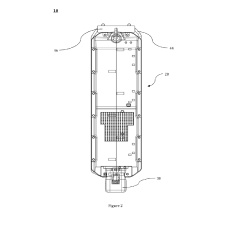

- Diagnostic and monitoring systems for early detection: Advanced diagnostic systems can identify potential thermal runaway risks in reconditioned battery packs before they escalate. These systems monitor parameters such as voltage imbalances, internal resistance changes, and unusual thermal signatures that might indicate degradation or damage. Real-time monitoring allows for immediate intervention when abnormal conditions are detected, reducing the risk of thermal events.

- Battery reconditioning protocols and quality standards: Standardized reconditioning protocols help minimize thermal runaway risks by ensuring consistent quality in refurbished battery packs. These protocols include thorough testing of individual cells, capacity matching, proper balancing, and aging assessment before reassembly. Implementing strict quality standards during the reconditioning process helps identify and remove cells that might pose safety risks when reused.

- Structural reinforcement and thermal insulation: Enhanced structural designs for reconditioned battery packs incorporate thermal insulation materials and reinforced casings to contain potential thermal events. These designs include heat-resistant barriers between modules, intumescent materials that expand when heated to create fire breaks, and specialized enclosures that can withstand high temperatures. Such structural modifications are essential for preventing thermal runaway from spreading throughout the battery system.

02 Battery cell monitoring and early detection systems

Monitoring systems that provide early detection of potential thermal issues are essential for reconditioned battery packs. These systems continuously track parameters such as cell voltage, temperature gradients, and internal resistance to identify abnormalities before they escalate to thermal runaway. Advanced battery management systems (BMS) incorporate predictive algorithms and real-time diagnostics to detect degradation patterns specific to used cells, enabling preventive measures to be implemented before critical failure occurs.Expand Specific Solutions03 Structural modifications and safety enhancements

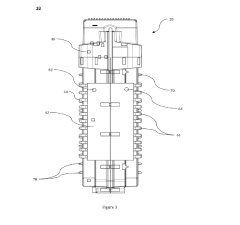

Structural modifications to reconditioned battery packs can significantly reduce thermal runaway risks. These include the implementation of fire-resistant barriers between cells, improved electrical isolation, and reinforced casings designed to contain potential failures. Safety enhancements such as pressure relief mechanisms, thermal fuses, and flame-retardant materials help mitigate the consequences of thermal events when they occur, preventing propagation throughout the battery pack.Expand Specific Solutions04 Cell selection and testing protocols for reconditioning

Rigorous cell selection and testing protocols are critical when reconditioning battery packs to minimize thermal runaway risks. These protocols include comprehensive capacity testing, internal resistance measurements, and accelerated aging tests to identify cells with potential safety issues. Advanced screening methods such as electrochemical impedance spectroscopy and differential voltage analysis help detect internal defects that could lead to thermal instability, ensuring only suitable cells are incorporated into reconditioned packs.Expand Specific Solutions05 Balancing and charge control strategies

Specialized balancing and charge control strategies are essential for managing thermal risks in reconditioned battery packs. These strategies include adaptive charging algorithms that account for the unique characteristics of used cells, precise cell balancing techniques to prevent overcharging of weaker cells, and state-of-health-based current limitations. By implementing sophisticated charge management systems tailored to reconditioned batteries, thermal stress can be minimized during charging and discharging cycles, significantly reducing the likelihood of thermal runaway incidents.Expand Specific Solutions

Leading Organizations in Battery Reconditioning Industry

The thermal runaway risk testing in reconditioned battery packs market is in its growth phase, with an estimated global market size of $2-3 billion and expanding at 15-20% annually as EV adoption increases. The technology maturity varies significantly among key players. Tesla and CATL lead with advanced diagnostic systems and proprietary testing protocols, while LG Energy Solution and Samsung SDI follow closely with robust thermal management innovations. Emerging players like Svolt and EVE Energy are rapidly advancing their capabilities through strategic R&D investments. Academic institutions such as Tsinghua University and industry collaborations with Panasonic Energy are accelerating standardization efforts, though comprehensive industry-wide testing protocols remain under development as the reconditioned battery market continues to evolve.

Tesla, Inc.

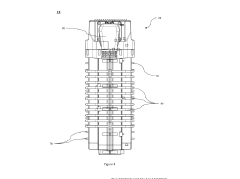

Technical Solution: Tesla has developed a comprehensive thermal runaway testing protocol for reconditioned battery packs that combines multiple detection methods. Their approach utilizes differential voltage analysis to identify internal short circuits before they escalate to thermal events. Tesla implements a multi-stage testing process including pulse testing that applies controlled current pulses to measure impedance changes indicative of degradation. Their thermal imaging system can detect hotspots as small as 2°C above ambient temperature during stress testing[1]. Tesla's proprietary Battery Management System (BMS) algorithms continuously monitor for voltage and temperature anomalies during reconditioning, with machine learning models trained on millions of battery cycles to predict potential failures. For physical testing, they employ accelerated aging chambers that simulate years of usage in weeks, followed by nail penetration and crush tests under controlled conditions to validate thermal containment systems[3]. Tesla's approach is particularly notable for its integration of testing throughout the entire reconditioning workflow rather than treating it as a final quality check.

Strengths: Tesla's integrated approach combines real-time monitoring with predictive analytics, allowing for early detection of potential thermal issues. Their extensive data collection from their vehicle fleet provides unparalleled training datasets for failure prediction algorithms. Weaknesses: The system requires significant computational resources and specialized equipment, making it expensive to implement. The proprietary nature of their testing protocols limits standardization across the industry.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered an advanced multi-dimensional testing framework for reconditioned battery packs focused on thermal runaway prevention. Their system employs electrochemical impedance spectroscopy (EIS) to create detailed "fingerprints" of cell health, detecting microscopic changes in internal resistance that precede thermal events. CATL's testing protocol includes a proprietary "thermal propagation barrier assessment" that evaluates how effectively reconditioned modules contain thermal events from spreading between cells[2]. Their approach incorporates accelerated thermal cycling between -40°C and 80°C to stress test cell connections and thermal management systems. CATL utilizes neutron radiography for non-destructive internal inspection of reconditioned cells, allowing visualization of lithium plating and dendrite formation without damaging the cells[4]. Their automated testing lines can process hundreds of cells simultaneously, using machine vision systems to detect physical deformations as small as 50 micrometers. For final validation, CATL employs a controlled thermal runaway initiation test where a single cell is deliberately triggered while monitoring the pack's ability to prevent propagation, with success defined as containing the event to fewer than three adjacent cells.

Strengths: CATL's testing methodology excels in identifying subtle precursors to thermal events through advanced diagnostic techniques. Their high-throughput automated systems enable comprehensive testing at commercial scale. Weaknesses: The sophisticated equipment required (particularly neutron radiography) makes implementation costly and limits deployment to specialized facilities. The testing protocol is time-intensive, potentially creating bottlenecks in reconditioning operations.

Critical Technologies for Early Failure Detection

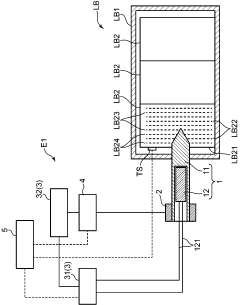

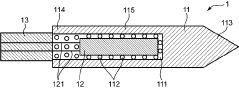

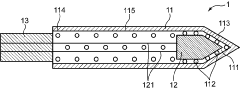

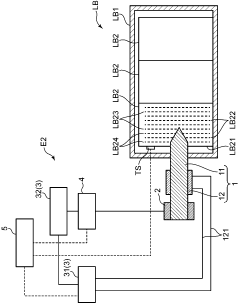

Test tool, test device, and test method of secondary battery

PatentActiveJP2022056886A

Innovation

- A test jig and apparatus that includes a nail portion with a built-in or attached heater to directly heat the inside of a secondary battery, inducing thermal runaway through direct heat transfer, and a moving mechanism to pierce the battery, allowing for efficient evaluation of safety.

A battery pack and a method for preventing thermal runaway of battery cells

PatentPendingIN202341001229A

Innovation

- A battery pack equipped with a charge dissipation device, an active cooling system, and a Battery Management System (BMS) that rapidly discharges or cools the battery cells to prevent thermal runaway by monitoring state of charge and temperature, using a resistor-capacitor circuit and coolant circulation to manage heat and potential fires.

Safety Standards and Compliance Requirements

The regulatory landscape for reconditioned battery pack testing has evolved significantly in response to increasing safety concerns around thermal runaway incidents. International standards such as IEC 62133 and UL 1642 establish baseline requirements for lithium-ion battery safety, with specific provisions for testing thermal stability and overcharge protection. These standards have been recently updated to address the unique challenges posed by reconditioned batteries, which may exhibit different risk profiles compared to new cells.

The UN Transportation Testing requirements (UN 38.3) mandate rigorous testing protocols for batteries intended for transport, including altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. For reconditioned battery packs, compliance with these requirements is particularly critical as internal structural changes during previous use cycles may create unpredictable thermal behaviors.

Regional regulations add another layer of complexity to compliance requirements. The European Union's Battery Directive (2006/66/EC) and its recent update (2023/1591) specifically address second-life batteries, requiring enhanced safety verification and documentation of thermal stability. Similarly, China's GB/T 36276-2018 standard outlines specific testing methodologies for evaluating thermal runaway risks in repurposed energy storage systems.

Industry-specific standards further refine testing requirements based on application contexts. For automotive applications, SAE J2464 and J2929 provide detailed procedures for abuse testing of electric vehicle batteries, with J2288 specifically addressing the evaluation of reconditioned battery packs. These standards emphasize controlled thermal propagation testing to ensure that thermal events remain contained within safe boundaries.

Certification bodies like UL, TÜV, and SGS have developed specialized testing protocols for reconditioned batteries that go beyond standard requirements. These include accelerated aging tests combined with thermal abuse conditions to simulate worst-case scenarios that might trigger thermal runaway in batteries with unknown usage histories.

Emerging compliance frameworks are beginning to incorporate advanced diagnostic requirements such as internal resistance mapping, electrochemical impedance spectroscopy, and thermal imaging during stress tests. These methods enable more precise identification of potential failure points in reconditioned cells that might lead to thermal instability under operational conditions.

Insurance providers have also established their own risk assessment criteria for systems utilizing reconditioned battery packs, often requiring more stringent thermal runaway mitigation measures and continuous monitoring capabilities compared to systems using new batteries. Meeting these requirements has become essential for commercial viability of second-life battery applications.

The UN Transportation Testing requirements (UN 38.3) mandate rigorous testing protocols for batteries intended for transport, including altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. For reconditioned battery packs, compliance with these requirements is particularly critical as internal structural changes during previous use cycles may create unpredictable thermal behaviors.

Regional regulations add another layer of complexity to compliance requirements. The European Union's Battery Directive (2006/66/EC) and its recent update (2023/1591) specifically address second-life batteries, requiring enhanced safety verification and documentation of thermal stability. Similarly, China's GB/T 36276-2018 standard outlines specific testing methodologies for evaluating thermal runaway risks in repurposed energy storage systems.

Industry-specific standards further refine testing requirements based on application contexts. For automotive applications, SAE J2464 and J2929 provide detailed procedures for abuse testing of electric vehicle batteries, with J2288 specifically addressing the evaluation of reconditioned battery packs. These standards emphasize controlled thermal propagation testing to ensure that thermal events remain contained within safe boundaries.

Certification bodies like UL, TÜV, and SGS have developed specialized testing protocols for reconditioned batteries that go beyond standard requirements. These include accelerated aging tests combined with thermal abuse conditions to simulate worst-case scenarios that might trigger thermal runaway in batteries with unknown usage histories.

Emerging compliance frameworks are beginning to incorporate advanced diagnostic requirements such as internal resistance mapping, electrochemical impedance spectroscopy, and thermal imaging during stress tests. These methods enable more precise identification of potential failure points in reconditioned cells that might lead to thermal instability under operational conditions.

Insurance providers have also established their own risk assessment criteria for systems utilizing reconditioned battery packs, often requiring more stringent thermal runaway mitigation measures and continuous monitoring capabilities compared to systems using new batteries. Meeting these requirements has become essential for commercial viability of second-life battery applications.

Environmental Impact of Battery Reconditioning Processes

The reconditioning of battery packs, while offering significant benefits in terms of extended product lifecycles, presents notable environmental considerations that must be carefully evaluated. The processes involved in battery reconditioning generate various environmental impacts, both positive and negative, which require comprehensive assessment.

Battery reconditioning significantly reduces electronic waste by extending the useful life of battery packs that would otherwise be discarded. This waste reduction is particularly important considering that lithium-ion batteries contain materials such as cobalt, nickel, and lithium that are resource-intensive to mine and process. By recirculating these materials through reconditioning, the demand for virgin material extraction decreases, leading to reduced habitat destruction, water pollution, and carbon emissions associated with mining operations.

However, the reconditioning process itself carries environmental implications. Chemical treatments used during reconditioning may include acids, solvents, and other potentially hazardous substances that require proper handling and disposal. Without adequate controls, these chemicals can contaminate soil and water systems, posing risks to ecosystems and human health. Additionally, the energy consumption during reconditioning processes contributes to carbon emissions, though this footprint is typically smaller than that of new battery production.

Testing for thermal runaway risk in reconditioned batteries introduces further environmental considerations. The testing equipment and facilities consume energy and resources, while failed batteries from testing must be properly disposed of according to hazardous waste regulations. However, these environmental costs must be weighed against the catastrophic environmental damage that could result from thermal runaway events in untested reconditioned batteries, including toxic fires and chemical releases.

The geographical distribution of reconditioning facilities also influences environmental impact. Localized reconditioning reduces transportation emissions compared to centralized operations requiring long-distance shipping of batteries. Furthermore, the energy sources powering reconditioning facilities significantly affect their carbon footprint, with renewable energy-powered operations offering substantially lower environmental impact than those relying on fossil fuels.

Regulatory frameworks governing battery reconditioning vary globally, with more stringent environmental protection measures in regions like the European Union under the Battery Directive compared to developing nations. These disparities create potential for environmental burden shifting, where environmentally harmful reconditioning practices migrate to regions with less stringent regulations.

Future improvements in reconditioning technologies promise reduced environmental impacts through more efficient processes, less hazardous chemicals, and improved energy efficiency. The development of standardized environmental impact assessment methodologies specific to battery reconditioning would enable better quantification and mitigation of environmental effects across the industry.

Battery reconditioning significantly reduces electronic waste by extending the useful life of battery packs that would otherwise be discarded. This waste reduction is particularly important considering that lithium-ion batteries contain materials such as cobalt, nickel, and lithium that are resource-intensive to mine and process. By recirculating these materials through reconditioning, the demand for virgin material extraction decreases, leading to reduced habitat destruction, water pollution, and carbon emissions associated with mining operations.

However, the reconditioning process itself carries environmental implications. Chemical treatments used during reconditioning may include acids, solvents, and other potentially hazardous substances that require proper handling and disposal. Without adequate controls, these chemicals can contaminate soil and water systems, posing risks to ecosystems and human health. Additionally, the energy consumption during reconditioning processes contributes to carbon emissions, though this footprint is typically smaller than that of new battery production.

Testing for thermal runaway risk in reconditioned batteries introduces further environmental considerations. The testing equipment and facilities consume energy and resources, while failed batteries from testing must be properly disposed of according to hazardous waste regulations. However, these environmental costs must be weighed against the catastrophic environmental damage that could result from thermal runaway events in untested reconditioned batteries, including toxic fires and chemical releases.

The geographical distribution of reconditioning facilities also influences environmental impact. Localized reconditioning reduces transportation emissions compared to centralized operations requiring long-distance shipping of batteries. Furthermore, the energy sources powering reconditioning facilities significantly affect their carbon footprint, with renewable energy-powered operations offering substantially lower environmental impact than those relying on fossil fuels.

Regulatory frameworks governing battery reconditioning vary globally, with more stringent environmental protection measures in regions like the European Union under the Battery Directive compared to developing nations. These disparities create potential for environmental burden shifting, where environmentally harmful reconditioning practices migrate to regions with less stringent regulations.

Future improvements in reconditioning technologies promise reduced environmental impacts through more efficient processes, less hazardous chemicals, and improved energy efficiency. The development of standardized environmental impact assessment methodologies specific to battery reconditioning would enable better quantification and mitigation of environmental effects across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!