Future Trends: Ferrofluid in Next-Gen Display Technology

Ferrofluid Display Evolution

The evolution of ferrofluid display technology represents a fascinating journey from scientific curiosity to potential next-generation display solutions. Initially discovered in the 1960s by NASA scientist Steve Papell, ferrofluids were primarily developed for spacecraft fuel systems. However, their unique properties soon caught the attention of researchers in various fields, including display technology.

In the early stages, ferrofluid displays were largely experimental, with artists and scientists exploring their visual potential through static installations and simple dynamic setups. These early demonstrations showcased the fluid's ability to form intricate patterns and shapes in response to magnetic fields, laying the groundwork for more advanced applications.

The late 1990s and early 2000s saw increased interest in ferrofluid displays for practical applications. Researchers began exploring ways to control ferrofluid behavior more precisely, leading to the development of pixel-like structures and rudimentary image formation techniques. This period marked the transition from purely artistic endeavors to potential technological applications.

A significant milestone in ferrofluid display evolution came with the introduction of microfluidic technologies in the mid-2000s. This allowed for more precise manipulation of ferrofluids on a smaller scale, enabling the creation of more complex and detailed displays. Concurrently, advancements in electromagnet design and control systems improved the responsiveness and resolution of ferrofluid-based displays.

The 2010s witnessed a surge in research focused on overcoming key challenges in ferrofluid display technology. Scientists worked on improving the stability of ferrofluids, enhancing color reproduction, and developing more efficient control mechanisms. This period also saw the first prototypes of ferrofluid displays capable of rendering dynamic images and video content, albeit with limitations in resolution and refresh rates.

Recent years have seen a convergence of ferrofluid technology with other emerging display technologies. Integration with flexible electronics, for instance, has opened up possibilities for bendable and shapeable ferrofluid displays. Additionally, researchers have begun exploring the potential of combining ferrofluids with other novel materials, such as quantum dots, to enhance color vibrancy and display performance.

Looking towards the future, the evolution of ferrofluid displays is likely to focus on several key areas. These include improving energy efficiency, enhancing resolution and refresh rates, and developing more sophisticated control systems. There is also growing interest in leveraging the unique properties of ferrofluids to create 3D volumetric displays, potentially revolutionizing how we interact with visual information.

Market Potential Analysis

The market potential for ferrofluid in next-generation display technology is poised for significant growth in the coming years. As consumers increasingly demand more immersive and interactive visual experiences, ferrofluid-based displays offer unique advantages that could revolutionize the industry. The global display market, currently valued at over $150 billion, is expected to expand further with the introduction of novel technologies like ferrofluid displays.

Ferrofluid displays have the potential to address several key market needs. They can provide enhanced contrast ratios and deeper blacks compared to traditional LCD or OLED displays, resulting in more vibrant and lifelike images. This improvement in visual quality aligns with the growing demand for high-definition and ultra-high-definition content across various sectors, including entertainment, advertising, and professional applications.

The dynamic nature of ferrofluid displays also opens up new possibilities for interactive and shape-shifting interfaces. This feature is particularly attractive in the rapidly growing markets of augmented reality (AR) and virtual reality (VR), where immersive experiences are paramount. As the AR and VR markets are projected to reach $300 billion by 2024, ferrofluid display technology could capture a significant portion of this expanding sector.

In the automotive industry, where advanced display technologies are becoming increasingly important for both infotainment systems and heads-up displays, ferrofluid-based solutions could offer unique advantages. The ability to create three-dimensional, reconfigurable displays could enhance driver information systems and passenger entertainment, addressing the growing demand for sophisticated in-vehicle experiences.

The education and museum sectors also present substantial market opportunities for ferrofluid display technology. Interactive, visually striking exhibits and learning tools could revolutionize how information is presented and absorbed, potentially driving adoption in these institutional markets.

However, the market potential of ferrofluid displays is not without challenges. The technology must overcome issues related to scalability, durability, and cost-effectiveness to compete with established display technologies. Additionally, concerns about the environmental impact and recyclability of ferrofluid materials need to be addressed to align with growing sustainability trends in consumer electronics.

Despite these challenges, the unique properties of ferrofluid displays position them well to capture niche markets initially, with the potential for broader adoption as the technology matures. As research and development efforts continue to improve the performance and reduce the costs associated with ferrofluid displays, their market share is expected to grow, potentially disrupting the current display technology landscape and creating new opportunities for innovation and market expansion.

Technical Hurdles

The integration of ferrofluid technology into next-generation display systems presents several significant technical hurdles that must be overcome for successful implementation. One of the primary challenges lies in achieving precise control over the ferrofluid's behavior within the display environment. The magnetic nanoparticles suspended in the fluid are highly sensitive to external magnetic fields, making it difficult to maintain stable and consistent formations for extended periods.

Another major obstacle is the development of suitable containment systems for the ferrofluid. Traditional display technologies rely on solid-state components, whereas ferrofluid-based displays require a liquid medium. This necessitates the creation of robust, leak-proof enclosures that can withstand the dynamic nature of the fluid while maintaining optical clarity and durability over time.

The optical properties of ferrofluids pose additional challenges. While the unique visual effects of these materials are central to their appeal in display applications, ensuring consistent color reproduction and brightness across the entire display surface remains problematic. Variations in fluid density, particle distribution, and magnetic field strength can lead to non-uniform visual output, potentially compromising image quality.

Power consumption is another critical concern. The manipulation of ferrofluids through magnetic fields requires a continuous energy input, which could result in higher power demands compared to conventional display technologies. Developing energy-efficient methods for ferrofluid control without sacrificing performance is crucial for the commercial viability of these displays.

Scalability presents yet another hurdle. While small-scale demonstrations of ferrofluid displays have shown promise, scaling up to larger screen sizes introduces complexities in maintaining uniform magnetic fields and fluid behavior across expansive surfaces. This challenge is particularly relevant for applications in large-format displays or outdoor signage.

Furthermore, the long-term stability of ferrofluids in display systems is a significant concern. Factors such as particle aggregation, fluid degradation, and potential chemical interactions with containment materials could impact the longevity and reliability of ferrofluid-based displays. Developing formulations and systems that can maintain consistent performance over extended periods is essential for commercial adoption.

Lastly, the integration of ferrofluid technology with existing display manufacturing processes and supply chains poses logistical and technical challenges. Adapting current production lines to accommodate the unique requirements of ferrofluid displays may require substantial investments and retooling of manufacturing facilities.

Current Ferrofluid Solutions

01 Ferrofluid display technology

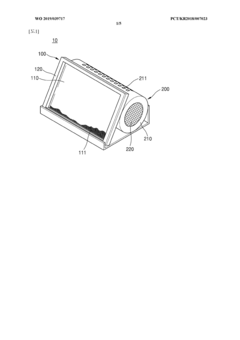

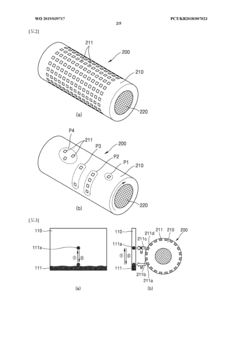

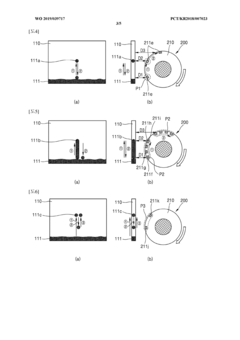

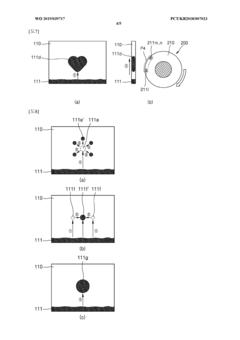

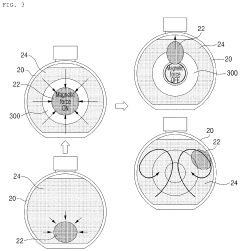

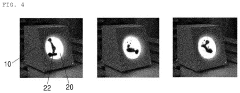

Ferrofluid displays utilize magnetic fluids to create dynamic visual effects. These displays can be used in various applications, including entertainment, advertising, and scientific demonstrations. The ferrofluid responds to magnetic fields, creating unique patterns and shapes that can be controlled and manipulated.- Ferrofluid display devices: Ferrofluid displays utilize magnetic fluids to create dynamic visual effects. These devices typically consist of a container filled with ferrofluid and a mechanism to manipulate the fluid using magnetic fields. The unique properties of ferrofluids allow for the creation of various shapes and patterns, resulting in visually appealing and interactive displays.

- Magnetic field manipulation techniques: Various techniques are employed to manipulate the magnetic fields in ferrofluid displays. These may include the use of electromagnets, permanent magnets, or a combination of both. The precise control of magnetic fields allows for the creation of complex patterns and movements in the ferrofluid, enhancing the display's visual appeal and functionality.

- Ferrofluid composition and properties: The composition and properties of ferrofluids play a crucial role in the performance of ferrofluid displays. Researchers focus on developing ferrofluids with optimal magnetic properties, viscosity, and stability to enhance the display's visual quality and longevity. Factors such as particle size, carrier fluid selection, and surfactant usage are considered in the formulation of ferrofluids for display applications.

- Integration with other technologies: Ferrofluid displays are often integrated with other technologies to enhance their functionality and applications. This may include combining ferrofluid displays with electronic control systems, sensors, or other display technologies. Such integrations can lead to novel applications in areas such as interactive art, scientific visualization, or user interfaces.

- Applications and design considerations: Ferrofluid displays find applications in various fields, including art installations, educational tools, and scientific demonstrations. Design considerations for these displays include container shape and material, sealing methods to prevent ferrofluid leakage, and strategies to maintain the long-term stability of the ferrofluid. Researchers also explore ways to enhance the contrast and visibility of ferrofluid patterns in different lighting conditions.

02 Magnetic field manipulation in ferrofluid displays

The manipulation of magnetic fields is crucial in controlling the behavior of ferrofluids in displays. Various techniques and devices are employed to generate and modify magnetic fields, allowing for precise control over the ferrofluid's movement and shape. This enables the creation of complex patterns and animations in the display.Expand Specific Solutions03 Ferrofluid composition and properties

The composition of ferrofluids used in displays is essential for achieving desired visual effects and performance. Researchers focus on developing ferrofluids with specific properties, such as viscosity, magnetic susceptibility, and color, to enhance the display's capabilities and visual appeal.Expand Specific Solutions04 Integration of ferrofluid displays in devices

Ferrofluid displays can be integrated into various devices and systems for different applications. This includes incorporating them into gaming devices, scientific instruments, and decorative objects. The integration process involves designing appropriate housing, control mechanisms, and power systems to support the ferrofluid display functionality.Expand Specific Solutions05 Measurement and sensing applications of ferrofluids

Beyond visual displays, ferrofluids have applications in measurement and sensing technologies. Their unique properties allow them to be used in various instruments for detecting and measuring magnetic fields, vibrations, and other physical phenomena. These applications extend the utility of ferrofluids beyond purely visual displays.Expand Specific Solutions

Industry Leaders

The ferrofluid display technology market is in its early development stage, with significant potential for growth and innovation. The competitive landscape is characterized by a mix of established electronics giants and specialized research institutions. Companies like LG Display, Sony, and Fujitsu are leveraging their expertise in display technologies to explore ferrofluid applications. Meanwhile, research-focused entities such as Industrial Technology Research Institute and Semiconductor Energy Laboratory are driving fundamental advancements. The market size is currently limited but expected to expand as the technology matures. Technical challenges remain in areas like stability and scalability, indicating that the technology is still in the experimental phase with commercialization efforts ongoing.

Dai Nippon Printing Co., Ltd.

Fujitsu Ltd.

Key Ferrofluid Patents

- A ferrofluid display unit incorporating a transparent liquid with magnetic fluid and a magnetic field generator that applies a magnetic field from the rear, allowing the magnetic fluid to move directionally and create images based on the interaction of the magnetic field and gravity, with adjustable magnetic field intensity and frequency to control the fluid's movement.

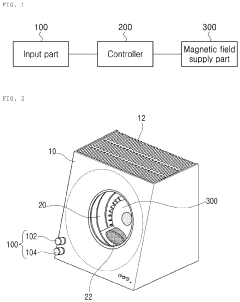

- A ferrofluid display control device featuring a transparent storage container with different specific gravities of ferrofluid and liquid, an input part for selecting frequency ranges, a controller for generating magnetic field control signals, and a single electromagnet to create directional and random movements of the ferrofluid in response to sound frequencies.

Environmental Impact

The integration of ferrofluid technology in next-generation display devices raises important environmental considerations that must be addressed as this innovation progresses. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, present both challenges and opportunities from an environmental perspective.

One primary concern is the potential for nanoparticle release into the environment during the manufacturing, use, and disposal of ferrofluid-based displays. These particles, typically iron oxides, could pose risks to ecosystems if not properly contained. However, the magnetic properties of ferrofluids may actually offer advantages in terms of containment and recycling, as the particles can be easily separated from other materials using magnetic fields.

The production of ferrofluids requires careful consideration of resource consumption and energy efficiency. While the raw materials for ferrofluids are generally abundant, the synthesis process can be energy-intensive. As the technology advances, there is a need to develop more sustainable production methods that minimize energy use and reduce waste.

End-of-life management for ferrofluid displays is another critical environmental factor. The unique properties of ferrofluids may facilitate more efficient recycling processes compared to conventional display technologies. Magnetic separation techniques could enable the recovery of valuable materials, potentially reducing electronic waste and promoting a circular economy approach.

The energy efficiency of ferrofluid-based displays during operation is a key area for environmental impact assessment. If these displays can achieve lower power consumption compared to current technologies, they could contribute to reduced energy demand and associated carbon emissions over their lifecycle.

Water usage and potential contamination in the manufacturing process must also be carefully managed. While ferrofluids themselves are often oil-based, the production of nanoparticles and other components may involve significant water consumption. Implementing closed-loop water systems and advanced filtration technologies can help mitigate these impacts.

As research and development in this field progresses, it is essential to conduct comprehensive life cycle assessments to fully understand and optimize the environmental footprint of ferrofluid display technology. This should include considerations of raw material sourcing, manufacturing processes, energy consumption during use, and end-of-life management. By proactively addressing these environmental aspects, the industry can work towards ensuring that the benefits of this innovative display technology are not outweighed by negative ecological impacts.

Manufacturing Challenges

The integration of ferrofluid technology into next-generation display systems presents several manufacturing challenges that must be addressed to ensure successful commercialization. One of the primary obstacles is the development of reliable and cost-effective production methods for ferrofluid-based display components. The precise control of ferrofluid properties, including magnetic susceptibility, viscosity, and particle size distribution, is crucial for achieving consistent display performance. Current manufacturing processes often struggle to maintain the required level of uniformity across large-scale production batches.

Another significant challenge lies in the encapsulation and sealing of ferrofluid within display units. The long-term stability of ferrofluid is essential for the durability and longevity of display devices. Manufacturers must develop robust encapsulation techniques that prevent leakage, contamination, and degradation of the ferrofluid over time. This includes the selection of compatible materials for containment and the design of effective sealing mechanisms that can withstand various environmental conditions and mechanical stresses.

The integration of ferrofluid components with existing display technologies also poses manufacturing hurdles. Adapting current production lines to incorporate ferrofluid elements requires significant retooling and process modifications. This may involve the development of new assembly techniques, quality control measures, and specialized equipment for handling and manipulating ferrofluids during the manufacturing process.

Furthermore, the scalability of ferrofluid display production presents challenges in terms of maintaining consistent quality and performance across different display sizes and configurations. As the demand for larger and more complex display formats grows, manufacturers must develop scalable production methods that can accommodate varying dimensions while preserving the unique optical and magnetic properties of ferrofluid-based displays.

Environmental and safety considerations also impact the manufacturing process. The production and handling of ferrofluids may involve potentially hazardous materials, necessitating the implementation of stringent safety protocols and waste management procedures. Manufacturers must navigate regulatory requirements and develop eco-friendly production methods to ensure compliance with environmental standards and minimize the ecological footprint of ferrofluid display manufacturing.

Lastly, the cost-effectiveness of ferrofluid display production remains a significant challenge. The specialized materials and processes required for ferrofluid-based displays currently result in higher production costs compared to conventional display technologies. Manufacturers must focus on optimizing production efficiency, exploring alternative materials, and leveraging economies of scale to reduce costs and make ferrofluid displays commercially viable for mass-market adoption.