Future Trends of Ferrofluid in High-Performance Electrical Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have evolved significantly over the past six decades. These unique liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, have garnered increasing attention in various high-performance electrical systems due to their remarkable magnetic and thermal properties.

The evolution of ferrofluids has been marked by continuous improvements in their composition, stability, and performance characteristics. Early ferrofluids faced challenges such as particle agglomeration and limited thermal stability. However, advancements in nanoparticle synthesis and surface modification techniques have led to the development of more stable and efficient ferrofluids.

In recent years, the focus has shifted towards enhancing the magnetic and thermal properties of ferrofluids for specific applications in electrical systems. This includes the development of ferrofluids with higher magnetic saturation, improved heat transfer capabilities, and enhanced dielectric strength. These advancements have opened up new possibilities for ferrofluid applications in areas such as cooling systems for high-power electronics, magnetic sealing in rotating shafts, and damping in precision instruments.

The primary objective in the field of ferrofluids for high-performance electrical systems is to optimize their properties for specific applications while ensuring long-term stability and reliability. This involves tailoring the composition of ferrofluids to achieve desired magnetic, thermal, and rheological characteristics. Additionally, there is a growing emphasis on developing environmentally friendly and cost-effective ferrofluid formulations to facilitate wider adoption in industrial applications.

Another key objective is to improve the integration of ferrofluids into existing electrical system designs. This includes developing novel methods for ferrofluid containment, circulation, and control within complex electrical assemblies. Researchers are also exploring ways to enhance the synergy between ferrofluids and other components in electrical systems, such as combining ferrofluid cooling with traditional heat sink designs for more efficient thermal management.

Looking ahead, the field of ferrofluids in high-performance electrical systems is poised for further innovation. Emerging trends include the development of smart ferrofluids with tunable properties, the exploration of hybrid ferrofluids combining multiple functional materials, and the integration of ferrofluids with advanced sensing and control technologies. These developments aim to create more adaptive and efficient electrical systems capable of meeting the increasing demands of modern applications.

The evolution of ferrofluids has been marked by continuous improvements in their composition, stability, and performance characteristics. Early ferrofluids faced challenges such as particle agglomeration and limited thermal stability. However, advancements in nanoparticle synthesis and surface modification techniques have led to the development of more stable and efficient ferrofluids.

In recent years, the focus has shifted towards enhancing the magnetic and thermal properties of ferrofluids for specific applications in electrical systems. This includes the development of ferrofluids with higher magnetic saturation, improved heat transfer capabilities, and enhanced dielectric strength. These advancements have opened up new possibilities for ferrofluid applications in areas such as cooling systems for high-power electronics, magnetic sealing in rotating shafts, and damping in precision instruments.

The primary objective in the field of ferrofluids for high-performance electrical systems is to optimize their properties for specific applications while ensuring long-term stability and reliability. This involves tailoring the composition of ferrofluids to achieve desired magnetic, thermal, and rheological characteristics. Additionally, there is a growing emphasis on developing environmentally friendly and cost-effective ferrofluid formulations to facilitate wider adoption in industrial applications.

Another key objective is to improve the integration of ferrofluids into existing electrical system designs. This includes developing novel methods for ferrofluid containment, circulation, and control within complex electrical assemblies. Researchers are also exploring ways to enhance the synergy between ferrofluids and other components in electrical systems, such as combining ferrofluid cooling with traditional heat sink designs for more efficient thermal management.

Looking ahead, the field of ferrofluids in high-performance electrical systems is poised for further innovation. Emerging trends include the development of smart ferrofluids with tunable properties, the exploration of hybrid ferrofluids combining multiple functional materials, and the integration of ferrofluids with advanced sensing and control technologies. These developments aim to create more adaptive and efficient electrical systems capable of meeting the increasing demands of modern applications.

Market Demand Analysis

The market demand for ferrofluids in high-performance electrical systems is experiencing significant growth, driven by the increasing need for efficient and compact power solutions across various industries. As energy consumption continues to rise globally, there is a growing emphasis on developing advanced electrical systems that can deliver higher performance while minimizing energy losses.

Ferrofluids, with their unique magnetic properties and thermal management capabilities, are poised to play a crucial role in addressing these market demands. The automotive sector, in particular, is showing strong interest in ferrofluid applications for electric vehicle (EV) powertrains. As the EV market expands rapidly, manufacturers are seeking innovative solutions to enhance motor efficiency, reduce heat generation, and improve overall system reliability.

In the renewable energy sector, ferrofluids are gaining traction for their potential use in wind turbine generators and solar power systems. The ability of ferrofluids to provide enhanced cooling and improved electromagnetic performance aligns well with the industry's push for more efficient and durable power generation equipment.

The data center industry, facing ever-increasing demands for processing power and energy efficiency, is another key market driver for ferrofluid technology. As data centers strive to reduce their carbon footprint and operational costs, the integration of ferrofluids in cooling systems and power distribution units is becoming an attractive option.

Aerospace and defense sectors are also showing interest in ferrofluid applications for advanced electrical systems in aircraft and military equipment. The potential for weight reduction, improved thermal management, and enhanced electromagnetic shielding makes ferrofluids an appealing solution for these high-performance environments.

The industrial automation sector is another area where ferrofluids are expected to see increased demand. As factories become more automated and reliant on sophisticated electrical systems, the need for reliable and efficient power solutions grows. Ferrofluids could play a role in improving the performance and longevity of industrial motors, sensors, and control systems.

Market analysts predict that the global ferrofluid market will continue to expand, with a significant portion of this growth attributed to applications in high-performance electrical systems. The increasing focus on energy efficiency, miniaturization of components, and the push for more sustainable technologies are all factors contributing to the positive market outlook for ferrofluids in this sector.

However, it is important to note that the adoption of ferrofluids in high-performance electrical systems is still in its early stages. While the potential benefits are clear, there are challenges related to long-term stability, cost-effectiveness, and integration with existing technologies that need to be addressed. As research and development efforts intensify, and as more real-world applications demonstrate the advantages of ferrofluid technology, the market demand is expected to accelerate further.

Ferrofluids, with their unique magnetic properties and thermal management capabilities, are poised to play a crucial role in addressing these market demands. The automotive sector, in particular, is showing strong interest in ferrofluid applications for electric vehicle (EV) powertrains. As the EV market expands rapidly, manufacturers are seeking innovative solutions to enhance motor efficiency, reduce heat generation, and improve overall system reliability.

In the renewable energy sector, ferrofluids are gaining traction for their potential use in wind turbine generators and solar power systems. The ability of ferrofluids to provide enhanced cooling and improved electromagnetic performance aligns well with the industry's push for more efficient and durable power generation equipment.

The data center industry, facing ever-increasing demands for processing power and energy efficiency, is another key market driver for ferrofluid technology. As data centers strive to reduce their carbon footprint and operational costs, the integration of ferrofluids in cooling systems and power distribution units is becoming an attractive option.

Aerospace and defense sectors are also showing interest in ferrofluid applications for advanced electrical systems in aircraft and military equipment. The potential for weight reduction, improved thermal management, and enhanced electromagnetic shielding makes ferrofluids an appealing solution for these high-performance environments.

The industrial automation sector is another area where ferrofluids are expected to see increased demand. As factories become more automated and reliant on sophisticated electrical systems, the need for reliable and efficient power solutions grows. Ferrofluids could play a role in improving the performance and longevity of industrial motors, sensors, and control systems.

Market analysts predict that the global ferrofluid market will continue to expand, with a significant portion of this growth attributed to applications in high-performance electrical systems. The increasing focus on energy efficiency, miniaturization of components, and the push for more sustainable technologies are all factors contributing to the positive market outlook for ferrofluids in this sector.

However, it is important to note that the adoption of ferrofluids in high-performance electrical systems is still in its early stages. While the potential benefits are clear, there are challenges related to long-term stability, cost-effectiveness, and integration with existing technologies that need to be addressed. As research and development efforts intensify, and as more real-world applications demonstrate the advantages of ferrofluid technology, the market demand is expected to accelerate further.

Technical Challenges

The integration of ferrofluids into high-performance electrical systems presents several significant technical challenges that researchers and engineers must overcome. One of the primary obstacles is the long-term stability of ferrofluids under intense electromagnetic fields and high temperatures. As electrical systems become more powerful and compact, the ferrofluids used in these applications are subjected to increasingly extreme conditions, which can lead to degradation of their magnetic properties and overall performance over time.

Another critical challenge lies in the precise control and manipulation of ferrofluids within complex electrical systems. While ferrofluids offer unique advantages in terms of heat transfer and magnetic field interaction, their behavior under varying electromagnetic conditions can be difficult to predict and manage. This unpredictability poses challenges in designing reliable and efficient systems that can maintain consistent performance across a wide range of operating conditions.

The development of ferrofluids with enhanced magnetic properties and thermal stability is also a significant hurdle. Current ferrofluids may not possess the ideal combination of magnetic susceptibility, thermal conductivity, and chemical stability required for advanced electrical applications. Researchers are working to synthesize new nanoparticle compositions and carrier fluids that can withstand higher temperatures and magnetic field strengths without compromising their unique properties.

Compatibility issues between ferrofluids and other materials used in electrical systems present another set of challenges. The potential for chemical reactions or physical interactions between ferrofluids and surrounding components, such as insulation materials or conductive elements, must be carefully considered and mitigated to ensure system integrity and longevity.

The scalability of ferrofluid-based solutions in high-performance electrical systems is also a concern. While ferrofluids have shown promise in small-scale applications and laboratory settings, translating these successes to large-scale industrial applications presents significant engineering challenges. Issues such as uniform distribution of nanoparticles, prevention of agglomeration, and maintenance of consistent properties across large volumes of fluid must be addressed.

Lastly, the environmental and safety implications of using ferrofluids in electrical systems require careful consideration. As these materials become more prevalent in industrial applications, concerns about their potential impact on human health and the environment during manufacturing, operation, and disposal must be thoroughly addressed. Developing safe handling procedures and environmentally friendly disposal methods for ferrofluids is crucial for their widespread adoption in high-performance electrical systems.

Another critical challenge lies in the precise control and manipulation of ferrofluids within complex electrical systems. While ferrofluids offer unique advantages in terms of heat transfer and magnetic field interaction, their behavior under varying electromagnetic conditions can be difficult to predict and manage. This unpredictability poses challenges in designing reliable and efficient systems that can maintain consistent performance across a wide range of operating conditions.

The development of ferrofluids with enhanced magnetic properties and thermal stability is also a significant hurdle. Current ferrofluids may not possess the ideal combination of magnetic susceptibility, thermal conductivity, and chemical stability required for advanced electrical applications. Researchers are working to synthesize new nanoparticle compositions and carrier fluids that can withstand higher temperatures and magnetic field strengths without compromising their unique properties.

Compatibility issues between ferrofluids and other materials used in electrical systems present another set of challenges. The potential for chemical reactions or physical interactions between ferrofluids and surrounding components, such as insulation materials or conductive elements, must be carefully considered and mitigated to ensure system integrity and longevity.

The scalability of ferrofluid-based solutions in high-performance electrical systems is also a concern. While ferrofluids have shown promise in small-scale applications and laboratory settings, translating these successes to large-scale industrial applications presents significant engineering challenges. Issues such as uniform distribution of nanoparticles, prevention of agglomeration, and maintenance of consistent properties across large volumes of fluid must be addressed.

Lastly, the environmental and safety implications of using ferrofluids in electrical systems require careful consideration. As these materials become more prevalent in industrial applications, concerns about their potential impact on human health and the environment during manufacturing, operation, and disposal must be thoroughly addressed. Developing safe handling procedures and environmentally friendly disposal methods for ferrofluids is crucial for their widespread adoption in high-performance electrical systems.

Current Ferrofluid Solutions

01 Composition and preparation of ferrofluids

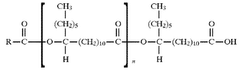

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly for electronic devices. They can be used in cooling systems where their magnetic properties allow for enhanced heat transfer and precise control of fluid flow, improving overall cooling efficiency.

- Sensor and actuator technologies: Ferrofluids are utilized in various sensor and actuator applications. Their unique magnetic properties allow for the development of highly sensitive position sensors, accelerometers, and other devices that can respond to changes in magnetic fields or mechanical forces.

- Medical and biomedical applications: Ferrofluids have potential applications in the medical field, including targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging (MRI). Their ability to be manipulated by external magnetic fields makes them valuable for non-invasive medical procedures.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide a unique combination of liquid properties with magnetic responsiveness, allowing for dynamic sealing and reduced friction in various mechanical systems.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The magnetic properties allow for controlled movement and distribution of the fluid, improving overall thermal management efficiency.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are employed in various sensing and measurement applications, including magnetic field sensors, accelerometers, and inclinometers. Their unique response to magnetic fields allows for precise detection and quantification of magnetic field strength and orientation.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have emerging applications in the medical and biomedical fields. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control these fluids using external magnetic fields offers new possibilities in minimally invasive medical procedures.Expand Specific Solutions

Key Industry Players

The ferrofluid market in high-performance electrical systems is in a growth phase, driven by increasing demand for advanced cooling and sealing solutions. The market size is expanding, with applications in electronics, automotive, and energy sectors. Technologically, ferrofluids are maturing, but innovation continues. Key players like TDK Corp., Koninklijke Philips NV, and LG Energy Solution Ltd. are investing in R&D to enhance ferrofluid properties and applications. Academic institutions such as Yale University and Chongqing University are contributing to fundamental research, while companies like IBM and Applied Materials are exploring industrial applications, indicating a collaborative ecosystem driving technological advancements in this field.

International Business Machines Corp.

Technical Solution: IBM has been pioneering the use of ferrofluids in high-performance electrical systems, particularly in data center cooling applications. Their innovative approach involves using magnetically-controlled ferrofluids to create adaptive cooling channels within server racks[1]. This system dynamically adjusts coolant flow based on real-time heat distribution, significantly improving cooling efficiency. IBM's research also extends to using ferrofluids in nanoscale heat pipes for next-generation chip cooling, where the magnetic properties of ferrofluids are exploited to enhance heat transfer in confined spaces[3]. Additionally, they are exploring ferrofluid-based flexible and stretchable electronics for wearable devices, leveraging the fluid's unique electromagnetic properties[5].

Strengths: Advanced cooling solutions for data centers, potential for miniaturization in chip cooling, and applications in flexible electronics. Weaknesses: High initial implementation costs and potential complexity in large-scale deployment.

Applied Materials, Inc.

Technical Solution: Applied Materials is focusing on integrating ferrofluids into semiconductor manufacturing processes to enhance high-performance electrical systems. They are developing ferrofluid-based polishing slurries for chemical mechanical planarization (CMP) in advanced chip fabrication[2]. These slurries offer superior planarity and reduced defectivity compared to conventional methods. The company is also exploring ferrofluid applications in next-generation lithography systems, where magnetically-controlled ferrofluids could potentially replace traditional immersion fluids, offering better heat dissipation and optical properties[4]. Furthermore, Applied Materials is investigating ferrofluid-enhanced thermal management solutions for high-power density chips, utilizing the fluid's unique heat transfer capabilities under magnetic fields[6].

Strengths: Improved semiconductor manufacturing processes, potential for advanced lithography techniques, and enhanced thermal management in high-power chips. Weaknesses: Integration challenges with existing manufacturing equipment and potential for increased process complexity.

Core Ferrofluid Innovations

Cooling composition for powertrain of electric vehicles

PatentWO2025061695A1

Innovation

- A ferrofluid comprising a liquid carrier, ferromagnetic particles, and a dispersant is used for direct contact cooling of powertrain elements in electric vehicles, enhancing heat extraction through the application of a magnetic field.

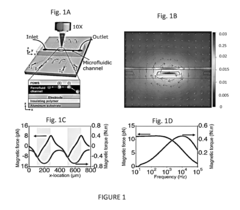

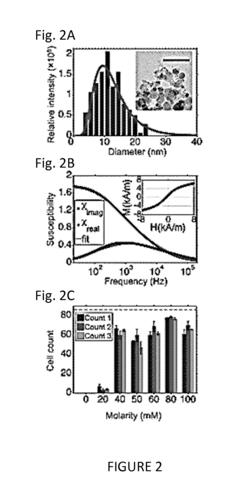

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

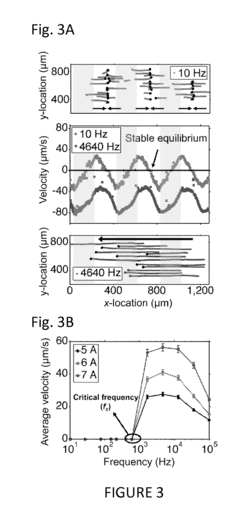

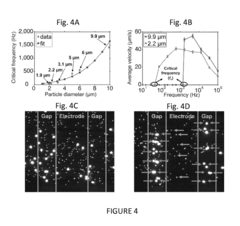

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Environmental Impact Assessment

The environmental impact of ferrofluids in high-performance electrical systems is a critical consideration as this technology continues to evolve. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance the efficiency and performance of electrical systems. However, their potential environmental implications must be carefully assessed.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle release into ecosystems. As these systems age or undergo maintenance, there is a risk of ferrofluid leakage. The long-term effects of these nanoparticles on soil, water, and air quality are not yet fully understood. Research suggests that some magnetic nanoparticles may accumulate in living organisms, potentially disrupting natural processes and food chains.

The production of ferrofluids also raises environmental questions. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. As the demand for ferrofluids in high-performance electrical systems grows, so too will the environmental footprint of their production. This necessitates the development of more sustainable manufacturing methods and the exploration of eco-friendly alternatives for ferrofluid components.

On the positive side, the use of ferrofluids in electrical systems can lead to significant improvements in energy efficiency. By enhancing heat dissipation and reducing friction in various components, ferrofluid-based systems can operate more efficiently, potentially reducing overall energy consumption and associated carbon emissions. This indirect environmental benefit could partially offset the environmental costs of ferrofluid production and potential nanoparticle release.

The disposal and recycling of ferrofluid-containing devices present another environmental challenge. As these systems reach the end of their life cycle, proper handling and recycling procedures must be established to prevent the release of nanoparticles into the environment. This may require the development of specialized recycling facilities and processes capable of safely extracting and repurposing ferrofluids.

Looking ahead, the environmental impact of ferrofluids in high-performance electrical systems will likely be a key focus of future research and development efforts. Innovations in biodegradable ferrofluids and environmentally benign nanoparticle coatings could mitigate some of the current concerns. Additionally, the integration of life cycle assessment methodologies into the design and implementation of ferrofluid-based systems will be crucial for minimizing their environmental footprint.

As the technology advances, regulatory frameworks will need to evolve to address the unique environmental challenges posed by ferrofluids. This may include the establishment of new guidelines for handling, disposal, and environmental monitoring of ferrofluid-containing systems. Collaboration between industry, academia, and regulatory bodies will be essential in developing comprehensive strategies to balance the technological benefits of ferrofluids with environmental protection.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle release into ecosystems. As these systems age or undergo maintenance, there is a risk of ferrofluid leakage. The long-term effects of these nanoparticles on soil, water, and air quality are not yet fully understood. Research suggests that some magnetic nanoparticles may accumulate in living organisms, potentially disrupting natural processes and food chains.

The production of ferrofluids also raises environmental questions. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. As the demand for ferrofluids in high-performance electrical systems grows, so too will the environmental footprint of their production. This necessitates the development of more sustainable manufacturing methods and the exploration of eco-friendly alternatives for ferrofluid components.

On the positive side, the use of ferrofluids in electrical systems can lead to significant improvements in energy efficiency. By enhancing heat dissipation and reducing friction in various components, ferrofluid-based systems can operate more efficiently, potentially reducing overall energy consumption and associated carbon emissions. This indirect environmental benefit could partially offset the environmental costs of ferrofluid production and potential nanoparticle release.

The disposal and recycling of ferrofluid-containing devices present another environmental challenge. As these systems reach the end of their life cycle, proper handling and recycling procedures must be established to prevent the release of nanoparticles into the environment. This may require the development of specialized recycling facilities and processes capable of safely extracting and repurposing ferrofluids.

Looking ahead, the environmental impact of ferrofluids in high-performance electrical systems will likely be a key focus of future research and development efforts. Innovations in biodegradable ferrofluids and environmentally benign nanoparticle coatings could mitigate some of the current concerns. Additionally, the integration of life cycle assessment methodologies into the design and implementation of ferrofluid-based systems will be crucial for minimizing their environmental footprint.

As the technology advances, regulatory frameworks will need to evolve to address the unique environmental challenges posed by ferrofluids. This may include the establishment of new guidelines for handling, disposal, and environmental monitoring of ferrofluid-containing systems. Collaboration between industry, academia, and regulatory bodies will be essential in developing comprehensive strategies to balance the technological benefits of ferrofluids with environmental protection.

Regulatory Framework

The regulatory framework surrounding ferrofluids in high-performance electrical systems is evolving to keep pace with technological advancements and potential applications. As these magnetic nanofluids gain traction in various industries, regulatory bodies are developing guidelines to ensure their safe and responsible use.

One of the primary concerns addressed by regulatory frameworks is the environmental impact of ferrofluids. Agencies such as the Environmental Protection Agency (EPA) in the United States are working on establishing standards for the production, handling, and disposal of ferrofluids. These regulations aim to prevent potential contamination of water sources and ecosystems, given the nanoparticle composition of ferrofluids.

Occupational safety is another critical aspect of the regulatory landscape. Organizations like the Occupational Safety and Health Administration (OSHA) are developing guidelines for workers handling ferrofluids in industrial settings. These guidelines cover proper handling procedures, personal protective equipment requirements, and exposure limits to minimize potential health risks associated with nanoparticle inhalation or skin contact.

In the context of electrical systems, regulatory bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are working on standards for the integration of ferrofluids in high-performance applications. These standards focus on ensuring the reliability, safety, and performance of ferrofluid-based components in electrical systems.

As ferrofluids find applications in medical devices and diagnostic equipment, regulatory agencies like the Food and Drug Administration (FDA) in the United States are developing frameworks for their use in healthcare settings. These regulations address biocompatibility, sterilization procedures, and long-term stability of ferrofluids in medical applications.

The transportation of ferrofluids is also subject to regulatory oversight. Agencies such as the Department of Transportation (DOT) are establishing guidelines for the safe transport of these materials, considering their magnetic properties and potential reactivity under certain conditions.

Intellectual property regulations are evolving to address the unique challenges posed by ferrofluid technologies. Patent offices worldwide are adapting their examination processes to properly evaluate and protect innovations in this field, considering the interdisciplinary nature of ferrofluid applications.

As the technology advances, regulatory frameworks are expected to become more comprehensive and specific. International collaboration among regulatory bodies will likely increase to harmonize standards and ensure consistent safety and performance requirements across different regions. This evolving regulatory landscape will play a crucial role in shaping the future of ferrofluids in high-performance electrical systems, balancing innovation with safety and environmental considerations.

One of the primary concerns addressed by regulatory frameworks is the environmental impact of ferrofluids. Agencies such as the Environmental Protection Agency (EPA) in the United States are working on establishing standards for the production, handling, and disposal of ferrofluids. These regulations aim to prevent potential contamination of water sources and ecosystems, given the nanoparticle composition of ferrofluids.

Occupational safety is another critical aspect of the regulatory landscape. Organizations like the Occupational Safety and Health Administration (OSHA) are developing guidelines for workers handling ferrofluids in industrial settings. These guidelines cover proper handling procedures, personal protective equipment requirements, and exposure limits to minimize potential health risks associated with nanoparticle inhalation or skin contact.

In the context of electrical systems, regulatory bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are working on standards for the integration of ferrofluids in high-performance applications. These standards focus on ensuring the reliability, safety, and performance of ferrofluid-based components in electrical systems.

As ferrofluids find applications in medical devices and diagnostic equipment, regulatory agencies like the Food and Drug Administration (FDA) in the United States are developing frameworks for their use in healthcare settings. These regulations address biocompatibility, sterilization procedures, and long-term stability of ferrofluids in medical applications.

The transportation of ferrofluids is also subject to regulatory oversight. Agencies such as the Department of Transportation (DOT) are establishing guidelines for the safe transport of these materials, considering their magnetic properties and potential reactivity under certain conditions.

Intellectual property regulations are evolving to address the unique challenges posed by ferrofluid technologies. Patent offices worldwide are adapting their examination processes to properly evaluate and protect innovations in this field, considering the interdisciplinary nature of ferrofluid applications.

As the technology advances, regulatory frameworks are expected to become more comprehensive and specific. International collaboration among regulatory bodies will likely increase to harmonize standards and ensure consistent safety and performance requirements across different regions. This evolving regulatory landscape will play a crucial role in shaping the future of ferrofluids in high-performance electrical systems, balancing innovation with safety and environmental considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!