GC-MS Temperature Programming: Optimize Cycle Times

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Temperature Programming Background and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved significantly since its inception in the 1950s, becoming an indispensable analytical technique in various industries including pharmaceuticals, environmental monitoring, food safety, and forensic science. Temperature programming, a critical aspect of GC-MS methodology, refers to the controlled variation of column temperature during analysis to optimize separation efficiency and detection sensitivity.

The historical development of GC-MS temperature programming has progressed from simple isothermal operations to sophisticated multi-ramp temperature profiles. Early GC-MS systems in the 1960s and 1970s offered limited temperature control capabilities, often resulting in extended analysis times and suboptimal separation of complex mixtures. The 1980s and 1990s witnessed significant advancements in temperature control precision and heating/cooling rates, enabling more efficient separations.

Recent technological innovations have focused on rapid temperature ramping capabilities, cryogenic cooling systems, and intelligent temperature profile algorithms. These developments have substantially reduced cycle times while maintaining or improving separation quality. However, despite these advancements, many laboratories still struggle with lengthy analysis cycles that limit sample throughput and increase operational costs.

The primary objective of optimizing GC-MS temperature programming is to achieve the shortest possible cycle time without compromising analytical performance. This involves balancing several competing factors: chromatographic resolution, sensitivity, peak capacity, and instrument durability. Specifically, we aim to develop temperature programming strategies that can reduce total analysis time by at least 30% compared to conventional methods while maintaining equivalent or superior separation efficiency.

Current industry trends indicate a growing demand for high-throughput GC-MS analysis, particularly in regulated environments such as pharmaceutical quality control and environmental monitoring. This demand is driven by economic pressures to increase laboratory productivity and reduce cost per sample. Additionally, emerging applications in metabolomics, food authentication, and real-time process monitoring require faster analytical cycles to handle increasing sample volumes.

The technical evolution trajectory suggests that future GC-MS systems will incorporate more sophisticated temperature control algorithms, potentially leveraging artificial intelligence to optimize temperature profiles based on sample characteristics. Innovations in column technology, including low thermal mass columns and advanced stationary phases, are expected to complement these improvements in temperature programming.

This technical research aims to comprehensively evaluate current temperature programming approaches, identify bottlenecks in cycle time reduction, and explore innovative solutions that can be implemented in both existing and next-generation GC-MS systems.

The historical development of GC-MS temperature programming has progressed from simple isothermal operations to sophisticated multi-ramp temperature profiles. Early GC-MS systems in the 1960s and 1970s offered limited temperature control capabilities, often resulting in extended analysis times and suboptimal separation of complex mixtures. The 1980s and 1990s witnessed significant advancements in temperature control precision and heating/cooling rates, enabling more efficient separations.

Recent technological innovations have focused on rapid temperature ramping capabilities, cryogenic cooling systems, and intelligent temperature profile algorithms. These developments have substantially reduced cycle times while maintaining or improving separation quality. However, despite these advancements, many laboratories still struggle with lengthy analysis cycles that limit sample throughput and increase operational costs.

The primary objective of optimizing GC-MS temperature programming is to achieve the shortest possible cycle time without compromising analytical performance. This involves balancing several competing factors: chromatographic resolution, sensitivity, peak capacity, and instrument durability. Specifically, we aim to develop temperature programming strategies that can reduce total analysis time by at least 30% compared to conventional methods while maintaining equivalent or superior separation efficiency.

Current industry trends indicate a growing demand for high-throughput GC-MS analysis, particularly in regulated environments such as pharmaceutical quality control and environmental monitoring. This demand is driven by economic pressures to increase laboratory productivity and reduce cost per sample. Additionally, emerging applications in metabolomics, food authentication, and real-time process monitoring require faster analytical cycles to handle increasing sample volumes.

The technical evolution trajectory suggests that future GC-MS systems will incorporate more sophisticated temperature control algorithms, potentially leveraging artificial intelligence to optimize temperature profiles based on sample characteristics. Innovations in column technology, including low thermal mass columns and advanced stationary phases, are expected to complement these improvements in temperature programming.

This technical research aims to comprehensively evaluate current temperature programming approaches, identify bottlenecks in cycle time reduction, and explore innovative solutions that can be implemented in both existing and next-generation GC-MS systems.

Market Demand for Rapid Analytical Cycle Times

The analytical chemistry market has witnessed a significant surge in demand for rapid analytical cycle times, particularly in Gas Chromatography-Mass Spectrometry (GC-MS) applications. This demand is driven by multiple factors across various industries that rely on analytical testing for quality control, research, and regulatory compliance.

In pharmaceutical manufacturing, the need for high-throughput screening has intensified as companies strive to accelerate drug development pipelines. Market research indicates that reducing analytical cycle times by even 20% can translate to millions in savings through faster batch releases and increased production capacity. The pharmaceutical analytical testing market, valued at $5.6 billion in 2022, is projected to grow at a CAGR of 8.2% through 2028, with efficiency improvements in analytical methods being a key driver.

Environmental testing laboratories face increasing sample volumes due to stricter regulations and growing public concern about pollutants. These facilities often operate under significant backlogs, with some reporting wait times of 2-3 weeks for standard analyses. Market surveys reveal that laboratories capable of delivering results in half the standard time can command premium pricing, typically 30-40% higher than competitors with standard turnaround times.

The food and beverage industry represents another significant market segment demanding faster analytical cycles. With global food safety testing market expected to reach $24.4 billion by 2025, manufacturers are seeking ways to minimize production holdups while waiting for analytical results. Reducing GC-MS cycle times directly impacts production efficiency and inventory costs.

Contract Research Organizations (CROs) have emerged as major stakeholders in this market, with their business models heavily dependent on analytical throughput. The global CRO market, valued at $63.8 billion in 2022, is experiencing consolidation where technological advantages in analytical speed become critical competitive differentiators.

From an economic perspective, the cost-benefit analysis strongly favors investments in cycle time optimization. Laboratory productivity studies demonstrate that optimized temperature programming in GC-MS can increase sample throughput by 30-50% without additional capital equipment purchases, representing one of the highest ROI opportunities in analytical laboratory operations.

Regional market analysis shows particularly strong demand in Asia-Pacific regions, where rapidly expanding manufacturing sectors are establishing new quality control laboratories that prioritize efficiency from the outset, rather than retrofitting existing workflows.

In pharmaceutical manufacturing, the need for high-throughput screening has intensified as companies strive to accelerate drug development pipelines. Market research indicates that reducing analytical cycle times by even 20% can translate to millions in savings through faster batch releases and increased production capacity. The pharmaceutical analytical testing market, valued at $5.6 billion in 2022, is projected to grow at a CAGR of 8.2% through 2028, with efficiency improvements in analytical methods being a key driver.

Environmental testing laboratories face increasing sample volumes due to stricter regulations and growing public concern about pollutants. These facilities often operate under significant backlogs, with some reporting wait times of 2-3 weeks for standard analyses. Market surveys reveal that laboratories capable of delivering results in half the standard time can command premium pricing, typically 30-40% higher than competitors with standard turnaround times.

The food and beverage industry represents another significant market segment demanding faster analytical cycles. With global food safety testing market expected to reach $24.4 billion by 2025, manufacturers are seeking ways to minimize production holdups while waiting for analytical results. Reducing GC-MS cycle times directly impacts production efficiency and inventory costs.

Contract Research Organizations (CROs) have emerged as major stakeholders in this market, with their business models heavily dependent on analytical throughput. The global CRO market, valued at $63.8 billion in 2022, is experiencing consolidation where technological advantages in analytical speed become critical competitive differentiators.

From an economic perspective, the cost-benefit analysis strongly favors investments in cycle time optimization. Laboratory productivity studies demonstrate that optimized temperature programming in GC-MS can increase sample throughput by 30-50% without additional capital equipment purchases, representing one of the highest ROI opportunities in analytical laboratory operations.

Regional market analysis shows particularly strong demand in Asia-Pacific regions, where rapidly expanding manufacturing sectors are establishing new quality control laboratories that prioritize efficiency from the outset, rather than retrofitting existing workflows.

Current Limitations in GC-MS Temperature Programming

Gas Chromatography-Mass Spectrometry (GC-MS) temperature programming faces several significant limitations that impact analytical efficiency and cycle times. Traditional temperature programming methods often require lengthy cooling periods between analytical runs, creating substantial bottlenecks in high-throughput environments. Current systems typically need 10-15 minutes to cool from maximum operating temperatures (often 350°C) to initial conditions (around 40-60°C), which can represent up to 50% of the total analysis cycle time in routine applications.

Thermal mass constraints of conventional GC ovens present a fundamental physical limitation. Most commercial systems utilize air-circulated ovens with significant thermal inertia, limiting heating rates to 50-120°C/minute and cooling rates to 200-400°C/minute under optimal conditions. These limitations become particularly problematic when analyzing complex mixtures requiring sophisticated multi-ramp temperature programs, as the thermal lag between programmed and actual column temperatures introduces variability in retention times.

Power consumption during rapid heating cycles creates another barrier, with standard GC ovens requiring 2-3 kW during maximum heating rates. This high power demand not only increases operational costs but also limits the implementation of ultra-fast temperature programming in portable or field-deployable instruments where power availability is constrained.

Temperature homogeneity across the column remains challenging, particularly during rapid temperature transitions. Current systems exhibit temperature gradients of 2-5°C across different regions of the column during fast programming, potentially compromising separation efficiency and reproducibility. This issue becomes more pronounced with larger oven volumes and when using multiple columns or complex configurations.

Software limitations further compound these challenges, as many instrument control systems lack sophisticated algorithms for optimizing temperature programs based on sample composition. Current software typically relies on linear or simple multi-ramp programs rather than mathematically optimized profiles that could potentially reduce analysis times while maintaining separation efficiency.

Detector response and data acquisition systems often struggle to keep pace with the increased peak density resulting from accelerated temperature programs. Modern mass spectrometers typically offer scan rates of 10-50 Hz, which may be insufficient for ultra-narrow peaks (often <1 second wide) generated by rapid temperature programming, leading to inadequate peak characterization and potential quantification errors.

These limitations collectively constrain the minimum achievable cycle times in GC-MS analysis, creating a technological barrier that impacts laboratory throughput, operational efficiency, and analytical capabilities across numerous application domains including environmental monitoring, forensic analysis, and high-throughput screening in pharmaceutical development.

Thermal mass constraints of conventional GC ovens present a fundamental physical limitation. Most commercial systems utilize air-circulated ovens with significant thermal inertia, limiting heating rates to 50-120°C/minute and cooling rates to 200-400°C/minute under optimal conditions. These limitations become particularly problematic when analyzing complex mixtures requiring sophisticated multi-ramp temperature programs, as the thermal lag between programmed and actual column temperatures introduces variability in retention times.

Power consumption during rapid heating cycles creates another barrier, with standard GC ovens requiring 2-3 kW during maximum heating rates. This high power demand not only increases operational costs but also limits the implementation of ultra-fast temperature programming in portable or field-deployable instruments where power availability is constrained.

Temperature homogeneity across the column remains challenging, particularly during rapid temperature transitions. Current systems exhibit temperature gradients of 2-5°C across different regions of the column during fast programming, potentially compromising separation efficiency and reproducibility. This issue becomes more pronounced with larger oven volumes and when using multiple columns or complex configurations.

Software limitations further compound these challenges, as many instrument control systems lack sophisticated algorithms for optimizing temperature programs based on sample composition. Current software typically relies on linear or simple multi-ramp programs rather than mathematically optimized profiles that could potentially reduce analysis times while maintaining separation efficiency.

Detector response and data acquisition systems often struggle to keep pace with the increased peak density resulting from accelerated temperature programs. Modern mass spectrometers typically offer scan rates of 10-50 Hz, which may be insufficient for ultra-narrow peaks (often <1 second wide) generated by rapid temperature programming, leading to inadequate peak characterization and potential quantification errors.

These limitations collectively constrain the minimum achievable cycle times in GC-MS analysis, creating a technological barrier that impacts laboratory throughput, operational efficiency, and analytical capabilities across numerous application domains including environmental monitoring, forensic analysis, and high-throughput screening in pharmaceutical development.

Current Temperature Programming Optimization Approaches

01 Optimization of temperature programming parameters

Temperature programming in GC-MS involves carefully controlling the temperature ramp rates, hold times, and cycle durations to achieve optimal separation of compounds. By adjusting these parameters, analysts can reduce analysis time while maintaining resolution. The programming typically includes initial temperature holds, controlled ramp rates, and final temperature plateaus to ensure complete elution of compounds with different volatilities.- Optimization of temperature ramp rates in GC-MS analysis: Temperature programming in GC-MS involves carefully controlled heating rates to improve separation efficiency. Optimized temperature ramp rates can significantly reduce analysis cycle times while maintaining chromatographic resolution. These methods typically involve initial holding periods at lower temperatures followed by programmed increases at specific rates to efficiently separate compounds with different volatilities.

- Fast GC-MS temperature cycling techniques: Advanced fast GC-MS methods employ rapid temperature cycling to decrease overall analysis time. These techniques utilize specialized hardware capable of quick heating and cooling, allowing for shorter cycle times between sample injections. Implementation of these fast temperature programs can reduce traditional analysis times from tens of minutes to just a few minutes while preserving analytical performance.

- Multi-stage temperature programming protocols: Multi-stage temperature programming involves complex heating profiles with multiple ramp rates and isothermal holds designed for specific analytical challenges. These protocols can be optimized to separate closely eluting compounds by applying different heating rates at critical separation points. Such approaches allow for customized temperature cycles that balance analysis speed with separation efficiency for complex sample matrices.

- Automated optimization of GC-MS temperature programs: Software algorithms and machine learning approaches can automatically determine optimal temperature programming parameters to minimize cycle times. These systems analyze compound characteristics and separation requirements to generate temperature profiles that achieve the desired resolution in the shortest possible time. Automated methods can significantly reduce method development time by rapidly testing multiple temperature program variations.

- Cryogenic cooling for rapid GC-MS cycle times: Incorporating cryogenic cooling systems allows for faster temperature cycling between analytical runs. These systems rapidly cool the GC column after high-temperature elution, reducing the waiting time before the next sample injection. The combination of controlled heating rates with efficient cooling mechanisms significantly decreases overall cycle times in high-throughput applications, enabling more samples to be processed in a given timeframe.

02 Fast cycle time techniques for high-throughput analysis

Advanced GC-MS methods employ rapid temperature programming cycles to increase sample throughput. These techniques utilize steep temperature gradients, optimized carrier gas flow rates, and specialized column technologies to reduce cycle times without compromising analytical performance. Fast cooling systems and efficient temperature control mechanisms allow for quicker return to initial conditions, minimizing the time between consecutive analyses.Expand Specific Solutions03 Temperature programming algorithms and automation

Sophisticated algorithms control temperature programming cycles in modern GC-MS systems. These algorithms can dynamically adjust temperature profiles based on sample characteristics, automatically optimize cycle times, and implement complex multi-stage temperature ramps. Computer-controlled systems ensure precise timing and reproducibility of temperature cycles, with feedback mechanisms that maintain temperature accuracy throughout the analytical run.Expand Specific Solutions04 Specialized temperature programming for complex matrices

For complex sample matrices, customized temperature programming cycles are developed to enhance separation efficiency. These specialized programs may include multiple ramp rates within a single analysis, isothermal holds at critical separation temperatures, and controlled cooling phases. Such approaches are particularly valuable for environmental samples, petroleum products, and biological specimens where component separation is challenging.Expand Specific Solutions05 Energy-efficient temperature cycling approaches

Modern GC-MS systems implement energy-efficient temperature programming strategies to reduce power consumption while maintaining analytical performance. These approaches include optimized heating and cooling cycles, insulation technologies, and intelligent power management. Some systems incorporate zone heating, where only portions of the column are heated as needed, or utilize alternative heating technologies that provide more direct and efficient temperature control.Expand Specific Solutions

Leading Manufacturers and Research Groups in GC-MS Technology

GC-MS Temperature Programming optimization for cycle times is currently in a mature development phase, with a global market size estimated at $3-4 billion and growing steadily. The technology landscape shows varying degrees of maturity across applications, with Thermo Fisher Scientific (Bremen) and Agilent Technologies leading innovation through advanced temperature ramping algorithms and hardware solutions. Companies like Siemens, Robert Bosch, and General Electric are integrating these technologies into broader analytical systems, while research institutions such as Kunming University of Science & Technology and Hunan Agricultural University are developing novel approaches to reduce analysis times. The competitive landscape is characterized by established players focusing on high-throughput solutions and emerging companies targeting specialized applications with optimized temperature programming protocols.

Robert Bosch GmbH

Technical Solution: Bosch has developed miniaturized GC-MS systems with advanced temperature programming capabilities for industrial process monitoring applications. Their approach utilizes microelectromechanical systems (MEMS) technology to create miniaturized GC columns with integrated heating elements that enable precise temperature control with minimal power consumption. The system incorporates multi-column parallel analysis with independent temperature programming for each column, allowing simultaneous optimization of multiple separation parameters. Bosch's proprietary thermal management system achieves temperature stability of ±0.1°C across the entire column, eliminating cold spots that can reduce separation efficiency. Their adaptive cycle time optimization algorithm continuously monitors separation quality and adjusts temperature programs in real-time to maintain optimal resolution while minimizing analysis time. The system's modular design allows for rapid column replacement and reconfiguration, reducing downtime between different analysis types and enabling quick adaptation to changing analytical requirements.

Strengths: Miniaturized design enables deployment in space-constrained industrial environments; extremely low power consumption makes it suitable for remote or portable applications; parallel column architecture increases sample throughput. Weaknesses: Limited to relatively simple mixtures compared to laboratory-scale GC-MS systems; smaller column dimensions may reduce separation capacity; specialized column technology increases maintenance costs.

Siemens Corp.

Technical Solution: Siemens has developed an integrated process GC-MS system with advanced temperature programming capabilities designed specifically for industrial process control applications. Their approach combines traditional temperature programming with predictive maintenance algorithms that optimize not just individual analysis cycles but overall system availability. The system employs a dual-oven design that allows one oven to be cooling while the other is actively analyzing, effectively eliminating cooling wait times from the overall cycle. Siemens' proprietary TurboRamp technology utilizes enhanced thermal transfer materials and optimized air flow patterns to achieve temperature ramp rates up to 150°C/min with exceptional temperature uniformity. Their ProcessIQ software platform continuously monitors separation quality and automatically adjusts temperature programs to compensate for column aging and other system changes, maintaining consistent analysis times throughout the column lifecycle. The system also incorporates automated calibration routines that can be executed during column cool-down phases, maximizing productive instrument time.

Strengths: Dual-oven design effectively eliminates cooling wait times from overall cycle; industrial-grade construction ensures reliability in demanding environments; automated adaptation to system changes maintains consistent performance over time. Weaknesses: Larger footprint and higher power consumption than single-oven systems; greater complexity increases potential failure points; primarily optimized for routine industrial analyses rather than research applications.

Key Innovations in Thermal Management for GC-MS

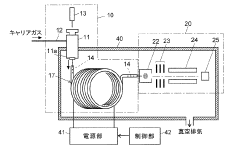

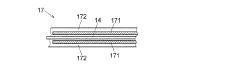

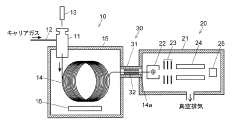

Gas chromatograph mass spectrometer

PatentInactiveJP2019007927A

Innovation

- The GC-MS system places the column and heat source inside a vacuum chamber, eliminating the need for external heat insulation, thereby reducing heat capacity and using direct heating/cooling methods such as heaters or refrigerant pipes within the vacuum chamber.

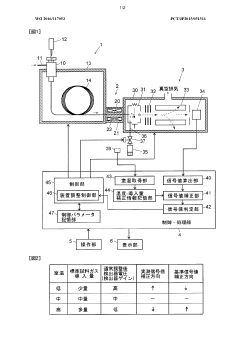

Mass spectroscopy device

PatentWO2016117053A1

Innovation

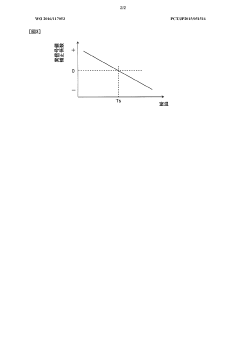

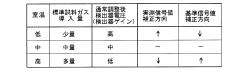

- A mass spectrometer configuration that includes a temperature detection unit, correction information storage, and a flow path switching unit to adjust the device settings based on measured room temperature, ensuring a constant amount of standard sample gas is introduced, using correction information to adjust the ion detector gain and maintain consistent sensitivity.

Method Validation and Regulatory Compliance

Method validation is a critical component in the optimization of GC-MS temperature programming protocols, ensuring that analytical procedures meet regulatory requirements while maintaining efficiency. For GC-MS methods involving temperature programming, validation must adhere to guidelines established by regulatory bodies such as the FDA, EMA, ICH, and ISO. These frameworks typically require demonstration of method specificity, linearity, accuracy, precision, detection limits, quantitation limits, and robustness—all of which can be significantly impacted by temperature programming parameters.

The validation process for optimized cycle times must include comprehensive documentation of temperature ramp rates, hold times, and total cycle duration. This documentation serves as evidence that the method consistently produces reliable results while meeting throughput requirements. Regulatory agencies increasingly scrutinize methods that claim improved efficiency to ensure that analytical integrity has not been compromised for the sake of speed.

System suitability tests (SSTs) play a vital role in method validation, particularly when optimizing temperature programs. These tests verify that the chromatographic system performs adequately under the accelerated conditions, with parameters such as resolution, tailing factor, and signal-to-noise ratio remaining within acceptable limits. For temperature-programmed methods, SSTs should be conducted across the operational range to ensure performance consistency.

Robustness testing takes on heightened importance when cycle times are optimized. Minor variations in temperature programming parameters can potentially have magnified effects in accelerated methods. Validation protocols should therefore include deliberate variations in critical parameters such as initial temperature, ramp rates, and final temperature to demonstrate method stability under realistic operational conditions.

Method transfer considerations must also be addressed during validation, especially when optimized methods will be implemented across multiple laboratories or instruments. Temperature calibration and verification procedures become particularly important, as even small discrepancies between instruments can lead to significant differences in retention times and separation quality when using rapid temperature programming.

Compliance with data integrity requirements presents additional challenges for optimized GC-MS methods. The validation process must demonstrate that faster cycle times do not compromise the quality or completeness of the analytical data. This includes validation of data acquisition rates, ensuring they remain sufficient to accurately characterize narrower peaks that typically result from optimized temperature programs.

The validation process for optimized cycle times must include comprehensive documentation of temperature ramp rates, hold times, and total cycle duration. This documentation serves as evidence that the method consistently produces reliable results while meeting throughput requirements. Regulatory agencies increasingly scrutinize methods that claim improved efficiency to ensure that analytical integrity has not been compromised for the sake of speed.

System suitability tests (SSTs) play a vital role in method validation, particularly when optimizing temperature programs. These tests verify that the chromatographic system performs adequately under the accelerated conditions, with parameters such as resolution, tailing factor, and signal-to-noise ratio remaining within acceptable limits. For temperature-programmed methods, SSTs should be conducted across the operational range to ensure performance consistency.

Robustness testing takes on heightened importance when cycle times are optimized. Minor variations in temperature programming parameters can potentially have magnified effects in accelerated methods. Validation protocols should therefore include deliberate variations in critical parameters such as initial temperature, ramp rates, and final temperature to demonstrate method stability under realistic operational conditions.

Method transfer considerations must also be addressed during validation, especially when optimized methods will be implemented across multiple laboratories or instruments. Temperature calibration and verification procedures become particularly important, as even small discrepancies between instruments can lead to significant differences in retention times and separation quality when using rapid temperature programming.

Compliance with data integrity requirements presents additional challenges for optimized GC-MS methods. The validation process must demonstrate that faster cycle times do not compromise the quality or completeness of the analytical data. This includes validation of data acquisition rates, ensuring they remain sufficient to accurately characterize narrower peaks that typically result from optimized temperature programs.

Energy Efficiency Considerations in GC-MS Operations

Energy efficiency has become a critical consideration in modern analytical laboratories, particularly in the operation of Gas Chromatography-Mass Spectrometry (GC-MS) systems. These instruments are known for their significant energy consumption, primarily due to the high temperatures required during analysis cycles and the power needed for vacuum systems in mass spectrometers.

Temperature programming in GC-MS operations represents one of the most energy-intensive aspects of the analytical process. Traditional temperature ramps can consume substantial electrical power, especially when rapid heating rates are employed or when final temperatures exceed 300°C. Studies indicate that a typical GC-MS system may consume between 1.5-3.0 kWh during a standard analytical run, with approximately 60-70% of this energy dedicated to heating elements.

Recent advancements in GC-MS technology have introduced several energy-efficient alternatives. Low thermal mass (LTM) column systems, for instance, require significantly less power to achieve and maintain target temperatures. These systems can reduce energy consumption by 30-45% compared to conventional ovens while simultaneously enabling faster temperature ramps and cooling cycles.

The implementation of intelligent standby modes represents another significant energy-saving strategy. Modern GC-MS systems can automatically reduce oven temperatures and MS vacuum levels during periods of inactivity, potentially saving 40-60% of energy during non-operational hours. Some manufacturers have developed sophisticated scheduling algorithms that optimize instrument readiness based on laboratory usage patterns.

Vacuum system efficiency has also seen substantial improvements. Next-generation turbomolecular pumps incorporate energy-efficient motors and advanced bearing systems that reduce friction and power requirements. These innovations can decrease the energy consumption of MS vacuum systems by 15-25% without compromising analytical performance.

Laboratory managers should consider total cost of ownership calculations that incorporate energy expenses when evaluating GC-MS systems. The energy savings from more efficient systems can offset higher initial purchase costs within 2-4 years of operation, depending on usage patterns and local energy costs. Additionally, reduced energy consumption aligns with corporate sustainability initiatives and can contribute to laboratory certification requirements.

Future developments in GC-MS energy efficiency will likely focus on ambient temperature ionization techniques, more efficient column heating technologies, and integration with renewable energy sources. These innovations promise to further reduce the environmental footprint of analytical laboratories while maintaining or improving analytical performance.

Temperature programming in GC-MS operations represents one of the most energy-intensive aspects of the analytical process. Traditional temperature ramps can consume substantial electrical power, especially when rapid heating rates are employed or when final temperatures exceed 300°C. Studies indicate that a typical GC-MS system may consume between 1.5-3.0 kWh during a standard analytical run, with approximately 60-70% of this energy dedicated to heating elements.

Recent advancements in GC-MS technology have introduced several energy-efficient alternatives. Low thermal mass (LTM) column systems, for instance, require significantly less power to achieve and maintain target temperatures. These systems can reduce energy consumption by 30-45% compared to conventional ovens while simultaneously enabling faster temperature ramps and cooling cycles.

The implementation of intelligent standby modes represents another significant energy-saving strategy. Modern GC-MS systems can automatically reduce oven temperatures and MS vacuum levels during periods of inactivity, potentially saving 40-60% of energy during non-operational hours. Some manufacturers have developed sophisticated scheduling algorithms that optimize instrument readiness based on laboratory usage patterns.

Vacuum system efficiency has also seen substantial improvements. Next-generation turbomolecular pumps incorporate energy-efficient motors and advanced bearing systems that reduce friction and power requirements. These innovations can decrease the energy consumption of MS vacuum systems by 15-25% without compromising analytical performance.

Laboratory managers should consider total cost of ownership calculations that incorporate energy expenses when evaluating GC-MS systems. The energy savings from more efficient systems can offset higher initial purchase costs within 2-4 years of operation, depending on usage patterns and local energy costs. Additionally, reduced energy consumption aligns with corporate sustainability initiatives and can contribute to laboratory certification requirements.

Future developments in GC-MS energy efficiency will likely focus on ambient temperature ionization techniques, more efficient column heating technologies, and integration with renewable energy sources. These innovations promise to further reduce the environmental footprint of analytical laboratories while maintaining or improving analytical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!