Graphene Battery: Catalyzing Transformations in Energy Models

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a revolutionary advancement in energy storage technology, marking a significant milestone in the evolution of power solutions. The journey of graphene batteries began with the discovery of graphene in 2004, which opened up new possibilities in material science and energy storage. Since then, researchers and engineers have been exploring ways to harness graphene's exceptional properties to enhance battery performance.

The primary objective of graphene battery technology is to address the limitations of conventional lithium-ion batteries, such as limited energy density, slow charging times, and degradation over repeated charge cycles. Graphene's unique characteristics, including high electrical conductivity, mechanical strength, and large surface area, make it an ideal candidate for improving battery efficiency and longevity.

One of the key goals in graphene battery development is to increase energy density, allowing for longer-lasting and more powerful batteries in a compact form factor. This is particularly crucial for applications in electric vehicles, portable electronics, and renewable energy storage systems. Researchers aim to achieve energy densities that surpass current lithium-ion batteries by a factor of two or more.

Another critical objective is to significantly reduce charging times. Graphene's excellent conductivity properties hold the promise of ultra-fast charging capabilities, potentially reducing charging times from hours to minutes. This breakthrough could revolutionize the adoption of electric vehicles and enhance the practicality of portable electronic devices.

Improving the cycle life of batteries is also a key focus area. Graphene's structural stability and resistance to degradation could lead to batteries that maintain their capacity over thousands of charge cycles, far exceeding the lifespan of current battery technologies. This would not only reduce the environmental impact of battery production and disposal but also lower the total cost of ownership for end-users.

The development of graphene batteries also aims to enhance safety features. By incorporating graphene into battery components, researchers seek to mitigate risks associated with thermal runaway and improve overall battery stability. This is particularly important for large-scale energy storage applications and in the automotive industry.

As the technology progresses, there is a growing emphasis on scalability and cost-effectiveness. While graphene batteries show immense potential in laboratory settings, the challenge lies in translating these advancements into commercially viable products. Researchers and industry players are working towards developing manufacturing processes that can produce graphene batteries at scale while keeping costs competitive with existing technologies.

In conclusion, the evolution of graphene batteries is driven by the overarching goal of catalyzing transformations in energy models. By pushing the boundaries of energy storage capabilities, graphene batteries have the potential to revolutionize various sectors, from transportation to renewable energy integration, paving the way for a more sustainable and efficient energy future.

The primary objective of graphene battery technology is to address the limitations of conventional lithium-ion batteries, such as limited energy density, slow charging times, and degradation over repeated charge cycles. Graphene's unique characteristics, including high electrical conductivity, mechanical strength, and large surface area, make it an ideal candidate for improving battery efficiency and longevity.

One of the key goals in graphene battery development is to increase energy density, allowing for longer-lasting and more powerful batteries in a compact form factor. This is particularly crucial for applications in electric vehicles, portable electronics, and renewable energy storage systems. Researchers aim to achieve energy densities that surpass current lithium-ion batteries by a factor of two or more.

Another critical objective is to significantly reduce charging times. Graphene's excellent conductivity properties hold the promise of ultra-fast charging capabilities, potentially reducing charging times from hours to minutes. This breakthrough could revolutionize the adoption of electric vehicles and enhance the practicality of portable electronic devices.

Improving the cycle life of batteries is also a key focus area. Graphene's structural stability and resistance to degradation could lead to batteries that maintain their capacity over thousands of charge cycles, far exceeding the lifespan of current battery technologies. This would not only reduce the environmental impact of battery production and disposal but also lower the total cost of ownership for end-users.

The development of graphene batteries also aims to enhance safety features. By incorporating graphene into battery components, researchers seek to mitigate risks associated with thermal runaway and improve overall battery stability. This is particularly important for large-scale energy storage applications and in the automotive industry.

As the technology progresses, there is a growing emphasis on scalability and cost-effectiveness. While graphene batteries show immense potential in laboratory settings, the challenge lies in translating these advancements into commercially viable products. Researchers and industry players are working towards developing manufacturing processes that can produce graphene batteries at scale while keeping costs competitive with existing technologies.

In conclusion, the evolution of graphene batteries is driven by the overarching goal of catalyzing transformations in energy models. By pushing the boundaries of energy storage capabilities, graphene batteries have the potential to revolutionize various sectors, from transportation to renewable energy integration, paving the way for a more sustainable and efficient energy future.

Market Demand Analysis for Advanced Energy Storage

The market demand for advanced energy storage solutions, particularly graphene batteries, is experiencing a significant surge driven by the global shift towards sustainable energy models. This trend is fueled by increasing environmental concerns, stringent regulations on carbon emissions, and the growing adoption of renewable energy sources. The automotive industry stands at the forefront of this demand, with electric vehicle (EV) manufacturers seeking high-performance, long-lasting, and fast-charging battery solutions to overcome range anxiety and enhance consumer adoption.

The consumer electronics sector also contributes substantially to the market demand for graphene batteries. Smartphone, laptop, and wearable device manufacturers are constantly looking for ways to extend battery life while reducing device weight and size. Graphene batteries, with their potential for higher energy density and faster charging capabilities, align perfectly with these requirements, positioning them as a highly sought-after technology in this space.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage solutions. Graphene batteries offer promising characteristics for grid-scale energy storage, including improved cycle life and faster charge/discharge rates, making them attractive for utility companies and renewable energy project developers.

The industrial and aerospace sectors are also showing increasing interest in graphene battery technology. The potential for lighter, more powerful batteries is particularly appealing for electric aircraft development and space exploration missions, where weight and energy density are critical factors.

Market analysts project substantial growth in the advanced energy storage market, with graphene batteries expected to play a significant role. The global lithium-ion battery market, which graphene batteries aim to enhance or potentially replace, is forecasted to expand rapidly in the coming years. This growth is underpinned by declining battery costs, technological advancements, and supportive government policies promoting clean energy adoption.

However, the market demand for graphene batteries is not without challenges. The technology is still in its early stages of commercialization, and concerns about production scalability and cost-effectiveness need to be addressed. Additionally, the established lithium-ion battery infrastructure presents a barrier to rapid market penetration, requiring significant investment in new manufacturing processes and supply chains.

Despite these challenges, the potential benefits of graphene batteries in terms of performance, sustainability, and versatility continue to drive strong market interest. As research and development efforts intensify and pilot projects demonstrate real-world applications, the demand for graphene batteries is expected to accelerate across multiple industries, reshaping the energy storage landscape and catalyzing transformations in global energy models.

The consumer electronics sector also contributes substantially to the market demand for graphene batteries. Smartphone, laptop, and wearable device manufacturers are constantly looking for ways to extend battery life while reducing device weight and size. Graphene batteries, with their potential for higher energy density and faster charging capabilities, align perfectly with these requirements, positioning them as a highly sought-after technology in this space.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage solutions. Graphene batteries offer promising characteristics for grid-scale energy storage, including improved cycle life and faster charge/discharge rates, making them attractive for utility companies and renewable energy project developers.

The industrial and aerospace sectors are also showing increasing interest in graphene battery technology. The potential for lighter, more powerful batteries is particularly appealing for electric aircraft development and space exploration missions, where weight and energy density are critical factors.

Market analysts project substantial growth in the advanced energy storage market, with graphene batteries expected to play a significant role. The global lithium-ion battery market, which graphene batteries aim to enhance or potentially replace, is forecasted to expand rapidly in the coming years. This growth is underpinned by declining battery costs, technological advancements, and supportive government policies promoting clean energy adoption.

However, the market demand for graphene batteries is not without challenges. The technology is still in its early stages of commercialization, and concerns about production scalability and cost-effectiveness need to be addressed. Additionally, the established lithium-ion battery infrastructure presents a barrier to rapid market penetration, requiring significant investment in new manufacturing processes and supply chains.

Despite these challenges, the potential benefits of graphene batteries in terms of performance, sustainability, and versatility continue to drive strong market interest. As research and development efforts intensify and pilot projects demonstrate real-world applications, the demand for graphene batteries is expected to accelerate across multiple industries, reshaping the energy storage landscape and catalyzing transformations in global energy models.

Current Graphene Battery Technology Landscape

The current graphene battery technology landscape is characterized by significant advancements and promising potential, yet it still faces several challenges in commercialization and large-scale production. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has emerged as a revolutionary material in battery technology due to its exceptional electrical conductivity, mechanical strength, and high surface area.

In the realm of energy storage, graphene-based batteries have shown remarkable improvements over traditional lithium-ion batteries. These advancements include faster charging times, increased energy density, and enhanced cycle life. Several research institutions and companies are actively developing graphene-enhanced electrodes, electrolytes, and other battery components to leverage these properties.

One of the primary areas of focus in graphene battery technology is the development of graphene-based anodes. These anodes have demonstrated the ability to significantly increase the battery's capacity and charging speed. Some prototypes have shown the potential to charge up to five times faster than conventional lithium-ion batteries while maintaining a higher energy density.

Another promising application is the use of graphene in supercapacitors. Graphene-based supercapacitors offer rapid charging and discharging capabilities, making them ideal for applications requiring quick bursts of power. This technology is particularly relevant in electric vehicles, where it could complement traditional batteries to provide enhanced acceleration and regenerative braking efficiency.

Despite these advancements, the graphene battery industry faces several challenges. The primary obstacle is the cost-effective production of high-quality graphene at scale. Current manufacturing processes are often expensive and difficult to scale up, hindering widespread adoption. Additionally, ensuring consistent quality and performance across large-scale production remains a significant hurdle.

Researchers are also grappling with the challenge of effectively integrating graphene into existing battery architectures without compromising stability or safety. The long-term performance and safety of graphene-enhanced batteries in real-world conditions are still under investigation, as the technology is relatively new compared to well-established battery chemistries.

Several companies and startups are at the forefront of graphene battery development. These include established players in the battery industry as well as new entrants focused specifically on graphene technology. Collaborations between academic institutions, research labs, and industry partners are driving much of the innovation in this field.

In the realm of energy storage, graphene-based batteries have shown remarkable improvements over traditional lithium-ion batteries. These advancements include faster charging times, increased energy density, and enhanced cycle life. Several research institutions and companies are actively developing graphene-enhanced electrodes, electrolytes, and other battery components to leverage these properties.

One of the primary areas of focus in graphene battery technology is the development of graphene-based anodes. These anodes have demonstrated the ability to significantly increase the battery's capacity and charging speed. Some prototypes have shown the potential to charge up to five times faster than conventional lithium-ion batteries while maintaining a higher energy density.

Another promising application is the use of graphene in supercapacitors. Graphene-based supercapacitors offer rapid charging and discharging capabilities, making them ideal for applications requiring quick bursts of power. This technology is particularly relevant in electric vehicles, where it could complement traditional batteries to provide enhanced acceleration and regenerative braking efficiency.

Despite these advancements, the graphene battery industry faces several challenges. The primary obstacle is the cost-effective production of high-quality graphene at scale. Current manufacturing processes are often expensive and difficult to scale up, hindering widespread adoption. Additionally, ensuring consistent quality and performance across large-scale production remains a significant hurdle.

Researchers are also grappling with the challenge of effectively integrating graphene into existing battery architectures without compromising stability or safety. The long-term performance and safety of graphene-enhanced batteries in real-world conditions are still under investigation, as the technology is relatively new compared to well-established battery chemistries.

Several companies and startups are at the forefront of graphene battery development. These include established players in the battery industry as well as new entrants focused specifically on graphene technology. Collaborations between academic institutions, research labs, and industry partners are driving much of the innovation in this field.

Existing Graphene Battery Solutions

01 Graphene-based electrode materials

Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This can enhance the energy storage capacity and charge/discharge rates of batteries. Various forms of graphene, such as graphene oxide or reduced graphene oxide, are incorporated into electrode structures to improve battery performance.- Graphene-based electrode materials: Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This can enhance the energy storage capacity and charge/discharge rates of batteries. Various forms of graphene, such as graphene oxide or reduced graphene oxide, are incorporated into electrode structures to improve battery performance.

- Graphene-enhanced electrolytes: Graphene is utilized to improve electrolyte performance in batteries. It can be added to liquid electrolytes or used to create solid-state electrolytes. These graphene-enhanced electrolytes can increase ionic conductivity, improve stability, and enhance overall battery efficiency.

- Graphene-based composite materials: Composite materials incorporating graphene are developed for battery applications. These composites often combine graphene with other materials like metal oxides or polymers to create hybrid structures with enhanced properties. Such composites can improve energy density, cycling stability, and overall battery performance.

- Graphene-enabled battery architectures: Novel battery architectures are designed using graphene as a key component. These designs may include 3D structures, sandwich-type configurations, or hierarchical arrangements that leverage graphene's unique properties. Such architectures aim to optimize energy storage, power delivery, and battery lifespan.

- Graphene-based energy storage modeling: Computational models and simulations are developed to understand and predict the behavior of graphene-based energy storage systems. These models consider factors such as charge transfer kinetics, ion diffusion, and structural changes during cycling. They help in optimizing battery design and predicting long-term performance.

02 Graphene-enhanced electrolytes

Graphene or graphene derivatives are added to battery electrolytes to improve ionic conductivity and stability. This can lead to better overall battery performance, including increased energy density and longer cycle life. The graphene additives can also help in forming a stable solid electrolyte interphase (SEI) layer.Expand Specific Solutions03 Graphene-based composite materials

Composite materials combining graphene with other active materials are developed to create high-performance battery components. These composites can leverage the properties of graphene while addressing its limitations. Examples include graphene-metal oxide composites for cathodes or graphene-silicon composites for anodes.Expand Specific Solutions04 Graphene-enhanced thermal management

Graphene's excellent thermal conductivity is utilized to improve heat dissipation in batteries. This can lead to better temperature control during charging and discharging, potentially increasing battery life and safety. Graphene-based heat spreaders or thermally conductive coatings are incorporated into battery designs.Expand Specific Solutions05 Graphene-based flexible and wearable batteries

Graphene's mechanical flexibility and strength are exploited to create bendable and stretchable battery designs. These batteries can be integrated into wearable devices or flexible electronics. The graphene components can help maintain electrical performance under mechanical stress and strain.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, characterized by intense research and development efforts across academia and industry. While the technology shows immense potential for revolutionizing energy storage, it has not yet reached full commercial maturity. The market size is projected to expand significantly in the coming years, driven by increasing demand for high-performance batteries in various sectors. Companies like Sony Group Corp., NEC Corp., and China Petroleum & Chemical Corp. are investing heavily in graphene battery research, leveraging their expertise in electronics and materials science. Emerging players such as Nanosys, Inc. and OneD Material, Inc. are also making strides in developing innovative graphene-based energy solutions. The competitive landscape is dynamic, with collaborations between industry leaders and research institutions like Zhejiang University and Harbin Institute of Technology accelerating technological advancements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested heavily in graphene research and development for energy storage applications. Their "Graphene-Enhanced Lithium-Ion Battery" (GELIB) technology incorporates graphene into both the anode and cathode materials of lithium-ion batteries. Sinopec's approach utilizes a proprietary graphene synthesis method that produces high-quality, defect-free graphene sheets at scale. The GELIB technology has demonstrated a 30% increase in energy density compared to conventional lithium-ion batteries, with capacities reaching up to 300 mAh/g for graphene-enhanced anodes [8][10]. Sinopec has also developed graphene-based composite materials that improve the thermal management and safety of battery systems. The company's large-scale production capabilities and extensive research facilities have positioned them as a key player in the commercialization of graphene-enhanced energy storage solutions. Sinopec's GELIB technology is being tested in electric vehicle prototypes and stationary energy storage systems for renewable energy integration.

Strengths: Large-scale production capabilities, comprehensive research facilities, and improvements in energy density and safety. Weaknesses: Potential regulatory challenges and competition from established battery manufacturers.

Cappatery, Inc.

Technical Solution: Cappatery has developed a unique graphene-based supercapacitor technology that combines the high power density of supercapacitors with the energy density of batteries. Their proprietary "Graphene-Enhanced Electrochemical Capacitors" (GEEC) utilize a nanostructured graphene electrode material that significantly increases the surface area for charge storage. This approach allows for rapid charging and discharging capabilities while maintaining a higher energy density than traditional supercapacitors. Cappatery's GEECs have demonstrated power densities of up to 15 kW/kg and energy densities reaching 60 Wh/kg [2][5]. The company has also focused on developing environmentally friendly electrolytes to enhance the safety and sustainability of their energy storage solutions. Cappatery's technology is particularly suitable for applications requiring both high power and energy density, such as regenerative braking systems in electric vehicles and grid stabilization for renewable energy integration.

Strengths: Rapid charging/discharging, high power density, and improved safety. Weaknesses: Lower energy density compared to lithium-ion batteries and potential scalability challenges.

Core Innovations in Graphene Battery Technology

Chemical-free production method of graphene-encapsulated electrode active material particles for battery applications

PatentInactiveUS20200266426A1

Innovation

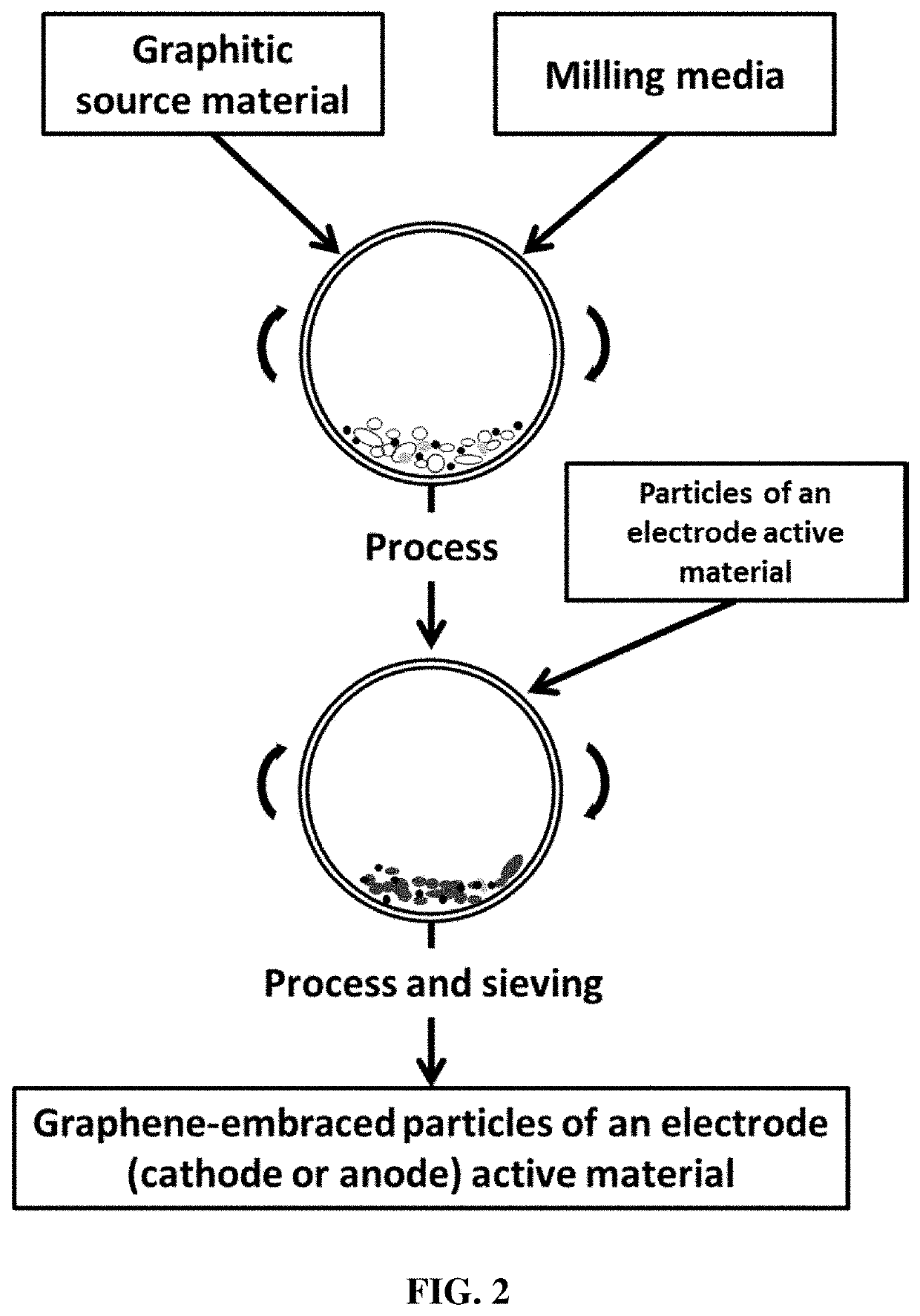

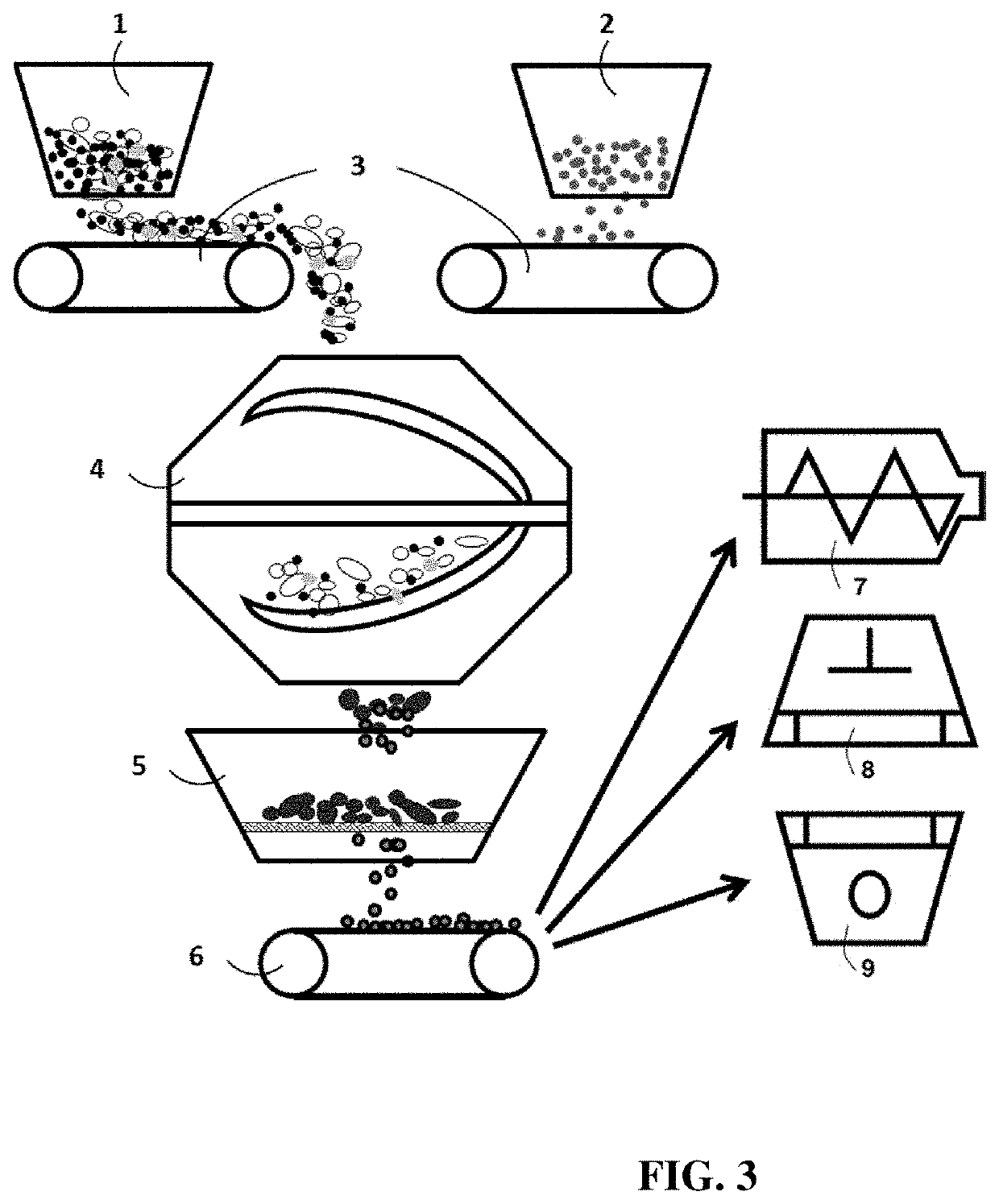

- A method is developed to produce graphene-embraced electrode active materials by directly peeling off graphene sheets from a graphitic material and transferring them onto electrode active material particles, creating a protective and conductive layer that wraps around the particles, enhancing their mechanical stability and conductivity without the need for excessive conductive additives.

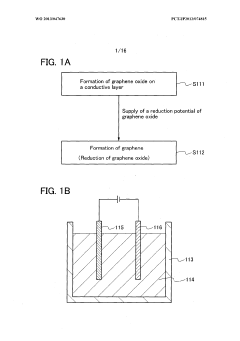

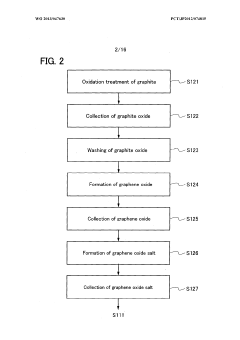

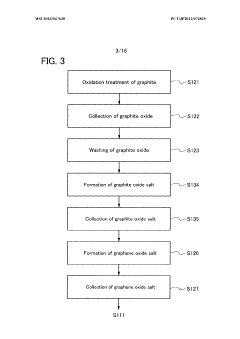

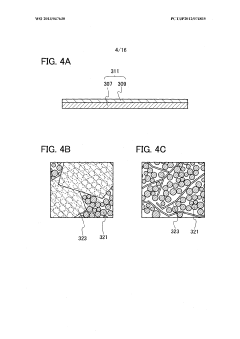

Graphene and power storage device, and manufacturing method thereof

PatentWO2013047630A1

Innovation

- The method involves electrochemically reducing graphene oxide to form graphene, which is integrated into the electrode active material layer, using a potential range of 1.4 V to 2.6 V to enhance conductivity and durability, thereby increasing the charge and discharge capacity while maintaining electrode integrity.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration as this technology advances towards widespread adoption. Graphene batteries offer significant potential for reducing the carbon footprint associated with energy storage systems. Unlike traditional lithium-ion batteries, graphene-based batteries have a longer lifespan and higher energy density, which translates to fewer replacements and less waste generation over time.

One of the primary environmental benefits of graphene batteries is their potential to accelerate the transition to renewable energy sources. By providing more efficient and reliable energy storage solutions, these batteries can help overcome the intermittency challenges associated with solar and wind power. This could lead to a substantial reduction in greenhouse gas emissions from the energy sector, as renewable sources replace fossil fuel-based power generation.

The production of graphene batteries also presents some environmental advantages compared to conventional battery technologies. The raw materials required for graphene production are abundant and can be sourced from various carbon-rich substances, including waste biomass. This reduces the reliance on rare earth elements and other scarce resources that are often mined using environmentally destructive methods.

However, the large-scale production of graphene itself raises some environmental concerns. The energy-intensive processes currently used to manufacture high-quality graphene could potentially offset some of the environmental gains if not managed properly. Research is ongoing to develop more sustainable and scalable production methods, such as using renewable energy sources for graphene synthesis.

End-of-life management of graphene batteries is another critical aspect of their environmental impact. While these batteries are expected to have longer lifespans, proper recycling and disposal methods must be developed to prevent potential environmental contamination. The good news is that graphene is a highly recyclable material, and efforts are underway to establish efficient recycling processes for graphene-based energy storage devices.

Water usage and potential contamination during the production and recycling of graphene batteries are additional environmental factors that require careful consideration. Implementing closed-loop water systems and developing water-efficient manufacturing processes will be essential to minimize the environmental footprint of this technology.

As graphene battery technology continues to evolve, ongoing research and development efforts are focused on further improving their environmental performance. This includes exploring bio-based precursors for graphene production, optimizing manufacturing processes to reduce energy consumption, and developing advanced recycling techniques to maximize material recovery and minimize waste.

One of the primary environmental benefits of graphene batteries is their potential to accelerate the transition to renewable energy sources. By providing more efficient and reliable energy storage solutions, these batteries can help overcome the intermittency challenges associated with solar and wind power. This could lead to a substantial reduction in greenhouse gas emissions from the energy sector, as renewable sources replace fossil fuel-based power generation.

The production of graphene batteries also presents some environmental advantages compared to conventional battery technologies. The raw materials required for graphene production are abundant and can be sourced from various carbon-rich substances, including waste biomass. This reduces the reliance on rare earth elements and other scarce resources that are often mined using environmentally destructive methods.

However, the large-scale production of graphene itself raises some environmental concerns. The energy-intensive processes currently used to manufacture high-quality graphene could potentially offset some of the environmental gains if not managed properly. Research is ongoing to develop more sustainable and scalable production methods, such as using renewable energy sources for graphene synthesis.

End-of-life management of graphene batteries is another critical aspect of their environmental impact. While these batteries are expected to have longer lifespans, proper recycling and disposal methods must be developed to prevent potential environmental contamination. The good news is that graphene is a highly recyclable material, and efforts are underway to establish efficient recycling processes for graphene-based energy storage devices.

Water usage and potential contamination during the production and recycling of graphene batteries are additional environmental factors that require careful consideration. Implementing closed-loop water systems and developing water-efficient manufacturing processes will be essential to minimize the environmental footprint of this technology.

As graphene battery technology continues to evolve, ongoing research and development efforts are focused on further improving their environmental performance. This includes exploring bio-based precursors for graphene production, optimizing manufacturing processes to reduce energy consumption, and developing advanced recycling techniques to maximize material recovery and minimize waste.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges of graphene batteries represent significant hurdles in their widespread adoption and commercialization. While graphene's exceptional properties offer immense potential for energy storage, translating these benefits from laboratory-scale experiments to industrial-scale production remains a complex task.

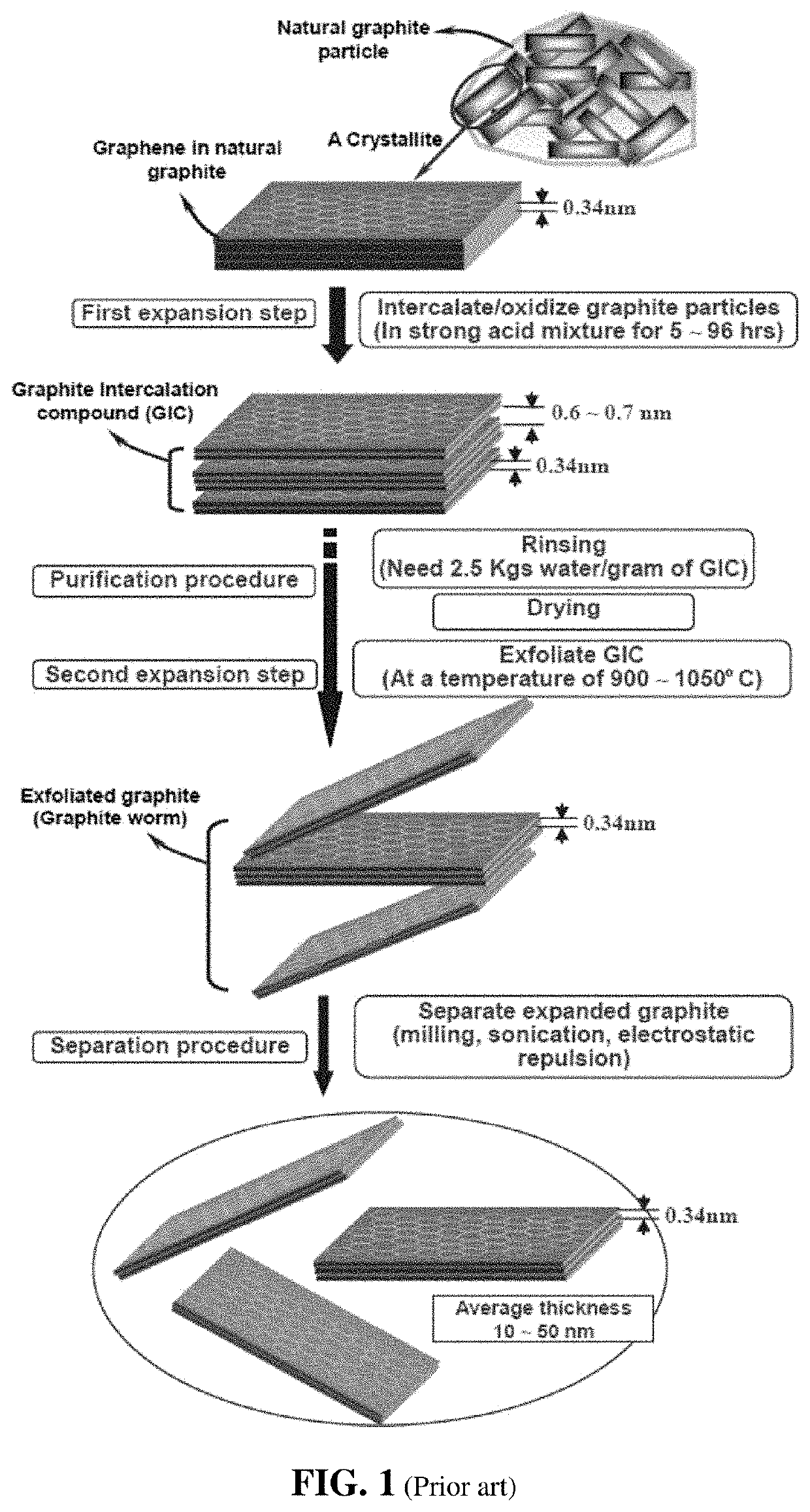

One of the primary challenges lies in the mass production of high-quality graphene. Current methods, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, struggle to maintain consistency and purity when scaled up. The CVD process, while producing high-quality graphene, is limited by its slow growth rate and high production costs. Liquid-phase exfoliation, though more scalable, often results in graphene with structural defects and impurities that can compromise battery performance.

The integration of graphene into existing battery manufacturing processes presents another significant challenge. Traditional battery production lines are not optimized for handling nanomaterials like graphene, requiring substantial modifications to equipment and procedures. This adaptation process is both time-consuming and capital-intensive, potentially deterring manufacturers from embracing the technology.

Quality control and standardization pose additional obstacles. The performance of graphene batteries heavily depends on the uniformity and purity of the graphene used. Developing reliable quality assurance methods for large-scale production is crucial but technically challenging due to graphene's nanoscale nature.

Environmental and safety concerns also impact scalability. The production of graphene and its incorporation into batteries must adhere to strict environmental regulations. Ensuring worker safety when handling nanomaterials at an industrial scale requires the development of new safety protocols and specialized equipment.

Cost-effectiveness remains a critical factor in scaling up graphene battery production. While graphene promises enhanced performance, the current high production costs make it difficult to compete with established battery technologies on price. Achieving economies of scale is essential but requires significant upfront investment in research, development, and manufacturing infrastructure.

Addressing these challenges requires a multifaceted approach involving collaboration between materials scientists, chemical engineers, and manufacturing experts. Innovations in graphene synthesis, such as roll-to-roll production methods, show promise for scalable manufacturing. Similarly, advancements in nanomaterial handling and integration techniques could pave the way for more efficient production processes. As research progresses and manufacturing techniques evolve, the path to large-scale production of graphene batteries becomes clearer, potentially revolutionizing the energy storage landscape.

One of the primary challenges lies in the mass production of high-quality graphene. Current methods, such as chemical vapor deposition (CVD) and liquid-phase exfoliation, struggle to maintain consistency and purity when scaled up. The CVD process, while producing high-quality graphene, is limited by its slow growth rate and high production costs. Liquid-phase exfoliation, though more scalable, often results in graphene with structural defects and impurities that can compromise battery performance.

The integration of graphene into existing battery manufacturing processes presents another significant challenge. Traditional battery production lines are not optimized for handling nanomaterials like graphene, requiring substantial modifications to equipment and procedures. This adaptation process is both time-consuming and capital-intensive, potentially deterring manufacturers from embracing the technology.

Quality control and standardization pose additional obstacles. The performance of graphene batteries heavily depends on the uniformity and purity of the graphene used. Developing reliable quality assurance methods for large-scale production is crucial but technically challenging due to graphene's nanoscale nature.

Environmental and safety concerns also impact scalability. The production of graphene and its incorporation into batteries must adhere to strict environmental regulations. Ensuring worker safety when handling nanomaterials at an industrial scale requires the development of new safety protocols and specialized equipment.

Cost-effectiveness remains a critical factor in scaling up graphene battery production. While graphene promises enhanced performance, the current high production costs make it difficult to compete with established battery technologies on price. Achieving economies of scale is essential but requires significant upfront investment in research, development, and manufacturing infrastructure.

Addressing these challenges requires a multifaceted approach involving collaboration between materials scientists, chemical engineers, and manufacturing experts. Innovations in graphene synthesis, such as roll-to-roll production methods, show promise for scalable manufacturing. Similarly, advancements in nanomaterial handling and integration techniques could pave the way for more efficient production processes. As research progresses and manufacturing techniques evolve, the path to large-scale production of graphene batteries becomes clearer, potentially revolutionizing the energy storage landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!