Graphene Battery's Role in Electrifying Future Transport

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution

Graphene batteries have undergone a remarkable evolution since their inception, marking significant milestones in the quest for more efficient and sustainable energy storage solutions. The journey began with the discovery of graphene in 2004, which opened up new possibilities in battery technology. Initially, researchers focused on incorporating graphene into existing lithium-ion battery designs to enhance their performance.

The first major breakthrough came in the early 2010s when scientists successfully developed graphene-based anodes. These anodes demonstrated superior conductivity and increased surface area, leading to faster charging times and improved energy density. This development paved the way for the next phase of graphene battery evolution, which focused on optimizing the cathode materials.

By the mid-2010s, researchers had made significant progress in developing graphene-enhanced cathodes. These new cathodes, often incorporating graphene oxide or reduced graphene oxide, showed improved stability and higher capacity retention over multiple charge-discharge cycles. This advancement addressed one of the key limitations of traditional lithium-ion batteries: capacity fade over time.

The late 2010s saw a shift towards developing full graphene batteries, where both the anode and cathode were graphene-based. These prototypes demonstrated unprecedented energy density and charging speeds, with some models achieving charging times of less than 15 minutes for a full charge. However, challenges in scalability and manufacturing costs initially limited their commercial viability.

As we entered the 2020s, the focus shifted towards overcoming these production challenges. Researchers and companies invested heavily in developing cost-effective manufacturing processes for graphene batteries. This period also saw increased attention on enhancing the safety features of graphene batteries, particularly in addressing thermal management issues.

Recent years have witnessed a growing interest in applying graphene battery technology to electric vehicles. The potential for faster charging times and increased energy density aligns perfectly with the needs of the automotive industry. Several major car manufacturers have announced partnerships with graphene battery developers, signaling a potential shift in the electric vehicle landscape.

Looking ahead, the evolution of graphene batteries is expected to continue at a rapid pace. Current research is focusing on further improving energy density, extending cycle life, and reducing production costs. There is also growing interest in exploring hybrid systems that combine graphene with other advanced materials to create even more efficient energy storage solutions. As these developments progress, graphene batteries are poised to play a crucial role in electrifying future transport, potentially revolutionizing the way we power our vehicles and contributing significantly to sustainable mobility solutions.

The first major breakthrough came in the early 2010s when scientists successfully developed graphene-based anodes. These anodes demonstrated superior conductivity and increased surface area, leading to faster charging times and improved energy density. This development paved the way for the next phase of graphene battery evolution, which focused on optimizing the cathode materials.

By the mid-2010s, researchers had made significant progress in developing graphene-enhanced cathodes. These new cathodes, often incorporating graphene oxide or reduced graphene oxide, showed improved stability and higher capacity retention over multiple charge-discharge cycles. This advancement addressed one of the key limitations of traditional lithium-ion batteries: capacity fade over time.

The late 2010s saw a shift towards developing full graphene batteries, where both the anode and cathode were graphene-based. These prototypes demonstrated unprecedented energy density and charging speeds, with some models achieving charging times of less than 15 minutes for a full charge. However, challenges in scalability and manufacturing costs initially limited their commercial viability.

As we entered the 2020s, the focus shifted towards overcoming these production challenges. Researchers and companies invested heavily in developing cost-effective manufacturing processes for graphene batteries. This period also saw increased attention on enhancing the safety features of graphene batteries, particularly in addressing thermal management issues.

Recent years have witnessed a growing interest in applying graphene battery technology to electric vehicles. The potential for faster charging times and increased energy density aligns perfectly with the needs of the automotive industry. Several major car manufacturers have announced partnerships with graphene battery developers, signaling a potential shift in the electric vehicle landscape.

Looking ahead, the evolution of graphene batteries is expected to continue at a rapid pace. Current research is focusing on further improving energy density, extending cycle life, and reducing production costs. There is also growing interest in exploring hybrid systems that combine graphene with other advanced materials to create even more efficient energy storage solutions. As these developments progress, graphene batteries are poised to play a crucial role in electrifying future transport, potentially revolutionizing the way we power our vehicles and contributing significantly to sustainable mobility solutions.

Market Demand Analysis

The market demand for graphene batteries in the transport sector is experiencing a significant upward trajectory, driven by the global push towards electrification and sustainable mobility solutions. As governments worldwide implement stricter emissions regulations and set ambitious targets for electric vehicle (EV) adoption, the need for advanced energy storage technologies has become paramount.

Graphene batteries offer several advantages over traditional lithium-ion batteries, including higher energy density, faster charging capabilities, and improved safety features. These characteristics align well with the evolving needs of the automotive industry, where range anxiety and charging time remain key concerns for potential EV buyers. The market for graphene batteries in transportation is expected to grow substantially in the coming years, with some industry analysts projecting a compound annual growth rate (CAGR) of over 20% through 2030.

The passenger vehicle segment currently represents the largest market share for graphene batteries in transportation. Major automakers are investing heavily in research and development to incorporate graphene-enhanced batteries into their EV lineups, aiming to offer vehicles with longer ranges and shorter charging times. This trend is particularly evident in the premium and luxury car segments, where early adoption of cutting-edge technologies is more common.

Commercial vehicles, including buses and trucks, are also emerging as a significant market for graphene batteries. The logistics and public transportation sectors are increasingly looking to electrify their fleets to reduce operational costs and meet environmental regulations. Graphene batteries' potential for faster charging and longer lifespan makes them particularly attractive for these applications, where vehicle downtime can have substantial economic impacts.

The aerospace industry is another sector showing growing interest in graphene battery technology. Electric and hybrid-electric aircraft concepts are gaining traction, and graphene batteries could play a crucial role in making these designs viable. The lightweight nature of graphene-enhanced batteries aligns well with the aerospace industry's constant pursuit of weight reduction to improve fuel efficiency and range.

Market demand is also being driven by the broader trend towards smart cities and sustainable urban transportation solutions. Electric bikes, scooters, and other micromobility vehicles are becoming increasingly popular in urban areas, and graphene batteries could enhance the performance and convenience of these small-scale electric vehicles.

While the potential market for graphene batteries in transportation is substantial, it's important to note that the technology is still in its early stages of commercialization. Challenges such as high production costs and scalability issues need to be addressed to fully capitalize on the market demand. However, ongoing research and development efforts, coupled with increasing investment in the sector, suggest that these hurdles may be overcome in the near future, paving the way for widespread adoption of graphene batteries in the transport industry.

Graphene batteries offer several advantages over traditional lithium-ion batteries, including higher energy density, faster charging capabilities, and improved safety features. These characteristics align well with the evolving needs of the automotive industry, where range anxiety and charging time remain key concerns for potential EV buyers. The market for graphene batteries in transportation is expected to grow substantially in the coming years, with some industry analysts projecting a compound annual growth rate (CAGR) of over 20% through 2030.

The passenger vehicle segment currently represents the largest market share for graphene batteries in transportation. Major automakers are investing heavily in research and development to incorporate graphene-enhanced batteries into their EV lineups, aiming to offer vehicles with longer ranges and shorter charging times. This trend is particularly evident in the premium and luxury car segments, where early adoption of cutting-edge technologies is more common.

Commercial vehicles, including buses and trucks, are also emerging as a significant market for graphene batteries. The logistics and public transportation sectors are increasingly looking to electrify their fleets to reduce operational costs and meet environmental regulations. Graphene batteries' potential for faster charging and longer lifespan makes them particularly attractive for these applications, where vehicle downtime can have substantial economic impacts.

The aerospace industry is another sector showing growing interest in graphene battery technology. Electric and hybrid-electric aircraft concepts are gaining traction, and graphene batteries could play a crucial role in making these designs viable. The lightweight nature of graphene-enhanced batteries aligns well with the aerospace industry's constant pursuit of weight reduction to improve fuel efficiency and range.

Market demand is also being driven by the broader trend towards smart cities and sustainable urban transportation solutions. Electric bikes, scooters, and other micromobility vehicles are becoming increasingly popular in urban areas, and graphene batteries could enhance the performance and convenience of these small-scale electric vehicles.

While the potential market for graphene batteries in transportation is substantial, it's important to note that the technology is still in its early stages of commercialization. Challenges such as high production costs and scalability issues need to be addressed to fully capitalize on the market demand. However, ongoing research and development efforts, coupled with increasing investment in the sector, suggest that these hurdles may be overcome in the near future, paving the way for widespread adoption of graphene batteries in the transport industry.

Technical Challenges

Despite the promising potential of graphene batteries in electrifying future transport, several significant technical challenges persist. One of the primary obstacles is the scalability of graphene production. While laboratory-scale synthesis of high-quality graphene has been achieved, translating this to industrial-scale production while maintaining consistent quality and properties remains a formidable challenge. The current methods of graphene synthesis, such as chemical vapor deposition and liquid-phase exfoliation, are either too expensive or too slow for mass production, hindering the widespread adoption of graphene batteries in the automotive industry.

Another critical challenge lies in the integration of graphene into existing battery architectures. While graphene exhibits exceptional electrical and thermal conductivity, incorporating it into conventional lithium-ion battery designs without compromising other essential properties, such as energy density and cycle life, requires extensive research and development. The interface between graphene and other battery components, particularly the electrolyte, needs to be optimized to ensure efficient ion transport and prevent unwanted side reactions that could lead to capacity fade or safety issues.

The long-term stability of graphene-based electrodes in battery environments is another area of concern. Under repeated charge-discharge cycles and exposure to aggressive electrolytes, graphene structures may degrade or undergo undesirable transformations, potentially leading to reduced performance or premature battery failure. Developing strategies to mitigate these degradation mechanisms and enhance the long-term durability of graphene batteries is crucial for their successful implementation in electric vehicles.

Furthermore, the cost of graphene production and battery manufacturing remains a significant barrier to commercialization. While the raw materials for graphene (carbon) are abundant and inexpensive, the processing and purification steps required to produce high-quality graphene suitable for battery applications are currently cost-prohibitive for mass-market adoption. Reducing these production costs while maintaining the desired material properties is essential for making graphene batteries economically viable for the automotive industry.

Lastly, safety concerns associated with high-energy-density batteries pose a challenge for graphene battery development. As graphene enables faster charging and higher power output, managing thermal runaway risks and ensuring safe operation under various environmental conditions become critical. Developing robust safety mechanisms and thermal management systems tailored to the unique properties of graphene batteries is necessary to meet stringent automotive safety standards and gain consumer trust.

Another critical challenge lies in the integration of graphene into existing battery architectures. While graphene exhibits exceptional electrical and thermal conductivity, incorporating it into conventional lithium-ion battery designs without compromising other essential properties, such as energy density and cycle life, requires extensive research and development. The interface between graphene and other battery components, particularly the electrolyte, needs to be optimized to ensure efficient ion transport and prevent unwanted side reactions that could lead to capacity fade or safety issues.

The long-term stability of graphene-based electrodes in battery environments is another area of concern. Under repeated charge-discharge cycles and exposure to aggressive electrolytes, graphene structures may degrade or undergo undesirable transformations, potentially leading to reduced performance or premature battery failure. Developing strategies to mitigate these degradation mechanisms and enhance the long-term durability of graphene batteries is crucial for their successful implementation in electric vehicles.

Furthermore, the cost of graphene production and battery manufacturing remains a significant barrier to commercialization. While the raw materials for graphene (carbon) are abundant and inexpensive, the processing and purification steps required to produce high-quality graphene suitable for battery applications are currently cost-prohibitive for mass-market adoption. Reducing these production costs while maintaining the desired material properties is essential for making graphene batteries economically viable for the automotive industry.

Lastly, safety concerns associated with high-energy-density batteries pose a challenge for graphene battery development. As graphene enables faster charging and higher power output, managing thermal runaway risks and ensuring safe operation under various environmental conditions become critical. Developing robust safety mechanisms and thermal management systems tailored to the unique properties of graphene batteries is necessary to meet stringent automotive safety standards and gain consumer trust.

Current Solutions

01 Graphene-based electrode materials

Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This can improve the battery's capacity, charge/discharge rates, and overall performance. Various forms of graphene, such as graphene oxide or reduced graphene oxide, are incorporated into electrode structures to enhance energy storage capabilities.- Graphene-based electrode materials: Graphene is used as a key component in battery electrodes due to its excellent electrical conductivity and high surface area. This enhances the battery's charge/discharge rates and overall performance. Graphene can be incorporated into both anode and cathode materials, often in combination with other materials like metal oxides or silicon.

- Graphene-enhanced electrolytes: Graphene or graphene oxide can be used to improve battery electrolytes. These materials can enhance ionic conductivity, stabilize the electrolyte, and improve the formation of a stable solid electrolyte interphase (SEI) layer. This results in better battery performance and longevity.

- Graphene-based composite materials: Composite materials combining graphene with other substances like metal oxides, polymers, or carbon nanotubes are developed to leverage the benefits of each component. These composites can offer improved capacity, cycling stability, and mechanical properties compared to traditional battery materials.

- Graphene production and modification for battery applications: Various methods for producing and modifying graphene specifically for battery applications are developed. These include techniques for creating graphene with specific properties, functionalization of graphene surfaces, and methods to integrate graphene into existing battery manufacturing processes.

- Graphene-based flexible and wearable batteries: Graphene's unique properties are utilized in the development of flexible and wearable battery technologies. These batteries can maintain performance while being bent or stretched, opening up new applications in wearable electronics and flexible devices.

02 Graphene-enhanced electrolytes

Graphene or its derivatives are incorporated into battery electrolytes to improve ionic conductivity and stability. This can lead to better battery performance, increased safety, and longer lifespan. The addition of graphene to electrolytes can also help in reducing dendrite formation in lithium-based batteries.Expand Specific Solutions03 Graphene composite materials for battery components

Graphene is combined with other materials to create composite structures for various battery components, including electrodes and separators. These composites can enhance mechanical strength, thermal management, and overall battery performance. Examples include graphene-polymer composites and graphene-metal oxide hybrids.Expand Specific Solutions04 Graphene-based flexible and wearable batteries

Graphene's flexibility and strength make it suitable for developing flexible and wearable battery technologies. These batteries can be integrated into clothing, accessories, or other flexible devices, opening up new applications in wearable electronics and IoT devices.Expand Specific Solutions05 Graphene production and processing for battery applications

Various methods for producing and processing graphene specifically for battery applications are developed. These include techniques for large-scale graphene production, functionalization of graphene for better integration into battery components, and methods for creating specific graphene structures optimized for energy storage.Expand Specific Solutions

Key Industry Players

The graphene battery market for electrifying future transport is in an early growth stage, with significant potential for expansion. The technology's maturity is advancing rapidly, driven by research from institutions like Northwestern University and companies such as Semiconductor Energy Laboratory. Market players include established firms like Western Digital and China Petroleum & Chemical Corp, alongside specialized entities like Morion NanoTech and Qinghai Yingtian Energy. The competitive landscape is diverse, featuring collaborations between academia and industry, with major automotive players like Volvo showing interest. As the technology progresses, we can expect increased market consolidation and potential breakthroughs in energy density and charging speeds, crucial for widespread adoption in electric vehicles.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is investing heavily in graphene battery technology for electric vehicles. Their research focuses on developing graphene-enhanced lithium-sulfur (Li-S) batteries, which offer potentially higher energy densities than traditional lithium-ion batteries[13]. Sinopec's approach involves using graphene as a conductive scaffold for sulfur cathodes, addressing the typical challenges of Li-S batteries such as the "shuttle effect" and poor cycle life[14]. The company claims their graphene-enhanced Li-S batteries can achieve energy densities up to 650 Wh/kg, more than double that of current lithium-ion batteries[15]. Sinopec is also exploring the use of their extensive petrochemical infrastructure to produce high-quality graphene at scale, potentially reducing the cost of graphene-based battery technologies.

Strengths: Potential for very high energy density. Leveraging existing petrochemical infrastructure for graphene production. Weaknesses: Challenges in overcoming inherent issues with Li-S chemistry. Relatively early stage of development compared to more established battery technologies.

NEC Corp.

Technical Solution: NEC Corp. is advancing graphene battery technology for electric vehicles through their innovative "graphene supercapacitor" approach. This technology combines the high power density of supercapacitors with the energy storage capacity of batteries[10]. NEC's graphene supercapacitors utilize a highly porous graphene structure that allows for rapid charge and discharge cycles while maintaining a high energy density. The company claims their technology can achieve charging times up to 10 times faster than conventional lithium-ion batteries while still providing comparable energy storage[11]. NEC is also exploring the integration of their graphene supercapacitors with traditional batteries in a hybrid system, potentially offering both high power and high energy density for electric vehicles[12].

Strengths: Extremely fast charging capabilities and high power density. Potential for long cycle life. Weaknesses: Lower energy density compared to pure battery systems. Challenges in large-scale manufacturing of high-quality graphene materials.

Core Innovations

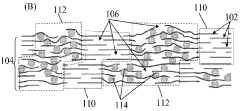

Rapid macro-scale synthesis of free-standing graphene, high performance, binder-free graphene anode material, and methods of synthesizing the anode material

PatentInactiveUS20140050910A1

Innovation

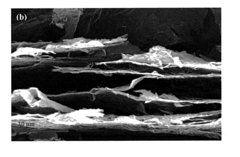

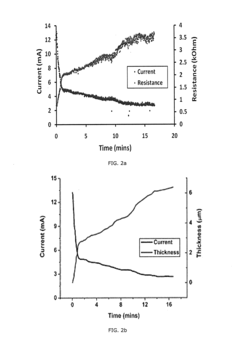

- A method involving the combination of graphite oxide with water to form a colloidal suspension, applying a potentiostatic field, and drying to create a graphene oxide paper, followed by photo-thermal or thermal exfoliation to produce reduced graphene oxide (RGO) paper with high thickness and surface area, enabling scalable and efficient production.

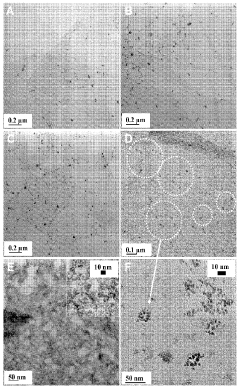

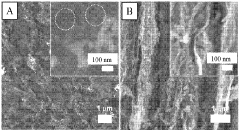

Graphene materials having randomly distributed two-dimensional structural defects

PatentWO2012154183A1

Innovation

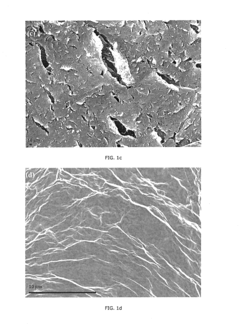

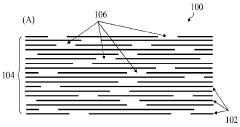

- Graphene-based materials with randomly distributed two-dimensional structural defects, such as carbon vacancies, are used to create a vertical stack with a continuous network of graphitic regions and disordered portions, integrated with electrochemically active materials like silicon nanoparticles, facilitating enhanced Li ion diffusion and mechanical integrity.

Environmental Impact

The adoption of graphene batteries in future transport systems presents a significant opportunity to reduce the environmental impact of the transportation sector. Graphene's unique properties allow for the development of batteries with higher energy density, faster charging capabilities, and longer lifespans compared to traditional lithium-ion batteries. These characteristics contribute to a more sustainable and eco-friendly transportation ecosystem.

One of the primary environmental benefits of graphene batteries is their potential to extend the range of electric vehicles (EVs) while reducing battery weight. This increased efficiency translates to fewer raw materials required for battery production and less energy consumption during vehicle operation. As a result, the overall carbon footprint associated with EV manufacturing and use is significantly reduced.

Moreover, the enhanced durability and longer lifespan of graphene batteries contribute to a reduction in electronic waste. Traditional lithium-ion batteries often require replacement after a few years of use, leading to increased waste and resource consumption. Graphene batteries, with their improved cycle life, can remain operational for longer periods, minimizing the need for frequent replacements and reducing the environmental burden of battery disposal.

The faster charging capabilities of graphene batteries also have positive environmental implications. Reduced charging times can lead to more efficient use of charging infrastructure, potentially decreasing the number of charging stations required and the associated land use. Additionally, faster charging enables more widespread adoption of electric vehicles, accelerating the transition away from fossil fuel-dependent transportation.

From a manufacturing perspective, graphene batteries have the potential to be produced using more environmentally friendly processes. The synthesis of graphene can be achieved through various methods, some of which are less energy-intensive and produce fewer harmful byproducts compared to traditional battery material production. This aspect further contributes to the overall reduction of the environmental impact associated with battery manufacturing.

However, it is important to consider the potential environmental challenges associated with large-scale graphene production. Ensuring sustainable sourcing of raw materials and developing eco-friendly manufacturing processes for graphene will be crucial in maximizing the environmental benefits of this technology. Additionally, establishing effective recycling systems for graphene batteries will be essential to fully realize their potential for reducing electronic waste and conserving resources.

One of the primary environmental benefits of graphene batteries is their potential to extend the range of electric vehicles (EVs) while reducing battery weight. This increased efficiency translates to fewer raw materials required for battery production and less energy consumption during vehicle operation. As a result, the overall carbon footprint associated with EV manufacturing and use is significantly reduced.

Moreover, the enhanced durability and longer lifespan of graphene batteries contribute to a reduction in electronic waste. Traditional lithium-ion batteries often require replacement after a few years of use, leading to increased waste and resource consumption. Graphene batteries, with their improved cycle life, can remain operational for longer periods, minimizing the need for frequent replacements and reducing the environmental burden of battery disposal.

The faster charging capabilities of graphene batteries also have positive environmental implications. Reduced charging times can lead to more efficient use of charging infrastructure, potentially decreasing the number of charging stations required and the associated land use. Additionally, faster charging enables more widespread adoption of electric vehicles, accelerating the transition away from fossil fuel-dependent transportation.

From a manufacturing perspective, graphene batteries have the potential to be produced using more environmentally friendly processes. The synthesis of graphene can be achieved through various methods, some of which are less energy-intensive and produce fewer harmful byproducts compared to traditional battery material production. This aspect further contributes to the overall reduction of the environmental impact associated with battery manufacturing.

However, it is important to consider the potential environmental challenges associated with large-scale graphene production. Ensuring sustainable sourcing of raw materials and developing eco-friendly manufacturing processes for graphene will be crucial in maximizing the environmental benefits of this technology. Additionally, establishing effective recycling systems for graphene batteries will be essential to fully realize their potential for reducing electronic waste and conserving resources.

Regulatory Framework

The regulatory framework surrounding graphene batteries in the context of electrifying future transport is a complex and evolving landscape. As this technology advances, governments and international bodies are working to establish guidelines that ensure safety, environmental protection, and fair market competition.

At the forefront of regulatory considerations is the need for standardization in graphene battery production and performance metrics. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are developing standards to ensure consistency in manufacturing processes, safety protocols, and performance benchmarks. These standards will be crucial for the widespread adoption of graphene batteries in the transport sector.

Environmental regulations play a significant role in shaping the future of graphene battery technology. Many countries are implementing stricter emissions standards for vehicles, which indirectly promotes the development and adoption of more efficient energy storage solutions like graphene batteries. The European Union's Green Deal and similar initiatives worldwide are creating a regulatory environment that favors low-carbon technologies, potentially accelerating the integration of graphene batteries into electric vehicles.

Safety regulations are another critical aspect of the regulatory framework. Agencies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) are developing guidelines for the safe implementation of new battery technologies in vehicles. These regulations address issues such as thermal runaway prevention, crash safety, and electrical system integrity.

Intellectual property rights and patent regulations are also shaping the graphene battery landscape. As research institutions and companies invest heavily in developing this technology, clear guidelines on patent protection and licensing are essential to foster innovation while ensuring fair competition. The World Intellectual Property Organization (WIPO) is working to establish a global framework for graphene-related patents.

Trade regulations and international agreements will play a crucial role in the global adoption of graphene battery technology. As countries seek to secure their position in the emerging market, trade policies may influence the flow of raw materials, technology transfer, and finished products. The World Trade Organization (WTO) and bilateral trade agreements will likely address specific provisions for graphene battery technology and its components.

Lastly, end-of-life regulations and recycling mandates are being developed to address the environmental impact of graphene batteries. The European Union's Battery Directive, which is currently being updated, is expected to include specific provisions for advanced battery technologies, including potential requirements for graphene battery recycling and disposal.

At the forefront of regulatory considerations is the need for standardization in graphene battery production and performance metrics. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are developing standards to ensure consistency in manufacturing processes, safety protocols, and performance benchmarks. These standards will be crucial for the widespread adoption of graphene batteries in the transport sector.

Environmental regulations play a significant role in shaping the future of graphene battery technology. Many countries are implementing stricter emissions standards for vehicles, which indirectly promotes the development and adoption of more efficient energy storage solutions like graphene batteries. The European Union's Green Deal and similar initiatives worldwide are creating a regulatory environment that favors low-carbon technologies, potentially accelerating the integration of graphene batteries into electric vehicles.

Safety regulations are another critical aspect of the regulatory framework. Agencies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) are developing guidelines for the safe implementation of new battery technologies in vehicles. These regulations address issues such as thermal runaway prevention, crash safety, and electrical system integrity.

Intellectual property rights and patent regulations are also shaping the graphene battery landscape. As research institutions and companies invest heavily in developing this technology, clear guidelines on patent protection and licensing are essential to foster innovation while ensuring fair competition. The World Intellectual Property Organization (WIPO) is working to establish a global framework for graphene-related patents.

Trade regulations and international agreements will play a crucial role in the global adoption of graphene battery technology. As countries seek to secure their position in the emerging market, trade policies may influence the flow of raw materials, technology transfer, and finished products. The World Trade Organization (WTO) and bilateral trade agreements will likely address specific provisions for graphene battery technology and its components.

Lastly, end-of-life regulations and recycling mandates are being developed to address the environmental impact of graphene batteries. The European Union's Battery Directive, which is currently being updated, is expected to include specific provisions for advanced battery technologies, including potential requirements for graphene battery recycling and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!