Graphene Battery: The Future of Renewable and Efficient Energy

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a revolutionary advancement in energy storage technology, marking a significant milestone in the evolution of renewable and efficient energy solutions. The development of graphene-based batteries can be traced back to the early 2010s when researchers first began exploring the potential of this two-dimensional carbon material in energy applications.

The journey of graphene batteries has been characterized by rapid progress and breakthrough discoveries. Initially, scientists focused on understanding the unique properties of graphene, such as its exceptional electrical conductivity, high surface area, and mechanical strength. These attributes promised to address many of the limitations faced by traditional lithium-ion batteries, including slow charging times, limited capacity, and degradation over time.

As research intensified, several key objectives emerged in the development of graphene batteries. The primary goal has been to significantly increase energy density, allowing for longer-lasting and more powerful batteries. This is particularly crucial for applications in electric vehicles and renewable energy storage systems. Another critical objective has been to reduce charging times, with some prototypes demonstrating the ability to charge to full capacity in mere minutes.

Durability and safety have also been at the forefront of graphene battery development. Researchers aim to create batteries that can withstand thousands of charge-discharge cycles without significant degradation, far surpassing the lifespan of current lithium-ion batteries. Additionally, the thermal stability of graphene offers the potential for safer batteries, reducing the risk of overheating and combustion.

The evolution of graphene batteries has been marked by several technological milestones. Early experiments focused on using graphene as an additive to enhance existing battery chemistries. This gradually evolved into the development of graphene-dominant electrodes and, more recently, the exploration of all-graphene battery structures. Each stage has brought improvements in performance, edging closer to the ultimate goal of a high-capacity, fast-charging, and long-lasting energy storage solution.

Looking ahead, the objectives for graphene battery technology continue to expand. Researchers are now exploring ways to scale up production for commercial viability, a crucial step in bringing this technology to market. There is also a growing focus on sustainability, with efforts to develop environmentally friendly manufacturing processes and improve the recyclability of graphene batteries.

As the technology matures, the potential applications of graphene batteries are broadening. Beyond electric vehicles and grid storage, there is increasing interest in their use in portable electronics, aerospace, and even medical devices. The ultimate objective is to create a versatile, high-performance energy storage solution that can revolutionize multiple industries and contribute significantly to the global transition towards renewable energy sources.

The journey of graphene batteries has been characterized by rapid progress and breakthrough discoveries. Initially, scientists focused on understanding the unique properties of graphene, such as its exceptional electrical conductivity, high surface area, and mechanical strength. These attributes promised to address many of the limitations faced by traditional lithium-ion batteries, including slow charging times, limited capacity, and degradation over time.

As research intensified, several key objectives emerged in the development of graphene batteries. The primary goal has been to significantly increase energy density, allowing for longer-lasting and more powerful batteries. This is particularly crucial for applications in electric vehicles and renewable energy storage systems. Another critical objective has been to reduce charging times, with some prototypes demonstrating the ability to charge to full capacity in mere minutes.

Durability and safety have also been at the forefront of graphene battery development. Researchers aim to create batteries that can withstand thousands of charge-discharge cycles without significant degradation, far surpassing the lifespan of current lithium-ion batteries. Additionally, the thermal stability of graphene offers the potential for safer batteries, reducing the risk of overheating and combustion.

The evolution of graphene batteries has been marked by several technological milestones. Early experiments focused on using graphene as an additive to enhance existing battery chemistries. This gradually evolved into the development of graphene-dominant electrodes and, more recently, the exploration of all-graphene battery structures. Each stage has brought improvements in performance, edging closer to the ultimate goal of a high-capacity, fast-charging, and long-lasting energy storage solution.

Looking ahead, the objectives for graphene battery technology continue to expand. Researchers are now exploring ways to scale up production for commercial viability, a crucial step in bringing this technology to market. There is also a growing focus on sustainability, with efforts to develop environmentally friendly manufacturing processes and improve the recyclability of graphene batteries.

As the technology matures, the potential applications of graphene batteries are broadening. Beyond electric vehicles and grid storage, there is increasing interest in their use in portable electronics, aerospace, and even medical devices. The ultimate objective is to create a versatile, high-performance energy storage solution that can revolutionize multiple industries and contribute significantly to the global transition towards renewable energy sources.

Market Demand for Advanced Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing demand for advanced energy storage solutions. This surge is primarily fueled by the rapid adoption of renewable energy sources, the electrification of transportation, and the need for grid stability. As traditional energy storage technologies reach their limits, there is a growing market demand for innovative solutions that can offer higher energy density, faster charging capabilities, and improved longevity.

Graphene batteries have emerged as a promising technology to meet these evolving market needs. The unique properties of graphene, including its high electrical conductivity, mechanical strength, and large surface area, make it an ideal material for next-generation energy storage devices. The market for graphene batteries is expected to grow significantly in the coming years, with applications spanning across various sectors such as consumer electronics, electric vehicles, and grid-scale energy storage.

In the consumer electronics sector, there is a strong demand for batteries that can provide longer-lasting power in smaller, lighter form factors. Graphene batteries have the potential to meet this need by offering higher energy density and faster charging times compared to traditional lithium-ion batteries. This could revolutionize the design and functionality of smartphones, laptops, and wearable devices.

The electric vehicle (EV) market is another key driver for advanced energy storage solutions. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for EVs is soaring. Graphene batteries could address some of the main challenges facing EV adoption, such as range anxiety and long charging times. The potential for graphene batteries to significantly increase driving range and reduce charging times to just a few minutes could accelerate the widespread adoption of electric vehicles.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage solutions. Graphene batteries could play a crucial role in grid stabilization and energy management by providing high-capacity, fast-response storage systems. This would enable better integration of renewable energy sources into the grid and improve overall energy efficiency.

The industrial and aerospace sectors are also showing increasing interest in graphene battery technology. The potential for lightweight, high-performance energy storage solutions could lead to significant advancements in electric aircraft, drones, and industrial equipment. These applications require batteries that can deliver high power output while maintaining a low weight profile, making graphene-based solutions particularly attractive.

As the global focus on sustainability and carbon neutrality intensifies, the demand for advanced energy storage solutions like graphene batteries is expected to grow exponentially. This technology has the potential to address critical challenges in energy storage across multiple industries, driving innovation and supporting the transition to a more sustainable energy future.

Graphene batteries have emerged as a promising technology to meet these evolving market needs. The unique properties of graphene, including its high electrical conductivity, mechanical strength, and large surface area, make it an ideal material for next-generation energy storage devices. The market for graphene batteries is expected to grow significantly in the coming years, with applications spanning across various sectors such as consumer electronics, electric vehicles, and grid-scale energy storage.

In the consumer electronics sector, there is a strong demand for batteries that can provide longer-lasting power in smaller, lighter form factors. Graphene batteries have the potential to meet this need by offering higher energy density and faster charging times compared to traditional lithium-ion batteries. This could revolutionize the design and functionality of smartphones, laptops, and wearable devices.

The electric vehicle (EV) market is another key driver for advanced energy storage solutions. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for EVs is soaring. Graphene batteries could address some of the main challenges facing EV adoption, such as range anxiety and long charging times. The potential for graphene batteries to significantly increase driving range and reduce charging times to just a few minutes could accelerate the widespread adoption of electric vehicles.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and large-scale energy storage solutions. Graphene batteries could play a crucial role in grid stabilization and energy management by providing high-capacity, fast-response storage systems. This would enable better integration of renewable energy sources into the grid and improve overall energy efficiency.

The industrial and aerospace sectors are also showing increasing interest in graphene battery technology. The potential for lightweight, high-performance energy storage solutions could lead to significant advancements in electric aircraft, drones, and industrial equipment. These applications require batteries that can deliver high power output while maintaining a low weight profile, making graphene-based solutions particularly attractive.

As the global focus on sustainability and carbon neutrality intensifies, the demand for advanced energy storage solutions like graphene batteries is expected to grow exponentially. This technology has the potential to address critical challenges in energy storage across multiple industries, driving innovation and supporting the transition to a more sustainable energy future.

Current Graphene Battery Technology Challenges

Despite the promising potential of graphene batteries, several significant challenges currently hinder their widespread adoption and commercialization. One of the primary obstacles is the high production cost associated with graphene synthesis and battery manufacturing processes. The complex and energy-intensive methods required to produce high-quality graphene materials contribute to the overall expense, making graphene batteries less economically viable compared to traditional lithium-ion batteries.

Another major challenge lies in scaling up graphene production to meet industrial demands. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing while maintaining consistent quality and performance remains a significant hurdle. The lack of standardized production methods and quality control measures further complicates this issue.

The integration of graphene into existing battery architectures poses additional technical challenges. Ensuring proper dispersion and adhesion of graphene within the electrode materials is crucial for optimal performance. However, achieving uniform distribution and preventing agglomeration of graphene sheets during the manufacturing process can be difficult, potentially leading to inconsistent battery performance and reduced efficiency.

Stability and long-term performance of graphene batteries are also areas of concern. While graphene exhibits excellent theoretical properties, its behavior in real-world battery applications over extended periods is not yet fully understood. Issues such as capacity fading, electrolyte decomposition, and potential side reactions between graphene and other battery components need to be addressed to ensure the longevity and reliability of graphene-based energy storage systems.

Furthermore, the development of suitable electrolytes compatible with graphene electrodes presents another challenge. Traditional electrolytes may not be optimized for graphene's unique properties, potentially limiting the full potential of graphene batteries. Research into novel electrolyte formulations that can effectively complement graphene's characteristics is ongoing but requires further advancement.

Safety concerns also need to be thoroughly addressed before widespread adoption of graphene batteries can occur. While graphene itself is generally considered safe, its interaction with other battery components and its behavior under extreme conditions (such as high temperatures or physical stress) must be extensively studied and validated to ensure consumer safety and regulatory compliance.

Lastly, the environmental impact and sustainability of graphene battery production and disposal need careful consideration. While graphene batteries have the potential to offer improved energy efficiency and longer lifespans, the environmental footprint of their production processes and end-of-life management must be thoroughly assessed to ensure they align with global sustainability goals.

Another major challenge lies in scaling up graphene production to meet industrial demands. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing while maintaining consistent quality and performance remains a significant hurdle. The lack of standardized production methods and quality control measures further complicates this issue.

The integration of graphene into existing battery architectures poses additional technical challenges. Ensuring proper dispersion and adhesion of graphene within the electrode materials is crucial for optimal performance. However, achieving uniform distribution and preventing agglomeration of graphene sheets during the manufacturing process can be difficult, potentially leading to inconsistent battery performance and reduced efficiency.

Stability and long-term performance of graphene batteries are also areas of concern. While graphene exhibits excellent theoretical properties, its behavior in real-world battery applications over extended periods is not yet fully understood. Issues such as capacity fading, electrolyte decomposition, and potential side reactions between graphene and other battery components need to be addressed to ensure the longevity and reliability of graphene-based energy storage systems.

Furthermore, the development of suitable electrolytes compatible with graphene electrodes presents another challenge. Traditional electrolytes may not be optimized for graphene's unique properties, potentially limiting the full potential of graphene batteries. Research into novel electrolyte formulations that can effectively complement graphene's characteristics is ongoing but requires further advancement.

Safety concerns also need to be thoroughly addressed before widespread adoption of graphene batteries can occur. While graphene itself is generally considered safe, its interaction with other battery components and its behavior under extreme conditions (such as high temperatures or physical stress) must be extensively studied and validated to ensure consumer safety and regulatory compliance.

Lastly, the environmental impact and sustainability of graphene battery production and disposal need careful consideration. While graphene batteries have the potential to offer improved energy efficiency and longer lifespans, the environmental footprint of their production processes and end-of-life management must be thoroughly assessed to ensure they align with global sustainability goals.

Existing Graphene Battery Solutions

01 Graphene-based electrode materials

Utilizing graphene-based materials for battery electrodes can significantly enhance efficiency. These materials offer high conductivity, large surface area, and excellent mechanical properties, leading to improved energy density and faster charge/discharge rates in batteries.- Graphene-based electrode materials: Utilizing graphene-based materials for battery electrodes can significantly enhance battery efficiency. Graphene's high conductivity and large surface area allow for improved electron transfer and increased energy storage capacity. These materials can be used in various forms, such as graphene sheets, graphene oxide, or graphene composites, to optimize battery performance.

- Graphene-enhanced electrolytes: Incorporating graphene or graphene derivatives into battery electrolytes can improve ionic conductivity and overall battery efficiency. These enhanced electrolytes facilitate faster ion transport between electrodes, reducing internal resistance and improving charge/discharge rates. Additionally, graphene-based electrolytes can contribute to better thermal management and increased stability of the battery system.

- Graphene-based current collectors: Utilizing graphene as a material for current collectors in batteries can enhance overall efficiency. Graphene's excellent electrical conductivity and mechanical strength make it an ideal candidate for this application. Graphene-based current collectors can improve electron transfer, reduce internal resistance, and contribute to better heat dissipation, ultimately leading to improved battery performance and longevity.

- Graphene-enhanced battery management systems: Integrating graphene-based components into battery management systems can lead to improved efficiency and performance. Graphene's unique properties can be leveraged to enhance thermal management, voltage regulation, and overall system monitoring. These advancements contribute to better battery life, faster charging times, and increased safety in various applications.

- Graphene-based hybrid energy storage systems: Combining graphene-enhanced batteries with other energy storage technologies, such as supercapacitors, can create highly efficient hybrid systems. These hybrid systems leverage the strengths of both technologies, offering improved power density, energy density, and cycle life. The integration of graphene in such systems can lead to faster charging, better energy retention, and overall enhanced performance in various applications.

02 Graphene-enhanced electrolytes

Incorporating graphene or graphene oxide into battery electrolytes can improve ionic conductivity and stability. This enhancement leads to better overall battery performance, including increased efficiency and longer cycle life.Expand Specific Solutions03 Graphene-based composite materials

Combining graphene with other materials to create composite electrodes or electrolytes can synergistically improve battery efficiency. These composites often exhibit enhanced conductivity, stability, and capacity compared to their individual components.Expand Specific Solutions04 Graphene modification techniques

Various modification techniques, such as doping, functionalization, or structural engineering of graphene, can be employed to tailor its properties for specific battery applications. These modifications can lead to improved efficiency, capacity, and cycling stability.Expand Specific Solutions05 Graphene in advanced battery designs

Incorporating graphene into novel battery architectures or designs, such as flexible or thin-film batteries, can lead to improved efficiency and performance. Graphene's unique properties enable the development of lightweight, high-performance energy storage solutions.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, characterized by significant research and development efforts across academia and industry. While the market size remains relatively small, it shows promising potential for rapid expansion due to graphene's exceptional properties. The technology's maturity is progressing, with companies like Honeycomb Battery Co. and NanoXplore, Inc. leading commercialization efforts. Academic institutions such as Northwestern University and Zhejiang University are contributing fundamental research. Major tech players like Apple, Inc. and NEC Corp. are also exploring graphene battery applications, indicating growing industry interest. However, challenges in large-scale production and cost-effectiveness still need to be addressed for widespread adoption.

Honeycomb Battery Co.

Technical Solution: Honeycomb Battery Co. is focusing on developing graphene-enhanced lithium-sulfur (Li-S) batteries, which offer potentially higher energy density than traditional lithium-ion batteries. Their approach involves using a graphene-based cathode structure to address the "shuttle effect" that typically limits the cycle life of Li-S batteries. The company claims their technology can achieve energy densities of up to 500 Wh/kg, more than double that of conventional lithium-ion batteries[8]. Honeycomb's graphene-enhanced Li-S batteries also demonstrate improved cycle life, with reports suggesting they can maintain over 80% capacity after 1000 cycles[9]. The use of sulfur as a cathode material potentially offers cost and environmental benefits compared to traditional lithium-ion chemistries.

Strengths: High energy density, potential cost advantages, improved sustainability. Weaknesses: Relatively new technology, potential challenges in scaling production, competition from established lithium-ion battery manufacturers.

NEC Corp.

Technical Solution: NEC Corporation has been actively researching and developing graphene-based energy storage solutions, including batteries and supercapacitors. Their approach focuses on using graphene as an electrode material to enhance the performance of lithium-ion batteries. NEC has reported achieving up to 1.5 times higher energy density and 5-10 times faster charging speeds compared to conventional lithium-ion batteries[6]. The company is also exploring the use of graphene in all-solid-state batteries, which could offer improved safety and energy density. NEC's research indicates that their graphene-enhanced batteries could maintain over 80% of their initial capacity after 2000 charge cycles, significantly extending battery lifespan[7].

Strengths: Established presence in electronics industry, significant improvements in energy density and charging speed. Weaknesses: Potential challenges in mass production, competition from other advanced battery technologies.

Core Graphene Battery Innovations

Graphene networks and methods for synthesis and use of the same

PatentPendingUS20230275229A1

Innovation

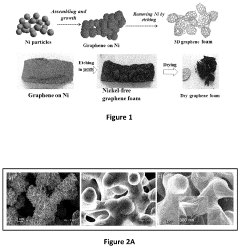

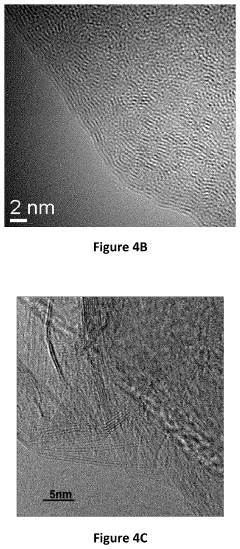

- A method for synthesizing a high crystalline, curved 3D graphene network with incommensurate multilayers by forming a metal catalyst template from non-uniform nickel particles, applying a hydrocarbon source, and removing the metal to produce a graphene foam with weak interplanar interactions, allowing for high reversible capacity as an anode material in lithium batteries.

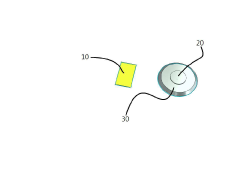

Graphene battery

PatentInactiveKR1020210055912A

Innovation

- Utilization of graphene in battery construction, resulting in a significantly lighter and faster-charging battery compared to conventional batteries.

- Integration of wireless charging capabilities with graphene battery technology, enhancing convenience and usability.

- Enhanced physical and chemical stability of the graphene battery, leading to improved safety and reduced failure rates.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a crucial consideration as this technology advances towards widespread adoption. Graphene batteries offer significant potential for improving energy storage efficiency and reducing the overall environmental footprint of battery production and usage.

One of the primary environmental benefits of graphene batteries is their potential to greatly enhance the performance and lifespan of electric vehicles (EVs). By enabling longer driving ranges and faster charging times, graphene batteries could accelerate the transition from fossil fuel-powered vehicles to EVs, leading to substantial reductions in greenhouse gas emissions from the transportation sector.

In terms of raw material extraction, graphene batteries may require less mining of rare earth elements compared to traditional lithium-ion batteries. This could result in reduced environmental degradation associated with mining activities, including habitat destruction, water pollution, and soil contamination. However, the large-scale production of graphene itself needs to be carefully managed to minimize any potential negative environmental impacts.

The manufacturing process of graphene batteries is generally considered to be less energy-intensive than that of conventional batteries. This could translate to lower carbon emissions during production, especially if renewable energy sources are utilized in the manufacturing facilities. Additionally, the improved energy density of graphene batteries means that smaller and lighter batteries can be produced for the same energy storage capacity, potentially reducing material usage and transportation-related emissions.

End-of-life considerations for graphene batteries are also promising from an environmental perspective. These batteries are expected to have a longer lifespan than current lithium-ion batteries, which could significantly reduce electronic waste. Furthermore, the materials used in graphene batteries may be more easily recyclable, allowing for a more circular economy approach to battery production and disposal.

However, it is important to note that the full environmental impact of graphene batteries is still being studied. As with any new technology, there may be unforeseen consequences that only become apparent with large-scale implementation. Ongoing research is needed to assess the long-term environmental effects of graphene production, battery manufacturing, and disposal processes.

In conclusion, while graphene batteries show great promise for reducing the environmental impact of energy storage solutions, careful consideration must be given to their entire lifecycle. Continued research and development should focus not only on improving performance but also on minimizing potential negative environmental impacts throughout the production, use, and disposal phases of graphene batteries.

One of the primary environmental benefits of graphene batteries is their potential to greatly enhance the performance and lifespan of electric vehicles (EVs). By enabling longer driving ranges and faster charging times, graphene batteries could accelerate the transition from fossil fuel-powered vehicles to EVs, leading to substantial reductions in greenhouse gas emissions from the transportation sector.

In terms of raw material extraction, graphene batteries may require less mining of rare earth elements compared to traditional lithium-ion batteries. This could result in reduced environmental degradation associated with mining activities, including habitat destruction, water pollution, and soil contamination. However, the large-scale production of graphene itself needs to be carefully managed to minimize any potential negative environmental impacts.

The manufacturing process of graphene batteries is generally considered to be less energy-intensive than that of conventional batteries. This could translate to lower carbon emissions during production, especially if renewable energy sources are utilized in the manufacturing facilities. Additionally, the improved energy density of graphene batteries means that smaller and lighter batteries can be produced for the same energy storage capacity, potentially reducing material usage and transportation-related emissions.

End-of-life considerations for graphene batteries are also promising from an environmental perspective. These batteries are expected to have a longer lifespan than current lithium-ion batteries, which could significantly reduce electronic waste. Furthermore, the materials used in graphene batteries may be more easily recyclable, allowing for a more circular economy approach to battery production and disposal.

However, it is important to note that the full environmental impact of graphene batteries is still being studied. As with any new technology, there may be unforeseen consequences that only become apparent with large-scale implementation. Ongoing research is needed to assess the long-term environmental effects of graphene production, battery manufacturing, and disposal processes.

In conclusion, while graphene batteries show great promise for reducing the environmental impact of energy storage solutions, careful consideration must be given to their entire lifecycle. Continued research and development should focus not only on improving performance but also on minimizing potential negative environmental impacts throughout the production, use, and disposal phases of graphene batteries.

Graphene Battery Manufacturing Processes

The manufacturing processes for graphene batteries involve several complex steps, each crucial for the production of high-quality, efficient energy storage devices. The process typically begins with the synthesis of graphene, which can be achieved through various methods such as chemical vapor deposition (CVD), exfoliation of graphite, or reduction of graphene oxide.

One of the most promising methods for large-scale production is the CVD process, where a carbon-containing gas is decomposed at high temperatures on a metal substrate, forming a thin layer of graphene. This method allows for precise control over the number of graphene layers and can produce high-quality, large-area graphene sheets.

Once the graphene is synthesized, it must be carefully integrated into the battery structure. This often involves creating a composite material by combining graphene with other battery components such as lithium compounds or metal oxides. The graphene-based composite is then used to form the electrodes of the battery.

The electrode fabrication process is critical and may involve techniques such as roll-to-roll manufacturing, which allows for continuous production of graphene-based electrodes. This process involves depositing the graphene composite onto a flexible substrate, which is then rolled and cut to the desired size and shape.

Assembly of the battery components is the next step, where the graphene-based electrodes are combined with other essential elements such as the electrolyte, separator, and current collectors. This assembly process must be carried out in a controlled environment to prevent contamination and ensure optimal battery performance.

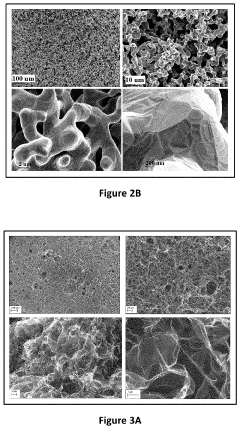

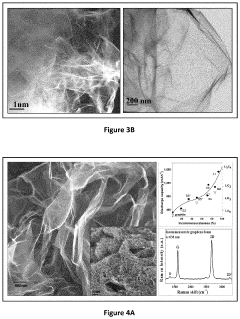

Quality control measures are implemented throughout the manufacturing process to maintain consistency and reliability. Advanced characterization techniques such as Raman spectroscopy and electron microscopy are used to assess the quality of the graphene and the overall battery structure.

The final stages of production involve packaging the battery cells into modules or packs, depending on the intended application. This may include the integration of battery management systems to monitor and control the performance of the graphene batteries.

As the technology advances, researchers and manufacturers are continually refining these processes to improve efficiency, reduce costs, and scale up production. Innovations in areas such as automated manufacturing, 3D printing of graphene structures, and novel graphene synthesis methods are expected to further enhance the manufacturing capabilities for graphene batteries in the near future.

One of the most promising methods for large-scale production is the CVD process, where a carbon-containing gas is decomposed at high temperatures on a metal substrate, forming a thin layer of graphene. This method allows for precise control over the number of graphene layers and can produce high-quality, large-area graphene sheets.

Once the graphene is synthesized, it must be carefully integrated into the battery structure. This often involves creating a composite material by combining graphene with other battery components such as lithium compounds or metal oxides. The graphene-based composite is then used to form the electrodes of the battery.

The electrode fabrication process is critical and may involve techniques such as roll-to-roll manufacturing, which allows for continuous production of graphene-based electrodes. This process involves depositing the graphene composite onto a flexible substrate, which is then rolled and cut to the desired size and shape.

Assembly of the battery components is the next step, where the graphene-based electrodes are combined with other essential elements such as the electrolyte, separator, and current collectors. This assembly process must be carried out in a controlled environment to prevent contamination and ensure optimal battery performance.

Quality control measures are implemented throughout the manufacturing process to maintain consistency and reliability. Advanced characterization techniques such as Raman spectroscopy and electron microscopy are used to assess the quality of the graphene and the overall battery structure.

The final stages of production involve packaging the battery cells into modules or packs, depending on the intended application. This may include the integration of battery management systems to monitor and control the performance of the graphene batteries.

As the technology advances, researchers and manufacturers are continually refining these processes to improve efficiency, reduce costs, and scale up production. Innovations in areas such as automated manufacturing, 3D printing of graphene structures, and novel graphene synthesis methods are expected to further enhance the manufacturing capabilities for graphene batteries in the near future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!