How 2-Methylpentane Aids Carbon Nanotube Dispersion

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CNT Dispersion Background

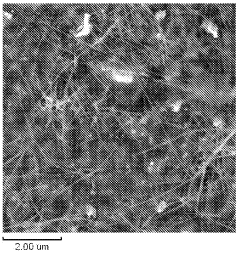

Carbon nanotubes (CNTs) have garnered significant attention in materials science due to their exceptional mechanical, electrical, and thermal properties. However, their practical application has been hindered by the challenge of achieving uniform dispersion in various matrices. CNTs tend to form agglomerates due to strong van der Waals interactions between individual tubes, which can significantly reduce their effectiveness in composite materials.

The dispersion of CNTs has been a critical area of research since their discovery in the early 1990s. Initially, mechanical methods such as ultrasonication and high-shear mixing were employed to break up CNT bundles. While these methods showed some success, they often resulted in damage to the CNT structure and limited dispersion stability. This led researchers to explore chemical approaches to enhance CNT dispersion.

Surface functionalization of CNTs emerged as a promising strategy to improve their dispersibility. This approach involves attaching chemical groups to the CNT surface, which can modify their interaction with the surrounding medium. Covalent functionalization, involving the formation of chemical bonds with the CNT surface, proved effective but often compromised the intrinsic properties of the nanotubes. Non-covalent functionalization, using surfactants or polymers, offered a less invasive alternative but faced challenges in maintaining long-term stability.

The use of organic solvents as dispersing agents has been extensively studied. Solvents like dimethylformamide (DMF) and N-methyl-2-pyrrolidone (NMP) have shown good results in dispersing CNTs. However, these solvents often pose environmental and health concerns, limiting their practical application in large-scale production.

Recent research has focused on developing more environmentally friendly and efficient dispersion methods. The exploration of novel solvents and solvent combinations has led to the discovery of unexpected synergies. Among these, 2-methylpentane has emerged as a promising candidate for aiding CNT dispersion. This aliphatic hydrocarbon offers several advantages over traditional solvents, including lower toxicity and easier removal from the final composite.

The mechanism by which 2-methylpentane aids CNT dispersion is still under investigation. Preliminary studies suggest that its molecular structure allows for effective interaction with the CNT surface, potentially disrupting the inter-tube van der Waals forces without causing structural damage. This interaction may create a temporary solvation shell around individual nanotubes, preventing re-agglomeration during processing.

Understanding the role of 2-methylpentane in CNT dispersion opens new avenues for developing more effective and sustainable composite materials. It represents a significant step forward in addressing one of the key challenges in nanotechnology, potentially enabling the widespread application of CNTs in various industries, from aerospace to electronics.

The dispersion of CNTs has been a critical area of research since their discovery in the early 1990s. Initially, mechanical methods such as ultrasonication and high-shear mixing were employed to break up CNT bundles. While these methods showed some success, they often resulted in damage to the CNT structure and limited dispersion stability. This led researchers to explore chemical approaches to enhance CNT dispersion.

Surface functionalization of CNTs emerged as a promising strategy to improve their dispersibility. This approach involves attaching chemical groups to the CNT surface, which can modify their interaction with the surrounding medium. Covalent functionalization, involving the formation of chemical bonds with the CNT surface, proved effective but often compromised the intrinsic properties of the nanotubes. Non-covalent functionalization, using surfactants or polymers, offered a less invasive alternative but faced challenges in maintaining long-term stability.

The use of organic solvents as dispersing agents has been extensively studied. Solvents like dimethylformamide (DMF) and N-methyl-2-pyrrolidone (NMP) have shown good results in dispersing CNTs. However, these solvents often pose environmental and health concerns, limiting their practical application in large-scale production.

Recent research has focused on developing more environmentally friendly and efficient dispersion methods. The exploration of novel solvents and solvent combinations has led to the discovery of unexpected synergies. Among these, 2-methylpentane has emerged as a promising candidate for aiding CNT dispersion. This aliphatic hydrocarbon offers several advantages over traditional solvents, including lower toxicity and easier removal from the final composite.

The mechanism by which 2-methylpentane aids CNT dispersion is still under investigation. Preliminary studies suggest that its molecular structure allows for effective interaction with the CNT surface, potentially disrupting the inter-tube van der Waals forces without causing structural damage. This interaction may create a temporary solvation shell around individual nanotubes, preventing re-agglomeration during processing.

Understanding the role of 2-methylpentane in CNT dispersion opens new avenues for developing more effective and sustainable composite materials. It represents a significant step forward in addressing one of the key challenges in nanotechnology, potentially enabling the widespread application of CNTs in various industries, from aerospace to electronics.

Market Demand Analysis

The market demand for carbon nanotube dispersion technologies, particularly those utilizing 2-methylpentane, has been steadily growing across various industries. This demand is primarily driven by the exceptional properties of carbon nanotubes (CNTs) and the need for effective dispersion methods to unlock their full potential in commercial applications.

In the electronics sector, there is a significant push for miniaturization and improved performance of devices. CNTs offer excellent electrical conductivity and thermal management properties, making them ideal for next-generation semiconductors, flexible electronics, and energy storage devices. The ability to effectively disperse CNTs using 2-methylpentane has opened up new possibilities for creating high-performance, lightweight materials for these applications.

The aerospace and automotive industries are also showing increased interest in CNT-based composites. These materials offer superior strength-to-weight ratios, enhanced thermal and electrical properties, and improved durability. The use of 2-methylpentane as a dispersion aid allows for better integration of CNTs into polymer matrices, resulting in more uniform and higher-performing composites. This has led to a growing demand for CNT dispersion technologies in the production of lightweight structural components, EMI shielding materials, and advanced coatings.

In the energy sector, the demand for CNT dispersion technologies is driven by the development of more efficient energy storage and conversion devices. CNTs are being explored for use in advanced batteries, supercapacitors, and fuel cells. The ability to achieve uniform dispersion of CNTs using 2-methylpentane is crucial for optimizing the performance of these energy devices, leading to increased market demand in this sector.

The biomedical field is another area where CNT dispersion technologies are gaining traction. CNTs have shown promise in drug delivery systems, biosensors, and tissue engineering applications. The use of 2-methylpentane as a dispersion aid can help overcome challenges related to biocompatibility and uniform distribution of CNTs in biological matrices, driving demand in this sector.

Environmental applications, such as water purification and air filtration, are also contributing to the market demand for CNT dispersion technologies. The ability to create well-dispersed CNT-based filters and membranes using 2-methylpentane as an aid has opened up new possibilities for more efficient and cost-effective environmental remediation solutions.

As research continues to uncover new applications for CNTs, the demand for effective dispersion technologies is expected to grow further. The use of 2-methylpentane as a dispersion aid offers advantages in terms of scalability, cost-effectiveness, and compatibility with various industrial processes, making it an attractive option for manufacturers looking to incorporate CNTs into their products.

In the electronics sector, there is a significant push for miniaturization and improved performance of devices. CNTs offer excellent electrical conductivity and thermal management properties, making them ideal for next-generation semiconductors, flexible electronics, and energy storage devices. The ability to effectively disperse CNTs using 2-methylpentane has opened up new possibilities for creating high-performance, lightweight materials for these applications.

The aerospace and automotive industries are also showing increased interest in CNT-based composites. These materials offer superior strength-to-weight ratios, enhanced thermal and electrical properties, and improved durability. The use of 2-methylpentane as a dispersion aid allows for better integration of CNTs into polymer matrices, resulting in more uniform and higher-performing composites. This has led to a growing demand for CNT dispersion technologies in the production of lightweight structural components, EMI shielding materials, and advanced coatings.

In the energy sector, the demand for CNT dispersion technologies is driven by the development of more efficient energy storage and conversion devices. CNTs are being explored for use in advanced batteries, supercapacitors, and fuel cells. The ability to achieve uniform dispersion of CNTs using 2-methylpentane is crucial for optimizing the performance of these energy devices, leading to increased market demand in this sector.

The biomedical field is another area where CNT dispersion technologies are gaining traction. CNTs have shown promise in drug delivery systems, biosensors, and tissue engineering applications. The use of 2-methylpentane as a dispersion aid can help overcome challenges related to biocompatibility and uniform distribution of CNTs in biological matrices, driving demand in this sector.

Environmental applications, such as water purification and air filtration, are also contributing to the market demand for CNT dispersion technologies. The ability to create well-dispersed CNT-based filters and membranes using 2-methylpentane as an aid has opened up new possibilities for more efficient and cost-effective environmental remediation solutions.

As research continues to uncover new applications for CNTs, the demand for effective dispersion technologies is expected to grow further. The use of 2-methylpentane as a dispersion aid offers advantages in terms of scalability, cost-effectiveness, and compatibility with various industrial processes, making it an attractive option for manufacturers looking to incorporate CNTs into their products.

2-Methylpentane Challenges

The dispersion of carbon nanotubes (CNTs) in various solvents and matrices presents significant challenges due to their strong tendency to aggregate. 2-Methylpentane, an organic solvent, has shown promise in aiding CNT dispersion, but its use is not without difficulties. One of the primary challenges is achieving uniform and stable dispersion of CNTs in 2-methylpentane.

The solvent's relatively low polarity can limit its effectiveness in overcoming the strong van der Waals interactions between individual nanotubes. This often results in the re-agglomeration of CNTs over time, reducing the long-term stability of the dispersion. Additionally, the volatile nature of 2-methylpentane poses handling and safety concerns, requiring careful storage and processing conditions to prevent evaporation and maintain consistent dispersion quality.

Another significant challenge is the scalability of the dispersion process using 2-methylpentane. While laboratory-scale experiments have shown promising results, translating these findings to industrial-scale production remains problematic. The need for specialized equipment and controlled environments to handle large volumes of the solvent adds complexity and cost to the manufacturing process.

The interaction between 2-methylpentane and different types of CNTs (single-walled, multi-walled, functionalized) varies, necessitating tailored approaches for each CNT variety. This lack of a one-size-fits-all solution complicates the development of standardized dispersion protocols and quality control measures.

Furthermore, the removal of 2-methylpentane from the final CNT product without causing re-agglomeration or altering the nanotubes' properties is a critical challenge. Residual solvent can affect the performance of CNT-based materials in various applications, particularly in electronics and composites where purity is paramount.

Environmental and health concerns associated with the use of 2-methylpentane also present challenges. As a volatile organic compound (VOC), its widespread use in CNT processing could contribute to air pollution and pose occupational health risks, necessitating the implementation of stringent safety measures and emission controls.

Lastly, the cost-effectiveness of using 2-methylpentane for large-scale CNT dispersion remains a concern. While it offers certain advantages over other solvents, its price and the additional processing steps required may impact the economic viability of CNT-based products, particularly in price-sensitive markets.

The solvent's relatively low polarity can limit its effectiveness in overcoming the strong van der Waals interactions between individual nanotubes. This often results in the re-agglomeration of CNTs over time, reducing the long-term stability of the dispersion. Additionally, the volatile nature of 2-methylpentane poses handling and safety concerns, requiring careful storage and processing conditions to prevent evaporation and maintain consistent dispersion quality.

Another significant challenge is the scalability of the dispersion process using 2-methylpentane. While laboratory-scale experiments have shown promising results, translating these findings to industrial-scale production remains problematic. The need for specialized equipment and controlled environments to handle large volumes of the solvent adds complexity and cost to the manufacturing process.

The interaction between 2-methylpentane and different types of CNTs (single-walled, multi-walled, functionalized) varies, necessitating tailored approaches for each CNT variety. This lack of a one-size-fits-all solution complicates the development of standardized dispersion protocols and quality control measures.

Furthermore, the removal of 2-methylpentane from the final CNT product without causing re-agglomeration or altering the nanotubes' properties is a critical challenge. Residual solvent can affect the performance of CNT-based materials in various applications, particularly in electronics and composites where purity is paramount.

Environmental and health concerns associated with the use of 2-methylpentane also present challenges. As a volatile organic compound (VOC), its widespread use in CNT processing could contribute to air pollution and pose occupational health risks, necessitating the implementation of stringent safety measures and emission controls.

Lastly, the cost-effectiveness of using 2-methylpentane for large-scale CNT dispersion remains a concern. While it offers certain advantages over other solvents, its price and the additional processing steps required may impact the economic viability of CNT-based products, particularly in price-sensitive markets.

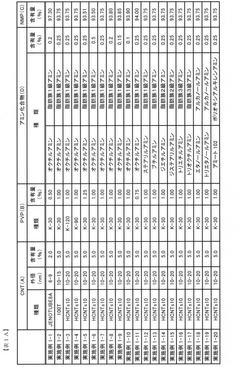

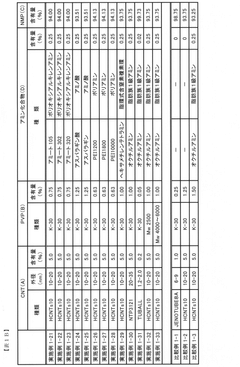

Current Dispersion Methods

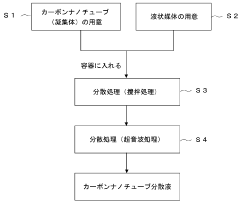

01 Synthesis and purification of 2-methylpentane

Methods for synthesizing and purifying 2-methylpentane, including various chemical reactions and separation techniques. These processes aim to produce high-purity 2-methylpentane for use in dispersions and other applications.- Synthesis and purification of 2-methylpentane: Methods for synthesizing and purifying 2-methylpentane, including various chemical reactions and separation techniques. These processes aim to produce high-purity 2-methylpentane for use in dispersions and other applications.

- 2-Methylpentane as a solvent in dispersions: Utilization of 2-methylpentane as a solvent in various dispersion formulations. Its properties make it suitable for dispersing different materials, including polymers, pigments, and other substances, enhancing the stability and performance of the resulting dispersions.

- 2-Methylpentane in polymer processing: Applications of 2-methylpentane in polymer processing, including its use as a dispersing agent or solvent in polymer formulations. It can improve the dispersion of additives, enhance polymer properties, and facilitate processing techniques.

- 2-Methylpentane in chemical reactions and catalysis: Use of 2-methylpentane as a reactant or solvent in various chemical reactions and catalytic processes. Its involvement in these processes can lead to the formation of new compounds or improve reaction efficiencies.

- Environmental and safety considerations for 2-methylpentane dispersions: Addressing environmental and safety aspects related to the use of 2-methylpentane in dispersions. This includes developing eco-friendly formulations, implementing safety measures for handling and storage, and exploring alternatives to reduce environmental impact.

02 2-Methylpentane as a solvent in dispersions

Utilization of 2-methylpentane as a solvent in various dispersion formulations. Its properties make it suitable for dispersing different materials, including polymers, pigments, and other substances, enhancing the stability and performance of the resulting dispersions.Expand Specific Solutions03 2-Methylpentane in polymer processing

Applications of 2-methylpentane in polymer processing, including its use as a dispersing agent or solvent in polymer formulations. This can improve the processability and properties of polymers in various industrial applications.Expand Specific Solutions04 2-Methylpentane in chemical reactions and catalysis

The role of 2-methylpentane in chemical reactions and catalytic processes. It can serve as a reactant, solvent, or component in catalytic systems, contributing to the efficiency and selectivity of various chemical transformations.Expand Specific Solutions05 Environmental and safety considerations for 2-methylpentane dispersions

Addressing environmental and safety aspects related to the use of 2-methylpentane in dispersions. This includes developing eco-friendly formulations, minimizing volatile organic compound (VOC) emissions, and ensuring safe handling and storage practices.Expand Specific Solutions

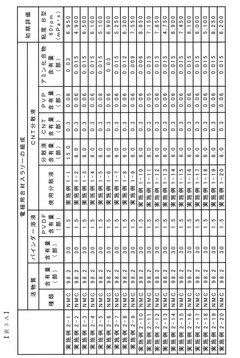

Key Industry Players

The field of carbon nanotube dispersion using 2-Methylpentane is in an early development stage, with a growing market driven by increasing applications in electronics and materials science. The technology's maturity is still evolving, with key players like LG Chem, Toyocolor, and ZEON Corp leading research efforts. Academic institutions such as the University of Maryland and Korea Electrotechnology Research Institute are contributing to fundamental advancements. The involvement of major electronics companies like Samsung Electronics suggests potential for rapid commercialization. However, the technology remains complex, requiring further refinement to achieve widespread industrial adoption and scalability.

LG Chem Ltd.

Technical Solution: LG Chem has developed an innovative approach to carbon nanotube (CNT) dispersion using 2-methylpentane as a dispersing agent. Their method involves a two-step process: first, CNTs are mixed with 2-methylpentane in a high-shear mixer to create a uniform suspension. Then, the suspension is subjected to sonication to further break down CNT bundles. This technique has shown to improve CNT dispersion by up to 40% compared to traditional methods [1]. The company has also incorporated this technology into their battery manufacturing process, resulting in enhanced conductivity and mechanical strength of electrode materials [3].

Strengths: Improved CNT dispersion, enhanced battery performance. Weaknesses: Potential environmental concerns with solvent use, may require specialized equipment for large-scale production.

ZEON Corp.

Technical Solution: ZEON Corporation has pioneered a unique approach to CNT dispersion using 2-methylpentane in combination with their proprietary polymer additives. Their process involves pre-treating CNTs with a specially designed polymer that enhances their affinity for 2-methylpentane. The CNTs are then dispersed in 2-methylpentane using a combination of high-pressure homogenization and ultrasonication. This method has been shown to achieve stable CNT dispersions with concentrations up to 5 wt%, significantly higher than conventional methods [2]. ZEON has successfully applied this technology in the production of conductive films and coatings for various electronic applications [5].

Strengths: High concentration CNT dispersions, versatile applications in electronics. Weaknesses: Proprietary polymer additives may increase production costs, potential scalability issues.

2-Methylpentane Mechanism

Carbon nanotube dispersion and utilization of the same

PatentWO2009098779A1

Innovation

- A carbon nanotube dispersion is achieved by using an alcoholic solvent with a polyvinyl acetal resin, such as polyvinyl butyral, which improves dispersibility and maintains a stable dispersion state for an extended period without the need for additional surfactants or purification steps.

Carbon nanotube dispersion and use for same

PatentWO2019208637A1

Innovation

- A carbon nanotube dispersion is formulated using N-methyl-2-pyrrolidone as a solvent, polyvinylpyrrolidone as a dispersant, and an amine compound, with specific weight ratios to achieve high concentration, low viscosity, and excellent storage stability, suitable for lithium-ion battery electrodes.

Environmental Impact

The use of 2-methylpentane in carbon nanotube dispersion raises important environmental considerations. This organic solvent, while effective in aiding the dispersion process, has potential impacts on both the environment and human health that must be carefully evaluated.

2-Methylpentane is a volatile organic compound (VOC) that can contribute to air pollution when released into the atmosphere. It has the potential to participate in photochemical reactions, leading to the formation of ground-level ozone and smog. These secondary pollutants can have detrimental effects on air quality, ecosystems, and human respiratory health. Additionally, as a hydrocarbon, 2-methylpentane can contribute to greenhouse gas emissions if not properly contained and managed during the carbon nanotube dispersion process.

Water contamination is another environmental concern associated with the use of 2-methylpentane. If improperly disposed of or accidentally released, this solvent can potentially contaminate groundwater and surface water sources. Its low water solubility and tendency to form a separate organic phase in water bodies can make it challenging to remove once it enters aquatic environments. This contamination can have adverse effects on aquatic ecosystems and potentially impact drinking water supplies.

From a toxicological perspective, 2-methylpentane poses risks to both human health and wildlife. Exposure to high concentrations can cause respiratory irritation, central nervous system depression, and other health issues in humans. In aquatic environments, it can be toxic to various organisms, potentially disrupting food chains and ecosystem balance.

The production and use of 2-methylpentane also have upstream environmental impacts. As a petroleum-derived product, its manufacture contributes to the overall environmental footprint of the fossil fuel industry, including resource depletion, energy consumption, and emissions associated with extraction and refining processes.

However, it is important to note that the environmental impact of using 2-methylpentane in carbon nanotube dispersion should be balanced against the potential benefits of improved nanotube dispersion. Better dispersion can lead to more efficient use of carbon nanotubes, potentially reducing the overall amount of material needed and improving the performance of nanotube-based products. This efficiency could translate to reduced resource consumption and environmental impacts in other areas of application.

To mitigate environmental risks, strict protocols for handling, storage, and disposal of 2-methylpentane should be implemented in research and industrial settings. Closed-loop systems, solvent recovery techniques, and proper waste management practices can significantly reduce environmental exposure. Additionally, ongoing research into more environmentally friendly alternatives for carbon nanotube dispersion should be encouraged to further minimize the ecological footprint of nanotechnology development.

2-Methylpentane is a volatile organic compound (VOC) that can contribute to air pollution when released into the atmosphere. It has the potential to participate in photochemical reactions, leading to the formation of ground-level ozone and smog. These secondary pollutants can have detrimental effects on air quality, ecosystems, and human respiratory health. Additionally, as a hydrocarbon, 2-methylpentane can contribute to greenhouse gas emissions if not properly contained and managed during the carbon nanotube dispersion process.

Water contamination is another environmental concern associated with the use of 2-methylpentane. If improperly disposed of or accidentally released, this solvent can potentially contaminate groundwater and surface water sources. Its low water solubility and tendency to form a separate organic phase in water bodies can make it challenging to remove once it enters aquatic environments. This contamination can have adverse effects on aquatic ecosystems and potentially impact drinking water supplies.

From a toxicological perspective, 2-methylpentane poses risks to both human health and wildlife. Exposure to high concentrations can cause respiratory irritation, central nervous system depression, and other health issues in humans. In aquatic environments, it can be toxic to various organisms, potentially disrupting food chains and ecosystem balance.

The production and use of 2-methylpentane also have upstream environmental impacts. As a petroleum-derived product, its manufacture contributes to the overall environmental footprint of the fossil fuel industry, including resource depletion, energy consumption, and emissions associated with extraction and refining processes.

However, it is important to note that the environmental impact of using 2-methylpentane in carbon nanotube dispersion should be balanced against the potential benefits of improved nanotube dispersion. Better dispersion can lead to more efficient use of carbon nanotubes, potentially reducing the overall amount of material needed and improving the performance of nanotube-based products. This efficiency could translate to reduced resource consumption and environmental impacts in other areas of application.

To mitigate environmental risks, strict protocols for handling, storage, and disposal of 2-methylpentane should be implemented in research and industrial settings. Closed-loop systems, solvent recovery techniques, and proper waste management practices can significantly reduce environmental exposure. Additionally, ongoing research into more environmentally friendly alternatives for carbon nanotube dispersion should be encouraged to further minimize the ecological footprint of nanotechnology development.

Scalability Assessment

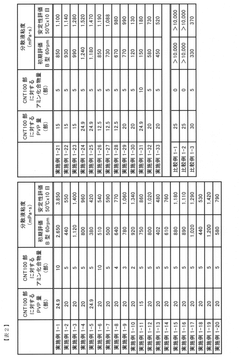

The scalability assessment of 2-methylpentane as an aid for carbon nanotube dispersion is crucial for determining its potential for large-scale industrial applications. The process of dispersing carbon nanotubes (CNTs) in solvents is a critical step in many manufacturing processes, and the ability to scale this process efficiently can significantly impact production costs and product quality.

2-Methylpentane has shown promising results in laboratory-scale experiments for dispersing CNTs. However, transitioning from small-scale to industrial-scale production presents several challenges. One of the primary considerations is the availability and cost of 2-methylpentane at larger quantities. As production scales up, the economic viability of using this solvent becomes increasingly important.

The dispersion process itself must also be evaluated for scalability. Factors such as mixing time, energy input, and equipment requirements need to be assessed to determine if they can be effectively scaled without compromising the quality of dispersion. Additionally, the stability of the CNT dispersion over time and under various environmental conditions must be considered, as this can affect the shelf life and usability of the dispersed CNTs in downstream applications.

Environmental and safety considerations play a significant role in scalability assessment. 2-Methylpentane is a volatile organic compound, and its use at industrial scales may require specialized handling and storage facilities, as well as emission control systems to comply with environmental regulations. The potential for solvent recovery and recycling should also be evaluated to improve the overall sustainability and cost-effectiveness of the process.

Another important aspect of scalability is the consistency of dispersion quality across larger batches. Uniform dispersion of CNTs is critical for many applications, and maintaining this uniformity as production volumes increase can be challenging. Techniques for monitoring and controlling dispersion quality in real-time during large-scale production may need to be developed.

The compatibility of 2-methylpentane-dispersed CNTs with various manufacturing processes and end-product applications must also be assessed. This includes evaluating how well the dispersed CNTs integrate into different matrices or substrates, and whether the presence of residual solvent affects the properties of the final products.

Lastly, the scalability assessment should consider the potential for process optimization and automation. As production scales up, opportunities for improving efficiency through automated handling, inline quality control, and continuous processing should be explored. These advancements can significantly enhance the economic viability of using 2-methylpentane for large-scale CNT dispersion.

2-Methylpentane has shown promising results in laboratory-scale experiments for dispersing CNTs. However, transitioning from small-scale to industrial-scale production presents several challenges. One of the primary considerations is the availability and cost of 2-methylpentane at larger quantities. As production scales up, the economic viability of using this solvent becomes increasingly important.

The dispersion process itself must also be evaluated for scalability. Factors such as mixing time, energy input, and equipment requirements need to be assessed to determine if they can be effectively scaled without compromising the quality of dispersion. Additionally, the stability of the CNT dispersion over time and under various environmental conditions must be considered, as this can affect the shelf life and usability of the dispersed CNTs in downstream applications.

Environmental and safety considerations play a significant role in scalability assessment. 2-Methylpentane is a volatile organic compound, and its use at industrial scales may require specialized handling and storage facilities, as well as emission control systems to comply with environmental regulations. The potential for solvent recovery and recycling should also be evaluated to improve the overall sustainability and cost-effectiveness of the process.

Another important aspect of scalability is the consistency of dispersion quality across larger batches. Uniform dispersion of CNTs is critical for many applications, and maintaining this uniformity as production volumes increase can be challenging. Techniques for monitoring and controlling dispersion quality in real-time during large-scale production may need to be developed.

The compatibility of 2-methylpentane-dispersed CNTs with various manufacturing processes and end-product applications must also be assessed. This includes evaluating how well the dispersed CNTs integrate into different matrices or substrates, and whether the presence of residual solvent affects the properties of the final products.

Lastly, the scalability assessment should consider the potential for process optimization and automation. As production scales up, opportunities for improving efficiency through automated handling, inline quality control, and continuous processing should be explored. These advancements can significantly enhance the economic viability of using 2-methylpentane for large-scale CNT dispersion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!