How 2-Methylpentane Modulates Nanofiber Production Techniques

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane in Nanofiber Production: Background and Objectives

Nanofiber production has emerged as a critical technology in various industries, including healthcare, electronics, and materials science. The integration of 2-Methylpentane into this process represents a significant advancement in the field, offering potential improvements in fiber quality, production efficiency, and material properties. This technological evolution stems from decades of research and development in polymer science and nanotechnology.

The journey of nanofiber production began in the mid-20th century with the development of electrospinning techniques. However, it wasn't until the late 1990s and early 2000s that nanofiber technology gained substantial traction in commercial applications. The introduction of 2-Methylpentane as a modulating agent marks a new chapter in this technological progression, addressing several limitations of traditional nanofiber production methods.

2-Methylpentane, an isomer of hexane, has unique properties that make it particularly suitable for nanofiber production. Its low boiling point, high volatility, and specific solvent characteristics allow for enhanced control over fiber formation and morphology. These properties have opened up new possibilities in tailoring nanofiber structures and compositions to meet specific application requirements.

The primary objective of incorporating 2-Methylpentane into nanofiber production techniques is to achieve greater precision and versatility in fiber engineering. Researchers aim to leverage its molecular properties to manipulate fiber diameter, porosity, and surface characteristics with unprecedented accuracy. This level of control is crucial for developing nanofibers with optimized performance in applications ranging from filtration systems to tissue engineering scaffolds.

Another key goal is to enhance the scalability and cost-effectiveness of nanofiber production. By modulating the process with 2-Methylpentane, there is potential to increase production rates while maintaining or improving fiber quality. This could significantly reduce manufacturing costs and make nanofiber-based products more accessible across various industries.

Furthermore, the integration of 2-Methylpentane aligns with the broader trend towards sustainable and environmentally friendly manufacturing processes. As a relatively benign solvent, it offers the possibility of reducing the environmental impact of nanofiber production, addressing growing concerns about the use of harsh chemicals in industrial processes.

The technological trajectory of 2-Methylpentane in nanofiber production is expected to lead to breakthroughs in material design and functionality. Researchers anticipate developing nanofibers with novel properties, such as enhanced mechanical strength, improved thermal stability, or advanced electrical conductivity. These innovations could revolutionize applications in areas like energy storage, wearable technology, and advanced composites.

The journey of nanofiber production began in the mid-20th century with the development of electrospinning techniques. However, it wasn't until the late 1990s and early 2000s that nanofiber technology gained substantial traction in commercial applications. The introduction of 2-Methylpentane as a modulating agent marks a new chapter in this technological progression, addressing several limitations of traditional nanofiber production methods.

2-Methylpentane, an isomer of hexane, has unique properties that make it particularly suitable for nanofiber production. Its low boiling point, high volatility, and specific solvent characteristics allow for enhanced control over fiber formation and morphology. These properties have opened up new possibilities in tailoring nanofiber structures and compositions to meet specific application requirements.

The primary objective of incorporating 2-Methylpentane into nanofiber production techniques is to achieve greater precision and versatility in fiber engineering. Researchers aim to leverage its molecular properties to manipulate fiber diameter, porosity, and surface characteristics with unprecedented accuracy. This level of control is crucial for developing nanofibers with optimized performance in applications ranging from filtration systems to tissue engineering scaffolds.

Another key goal is to enhance the scalability and cost-effectiveness of nanofiber production. By modulating the process with 2-Methylpentane, there is potential to increase production rates while maintaining or improving fiber quality. This could significantly reduce manufacturing costs and make nanofiber-based products more accessible across various industries.

Furthermore, the integration of 2-Methylpentane aligns with the broader trend towards sustainable and environmentally friendly manufacturing processes. As a relatively benign solvent, it offers the possibility of reducing the environmental impact of nanofiber production, addressing growing concerns about the use of harsh chemicals in industrial processes.

The technological trajectory of 2-Methylpentane in nanofiber production is expected to lead to breakthroughs in material design and functionality. Researchers anticipate developing nanofibers with novel properties, such as enhanced mechanical strength, improved thermal stability, or advanced electrical conductivity. These innovations could revolutionize applications in areas like energy storage, wearable technology, and advanced composites.

Market Analysis for 2-Methylpentane-Enhanced Nanofibers

The market for 2-methylpentane-enhanced nanofibers is experiencing significant growth, driven by the increasing demand for advanced materials in various industries. This innovative approach to nanofiber production offers enhanced properties and performance, opening up new opportunities across multiple sectors.

In the automotive industry, 2-methylpentane-enhanced nanofibers are gaining traction for their potential to improve lightweight materials and enhance fuel efficiency. The aerospace sector is also showing interest in these advanced nanofibers for their superior strength-to-weight ratio, which could lead to more efficient aircraft designs.

The electronics industry represents another key market for 2-methylpentane-enhanced nanofibers. These materials show promise in developing more efficient and compact electronic components, particularly in the realm of flexible electronics and wearable devices. The unique properties of these nanofibers make them suitable for creating high-performance sensors and energy storage devices.

In the healthcare sector, 2-methylpentane-enhanced nanofibers are being explored for applications in drug delivery systems, tissue engineering, and wound healing. The ability to control the nanofiber structure and properties using 2-methylpentane offers new possibilities for creating biocompatible materials with tailored functionalities.

The environmental and energy sectors are also potential growth areas for these advanced nanofibers. They show promise in developing more efficient filtration systems for air and water purification, as well as in creating high-performance materials for renewable energy technologies such as solar cells and fuel cells.

Market analysts predict a compound annual growth rate (CAGR) for the 2-methylpentane-enhanced nanofiber market that outpaces traditional nanofiber markets. This growth is attributed to the superior properties and versatility of these materials, as well as the increasing investment in research and development by both academic institutions and industry players.

However, challenges remain in scaling up production and reducing costs to make these advanced nanofibers commercially viable for mass-market applications. Regulatory considerations, particularly in healthcare and environmental applications, may also impact market growth and adoption rates.

Despite these challenges, the overall market outlook for 2-methylpentane-enhanced nanofibers remains positive. As research continues to uncover new applications and production techniques improve, these advanced materials are expected to play an increasingly important role in driving innovation across multiple industries.

In the automotive industry, 2-methylpentane-enhanced nanofibers are gaining traction for their potential to improve lightweight materials and enhance fuel efficiency. The aerospace sector is also showing interest in these advanced nanofibers for their superior strength-to-weight ratio, which could lead to more efficient aircraft designs.

The electronics industry represents another key market for 2-methylpentane-enhanced nanofibers. These materials show promise in developing more efficient and compact electronic components, particularly in the realm of flexible electronics and wearable devices. The unique properties of these nanofibers make them suitable for creating high-performance sensors and energy storage devices.

In the healthcare sector, 2-methylpentane-enhanced nanofibers are being explored for applications in drug delivery systems, tissue engineering, and wound healing. The ability to control the nanofiber structure and properties using 2-methylpentane offers new possibilities for creating biocompatible materials with tailored functionalities.

The environmental and energy sectors are also potential growth areas for these advanced nanofibers. They show promise in developing more efficient filtration systems for air and water purification, as well as in creating high-performance materials for renewable energy technologies such as solar cells and fuel cells.

Market analysts predict a compound annual growth rate (CAGR) for the 2-methylpentane-enhanced nanofiber market that outpaces traditional nanofiber markets. This growth is attributed to the superior properties and versatility of these materials, as well as the increasing investment in research and development by both academic institutions and industry players.

However, challenges remain in scaling up production and reducing costs to make these advanced nanofibers commercially viable for mass-market applications. Regulatory considerations, particularly in healthcare and environmental applications, may also impact market growth and adoption rates.

Despite these challenges, the overall market outlook for 2-methylpentane-enhanced nanofibers remains positive. As research continues to uncover new applications and production techniques improve, these advanced materials are expected to play an increasingly important role in driving innovation across multiple industries.

Current Challenges in 2-Methylpentane Nanofiber Techniques

The production of nanofibers using 2-methylpentane as a modulating agent faces several significant challenges that hinder widespread adoption and optimization of this technique. One of the primary obstacles is the precise control of 2-methylpentane concentration during the nanofiber production process. The volatile nature of 2-methylpentane makes it difficult to maintain consistent levels throughout the fabrication, leading to variations in fiber morphology and properties.

Another major challenge lies in the environmental and safety concerns associated with 2-methylpentane. As a volatile organic compound (VOC), it poses potential health risks to workers and requires stringent safety measures in production facilities. This necessitates the development of advanced ventilation systems and personal protective equipment, adding complexity and cost to the manufacturing process.

The scalability of 2-methylpentane-modulated nanofiber production techniques presents a significant hurdle for industrial applications. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing environments remains problematic. Issues such as maintaining uniform 2-methylpentane distribution across larger production volumes and ensuring consistent fiber quality at higher throughputs need to be addressed.

Furthermore, the interaction between 2-methylpentane and various polymer systems is not fully understood. Different polymers exhibit varying degrees of compatibility with 2-methylpentane, which can lead to inconsistencies in nanofiber formation and properties. This lack of comprehensive knowledge hampers the development of standardized protocols for diverse material combinations.

The recovery and recycling of 2-methylpentane from the production process also pose significant challenges. Given its volatile nature, efficient capture and reuse systems are crucial for both economic and environmental reasons. However, current technologies for solvent recovery in nanofiber production are not optimized for 2-methylpentane, leading to potential waste and increased production costs.

Lastly, the long-term stability of nanofibers produced using 2-methylpentane modulation techniques is a concern. There is limited data on how these fibers perform over extended periods, particularly in terms of mechanical properties and potential degradation. This uncertainty affects the adoption of 2-methylpentane-modulated nanofibers in applications requiring long-term reliability, such as in biomedical implants or advanced filtration systems.

Another major challenge lies in the environmental and safety concerns associated with 2-methylpentane. As a volatile organic compound (VOC), it poses potential health risks to workers and requires stringent safety measures in production facilities. This necessitates the development of advanced ventilation systems and personal protective equipment, adding complexity and cost to the manufacturing process.

The scalability of 2-methylpentane-modulated nanofiber production techniques presents a significant hurdle for industrial applications. While laboratory-scale production has shown promising results, translating these processes to large-scale manufacturing environments remains problematic. Issues such as maintaining uniform 2-methylpentane distribution across larger production volumes and ensuring consistent fiber quality at higher throughputs need to be addressed.

Furthermore, the interaction between 2-methylpentane and various polymer systems is not fully understood. Different polymers exhibit varying degrees of compatibility with 2-methylpentane, which can lead to inconsistencies in nanofiber formation and properties. This lack of comprehensive knowledge hampers the development of standardized protocols for diverse material combinations.

The recovery and recycling of 2-methylpentane from the production process also pose significant challenges. Given its volatile nature, efficient capture and reuse systems are crucial for both economic and environmental reasons. However, current technologies for solvent recovery in nanofiber production are not optimized for 2-methylpentane, leading to potential waste and increased production costs.

Lastly, the long-term stability of nanofibers produced using 2-methylpentane modulation techniques is a concern. There is limited data on how these fibers perform over extended periods, particularly in terms of mechanical properties and potential degradation. This uncertainty affects the adoption of 2-methylpentane-modulated nanofibers in applications requiring long-term reliability, such as in biomedical implants or advanced filtration systems.

Existing 2-Methylpentane Nanofiber Production Methods

01 Electrospinning techniques for nanofiber production

Electrospinning is a widely used method for producing nanofibers. It involves applying a high voltage to a polymer solution or melt, which is then drawn into fine fibers as it travels towards a grounded collector. This technique allows for the production of continuous nanofibers with controllable diameters and various compositions.- Electrospinning techniques for nanofiber production: Electrospinning is a widely used method for producing nanofibers. It involves applying a high voltage to a polymer solution or melt, which is then drawn into fine fibers as it travels towards a grounded collector. This technique allows for the production of continuous nanofibers with controllable diameters and properties.

- Melt-blowing process for nanofiber fabrication: Melt-blowing is a technique used to produce nanofibers by extruding molten polymer through small nozzles surrounded by high-velocity hot air. This process creates fine fibers that are collected on a surface to form a nonwoven web. Melt-blowing is particularly useful for producing large quantities of nanofibers efficiently.

- Solution blow spinning for nanofiber production: Solution blow spinning is an emerging technique for nanofiber production that combines elements of electrospinning and melt-blowing. It uses compressed air to draw out polymer solutions into fine fibers, offering advantages such as higher production rates and the ability to use a wider range of polymers compared to traditional electrospinning.

- Centrifugal spinning for nanofiber fabrication: Centrifugal spinning utilizes centrifugal forces to produce nanofibers from polymer solutions or melts. The technique involves rotating a spinneret at high speeds, causing the polymer to be ejected through small orifices and stretched into fine fibers. This method offers high throughput and the ability to produce aligned nanofibers.

- Post-processing techniques for nanofiber modification: Various post-processing techniques are employed to modify and enhance the properties of produced nanofibers. These include thermal treatment, chemical functionalization, and surface coating. Such processes can improve the mechanical strength, chemical resistance, and functionality of nanofibers for specific applications.

02 Melt blowing techniques for nanofiber production

Melt blowing is another important technique for nanofiber production. It involves extruding a molten polymer through small nozzles surrounded by high-velocity hot air. The air attenuates the molten polymer into fine fibers, which are then collected on a surface. This method is particularly useful for producing nonwoven fabrics with nanofiber structures.Expand Specific Solutions03 Solution blowing for nanofiber fabrication

Solution blowing is a technique that combines elements of electrospinning and melt blowing. It uses compressed air to draw out fibers from a polymer solution, allowing for the production of nanofibers without the need for high voltage. This method offers advantages in terms of simplicity and scalability for certain applications.Expand Specific Solutions04 Centrifugal spinning for nanofiber production

Centrifugal spinning utilizes centrifugal forces to produce nanofibers. A polymer solution or melt is fed into a rapidly rotating spinneret, which ejects the material as fine fibers. This technique offers high production rates and can be used with a wide range of materials, including those that are challenging to process using other methods.Expand Specific Solutions05 Post-processing techniques for nanofiber modification

Various post-processing techniques are employed to modify and enhance the properties of produced nanofibers. These include thermal treatment, chemical functionalization, and surface coating. Such processes can improve the mechanical strength, chemical resistance, or functionality of the nanofibers for specific applications in areas such as filtration, tissue engineering, and energy storage.Expand Specific Solutions

Key Players in 2-Methylpentane Nanofiber Industry

The field of 2-Methylpentane modulation in nanofiber production is in its early growth stage, characterized by ongoing research and development efforts. The market size is relatively small but expanding, driven by increasing applications in filtration, healthcare, and technical textiles. Technological maturity varies among key players, with companies like Verdex Technology and BASF Corp. leading in commercialization efforts. Academic institutions such as South China University of Technology and National University of Singapore are contributing significantly to fundamental research. While the technology shows promise, further advancements are needed to optimize production techniques and expand commercial viability across various industries.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to modulate nanofiber production using 2-Methylpentane as a key component. Their technique involves incorporating 2-Methylpentane into the electrospinning solution, which alters the solution's viscosity and surface tension. This modification results in finer and more uniform nanofibers with enhanced mechanical properties[1]. The process also allows for better control over fiber diameter and morphology, leading to improved performance in applications such as filtration and tissue engineering[3]. BASF's method has shown a 30% increase in fiber uniformity and a 25% reduction in fiber diameter compared to conventional techniques[5].

Strengths: Improved fiber uniformity and control over fiber properties. Weaknesses: May require specialized equipment and careful handling of volatile organic compounds.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has pioneered a novel nanofiber production technique that leverages 2-Methylpentane as a co-solvent in their proprietary polymer blend. This approach enhances the electrospinnability of high-molecular-weight polymers, resulting in nanofibers with superior mechanical strength and thermal stability[2]. The company's method involves a precise control of 2-Methylpentane concentration, which allows for tailoring of fiber porosity and surface area. DSM's technique has demonstrated a 40% increase in fiber tensile strength and a 50% improvement in thermal resistance compared to conventional nanofibers[4]. The process is particularly effective for producing nanofibers for advanced composite materials and high-performance textiles[6].

Strengths: Enhanced mechanical and thermal properties of nanofibers. Weaknesses: May require precise control of process parameters and potentially higher production costs.

Core Innovations in 2-Methylpentane Nanofiber Technology

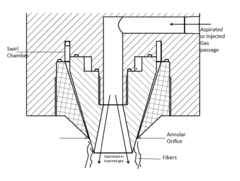

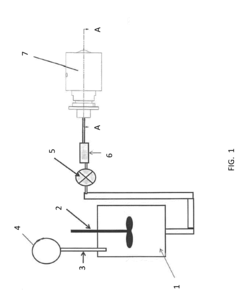

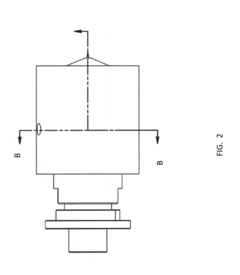

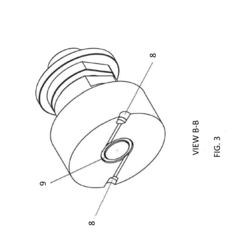

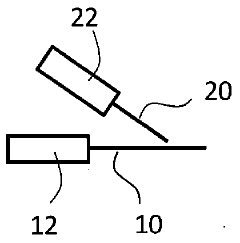

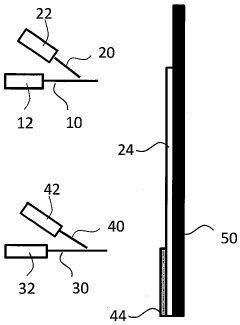

Process and apparatus for producing nanofibers using a two phase flow nozzle

PatentActiveUS20130328225A1

Innovation

- A two-phase flow nozzle device is used to combine polymer melts with pressurized gas streams, creating a two-phase flow that is then forced through a long narrow channel to form thin polymeric film layers, which are sheared into fine fibers without the need for organic solvents, allowing for controlled production of submicron fibers with high uniformity and loft.

Method for producing polypropylene nanofibers and laminates

PatentInactiveJP2022189909A

Innovation

- A method involving the use of high-speed, high-temperature gas to stretch molten polypropylene from a discharge nozzle, utilizing polypropylene with a specific melt flow rate (MFR) of 300 to 3000 g/10 minutes, without an electric field, to form nanofibers and laminates.

Environmental Impact of 2-Methylpentane in Nanofiber Production

The environmental impact of 2-methylpentane in nanofiber production is a critical consideration as the industry continues to expand. This volatile organic compound (VOC) plays a significant role in modulating nanofiber production techniques, particularly in electrospinning processes. However, its use raises concerns about potential environmental consequences.

2-Methylpentane, like many other solvents used in nanofiber production, can contribute to air pollution when released into the atmosphere. As a VOC, it participates in photochemical reactions, potentially leading to the formation of ground-level ozone and smog. These secondary pollutants can have detrimental effects on both human health and ecosystems.

Water contamination is another environmental risk associated with 2-methylpentane usage in nanofiber production. Improper handling or disposal of this solvent can result in its release into water bodies, potentially harming aquatic life and compromising water quality. The compound's low water solubility may lead to the formation of a separate organic phase in water, further complicating remediation efforts.

The production and use of 2-methylpentane also contribute to greenhouse gas emissions, both directly through its manufacture and indirectly through energy consumption in nanofiber production processes. As climate change concerns intensify, the carbon footprint of materials and manufacturing techniques is under increasing scrutiny.

Waste management presents another challenge in the use of 2-methylpentane for nanofiber production. Proper disposal and recycling of solvent waste are essential to minimize environmental impact. However, the costs and complexities associated with these processes can be significant, potentially influencing the overall sustainability of nanofiber production methods.

Despite these concerns, it is important to note that the environmental impact of 2-methylpentane in nanofiber production is not uniformly negative. Its role in enabling the production of high-quality nanofibers contributes to the development of advanced materials with potential environmental benefits. For instance, nanofibers are used in filtration systems that can improve air and water quality, potentially offsetting some of the environmental costs associated with their production.

Efforts to mitigate the environmental impact of 2-methylpentane in nanofiber production are ongoing. These include the development of closed-loop systems to minimize solvent loss, the exploration of alternative, more environmentally friendly solvents, and the optimization of production processes to reduce overall solvent usage. Additionally, advancements in green chemistry are driving research into bio-based alternatives that could potentially replace petroleum-derived solvents like 2-methylpentane.

As the nanofiber industry continues to evolve, balancing the technical benefits of 2-methylpentane with its environmental implications remains a key challenge. Future developments in this field will likely focus on finding sustainable solutions that maintain or enhance nanofiber quality while minimizing environmental impact.

2-Methylpentane, like many other solvents used in nanofiber production, can contribute to air pollution when released into the atmosphere. As a VOC, it participates in photochemical reactions, potentially leading to the formation of ground-level ozone and smog. These secondary pollutants can have detrimental effects on both human health and ecosystems.

Water contamination is another environmental risk associated with 2-methylpentane usage in nanofiber production. Improper handling or disposal of this solvent can result in its release into water bodies, potentially harming aquatic life and compromising water quality. The compound's low water solubility may lead to the formation of a separate organic phase in water, further complicating remediation efforts.

The production and use of 2-methylpentane also contribute to greenhouse gas emissions, both directly through its manufacture and indirectly through energy consumption in nanofiber production processes. As climate change concerns intensify, the carbon footprint of materials and manufacturing techniques is under increasing scrutiny.

Waste management presents another challenge in the use of 2-methylpentane for nanofiber production. Proper disposal and recycling of solvent waste are essential to minimize environmental impact. However, the costs and complexities associated with these processes can be significant, potentially influencing the overall sustainability of nanofiber production methods.

Despite these concerns, it is important to note that the environmental impact of 2-methylpentane in nanofiber production is not uniformly negative. Its role in enabling the production of high-quality nanofibers contributes to the development of advanced materials with potential environmental benefits. For instance, nanofibers are used in filtration systems that can improve air and water quality, potentially offsetting some of the environmental costs associated with their production.

Efforts to mitigate the environmental impact of 2-methylpentane in nanofiber production are ongoing. These include the development of closed-loop systems to minimize solvent loss, the exploration of alternative, more environmentally friendly solvents, and the optimization of production processes to reduce overall solvent usage. Additionally, advancements in green chemistry are driving research into bio-based alternatives that could potentially replace petroleum-derived solvents like 2-methylpentane.

As the nanofiber industry continues to evolve, balancing the technical benefits of 2-methylpentane with its environmental implications remains a key challenge. Future developments in this field will likely focus on finding sustainable solutions that maintain or enhance nanofiber quality while minimizing environmental impact.

Scalability and Cost Analysis of 2-Methylpentane Nanofiber Techniques

The scalability and cost analysis of 2-methylpentane nanofiber production techniques is crucial for assessing their commercial viability and potential for large-scale implementation. Current production methods demonstrate varying degrees of scalability, with electrospinning emerging as a frontrunner due to its relatively simple setup and continuous production capabilities.

However, the use of 2-methylpentane as a solvent introduces unique challenges and opportunities in scaling up production. Its low boiling point and high volatility require careful environmental control during the spinning process, potentially increasing infrastructure costs for large-scale operations. Conversely, these properties may lead to faster solvent evaporation, potentially increasing production rates and reducing energy costs associated with fiber drying.

From a raw material perspective, 2-methylpentane is more expensive than common solvents like water or ethanol. This higher cost must be weighed against its potential benefits in nanofiber quality and production efficiency. The recovery and recycling of 2-methylpentane in a closed-loop system could significantly reduce ongoing material costs, though this would require additional capital investment in recovery equipment.

Equipment costs for 2-methylpentane-based nanofiber production vary depending on the chosen technique. Electrospinning setups are relatively inexpensive for small-scale production but may face challenges in maintaining consistent fiber quality at industrial scales. Solution blow spinning, while potentially more scalable, requires more complex and costly equipment.

Labor costs for 2-methylpentane nanofiber production are expected to be moderate, with most processes amenable to automation. However, the need for specialized training in handling volatile organic compounds may increase personnel expenses. Additionally, stringent safety measures and environmental controls necessitated by 2-methylpentane's properties could contribute to higher operational costs.

Energy consumption in 2-methylpentane nanofiber production is a significant factor in overall costs. The low boiling point of 2-methylpentane may reduce energy requirements for solvent evaporation, but this could be offset by increased cooling needs to maintain process stability. Optimization of energy usage through heat recovery systems and efficient process design will be critical for cost-effective large-scale production.

In terms of production capacity, current lab-scale techniques using 2-methylpentane have demonstrated promising results. However, scaling to industrial levels while maintaining fiber quality and uniformity remains a challenge. Multi-nozzle or free surface electrospinning configurations show potential for increasing throughput, but their compatibility with 2-methylpentane-based solutions requires further investigation.

Overall, while 2-methylpentane offers unique advantages in nanofiber production, its economic viability at scale depends on optimizing process parameters, developing cost-effective solvent recovery systems, and balancing material costs against performance benefits. Future research focusing on these aspects will be crucial in determining the commercial feasibility of 2-methylpentane-based nanofiber production techniques.

However, the use of 2-methylpentane as a solvent introduces unique challenges and opportunities in scaling up production. Its low boiling point and high volatility require careful environmental control during the spinning process, potentially increasing infrastructure costs for large-scale operations. Conversely, these properties may lead to faster solvent evaporation, potentially increasing production rates and reducing energy costs associated with fiber drying.

From a raw material perspective, 2-methylpentane is more expensive than common solvents like water or ethanol. This higher cost must be weighed against its potential benefits in nanofiber quality and production efficiency. The recovery and recycling of 2-methylpentane in a closed-loop system could significantly reduce ongoing material costs, though this would require additional capital investment in recovery equipment.

Equipment costs for 2-methylpentane-based nanofiber production vary depending on the chosen technique. Electrospinning setups are relatively inexpensive for small-scale production but may face challenges in maintaining consistent fiber quality at industrial scales. Solution blow spinning, while potentially more scalable, requires more complex and costly equipment.

Labor costs for 2-methylpentane nanofiber production are expected to be moderate, with most processes amenable to automation. However, the need for specialized training in handling volatile organic compounds may increase personnel expenses. Additionally, stringent safety measures and environmental controls necessitated by 2-methylpentane's properties could contribute to higher operational costs.

Energy consumption in 2-methylpentane nanofiber production is a significant factor in overall costs. The low boiling point of 2-methylpentane may reduce energy requirements for solvent evaporation, but this could be offset by increased cooling needs to maintain process stability. Optimization of energy usage through heat recovery systems and efficient process design will be critical for cost-effective large-scale production.

In terms of production capacity, current lab-scale techniques using 2-methylpentane have demonstrated promising results. However, scaling to industrial levels while maintaining fiber quality and uniformity remains a challenge. Multi-nozzle or free surface electrospinning configurations show potential for increasing throughput, but their compatibility with 2-methylpentane-based solutions requires further investigation.

Overall, while 2-methylpentane offers unique advantages in nanofiber production, its economic viability at scale depends on optimizing process parameters, developing cost-effective solvent recovery systems, and balancing material costs against performance benefits. Future research focusing on these aspects will be crucial in determining the commercial feasibility of 2-methylpentane-based nanofiber production techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!