How 2-Methylpentane Modulates Polymer Melt Characteristics

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane and Polymer Melt Modulation: Background

The modulation of polymer melt characteristics by 2-methylpentane represents a significant area of research in polymer science and materials engineering. This branched alkane, also known as isohexane, has garnered attention for its potential to influence the behavior of polymer melts, which are crucial in various manufacturing processes.

2-Methylpentane belongs to the family of hydrocarbon solvents and is characterized by its branched structure, which distinguishes it from its linear isomer, n-hexane. This structural difference imparts unique properties that can significantly affect its interactions with polymer chains in a melt state. The use of 2-methylpentane as a modulating agent for polymer melts has emerged from the broader field of polymer rheology and processing.

Historically, the manipulation of polymer melt characteristics has been a key focus in the development of advanced materials and manufacturing techniques. The introduction of various additives, including low molecular weight hydrocarbons, has been explored to tailor the properties of polymer melts. 2-Methylpentane's role in this context has evolved as researchers sought more precise control over melt behavior.

The interaction between 2-methylpentane and polymer melts is fundamentally rooted in the principles of polymer physics and thermodynamics. When introduced into a polymer system, 2-methylpentane can act as a plasticizer, altering the free volume between polymer chains and consequently affecting the melt's viscosity, flow behavior, and other rheological properties.

Understanding the modulation effects of 2-methylpentane requires consideration of several factors, including the polymer's chemical structure, molecular weight distribution, and the processing conditions. The branched nature of 2-methylpentane can lead to unique entanglement dynamics with polymer chains, potentially influencing the melt's elasticity and relaxation behavior.

Recent advancements in analytical techniques, such as rheometry and spectroscopy, have enabled more detailed investigations into the molecular-level interactions between 2-methylpentane and various polymer systems. These studies have revealed complex relationships between solvent structure, concentration, and the resulting changes in polymer melt characteristics.

The growing interest in sustainable and efficient manufacturing processes has further propelled research into the use of 2-methylpentane as a modulating agent. Its potential to enhance processability and reduce energy requirements in polymer processing aligns with broader industry trends towards more environmentally friendly practices.

2-Methylpentane belongs to the family of hydrocarbon solvents and is characterized by its branched structure, which distinguishes it from its linear isomer, n-hexane. This structural difference imparts unique properties that can significantly affect its interactions with polymer chains in a melt state. The use of 2-methylpentane as a modulating agent for polymer melts has emerged from the broader field of polymer rheology and processing.

Historically, the manipulation of polymer melt characteristics has been a key focus in the development of advanced materials and manufacturing techniques. The introduction of various additives, including low molecular weight hydrocarbons, has been explored to tailor the properties of polymer melts. 2-Methylpentane's role in this context has evolved as researchers sought more precise control over melt behavior.

The interaction between 2-methylpentane and polymer melts is fundamentally rooted in the principles of polymer physics and thermodynamics. When introduced into a polymer system, 2-methylpentane can act as a plasticizer, altering the free volume between polymer chains and consequently affecting the melt's viscosity, flow behavior, and other rheological properties.

Understanding the modulation effects of 2-methylpentane requires consideration of several factors, including the polymer's chemical structure, molecular weight distribution, and the processing conditions. The branched nature of 2-methylpentane can lead to unique entanglement dynamics with polymer chains, potentially influencing the melt's elasticity and relaxation behavior.

Recent advancements in analytical techniques, such as rheometry and spectroscopy, have enabled more detailed investigations into the molecular-level interactions between 2-methylpentane and various polymer systems. These studies have revealed complex relationships between solvent structure, concentration, and the resulting changes in polymer melt characteristics.

The growing interest in sustainable and efficient manufacturing processes has further propelled research into the use of 2-methylpentane as a modulating agent. Its potential to enhance processability and reduce energy requirements in polymer processing aligns with broader industry trends towards more environmentally friendly practices.

Market Analysis for Modified Polymer Melts

The market for modified polymer melts, particularly those influenced by 2-methylpentane, has shown significant growth and potential in recent years. This sector is driven by the increasing demand for high-performance plastics across various industries, including automotive, packaging, and consumer goods.

The global market for modified polymers is estimated to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) exceeding the average for the broader chemicals industry. This growth is primarily attributed to the unique properties that modifiers like 2-methylpentane impart to polymer melts, enhancing their processability, mechanical strength, and thermal stability.

In the automotive sector, the demand for lightweight materials with improved performance characteristics has been a key driver for modified polymer melts. The use of 2-methylpentane as a modifier has enabled the production of polymer components with reduced weight and enhanced durability, contributing to improved fuel efficiency and overall vehicle performance.

The packaging industry has also shown increased interest in modified polymer melts. The ability of 2-methylpentane to alter the melt characteristics of polymers has led to the development of packaging materials with improved barrier properties, extended shelf life, and enhanced recyclability. This aligns well with the growing consumer demand for sustainable packaging solutions.

Consumer goods manufacturers have been exploring the benefits of 2-methylpentane-modified polymer melts for producing durable and aesthetically pleasing products. The improved flow properties and surface finish achieved through this modification have opened up new design possibilities and manufacturing efficiencies.

Geographically, North America and Europe have been at the forefront of adopting modified polymer melt technologies, driven by stringent regulations on material performance and environmental sustainability. However, the Asia-Pacific region is expected to witness the fastest growth in this market, fueled by rapid industrialization and increasing investments in research and development.

The market landscape is characterized by a mix of large chemical companies and specialized polymer manufacturers. Key players are investing heavily in research and development to optimize the use of 2-methylpentane and similar modifiers in polymer processing. Collaborations between material scientists and end-user industries are becoming more common, fostering innovation and tailored solutions.

Despite the positive outlook, challenges remain. The volatility in raw material prices, particularly petrochemical derivatives, can impact the cost-effectiveness of modified polymer melts. Additionally, the push towards bio-based and recyclable materials poses both a challenge and an opportunity for the industry to innovate further.

The global market for modified polymers is estimated to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) exceeding the average for the broader chemicals industry. This growth is primarily attributed to the unique properties that modifiers like 2-methylpentane impart to polymer melts, enhancing their processability, mechanical strength, and thermal stability.

In the automotive sector, the demand for lightweight materials with improved performance characteristics has been a key driver for modified polymer melts. The use of 2-methylpentane as a modifier has enabled the production of polymer components with reduced weight and enhanced durability, contributing to improved fuel efficiency and overall vehicle performance.

The packaging industry has also shown increased interest in modified polymer melts. The ability of 2-methylpentane to alter the melt characteristics of polymers has led to the development of packaging materials with improved barrier properties, extended shelf life, and enhanced recyclability. This aligns well with the growing consumer demand for sustainable packaging solutions.

Consumer goods manufacturers have been exploring the benefits of 2-methylpentane-modified polymer melts for producing durable and aesthetically pleasing products. The improved flow properties and surface finish achieved through this modification have opened up new design possibilities and manufacturing efficiencies.

Geographically, North America and Europe have been at the forefront of adopting modified polymer melt technologies, driven by stringent regulations on material performance and environmental sustainability. However, the Asia-Pacific region is expected to witness the fastest growth in this market, fueled by rapid industrialization and increasing investments in research and development.

The market landscape is characterized by a mix of large chemical companies and specialized polymer manufacturers. Key players are investing heavily in research and development to optimize the use of 2-methylpentane and similar modifiers in polymer processing. Collaborations between material scientists and end-user industries are becoming more common, fostering innovation and tailored solutions.

Despite the positive outlook, challenges remain. The volatility in raw material prices, particularly petrochemical derivatives, can impact the cost-effectiveness of modified polymer melts. Additionally, the push towards bio-based and recyclable materials poses both a challenge and an opportunity for the industry to innovate further.

Current Challenges in Polymer Melt Modification

The modification of polymer melt characteristics using 2-methylpentane presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is achieving consistent and uniform dispersion of 2-methylpentane within the polymer matrix. The volatile nature of this organic compound makes it difficult to maintain a homogeneous distribution throughout the melt, leading to potential inconsistencies in the final product's properties.

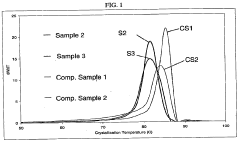

Another challenge lies in controlling the interaction between 2-methylpentane and various polymer types. Different polymers exhibit varying degrees of compatibility with this modifying agent, which can result in unpredictable changes in melt viscosity, crystallization behavior, and overall processability. This variability necessitates extensive experimentation and fine-tuning for each specific polymer-modifier combination.

The thermal stability of 2-methylpentane during polymer processing is also a concern. High processing temperatures can lead to the degradation or evaporation of the modifier, potentially altering its intended effects on the melt characteristics. This issue is particularly pronounced in high-temperature polymer systems, where maintaining the integrity of the modifying agent throughout the entire processing cycle is crucial.

Furthermore, the impact of 2-methylpentane on the long-term stability and performance of the final polymer product remains a subject of ongoing research. There are concerns about potential migration or leaching of the modifier over time, which could affect the durability and functional properties of the polymer in various applications.

Environmental and safety considerations pose additional challenges. The use of volatile organic compounds like 2-methylpentane raises questions about emissions during processing and potential health impacts on workers. Developing eco-friendly alternatives or finding ways to minimize the environmental footprint of this modification technique is an active area of investigation.

Scaling up the use of 2-methylpentane in industrial polymer processing presents its own set of challenges. Ensuring consistent quality and properties across large production batches requires sophisticated process control and monitoring systems. The economic viability of using this modifier on a large scale, considering factors such as cost, availability, and processing efficiency, is another aspect that needs careful evaluation.

Lastly, the regulatory landscape surrounding the use of chemical modifiers in polymer production is complex and evolving. Compliance with various regional and international standards while maintaining the desired melt characteristics adds another layer of complexity to the development and implementation of 2-methylpentane-based polymer modification techniques.

Another challenge lies in controlling the interaction between 2-methylpentane and various polymer types. Different polymers exhibit varying degrees of compatibility with this modifying agent, which can result in unpredictable changes in melt viscosity, crystallization behavior, and overall processability. This variability necessitates extensive experimentation and fine-tuning for each specific polymer-modifier combination.

The thermal stability of 2-methylpentane during polymer processing is also a concern. High processing temperatures can lead to the degradation or evaporation of the modifier, potentially altering its intended effects on the melt characteristics. This issue is particularly pronounced in high-temperature polymer systems, where maintaining the integrity of the modifying agent throughout the entire processing cycle is crucial.

Furthermore, the impact of 2-methylpentane on the long-term stability and performance of the final polymer product remains a subject of ongoing research. There are concerns about potential migration or leaching of the modifier over time, which could affect the durability and functional properties of the polymer in various applications.

Environmental and safety considerations pose additional challenges. The use of volatile organic compounds like 2-methylpentane raises questions about emissions during processing and potential health impacts on workers. Developing eco-friendly alternatives or finding ways to minimize the environmental footprint of this modification technique is an active area of investigation.

Scaling up the use of 2-methylpentane in industrial polymer processing presents its own set of challenges. Ensuring consistent quality and properties across large production batches requires sophisticated process control and monitoring systems. The economic viability of using this modifier on a large scale, considering factors such as cost, availability, and processing efficiency, is another aspect that needs careful evaluation.

Lastly, the regulatory landscape surrounding the use of chemical modifiers in polymer production is complex and evolving. Compliance with various regional and international standards while maintaining the desired melt characteristics adds another layer of complexity to the development and implementation of 2-methylpentane-based polymer modification techniques.

Existing 2-Methylpentane Modulation Methods

01 Melt flow characteristics of 2-methylpentane polymers

The melt flow characteristics of 2-methylpentane polymers are crucial for processing and end-use applications. These polymers exhibit specific melt flow rates and viscosities at different temperatures, which influence their processability in various manufacturing methods such as injection molding or extrusion. Understanding these properties is essential for optimizing processing conditions and achieving desired product performance.- Melt flow characteristics of 2-methylpentane polymers: The melt flow characteristics of 2-methylpentane polymers are crucial for processing and end-use applications. These polymers exhibit specific melt flow rates and viscosities that influence their behavior during extrusion, injection molding, and other thermal processing methods. Understanding these properties is essential for optimizing processing conditions and achieving desired product performance.

- Thermal properties and crystallization behavior: 2-Methylpentane polymers demonstrate unique thermal properties and crystallization behavior. These characteristics affect the polymer's melting point, glass transition temperature, and overall thermal stability. The crystallization kinetics and morphology of these polymers play a significant role in determining their mechanical and physical properties in the solid state.

- Rheological behavior and shear sensitivity: The rheological behavior of 2-methylpentane polymers, including their shear sensitivity, is critical for understanding their flow characteristics during processing. These polymers may exhibit non-Newtonian behavior, with viscosity changes under different shear rates. This information is vital for predicting and controlling polymer behavior in various processing operations and end-use applications.

- Molecular weight distribution and its effects: The molecular weight distribution of 2-methylpentane polymers significantly influences their melt characteristics. Polymers with broader molecular weight distributions may exhibit different flow behaviors compared to those with narrower distributions. This factor affects properties such as melt strength, elasticity, and processability, which are crucial for various manufacturing processes and product performance.

- Additives and their impact on melt properties: Various additives can be incorporated into 2-methylpentane polymers to modify their melt characteristics. These may include plasticizers, stabilizers, or other functional additives that can alter the polymer's flow behavior, thermal stability, or processing window. The selection and concentration of these additives can be tailored to achieve specific melt properties for different applications.

02 Thermal properties of 2-methylpentane polymer melts

The thermal properties of 2-methylpentane polymer melts, including melting point, glass transition temperature, and heat capacity, play a significant role in determining their behavior during processing and in final products. These properties affect the polymer's stability, crystallization behavior, and overall performance in different temperature ranges, which is crucial for various applications.Expand Specific Solutions03 Rheological behavior of 2-methylpentane polymer melts

The rheological behavior of 2-methylpentane polymer melts is characterized by their flow properties under different shear rates and temperatures. This includes aspects such as shear thinning, extensional viscosity, and melt strength. Understanding these properties is essential for predicting and controlling the polymer's behavior during processing and for designing products with specific performance requirements.Expand Specific Solutions04 Molecular weight and polydispersity effects on melt characteristics

The molecular weight and polydispersity of 2-methylpentane polymers significantly influence their melt characteristics. Higher molecular weight typically results in increased melt viscosity and improved mechanical properties, while polydispersity affects the breadth of the molecular weight distribution. These factors impact the processing window, melt stability, and final product properties of the polymer.Expand Specific Solutions05 Additives and modifiers for 2-methylpentane polymer melts

Various additives and modifiers can be incorporated into 2-methylpentane polymer melts to enhance their properties and processability. These may include plasticizers, stabilizers, nucleating agents, or compatibilizers. Such additives can alter the melt flow characteristics, thermal stability, and other properties of the polymer, allowing for tailored performance in specific applications.Expand Specific Solutions

Key Players in Polymer Melt Technology

The competitive landscape for modulating polymer melt characteristics with 2-Methylpentane is in a mature stage, with a global market size estimated in the billions. The technology has reached a high level of maturity, with established players like Mitsui Chemicals, ExxonMobil Chemical Patents, and Sinopec Shanghai Petrochemical leading the field. These companies have extensive research and development capabilities, allowing them to optimize polymer properties for various applications. Emerging players such as Wuxi Huitong Lightweight Materials and Chambroad Chemical Industry Research Institute are also contributing to innovation in this area. The market is characterized by ongoing efforts to improve polymer performance, reduce production costs, and develop more sustainable solutions, driving continued research and development activities across the industry.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed a proprietary technology that utilizes 2-methylpentane as a solvent and plasticizer in polymer processing. Their approach involves blending 2-methylpentane with various polymer resins to modify their melt characteristics. The company's research has demonstrated that the addition of 2-methylpentane can lower the melt temperature of certain polymers by up to 20°C, resulting in significant energy savings during processing[3]. Mitsui's technology also allows for the fine-tuning of polymer viscosity, enabling the production of ultra-thin films and fibers with improved mechanical properties[4]. The company has successfully applied this technology to a range of polymers, including polyethylene, polypropylene, and various engineering plastics.

Strengths: Energy-efficient processing, ability to produce ultra-thin materials, and versatility across multiple polymer types. Weaknesses: Potential for residual solvent in the final product and the need for careful control of 2-methylpentane concentration to avoid adverse effects on polymer properties.

Total Petrochemicals & Refining USA, Inc.

Technical Solution: Total Petrochemicals has developed a novel approach to using 2-methylpentane as a blending component in polymer formulations. Their technology involves incorporating small amounts of 2-methylpentane into polymer melts during the compounding process to modify their flow characteristics. The company's research has demonstrated that the addition of 2-methylpentane can reduce the melt viscosity of certain polymers by up to 30%, allowing for improved processability and faster production rates[7]. Total's approach also enables the production of polymer blends with unique combinations of properties, such as high impact strength and excellent flow characteristics. The company has successfully applied this technology to a range of polyolefins and engineering plastics, opening up new possibilities for complex part designs and thin-wall molding applications.

Strengths: Significant improvement in processability, ability to create unique property combinations, and applicability to a wide range of polymers. Weaknesses: Potential for volatilization of 2-methylpentane during high-temperature processing and the need for careful formulation to maintain desired mechanical properties.

Core Innovations in Polymer Melt Modulation

Propylene oxide recovery by azeotropic distillation of methyl formate-2-methylpentane

PatentInactiveUS4014753A

Innovation

- A single fractional distillation process using a distillation column where the crude mixture is fed in the middle, leveraging the azeotrope formation between propylene oxide and 2-methylpentane, with a sufficient ratio of methyl formate to 2-methylpentane, to recover pure propylene oxide without additional contaminants, utilizing conventional distillation columns and controlling reflux ratios.

Polymers made with metallocene catalysts, for use in rotomolding and injection molding products

PatentWO2008002379A2

Innovation

- The development of ethylene alpha-olefin copolymers produced using supported metallocene catalysts in a gas-phase reactor, with specific properties including density, melt index, melt index ratio, ESCR, and secant modulus, which allows for improved process flexibility and product specifications across wide density and melt flow ranges.

Environmental Impact of 2-Methylpentane Use

The use of 2-methylpentane in polymer processing has significant environmental implications that warrant careful consideration. As a volatile organic compound (VOC), 2-methylpentane can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. This poses potential risks to both human health and ecosystems, particularly in urban areas where industrial activities are concentrated.

The production and disposal of 2-methylpentane also raise environmental concerns. Its synthesis typically involves petroleum-based processes, which contribute to carbon emissions and resource depletion. Improper handling or disposal of 2-methylpentane can lead to soil and water contamination, potentially affecting local flora and fauna.

However, the use of 2-methylpentane in polymer melt processing may offer some environmental benefits. By modulating polymer melt characteristics, it can potentially improve processing efficiency, reducing energy consumption and waste generation in manufacturing processes. This could lead to a lower overall environmental footprint for polymer production.

The persistence of 2-methylpentane in the environment is relatively low due to its high volatility. It tends to evaporate quickly and does not bioaccumulate in organisms. Nevertheless, its short-term effects on air quality and potential for groundwater contamination remain significant concerns.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of VOCs like 2-methylpentane. Many countries have implemented strict emission controls and handling guidelines for such substances in industrial settings. Compliance with these regulations often necessitates investment in emission control technologies and improved waste management practices.

As the polymer industry continues to evolve, there is a growing emphasis on developing more environmentally friendly alternatives to traditional solvents and processing aids. This includes research into bio-based solvents and green chemistry approaches that could potentially replace or reduce the use of 2-methylpentane in polymer processing.

The lifecycle assessment of products involving 2-methylpentane is crucial for understanding its full environmental impact. This includes considering not only the direct emissions during use but also the upstream and downstream effects associated with its production, transportation, and eventual disposal or recycling of polymer products containing residual amounts of the compound.

The production and disposal of 2-methylpentane also raise environmental concerns. Its synthesis typically involves petroleum-based processes, which contribute to carbon emissions and resource depletion. Improper handling or disposal of 2-methylpentane can lead to soil and water contamination, potentially affecting local flora and fauna.

However, the use of 2-methylpentane in polymer melt processing may offer some environmental benefits. By modulating polymer melt characteristics, it can potentially improve processing efficiency, reducing energy consumption and waste generation in manufacturing processes. This could lead to a lower overall environmental footprint for polymer production.

The persistence of 2-methylpentane in the environment is relatively low due to its high volatility. It tends to evaporate quickly and does not bioaccumulate in organisms. Nevertheless, its short-term effects on air quality and potential for groundwater contamination remain significant concerns.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of VOCs like 2-methylpentane. Many countries have implemented strict emission controls and handling guidelines for such substances in industrial settings. Compliance with these regulations often necessitates investment in emission control technologies and improved waste management practices.

As the polymer industry continues to evolve, there is a growing emphasis on developing more environmentally friendly alternatives to traditional solvents and processing aids. This includes research into bio-based solvents and green chemistry approaches that could potentially replace or reduce the use of 2-methylpentane in polymer processing.

The lifecycle assessment of products involving 2-methylpentane is crucial for understanding its full environmental impact. This includes considering not only the direct emissions during use but also the upstream and downstream effects associated with its production, transportation, and eventual disposal or recycling of polymer products containing residual amounts of the compound.

Regulatory Framework for Polymer Additives

The regulatory framework for polymer additives plays a crucial role in ensuring the safety and quality of polymer products, including those modified with 2-methylpentane. In the context of polymer melt characteristics, regulatory bodies have established guidelines and standards to govern the use of additives and their impact on material properties.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of polymer additive regulation. Under REACH, manufacturers and importers must register substances used in polymer production, including additives like 2-methylpentane, and provide detailed information on their properties and potential risks. This ensures that the effects of such additives on polymer melt characteristics are thoroughly assessed and documented.

In the United States, the Food and Drug Administration (FDA) regulates polymer additives used in food contact materials. The FDA's Code of Federal Regulations Title 21 outlines specific requirements for additives that may affect polymer melt characteristics, ensuring that they do not compromise the safety or integrity of food packaging materials.

The International Organization for Standardization (ISO) has developed several standards relevant to polymer additives and their effects on melt characteristics. ISO 1133, for instance, provides standardized methods for determining the melt mass-flow rate and melt volume-flow rate of thermoplastics, which are critical parameters influenced by additives like 2-methylpentane.

Environmental regulations also impact the use of polymer additives. The EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, indirectly affecting the choice of additives that can be used to modulate polymer melt characteristics in these applications.

Industry-specific regulations further shape the landscape for polymer additives. In the automotive sector, for example, the Global Automotive Declarable Substance List (GADSL) provides guidelines on substances that must be declared when used in automotive parts, including polymer components whose melt characteristics may be influenced by additives.

Compliance with these regulatory frameworks often requires extensive testing and documentation. Manufacturers must demonstrate that additives like 2-methylpentane, when used to modulate polymer melt characteristics, do not introduce unacceptable risks to human health or the environment. This typically involves toxicological studies, environmental impact assessments, and detailed analysis of the additive's behavior in the polymer matrix.

As the understanding of polymer-additive interactions evolves, regulatory frameworks continue to adapt. Emerging concerns, such as the potential for additives to migrate from polymers or their long-term environmental impacts, are driving ongoing revisions to existing regulations and the development of new standards. This dynamic regulatory landscape necessitates continuous monitoring and compliance efforts from polymer manufacturers and additive suppliers.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of polymer additive regulation. Under REACH, manufacturers and importers must register substances used in polymer production, including additives like 2-methylpentane, and provide detailed information on their properties and potential risks. This ensures that the effects of such additives on polymer melt characteristics are thoroughly assessed and documented.

In the United States, the Food and Drug Administration (FDA) regulates polymer additives used in food contact materials. The FDA's Code of Federal Regulations Title 21 outlines specific requirements for additives that may affect polymer melt characteristics, ensuring that they do not compromise the safety or integrity of food packaging materials.

The International Organization for Standardization (ISO) has developed several standards relevant to polymer additives and their effects on melt characteristics. ISO 1133, for instance, provides standardized methods for determining the melt mass-flow rate and melt volume-flow rate of thermoplastics, which are critical parameters influenced by additives like 2-methylpentane.

Environmental regulations also impact the use of polymer additives. The EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, indirectly affecting the choice of additives that can be used to modulate polymer melt characteristics in these applications.

Industry-specific regulations further shape the landscape for polymer additives. In the automotive sector, for example, the Global Automotive Declarable Substance List (GADSL) provides guidelines on substances that must be declared when used in automotive parts, including polymer components whose melt characteristics may be influenced by additives.

Compliance with these regulatory frameworks often requires extensive testing and documentation. Manufacturers must demonstrate that additives like 2-methylpentane, when used to modulate polymer melt characteristics, do not introduce unacceptable risks to human health or the environment. This typically involves toxicological studies, environmental impact assessments, and detailed analysis of the additive's behavior in the polymer matrix.

As the understanding of polymer-additive interactions evolves, regulatory frameworks continue to adapt. Emerging concerns, such as the potential for additives to migrate from polymers or their long-term environmental impacts, are driving ongoing revisions to existing regulations and the development of new standards. This dynamic regulatory landscape necessitates continuous monitoring and compliance efforts from polymer manufacturers and additive suppliers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!