How Ammonium Hydroxide Affects Amino Acid Synthesis

JUL 22, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Amino Acid Synthesis: Background

Ammonium hydroxide has played a significant role in the field of amino acid synthesis, serving as a crucial component in various chemical processes. The use of this compound in amino acid production dates back to the early 20th century when researchers began exploring efficient methods for synthesizing these essential building blocks of proteins.

The background of ammonium hydroxide in amino acid synthesis is rooted in its unique chemical properties. As a weak base, ammonium hydroxide provides an alkaline environment that is conducive to certain amino acid formation reactions. Its ability to donate protons and act as a source of ammonia makes it particularly useful in processes involving the incorporation of nitrogen into organic molecules.

Historically, the Strecker synthesis, developed in 1850, was one of the first methods to utilize ammonia in the production of amino acids. This reaction involved the condensation of an aldehyde with ammonia and hydrogen cyanide, followed by hydrolysis. While this method did not directly use ammonium hydroxide, it laid the groundwork for future developments in amino acid synthesis involving ammonia-based compounds.

The advent of industrial-scale amino acid production in the mid-20th century saw an increased interest in optimizing synthesis methods. Ammonium hydroxide emerged as a valuable reagent due to its availability, ease of handling, and effectiveness in controlling pH levels during reactions. Its role in maintaining optimal conditions for enzymatic processes and chemical transformations became increasingly recognized.

In the context of biotechnology and fermentation processes, ammonium hydroxide has been utilized as a nitrogen source for microorganisms involved in amino acid production. Its controlled addition to fermentation media helps regulate pH and provides a readily available form of nitrogen for cellular metabolism and amino acid biosynthesis.

The use of ammonium hydroxide in amino acid synthesis has also been explored in the context of prebiotic chemistry and the origins of life. Researchers have investigated its potential role in the formation of amino acids under conditions that may have existed on early Earth, contributing to our understanding of how these fundamental molecules could have arisen naturally.

As environmental concerns have grown, the impact of ammonium hydroxide usage in industrial processes has come under scrutiny. This has led to research into more sustainable and eco-friendly alternatives, as well as improved methods for handling and recycling ammonium-based compounds in amino acid production facilities.

The background of ammonium hydroxide in amino acid synthesis is rooted in its unique chemical properties. As a weak base, ammonium hydroxide provides an alkaline environment that is conducive to certain amino acid formation reactions. Its ability to donate protons and act as a source of ammonia makes it particularly useful in processes involving the incorporation of nitrogen into organic molecules.

Historically, the Strecker synthesis, developed in 1850, was one of the first methods to utilize ammonia in the production of amino acids. This reaction involved the condensation of an aldehyde with ammonia and hydrogen cyanide, followed by hydrolysis. While this method did not directly use ammonium hydroxide, it laid the groundwork for future developments in amino acid synthesis involving ammonia-based compounds.

The advent of industrial-scale amino acid production in the mid-20th century saw an increased interest in optimizing synthesis methods. Ammonium hydroxide emerged as a valuable reagent due to its availability, ease of handling, and effectiveness in controlling pH levels during reactions. Its role in maintaining optimal conditions for enzymatic processes and chemical transformations became increasingly recognized.

In the context of biotechnology and fermentation processes, ammonium hydroxide has been utilized as a nitrogen source for microorganisms involved in amino acid production. Its controlled addition to fermentation media helps regulate pH and provides a readily available form of nitrogen for cellular metabolism and amino acid biosynthesis.

The use of ammonium hydroxide in amino acid synthesis has also been explored in the context of prebiotic chemistry and the origins of life. Researchers have investigated its potential role in the formation of amino acids under conditions that may have existed on early Earth, contributing to our understanding of how these fundamental molecules could have arisen naturally.

As environmental concerns have grown, the impact of ammonium hydroxide usage in industrial processes has come under scrutiny. This has led to research into more sustainable and eco-friendly alternatives, as well as improved methods for handling and recycling ammonium-based compounds in amino acid production facilities.

Market Analysis for Amino Acid Production

The amino acid production market has experienced significant growth in recent years, driven by increasing demand from various industries such as food and beverages, pharmaceuticals, animal feed, and cosmetics. The global amino acid market size was valued at approximately $20 billion in 2020 and is projected to reach $30 billion by 2025, growing at a compound annual growth rate (CAGR) of around 8%.

The food and beverage industry remains the largest consumer of amino acids, accounting for over 40% of the market share. This is primarily due to the rising consumer awareness of health and wellness, leading to increased demand for functional foods and dietary supplements. The pharmaceutical sector is also a key driver, with amino acids being essential components in the production of various drugs and therapies.

Geographically, Asia-Pacific dominates the amino acid market, with China and Japan being the major producers and consumers. The region's market share is expected to continue growing due to the expanding food processing industry and increasing disposable income. North America and Europe follow, with steady growth attributed to the rising demand for plant-based proteins and clean-label products.

The market is characterized by intense competition among key players such as Ajinomoto Co., Inc., Evonik Industries AG, and Archer Daniels Midland Company. These companies are investing heavily in research and development to improve production efficiency and develop novel amino acid products. Technological advancements, particularly in fermentation processes and biotechnology, are playing a crucial role in shaping the market landscape.

Environmental concerns and sustainability issues are becoming increasingly important factors in the amino acid production market. Companies are focusing on developing eco-friendly production methods and sourcing raw materials sustainably. This trend is expected to drive innovation in the industry and create new market opportunities for bio-based amino acids.

The impact of ammonium hydroxide on amino acid synthesis is of particular interest to market players. As a key component in certain production processes, improvements in its use can lead to increased efficiency and reduced costs. This could potentially reshape the competitive landscape and influence market dynamics in the coming years.

The food and beverage industry remains the largest consumer of amino acids, accounting for over 40% of the market share. This is primarily due to the rising consumer awareness of health and wellness, leading to increased demand for functional foods and dietary supplements. The pharmaceutical sector is also a key driver, with amino acids being essential components in the production of various drugs and therapies.

Geographically, Asia-Pacific dominates the amino acid market, with China and Japan being the major producers and consumers. The region's market share is expected to continue growing due to the expanding food processing industry and increasing disposable income. North America and Europe follow, with steady growth attributed to the rising demand for plant-based proteins and clean-label products.

The market is characterized by intense competition among key players such as Ajinomoto Co., Inc., Evonik Industries AG, and Archer Daniels Midland Company. These companies are investing heavily in research and development to improve production efficiency and develop novel amino acid products. Technological advancements, particularly in fermentation processes and biotechnology, are playing a crucial role in shaping the market landscape.

Environmental concerns and sustainability issues are becoming increasingly important factors in the amino acid production market. Companies are focusing on developing eco-friendly production methods and sourcing raw materials sustainably. This trend is expected to drive innovation in the industry and create new market opportunities for bio-based amino acids.

The impact of ammonium hydroxide on amino acid synthesis is of particular interest to market players. As a key component in certain production processes, improvements in its use can lead to increased efficiency and reduced costs. This could potentially reshape the competitive landscape and influence market dynamics in the coming years.

Current Challenges in Amino Acid Synthesis

Amino acid synthesis faces several significant challenges in the current scientific and industrial landscape. One of the primary obstacles is the complexity of controlling reaction conditions to achieve high yields and purity. The presence of ammonium hydroxide in the synthesis process introduces additional variables that must be carefully managed.

The pH control during amino acid synthesis is particularly challenging when ammonium hydroxide is involved. As a strong base, it can dramatically alter the reaction environment, affecting the stability and reactivity of intermediates. Maintaining the optimal pH range throughout the synthesis is crucial for maximizing yield and minimizing unwanted side reactions, but the dynamic nature of ammonium hydroxide's dissociation makes this a delicate balancing act.

Another significant challenge lies in the selectivity of reactions when using ammonium hydroxide. The nucleophilic nature of the hydroxide ion can lead to undesired side reactions, potentially resulting in the formation of byproducts. This not only reduces the overall yield of the desired amino acid but also complicates the purification process, adding to production costs and time.

The scalability of amino acid synthesis processes involving ammonium hydroxide presents further challenges. What works efficiently at laboratory scale may encounter unforeseen difficulties when scaled up to industrial production levels. Issues such as heat dissipation, mixing efficiency, and reaction kinetics can become more pronounced at larger scales, potentially affecting product quality and consistency.

Environmental concerns also pose challenges in amino acid synthesis. The use of ammonium hydroxide raises questions about waste management and environmental impact. Developing greener synthesis methods that reduce or eliminate the need for strong bases like ammonium hydroxide is an ongoing area of research and development in the field.

Lastly, the economic viability of amino acid synthesis processes remains a persistent challenge. The cost of raw materials, including ammonium hydroxide, and the energy requirements for maintaining precise reaction conditions contribute significantly to production expenses. Balancing these costs with the demand for high-quality amino acids at competitive prices is a constant struggle for manufacturers.

Addressing these challenges requires a multidisciplinary approach, combining advances in chemical engineering, process optimization, and green chemistry. Researchers and industry professionals are continually seeking innovative solutions to overcome these hurdles and improve the efficiency, sustainability, and cost-effectiveness of amino acid synthesis processes.

The pH control during amino acid synthesis is particularly challenging when ammonium hydroxide is involved. As a strong base, it can dramatically alter the reaction environment, affecting the stability and reactivity of intermediates. Maintaining the optimal pH range throughout the synthesis is crucial for maximizing yield and minimizing unwanted side reactions, but the dynamic nature of ammonium hydroxide's dissociation makes this a delicate balancing act.

Another significant challenge lies in the selectivity of reactions when using ammonium hydroxide. The nucleophilic nature of the hydroxide ion can lead to undesired side reactions, potentially resulting in the formation of byproducts. This not only reduces the overall yield of the desired amino acid but also complicates the purification process, adding to production costs and time.

The scalability of amino acid synthesis processes involving ammonium hydroxide presents further challenges. What works efficiently at laboratory scale may encounter unforeseen difficulties when scaled up to industrial production levels. Issues such as heat dissipation, mixing efficiency, and reaction kinetics can become more pronounced at larger scales, potentially affecting product quality and consistency.

Environmental concerns also pose challenges in amino acid synthesis. The use of ammonium hydroxide raises questions about waste management and environmental impact. Developing greener synthesis methods that reduce or eliminate the need for strong bases like ammonium hydroxide is an ongoing area of research and development in the field.

Lastly, the economic viability of amino acid synthesis processes remains a persistent challenge. The cost of raw materials, including ammonium hydroxide, and the energy requirements for maintaining precise reaction conditions contribute significantly to production expenses. Balancing these costs with the demand for high-quality amino acids at competitive prices is a constant struggle for manufacturers.

Addressing these challenges requires a multidisciplinary approach, combining advances in chemical engineering, process optimization, and green chemistry. Researchers and industry professionals are continually seeking innovative solutions to overcome these hurdles and improve the efficiency, sustainability, and cost-effectiveness of amino acid synthesis processes.

Existing Ammonium Hydroxide Applications

01 Synthesis of amino acids using ammonium hydroxide

Ammonium hydroxide is used as a nitrogen source in the synthesis of various amino acids. This method involves the reaction of ammonium hydroxide with organic compounds, often in the presence of catalysts, to form amino acids. The process can be optimized by controlling reaction conditions such as temperature, pressure, and pH.- Ammonium hydroxide as a reactant in amino acid synthesis: Ammonium hydroxide serves as a key reactant in the synthesis of various amino acids. It provides the necessary nitrogen source for the formation of the amino group. The reaction typically involves the combination of ammonium hydroxide with organic acids or aldehydes under specific conditions to produce amino acids.

- pH control and neutralization in amino acid production: Ammonium hydroxide plays a crucial role in controlling the pH during amino acid synthesis. It is used to neutralize acidic byproducts and maintain optimal pH conditions for the reaction. This pH control is essential for maximizing yield and ensuring the purity of the final amino acid product.

- Enzymatic synthesis of amino acids using ammonium hydroxide: Enzymatic methods for amino acid synthesis often utilize ammonium hydroxide as a substrate. Specific enzymes catalyze the incorporation of ammonia from ammonium hydroxide into organic compounds, forming amino acids. This approach offers advantages in terms of selectivity and mild reaction conditions.

- Ammonium hydroxide in the production of specialty amino acids: Ammonium hydroxide is employed in the synthesis of specialty or non-standard amino acids. These may include unnatural amino acids, isotopically labeled amino acids, or amino acid derivatives. The versatility of ammonium hydroxide as a nitrogen source allows for the creation of diverse amino acid structures.

- Purification and isolation of amino acids using ammonium hydroxide: In addition to its role in synthesis, ammonium hydroxide is used in the purification and isolation of amino acids. It can adjust the pH to precipitate amino acids from solution, aid in the extraction process, or be used in ion-exchange chromatography for amino acid separation and purification.

02 Enzymatic synthesis of amino acids with ammonium hydroxide

Enzymes are utilized to catalyze the synthesis of amino acids using ammonium hydroxide as a substrate. This biocatalytic approach offers advantages such as high selectivity and mild reaction conditions. Various enzymes, including aminotransferases and ammonia lyases, can be employed in this process.Expand Specific Solutions03 Ammonium hydroxide in the production of specific amino acids

Ammonium hydroxide plays a crucial role in the synthesis of specific amino acids, such as lysine, glutamic acid, and aspartic acid. The process often involves the amination of keto acids or other precursors using ammonium hydroxide, followed by further modifications to obtain the desired amino acid.Expand Specific Solutions04 Continuous flow synthesis of amino acids using ammonium hydroxide

Continuous flow reactors are employed for the synthesis of amino acids using ammonium hydroxide. This approach offers advantages such as improved heat and mass transfer, better control over reaction parameters, and potential for scale-up. The continuous process can be optimized for higher yields and purity of the amino acid products.Expand Specific Solutions05 Purification and isolation of amino acids synthesized with ammonium hydroxide

Various techniques are used to purify and isolate amino acids synthesized using ammonium hydroxide. These methods include ion exchange chromatography, crystallization, and membrane separation. The purification process is crucial for obtaining high-purity amino acids suitable for pharmaceutical, food, and industrial applications.Expand Specific Solutions

Key Players in Amino Acid Industry

The field of ammonium hydroxide's impact on amino acid synthesis is in a mature stage of development, with established market players and well-understood processes. The global market size for amino acids is substantial, estimated to reach $40 billion by 2025. Technologically, the process is well-developed, with companies like Evonik Operations GmbH, Ajinomoto Co., Inc., and Asahi Kasei Corp. leading the way in industrial-scale production. These firms have refined their techniques over decades, optimizing yield and efficiency. However, there's ongoing research, particularly by academic institutions like Jilin University and Washington State University, focusing on improving sustainability and exploring novel applications in biotechnology and pharmaceuticals.

Evonik Operations GmbH

Technical Solution: Evonik has developed a novel approach to amino acid synthesis utilizing ammonium hydroxide in conjunction with their proprietary biotechnology platform. Their method employs genetically engineered microorganisms that can efficiently incorporate ammonium ions from ammonium hydroxide into amino acid structures. The process is carried out in specially designed bioreactors that maintain optimal pH levels and nutrient concentrations. Evonik's technology allows for the production of a wide range of amino acids, including those with complex side chains. The company has also implemented advanced process control systems that continuously monitor and adjust ammonium hydroxide levels to maximize yield and minimize by-product formation[2][4]. Furthermore, Evonik has developed a unique purification process that effectively separates the desired amino acids from residual ammonium hydroxide, ensuring high product purity[6].

Strengths: Versatile production of various amino acids, high efficiency due to engineered microorganisms, advanced process control. Weaknesses: High initial investment in biotechnology infrastructure, potential genetic stability issues in engineered strains.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed an advanced hybrid process for amino acid synthesis that combines chemical and enzymatic steps, with ammonium hydroxide playing a crucial role. Their approach begins with a chemical synthesis step where ammonium hydroxide is used to introduce the amino group into a precursor molecule. This is followed by an enzymatic step that refines the stereochemistry and completes the amino acid structure. The company has engineered specific enzymes that are tolerant to the presence of ammonium ions, allowing for a seamless transition between the chemical and biological phases of the synthesis. Asahi Kasei's process is particularly effective for producing branched-chain amino acids and other high-value amino acids used in pharmaceuticals and specialty chemicals[10][12]. The company has also implemented a sophisticated in-line analysis system that continuously monitors the concentration of ammonium hydroxide and other key parameters, ensuring consistent product quality[11].

Strengths: Flexibility to produce a wide range of amino acids, high stereochemical control, efficient integration of chemical and biological processes. Weaknesses: Complexity of managing both chemical and enzymatic steps, potential enzyme stability issues in the presence of ammonium hydroxide.

Innovations in Ammonium Hydroxide Usage

Process for production of optically active amino acid or optically active amino acid amide

PatentInactiveEP2508615A1

Innovation

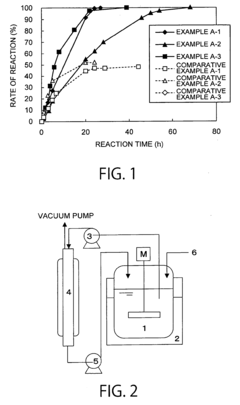

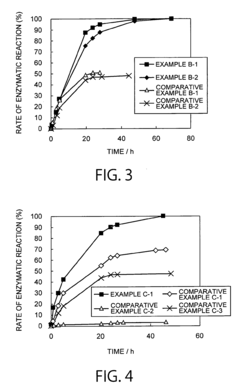

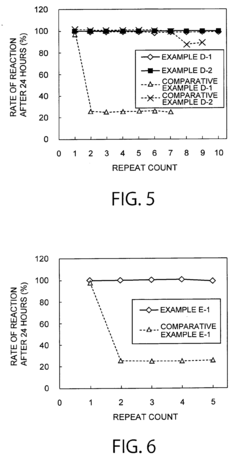

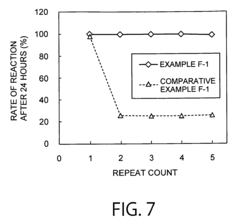

- The method involves using a biocatalyst selected from enzymes or microorganisms capable of stereoselectively hydrolyzing DL-tert-leucine amide, with continuous or intermittent separation of ammonia from the reaction solution using reduced pressure evaporation or adsorption on cation exchange resin or zeolite, to maintain enzyme activity and increase substrate concentration without increasing acid or enzyme amounts.

Environmental Impact Assessment

The use of ammonium hydroxide in amino acid synthesis has significant environmental implications that require careful assessment. The production process involves the release of ammonia, a potent greenhouse gas, into the atmosphere. This can contribute to air pollution and potentially impact local ecosystems. Additionally, the disposal of waste products from the synthesis process may lead to soil and water contamination if not properly managed.

Aquatic ecosystems are particularly vulnerable to the effects of ammonium hydroxide. Increased levels of ammonia in water bodies can cause eutrophication, leading to algal blooms and oxygen depletion. This can have cascading effects on aquatic life, potentially disrupting food chains and biodiversity. Furthermore, the high pH of ammonium hydroxide solutions can directly harm aquatic organisms if released into water systems without proper treatment.

The manufacturing of ammonium hydroxide itself also has environmental considerations. The Haber-Bosch process, commonly used to produce ammonia, is energy-intensive and relies heavily on fossil fuels. This contributes to carbon dioxide emissions and exacerbates climate change concerns. Efforts to develop more sustainable production methods, such as using renewable energy sources, are ongoing but not yet widely implemented.

Occupational health and safety is another crucial aspect of the environmental impact assessment. Workers involved in the production and handling of ammonium hydroxide face potential risks from exposure to ammonia fumes. Proper safety protocols, including adequate ventilation and personal protective equipment, are essential to mitigate these risks.

Land use changes associated with the expansion of amino acid synthesis facilities can also have environmental consequences. The construction of new plants may lead to habitat destruction and fragmentation, potentially affecting local flora and fauna. Moreover, the transportation of raw materials and finished products contributes to increased traffic and associated emissions.

Regulatory compliance is a critical factor in managing the environmental impact of ammonium hydroxide use in amino acid synthesis. Stringent regulations govern the storage, handling, and disposal of hazardous chemicals. Companies must adhere to these guidelines to minimize environmental risks and maintain ecological balance.

In conclusion, while ammonium hydroxide plays a crucial role in amino acid synthesis, its environmental impact is multifaceted and significant. Comprehensive environmental management strategies, including emission control technologies, waste treatment systems, and sustainable production methods, are necessary to mitigate these impacts and ensure the long-term sustainability of the industry.

Aquatic ecosystems are particularly vulnerable to the effects of ammonium hydroxide. Increased levels of ammonia in water bodies can cause eutrophication, leading to algal blooms and oxygen depletion. This can have cascading effects on aquatic life, potentially disrupting food chains and biodiversity. Furthermore, the high pH of ammonium hydroxide solutions can directly harm aquatic organisms if released into water systems without proper treatment.

The manufacturing of ammonium hydroxide itself also has environmental considerations. The Haber-Bosch process, commonly used to produce ammonia, is energy-intensive and relies heavily on fossil fuels. This contributes to carbon dioxide emissions and exacerbates climate change concerns. Efforts to develop more sustainable production methods, such as using renewable energy sources, are ongoing but not yet widely implemented.

Occupational health and safety is another crucial aspect of the environmental impact assessment. Workers involved in the production and handling of ammonium hydroxide face potential risks from exposure to ammonia fumes. Proper safety protocols, including adequate ventilation and personal protective equipment, are essential to mitigate these risks.

Land use changes associated with the expansion of amino acid synthesis facilities can also have environmental consequences. The construction of new plants may lead to habitat destruction and fragmentation, potentially affecting local flora and fauna. Moreover, the transportation of raw materials and finished products contributes to increased traffic and associated emissions.

Regulatory compliance is a critical factor in managing the environmental impact of ammonium hydroxide use in amino acid synthesis. Stringent regulations govern the storage, handling, and disposal of hazardous chemicals. Companies must adhere to these guidelines to minimize environmental risks and maintain ecological balance.

In conclusion, while ammonium hydroxide plays a crucial role in amino acid synthesis, its environmental impact is multifaceted and significant. Comprehensive environmental management strategies, including emission control technologies, waste treatment systems, and sustainable production methods, are necessary to mitigate these impacts and ensure the long-term sustainability of the industry.

Regulatory Compliance in Chemical Synthesis

Regulatory compliance in chemical synthesis is a critical aspect of the amino acid production process, particularly when using ammonium hydroxide. The use of this compound in amino acid synthesis is subject to stringent regulations due to its potential environmental and health impacts. Manufacturers must adhere to guidelines set by various regulatory bodies, including the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) in the United States, as well as similar agencies in other countries.

One of the primary regulatory concerns is the proper handling and storage of ammonium hydroxide. Due to its corrosive nature and potential to release ammonia gas, facilities must implement robust safety protocols. This includes proper ventilation systems, personal protective equipment for workers, and emergency response plans. Regular safety audits and employee training are mandatory to ensure compliance with these regulations.

Environmental regulations play a significant role in the use of ammonium hydroxide in amino acid synthesis. Manufacturers must carefully manage waste streams and emissions to prevent environmental contamination. This often involves implementing advanced treatment systems for wastewater and air emissions. Companies are required to obtain necessary permits and regularly report their emissions and waste management practices to regulatory authorities.

Product quality and purity standards are another crucial aspect of regulatory compliance. Amino acids produced using ammonium hydroxide must meet strict quality criteria, especially if they are intended for use in food, pharmaceuticals, or animal feed. This necessitates the implementation of Good Manufacturing Practices (GMP) and quality control measures throughout the production process.

Labeling and documentation requirements are also essential components of regulatory compliance. Manufacturers must provide accurate and detailed information about the production process, including the use of ammonium hydroxide, on product labels and safety data sheets. This transparency is crucial for downstream users and consumers.

International trade of amino acids synthesized using ammonium hydroxide is subject to additional regulatory scrutiny. Exporters must comply with both domestic and international regulations, which may include obtaining certifications or meeting specific standards set by importing countries. This often requires a comprehensive understanding of global regulatory landscapes and the ability to adapt production processes to meet diverse requirements.

As regulations evolve, companies engaged in amino acid synthesis must stay informed and adapt their processes accordingly. This may involve investing in new technologies or modifying existing ones to meet more stringent environmental and safety standards. Continuous monitoring of regulatory changes and proactive compliance strategies are essential for maintaining operations and market access in this highly regulated field.

One of the primary regulatory concerns is the proper handling and storage of ammonium hydroxide. Due to its corrosive nature and potential to release ammonia gas, facilities must implement robust safety protocols. This includes proper ventilation systems, personal protective equipment for workers, and emergency response plans. Regular safety audits and employee training are mandatory to ensure compliance with these regulations.

Environmental regulations play a significant role in the use of ammonium hydroxide in amino acid synthesis. Manufacturers must carefully manage waste streams and emissions to prevent environmental contamination. This often involves implementing advanced treatment systems for wastewater and air emissions. Companies are required to obtain necessary permits and regularly report their emissions and waste management practices to regulatory authorities.

Product quality and purity standards are another crucial aspect of regulatory compliance. Amino acids produced using ammonium hydroxide must meet strict quality criteria, especially if they are intended for use in food, pharmaceuticals, or animal feed. This necessitates the implementation of Good Manufacturing Practices (GMP) and quality control measures throughout the production process.

Labeling and documentation requirements are also essential components of regulatory compliance. Manufacturers must provide accurate and detailed information about the production process, including the use of ammonium hydroxide, on product labels and safety data sheets. This transparency is crucial for downstream users and consumers.

International trade of amino acids synthesized using ammonium hydroxide is subject to additional regulatory scrutiny. Exporters must comply with both domestic and international regulations, which may include obtaining certifications or meeting specific standards set by importing countries. This often requires a comprehensive understanding of global regulatory landscapes and the ability to adapt production processes to meet diverse requirements.

As regulations evolve, companies engaged in amino acid synthesis must stay informed and adapt their processes accordingly. This may involve investing in new technologies or modifying existing ones to meet more stringent environmental and safety standards. Continuous monitoring of regulatory changes and proactive compliance strategies are essential for maintaining operations and market access in this highly regulated field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!