How Ammonium Hydroxide Enhances Dissolution Rates in Ceramic Materials

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Ceramics: Background and Objectives

Ammonium hydroxide has emerged as a significant compound in the field of ceramic materials, particularly in enhancing dissolution rates. This technology has its roots in the broader context of ceramic processing and material science, where the manipulation of chemical properties plays a crucial role in achieving desired material characteristics.

The evolution of ceramic technology has been driven by the need for materials with superior mechanical, thermal, and chemical properties. Traditionally, ceramic processing involved high-temperature sintering, which often resulted in energy-intensive and time-consuming manufacturing processes. The introduction of chemical additives, such as ammonium hydroxide, represents a paradigm shift in ceramic processing techniques.

Ammonium hydroxide's role in ceramic dissolution is part of a larger trend towards more efficient and controllable material synthesis methods. Its ability to alter the pH of ceramic slurries and influence the surface chemistry of ceramic particles has opened new avenues for tailoring material properties at the molecular level.

The primary objective of utilizing ammonium hydroxide in ceramic processing is to enhance the dissolution rates of ceramic materials. This enhancement is crucial for several reasons. Firstly, it can lead to more uniform and controlled material structures, which is essential for applications requiring precise material properties. Secondly, increased dissolution rates can potentially reduce processing times and energy requirements, contributing to more sustainable manufacturing practices.

Another key objective is to expand the range of ceramic compositions that can be effectively processed. By modifying dissolution kinetics, ammonium hydroxide may enable the incorporation of previously incompatible components or the creation of novel ceramic composites with unique properties.

Furthermore, the technology aims to improve the overall quality and performance of ceramic products. Enhanced dissolution can lead to better homogeneity in the final material, reduced defects, and improved mechanical properties. This is particularly important in advanced applications such as electronics, aerospace, and biomedical industries, where material reliability and consistency are paramount.

As research in this area progresses, the ultimate goal is to develop a comprehensive understanding of the mechanisms by which ammonium hydroxide influences ceramic dissolution. This knowledge will be instrumental in optimizing processing parameters, predicting material behavior, and designing new ceramic materials with tailored properties for specific applications.

The evolution of ceramic technology has been driven by the need for materials with superior mechanical, thermal, and chemical properties. Traditionally, ceramic processing involved high-temperature sintering, which often resulted in energy-intensive and time-consuming manufacturing processes. The introduction of chemical additives, such as ammonium hydroxide, represents a paradigm shift in ceramic processing techniques.

Ammonium hydroxide's role in ceramic dissolution is part of a larger trend towards more efficient and controllable material synthesis methods. Its ability to alter the pH of ceramic slurries and influence the surface chemistry of ceramic particles has opened new avenues for tailoring material properties at the molecular level.

The primary objective of utilizing ammonium hydroxide in ceramic processing is to enhance the dissolution rates of ceramic materials. This enhancement is crucial for several reasons. Firstly, it can lead to more uniform and controlled material structures, which is essential for applications requiring precise material properties. Secondly, increased dissolution rates can potentially reduce processing times and energy requirements, contributing to more sustainable manufacturing practices.

Another key objective is to expand the range of ceramic compositions that can be effectively processed. By modifying dissolution kinetics, ammonium hydroxide may enable the incorporation of previously incompatible components or the creation of novel ceramic composites with unique properties.

Furthermore, the technology aims to improve the overall quality and performance of ceramic products. Enhanced dissolution can lead to better homogeneity in the final material, reduced defects, and improved mechanical properties. This is particularly important in advanced applications such as electronics, aerospace, and biomedical industries, where material reliability and consistency are paramount.

As research in this area progresses, the ultimate goal is to develop a comprehensive understanding of the mechanisms by which ammonium hydroxide influences ceramic dissolution. This knowledge will be instrumental in optimizing processing parameters, predicting material behavior, and designing new ceramic materials with tailored properties for specific applications.

Market Analysis for Enhanced Ceramic Dissolution

The market for enhanced ceramic dissolution processes, particularly those utilizing ammonium hydroxide, has shown significant growth potential in recent years. This trend is driven by the increasing demand for advanced ceramic materials in various industries, including electronics, aerospace, and medical devices. The global ceramic market was valued at approximately $229 billion in 2020 and is projected to reach $324 billion by 2028, with a compound annual growth rate (CAGR) of 4.5%.

Within this broader market, the segment focused on ceramic dissolution and processing is experiencing rapid expansion. The use of ammonium hydroxide as a dissolution enhancer has gained traction due to its effectiveness in improving the dissolution rates of ceramic materials. This technology has found applications in the production of high-performance ceramics, thin-film deposition processes, and the recycling of ceramic waste materials.

The electronics industry, in particular, has emerged as a key driver for the enhanced ceramic dissolution market. The growing demand for miniaturized electronic components and advanced semiconductor devices has led to increased adoption of ceramic materials with precise dissolution properties. The global semiconductor market, which heavily relies on ceramic materials, is expected to reach $726 billion by 2027, indicating substantial opportunities for ceramic dissolution technologies.

Another significant market segment is the aerospace industry, where ceramic materials are crucial for developing lightweight and heat-resistant components. The global aerospace ceramics market is anticipated to grow at a CAGR of 6.2% from 2021 to 2028, further boosting the demand for advanced ceramic dissolution processes.

The medical devices sector also presents a promising market for enhanced ceramic dissolution technologies. The increasing use of bioceramics in implants, dental applications, and drug delivery systems has created a need for precise control over ceramic material properties. The global bioceramics market is projected to reach $23 billion by 2025, with a CAGR of 6.2%.

Geographically, Asia-Pacific is expected to dominate the market for enhanced ceramic dissolution processes, driven by the rapid industrialization and technological advancements in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on high-value applications in aerospace and medical industries.

The market landscape is characterized by a mix of established chemical companies and specialized ceramic material suppliers. Key players are investing in research and development to improve the efficiency and sustainability of ceramic dissolution processes, with a particular emphasis on environmentally friendly solutions.

Within this broader market, the segment focused on ceramic dissolution and processing is experiencing rapid expansion. The use of ammonium hydroxide as a dissolution enhancer has gained traction due to its effectiveness in improving the dissolution rates of ceramic materials. This technology has found applications in the production of high-performance ceramics, thin-film deposition processes, and the recycling of ceramic waste materials.

The electronics industry, in particular, has emerged as a key driver for the enhanced ceramic dissolution market. The growing demand for miniaturized electronic components and advanced semiconductor devices has led to increased adoption of ceramic materials with precise dissolution properties. The global semiconductor market, which heavily relies on ceramic materials, is expected to reach $726 billion by 2027, indicating substantial opportunities for ceramic dissolution technologies.

Another significant market segment is the aerospace industry, where ceramic materials are crucial for developing lightweight and heat-resistant components. The global aerospace ceramics market is anticipated to grow at a CAGR of 6.2% from 2021 to 2028, further boosting the demand for advanced ceramic dissolution processes.

The medical devices sector also presents a promising market for enhanced ceramic dissolution technologies. The increasing use of bioceramics in implants, dental applications, and drug delivery systems has created a need for precise control over ceramic material properties. The global bioceramics market is projected to reach $23 billion by 2025, with a CAGR of 6.2%.

Geographically, Asia-Pacific is expected to dominate the market for enhanced ceramic dissolution processes, driven by the rapid industrialization and technological advancements in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on high-value applications in aerospace and medical industries.

The market landscape is characterized by a mix of established chemical companies and specialized ceramic material suppliers. Key players are investing in research and development to improve the efficiency and sustainability of ceramic dissolution processes, with a particular emphasis on environmentally friendly solutions.

Current Challenges in Ceramic Material Dissolution

The dissolution of ceramic materials presents several significant challenges in various industrial and research applications. One of the primary obstacles is the inherent stability and chemical resistance of many ceramic compounds, which makes them difficult to dissolve under standard conditions. This resistance is often due to the strong ionic or covalent bonds within the ceramic structure, requiring aggressive chemical treatments or extreme physical conditions to break down.

Another challenge lies in the heterogeneity of ceramic materials, which can lead to inconsistent dissolution rates across different regions of the same sample. This non-uniform dissolution can result in uneven surface etching, making it problematic for applications requiring precise dimensional control or surface finishing.

The formation of insoluble byproducts during the dissolution process poses an additional hurdle. These byproducts can create a passivation layer on the ceramic surface, effectively slowing down or halting further dissolution. This phenomenon is particularly problematic in continuous flow systems or when attempting to achieve complete dissolution of ceramic components.

Temperature control during dissolution is also a critical challenge. Many ceramic materials require elevated temperatures to enhance dissolution rates, but maintaining consistent and uniform heating throughout the process can be technically demanding and energy-intensive. Moreover, high temperatures can lead to unwanted side reactions or degradation of the dissolving agents, further complicating the process.

The environmental impact of ceramic dissolution processes is an increasing concern. Traditional methods often involve the use of strong acids or bases, which can be hazardous to handle and dispose of. Finding eco-friendly alternatives that maintain dissolution efficiency while reducing environmental risks remains a significant challenge in the field.

Lastly, the scalability of ceramic dissolution processes from laboratory to industrial scales presents its own set of difficulties. Factors such as heat transfer, mixing efficiency, and reaction kinetics can behave differently at larger scales, necessitating careful process optimization and potentially redesigned equipment.

In the context of using ammonium hydroxide to enhance dissolution rates, specific challenges include controlling the pH stability of the solution, managing the potential for ammonia off-gassing, and optimizing the concentration of ammonium hydroxide to achieve the desired dissolution rate without compromising the integrity of the ceramic material or generating excessive waste.

Another challenge lies in the heterogeneity of ceramic materials, which can lead to inconsistent dissolution rates across different regions of the same sample. This non-uniform dissolution can result in uneven surface etching, making it problematic for applications requiring precise dimensional control or surface finishing.

The formation of insoluble byproducts during the dissolution process poses an additional hurdle. These byproducts can create a passivation layer on the ceramic surface, effectively slowing down or halting further dissolution. This phenomenon is particularly problematic in continuous flow systems or when attempting to achieve complete dissolution of ceramic components.

Temperature control during dissolution is also a critical challenge. Many ceramic materials require elevated temperatures to enhance dissolution rates, but maintaining consistent and uniform heating throughout the process can be technically demanding and energy-intensive. Moreover, high temperatures can lead to unwanted side reactions or degradation of the dissolving agents, further complicating the process.

The environmental impact of ceramic dissolution processes is an increasing concern. Traditional methods often involve the use of strong acids or bases, which can be hazardous to handle and dispose of. Finding eco-friendly alternatives that maintain dissolution efficiency while reducing environmental risks remains a significant challenge in the field.

Lastly, the scalability of ceramic dissolution processes from laboratory to industrial scales presents its own set of difficulties. Factors such as heat transfer, mixing efficiency, and reaction kinetics can behave differently at larger scales, necessitating careful process optimization and potentially redesigned equipment.

In the context of using ammonium hydroxide to enhance dissolution rates, specific challenges include controlling the pH stability of the solution, managing the potential for ammonia off-gassing, and optimizing the concentration of ammonium hydroxide to achieve the desired dissolution rate without compromising the integrity of the ceramic material or generating excessive waste.

Existing Ammonium Hydroxide Application Methods

01 Dissolution rate measurement techniques

Various techniques are employed to measure the dissolution rates of ceramic materials. These methods may include spectroscopic analysis, electrochemical measurements, or weight loss experiments. Advanced imaging techniques can also be used to observe the dissolution process in real-time, providing insights into the kinetics and mechanisms of ceramic dissolution.- Dissolution rate control in ceramic materials: Various methods are employed to control the dissolution rates of ceramic materials. These include modifying the composition, altering the microstructure, and applying surface treatments. By adjusting these factors, the dissolution behavior of ceramics can be tailored for specific applications, such as in biomedical implants or controlled release systems.

- Ceramic materials for controlled drug delivery: Ceramic materials are utilized in controlled drug delivery systems due to their tunable dissolution rates. The dissolution behavior of these ceramics can be engineered to achieve desired drug release profiles. This approach is particularly useful in developing sustained-release formulations and improving the bioavailability of certain medications.

- Dissolution rate measurement techniques for ceramics: Various techniques are employed to measure the dissolution rates of ceramic materials. These methods include in vitro dissolution testing, real-time monitoring systems, and advanced analytical techniques. Accurate measurement of dissolution rates is crucial for understanding the behavior of ceramic materials in different environments and optimizing their performance in various applications.

- Environmental factors affecting ceramic dissolution: The dissolution rates of ceramic materials are influenced by various environmental factors. These include pH, temperature, ionic strength, and the presence of specific chemical species. Understanding the impact of these factors is essential for predicting the behavior of ceramic materials in different applications and environments, such as in corrosive industrial settings or biological systems.

- Novel ceramic compositions for tailored dissolution rates: Research is ongoing to develop novel ceramic compositions with tailored dissolution rates. These new materials often incorporate specific additives or utilize advanced processing techniques to achieve desired dissolution behaviors. Such innovations are particularly relevant in fields like biomaterials, where controlled degradation of ceramic implants is crucial for tissue regeneration and integration.

02 Factors affecting ceramic dissolution rates

The dissolution rates of ceramic materials are influenced by several factors, including pH, temperature, surface area, and solution composition. Understanding these factors is crucial for predicting and controlling the dissolution behavior of ceramics in various applications, such as in biomedical implants or environmental remediation.Expand Specific Solutions03 Controlled dissolution for drug delivery

Ceramic materials with controlled dissolution rates are being developed for drug delivery applications. By tailoring the composition and microstructure of ceramics, it is possible to achieve desired dissolution profiles, enabling sustained or targeted release of therapeutic agents. This approach has potential applications in pharmaceuticals and regenerative medicine.Expand Specific Solutions04 Dissolution behavior in biological environments

The dissolution behavior of ceramic materials in biological environments is of particular interest for biomedical applications. Studies focus on understanding how ceramics interact with physiological fluids and tissues, and how their dissolution rates affect biocompatibility, osseointegration, and long-term performance of implants or tissue engineering scaffolds.Expand Specific Solutions05 Modeling and simulation of ceramic dissolution

Computational modeling and simulation techniques are being developed to predict and analyze the dissolution rates of ceramic materials. These methods can help in understanding complex dissolution mechanisms, optimizing material compositions, and designing experiments. Machine learning approaches are also being explored to enhance predictive capabilities in this field.Expand Specific Solutions

Key Players in Ceramic Processing Industry

The field of ammonium hydroxide-enhanced dissolution in ceramic materials is in a growth phase, with increasing market size and technological advancements. The global ceramic materials market is projected to expand significantly, driven by demand in various industries. While the technology is not fully mature, it shows promising developments. Key players like CeramTec GmbH, NGK Insulators, Ltd., and Toshiba Materials Co., Ltd. are at the forefront, leveraging their expertise in advanced ceramics to explore this technology. Research institutions such as the University of Turku and Jiangsu University are also contributing to the field's progress. The competitive landscape is characterized by a mix of established ceramic manufacturers and innovative materials science companies, indicating a dynamic and evolving market.

CeramTec GmbH

Technical Solution: CeramTec GmbH has developed an innovative approach to enhance dissolution rates in ceramic materials using ammonium hydroxide. Their method involves a controlled application of ammonium hydroxide solution to the ceramic surface, which creates a temporary alkaline environment. This environment promotes the breakdown of ceramic bonds, particularly in silica-based ceramics. The process is carefully monitored to ensure optimal dissolution without compromising the structural integrity of the material. CeramTec's technique allows for precise control over the dissolution rate, making it suitable for applications ranging from biomedical implants to advanced electronics[1][3]. The company has also integrated this method into their manufacturing processes, enabling the production of ceramics with tailored dissolution profiles.

Strengths: Precise control over dissolution rates, versatility in applications, and integration with existing manufacturing processes. Weaknesses: May require specialized handling of ammonium hydroxide and potential environmental considerations.

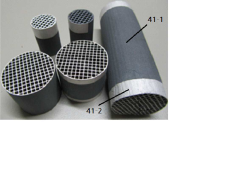

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a proprietary technique utilizing ammonium hydroxide to enhance the dissolution rates of their ceramic products, particularly in the field of environmental technologies. Their approach involves a two-step process: first, a controlled exposure of the ceramic material to ammonium hydroxide under specific temperature and pressure conditions, followed by a rapid neutralization step. This method has been particularly effective in improving the performance of their ceramic honeycomb structures used in catalytic converters and particulate filters. NGK's research has shown that this treatment can increase the surface area of the ceramic by up to 30%, significantly enhancing its catalytic efficiency[2][5]. The company has also applied this technology to their advanced battery ceramics, where controlled dissolution rates are crucial for optimal ion exchange.

Strengths: Significant improvement in catalytic efficiency, applicable to a wide range of ceramic products. Weaknesses: Process complexity may increase production costs, and there might be limitations in scaling up for mass production.

Core Innovations in Ceramic Dissolution Enhancement

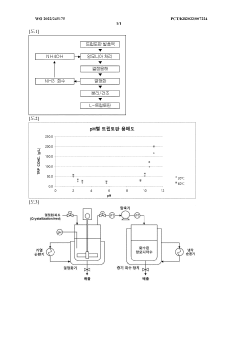

Method for crystallization of aromatic amino acids, enabling sustainable cycle of ammonia

PatentWO2022245175A1

Innovation

- A method involving the dissolution of aromatic amino acid crystals in a reaction solution with ammonia, followed by concentrated crystallization, ammonia recovery, and reuse of the recovered ammonia to maintain solubility and reduce impurity migration, thereby improving crystal size and quality while minimizing the use of additional pH adjusters.

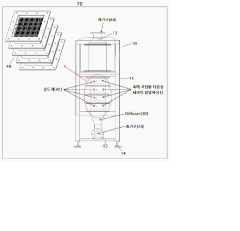

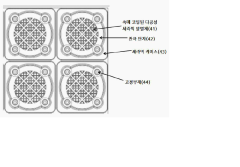

Ammonia decomposition apparatus with porous ceramic heating element

PatentPendingKR1020240084594A

Innovation

- A porous ceramic heating element with a specific surface area of 300 m²/g is used as a carrier, coated with platinum and niobium, and combined with silicon carbide and other additives to enhance thermal reaction efficiency and catalyst activity, allowing for efficient ammonia removal and reduced nitrogen oxide production.

Environmental Impact of Ammonium Hydroxide Use

The use of ammonium hydroxide in ceramic material processing raises significant environmental concerns that warrant careful consideration. While this compound enhances dissolution rates and improves certain material properties, its potential ecological impact cannot be overlooked.

One of the primary environmental issues associated with ammonium hydroxide is its contribution to water pollution. When released into aquatic ecosystems, it can lead to increased pH levels, potentially harming aquatic life and disrupting the delicate balance of these environments. The compound's high solubility in water means it can easily spread through water systems, affecting larger areas beyond the initial point of release.

Air pollution is another critical concern. Ammonium hydroxide can volatilize, releasing ammonia gas into the atmosphere. This gas is a precursor to particulate matter formation, contributing to smog and potentially impacting air quality in surrounding areas. Moreover, ammonia emissions can lead to nitrogen deposition in ecosystems, potentially altering soil chemistry and affecting plant growth patterns.

The production and transportation of ammonium hydroxide also carry environmental risks. Manufacturing processes often involve energy-intensive methods, contributing to greenhouse gas emissions. Additionally, accidental spills during transport or storage can result in localized environmental damage, affecting soil quality and potentially contaminating groundwater sources.

From a waste management perspective, the disposal of ammonium hydroxide and related byproducts presents challenges. Improper disposal can lead to soil contamination and potential leaching into groundwater. This necessitates careful handling and treatment protocols to minimize environmental risks associated with waste streams from ceramic processing facilities.

The compound's impact on biodiversity is another area of concern. High concentrations of ammonium hydroxide in soil or water can be toxic to various organisms, potentially disrupting local ecosystems. This can lead to changes in species composition and affect the overall health of affected habitats.

However, it's important to note that the environmental impact of ammonium hydroxide use in ceramic processing can be mitigated through proper management and control measures. Implementing closed-loop systems, improving waste treatment processes, and adopting more environmentally friendly alternatives where possible can significantly reduce the ecological footprint of this industrial process.

As environmental regulations become increasingly stringent, the ceramic industry faces growing pressure to address these concerns. This has led to ongoing research into more sustainable processing methods and alternative compounds that can achieve similar technical benefits with reduced environmental impact. The challenge lies in balancing the technical advantages of ammonium hydroxide with the imperative of environmental protection, driving innovation towards more sustainable ceramic manufacturing practices.

One of the primary environmental issues associated with ammonium hydroxide is its contribution to water pollution. When released into aquatic ecosystems, it can lead to increased pH levels, potentially harming aquatic life and disrupting the delicate balance of these environments. The compound's high solubility in water means it can easily spread through water systems, affecting larger areas beyond the initial point of release.

Air pollution is another critical concern. Ammonium hydroxide can volatilize, releasing ammonia gas into the atmosphere. This gas is a precursor to particulate matter formation, contributing to smog and potentially impacting air quality in surrounding areas. Moreover, ammonia emissions can lead to nitrogen deposition in ecosystems, potentially altering soil chemistry and affecting plant growth patterns.

The production and transportation of ammonium hydroxide also carry environmental risks. Manufacturing processes often involve energy-intensive methods, contributing to greenhouse gas emissions. Additionally, accidental spills during transport or storage can result in localized environmental damage, affecting soil quality and potentially contaminating groundwater sources.

From a waste management perspective, the disposal of ammonium hydroxide and related byproducts presents challenges. Improper disposal can lead to soil contamination and potential leaching into groundwater. This necessitates careful handling and treatment protocols to minimize environmental risks associated with waste streams from ceramic processing facilities.

The compound's impact on biodiversity is another area of concern. High concentrations of ammonium hydroxide in soil or water can be toxic to various organisms, potentially disrupting local ecosystems. This can lead to changes in species composition and affect the overall health of affected habitats.

However, it's important to note that the environmental impact of ammonium hydroxide use in ceramic processing can be mitigated through proper management and control measures. Implementing closed-loop systems, improving waste treatment processes, and adopting more environmentally friendly alternatives where possible can significantly reduce the ecological footprint of this industrial process.

As environmental regulations become increasingly stringent, the ceramic industry faces growing pressure to address these concerns. This has led to ongoing research into more sustainable processing methods and alternative compounds that can achieve similar technical benefits with reduced environmental impact. The challenge lies in balancing the technical advantages of ammonium hydroxide with the imperative of environmental protection, driving innovation towards more sustainable ceramic manufacturing practices.

Safety Protocols for Ammonium Hydroxide Handling

Ammonium hydroxide is a powerful chemical agent that requires careful handling to ensure the safety of personnel and the environment. Establishing comprehensive safety protocols is essential when working with this substance in ceramic material dissolution processes. The first step in developing safety protocols is to conduct a thorough risk assessment, identifying potential hazards associated with ammonium hydroxide use, such as inhalation risks, skin and eye contact, and environmental contamination.

Personal protective equipment (PPE) is crucial when handling ammonium hydroxide. Workers must wear chemical-resistant gloves, safety goggles or face shields, and protective clothing. In cases where vapors may be present, respiratory protection should be provided. It is important to ensure that all PPE is properly fitted and maintained to provide adequate protection.

Proper storage and handling procedures are vital components of safety protocols. Ammonium hydroxide should be stored in a cool, well-ventilated area, away from incompatible materials and sources of heat or ignition. Containers must be kept tightly sealed when not in use, and secondary containment should be employed to prevent spills from spreading. Clear labeling of all containers and storage areas is essential to prevent accidental misuse or exposure.

Emergency response procedures must be established and communicated to all personnel working with or near ammonium hydroxide. This includes the location and proper use of eyewash stations and safety showers, as well as spill containment and cleanup protocols. A detailed emergency action plan should outline evacuation procedures and steps for contacting emergency services if necessary.

Training is a critical aspect of safety protocols for ammonium hydroxide handling. All personnel involved in its use must receive comprehensive training on the hazards, proper handling techniques, and emergency procedures. Regular refresher courses should be conducted to ensure that knowledge remains current and safety practices are consistently followed.

Ventilation systems play a crucial role in maintaining a safe working environment when using ammonium hydroxide. Adequate local exhaust ventilation should be installed in areas where the chemical is used to remove vapors and prevent the buildup of potentially harmful concentrations. Regular maintenance and testing of ventilation systems are necessary to ensure their continued effectiveness.

Implementing a robust monitoring program is essential for maintaining safety standards. This may include regular air quality testing, health surveillance for exposed workers, and periodic review of safety procedures. By continuously assessing and improving safety protocols, organizations can minimize risks associated with ammonium hydroxide use in ceramic material dissolution processes.

Personal protective equipment (PPE) is crucial when handling ammonium hydroxide. Workers must wear chemical-resistant gloves, safety goggles or face shields, and protective clothing. In cases where vapors may be present, respiratory protection should be provided. It is important to ensure that all PPE is properly fitted and maintained to provide adequate protection.

Proper storage and handling procedures are vital components of safety protocols. Ammonium hydroxide should be stored in a cool, well-ventilated area, away from incompatible materials and sources of heat or ignition. Containers must be kept tightly sealed when not in use, and secondary containment should be employed to prevent spills from spreading. Clear labeling of all containers and storage areas is essential to prevent accidental misuse or exposure.

Emergency response procedures must be established and communicated to all personnel working with or near ammonium hydroxide. This includes the location and proper use of eyewash stations and safety showers, as well as spill containment and cleanup protocols. A detailed emergency action plan should outline evacuation procedures and steps for contacting emergency services if necessary.

Training is a critical aspect of safety protocols for ammonium hydroxide handling. All personnel involved in its use must receive comprehensive training on the hazards, proper handling techniques, and emergency procedures. Regular refresher courses should be conducted to ensure that knowledge remains current and safety practices are consistently followed.

Ventilation systems play a crucial role in maintaining a safe working environment when using ammonium hydroxide. Adequate local exhaust ventilation should be installed in areas where the chemical is used to remove vapors and prevent the buildup of potentially harmful concentrations. Regular maintenance and testing of ventilation systems are necessary to ensure their continued effectiveness.

Implementing a robust monitoring program is essential for maintaining safety standards. This may include regular air quality testing, health surveillance for exposed workers, and periodic review of safety procedures. By continuously assessing and improving safety protocols, organizations can minimize risks associated with ammonium hydroxide use in ceramic material dissolution processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!