How Ammonium Hydroxide Improves Surfactant-Based Oil Recovery

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide EOR Background

Enhanced Oil Recovery (EOR) techniques have been a crucial focus in the petroleum industry for decades, aiming to maximize oil production from existing reservoirs. Among these techniques, surfactant-based oil recovery has shown significant promise. However, the effectiveness of surfactants can be limited by various factors, including reservoir conditions and oil properties. In recent years, the addition of ammonium hydroxide to surfactant-based EOR processes has emerged as a potential game-changer in improving oil recovery rates.

Ammonium hydroxide, also known as aqueous ammonia, is a solution of ammonia in water. Its application in EOR stems from its unique chemical properties and interactions with both the reservoir rock and the oil-water interface. The use of ammonium hydroxide in conjunction with surfactants represents a synergistic approach to enhancing oil recovery, addressing some of the limitations faced by traditional surfactant flooding methods.

The concept of using ammonium hydroxide in EOR builds upon the established principles of alkaline flooding, which has been employed in the oil industry since the 1920s. Alkaline agents, such as sodium hydroxide or sodium carbonate, have been used to alter the wettability of reservoir rocks and reduce interfacial tension between oil and water. Ammonium hydroxide, however, offers several advantages over conventional alkaline agents, including its ability to penetrate deeper into the reservoir and its lower tendency to form scale or precipitates.

The integration of ammonium hydroxide into surfactant-based EOR processes is rooted in the understanding of complex fluid-fluid and fluid-rock interactions within the reservoir. Ammonium hydroxide acts as a pH modifier, creating an alkaline environment that can significantly enhance the performance of surfactants. This alkaline condition promotes the formation of in-situ surfactants through saponification of acidic components in crude oil, further reducing interfacial tension and improving oil mobilization.

Moreover, the presence of ammonium hydroxide can alter the electrical charges at the oil-water interface and on the rock surface, potentially leading to more favorable wettability conditions for oil recovery. This charge alteration can result in the release of oil droplets that were previously adhered to the rock surface, allowing for their easier mobilization and production.

The development of ammonium hydroxide as an EOR additive has been driven by the need for more efficient and cost-effective recovery methods, especially in mature fields where conventional techniques have reached their limits. As global energy demand continues to rise and easily accessible oil reserves become scarcer, the importance of advanced EOR techniques like ammonium hydroxide-enhanced surfactant flooding is likely to grow, prompting further research and field applications in this promising area of petroleum engineering.

Ammonium hydroxide, also known as aqueous ammonia, is a solution of ammonia in water. Its application in EOR stems from its unique chemical properties and interactions with both the reservoir rock and the oil-water interface. The use of ammonium hydroxide in conjunction with surfactants represents a synergistic approach to enhancing oil recovery, addressing some of the limitations faced by traditional surfactant flooding methods.

The concept of using ammonium hydroxide in EOR builds upon the established principles of alkaline flooding, which has been employed in the oil industry since the 1920s. Alkaline agents, such as sodium hydroxide or sodium carbonate, have been used to alter the wettability of reservoir rocks and reduce interfacial tension between oil and water. Ammonium hydroxide, however, offers several advantages over conventional alkaline agents, including its ability to penetrate deeper into the reservoir and its lower tendency to form scale or precipitates.

The integration of ammonium hydroxide into surfactant-based EOR processes is rooted in the understanding of complex fluid-fluid and fluid-rock interactions within the reservoir. Ammonium hydroxide acts as a pH modifier, creating an alkaline environment that can significantly enhance the performance of surfactants. This alkaline condition promotes the formation of in-situ surfactants through saponification of acidic components in crude oil, further reducing interfacial tension and improving oil mobilization.

Moreover, the presence of ammonium hydroxide can alter the electrical charges at the oil-water interface and on the rock surface, potentially leading to more favorable wettability conditions for oil recovery. This charge alteration can result in the release of oil droplets that were previously adhered to the rock surface, allowing for their easier mobilization and production.

The development of ammonium hydroxide as an EOR additive has been driven by the need for more efficient and cost-effective recovery methods, especially in mature fields where conventional techniques have reached their limits. As global energy demand continues to rise and easily accessible oil reserves become scarcer, the importance of advanced EOR techniques like ammonium hydroxide-enhanced surfactant flooding is likely to grow, prompting further research and field applications in this promising area of petroleum engineering.

Oil Recovery Market Analysis

The global oil recovery market has been experiencing significant growth, driven by increasing energy demands and the need to maximize production from existing oil fields. As conventional oil reserves become depleted, enhanced oil recovery (EOR) techniques, including surfactant-based methods, have gained prominence. The market for surfactant-based oil recovery is expected to expand substantially in the coming years, with a compound annual growth rate (CAGR) projected to be in the high single digits.

The demand for surfactant-based oil recovery is particularly strong in regions with mature oil fields, such as North America, the Middle East, and parts of Asia. These areas are seeking to extend the life of their existing reservoirs and improve recovery rates. The United States, in particular, has been a leader in adopting and advancing surfactant-based EOR technologies, driven by the shale oil boom and the need to optimize production from conventional fields.

Market trends indicate a growing interest in environmentally friendly and cost-effective surfactant formulations. This has led to increased research and development efforts focused on bio-based surfactants and optimized chemical blends that can improve oil recovery while minimizing environmental impact. The integration of ammonium hydroxide into surfactant-based recovery methods represents a promising development in this direction.

The competitive landscape of the oil recovery market is characterized by a mix of major oil and gas companies, oilfield service providers, and specialized chemical manufacturers. Key players are investing heavily in research and development to enhance their surfactant technologies and gain a competitive edge. Collaborations between oil companies and chemical suppliers are becoming more common, fostering innovation in surfactant-based recovery solutions.

Economic factors, such as oil prices and production costs, play a crucial role in the adoption of surfactant-based oil recovery techniques. When oil prices are high, there is greater incentive for companies to invest in advanced recovery methods. However, the volatility of oil prices in recent years has led to a focus on developing more cost-effective surfactant formulations that can remain economically viable even in lower price environments.

Regulatory frameworks and environmental policies are increasingly influencing the oil recovery market. Stricter environmental regulations are driving the development of more sustainable EOR methods, including improved surfactant-based techniques. This trend is expected to continue, potentially accelerating the adoption of innovative approaches like the use of ammonium hydroxide in surfactant formulations.

The demand for surfactant-based oil recovery is particularly strong in regions with mature oil fields, such as North America, the Middle East, and parts of Asia. These areas are seeking to extend the life of their existing reservoirs and improve recovery rates. The United States, in particular, has been a leader in adopting and advancing surfactant-based EOR technologies, driven by the shale oil boom and the need to optimize production from conventional fields.

Market trends indicate a growing interest in environmentally friendly and cost-effective surfactant formulations. This has led to increased research and development efforts focused on bio-based surfactants and optimized chemical blends that can improve oil recovery while minimizing environmental impact. The integration of ammonium hydroxide into surfactant-based recovery methods represents a promising development in this direction.

The competitive landscape of the oil recovery market is characterized by a mix of major oil and gas companies, oilfield service providers, and specialized chemical manufacturers. Key players are investing heavily in research and development to enhance their surfactant technologies and gain a competitive edge. Collaborations between oil companies and chemical suppliers are becoming more common, fostering innovation in surfactant-based recovery solutions.

Economic factors, such as oil prices and production costs, play a crucial role in the adoption of surfactant-based oil recovery techniques. When oil prices are high, there is greater incentive for companies to invest in advanced recovery methods. However, the volatility of oil prices in recent years has led to a focus on developing more cost-effective surfactant formulations that can remain economically viable even in lower price environments.

Regulatory frameworks and environmental policies are increasingly influencing the oil recovery market. Stricter environmental regulations are driving the development of more sustainable EOR methods, including improved surfactant-based techniques. This trend is expected to continue, potentially accelerating the adoption of innovative approaches like the use of ammonium hydroxide in surfactant formulations.

Current EOR Challenges

Enhanced Oil Recovery (EOR) techniques have become increasingly crucial in the oil and gas industry as conventional extraction methods reach their limits. However, current EOR methods face several significant challenges that hinder their widespread adoption and effectiveness.

One of the primary challenges is the high cost associated with implementing EOR technologies. Many EOR techniques require substantial capital investment in infrastructure, chemicals, and specialized equipment. This financial barrier often deters smaller operators from adopting these advanced recovery methods, limiting their application to larger, well-funded projects.

Another major hurdle is the environmental impact of certain EOR techniques. Chemical flooding methods, for instance, can introduce potentially harmful substances into reservoirs, raising concerns about groundwater contamination and long-term ecological effects. Balancing the need for increased oil recovery with environmental stewardship remains a significant challenge for the industry.

The complexity of reservoir characterization also poses a substantial obstacle. Each oil reservoir has unique geological properties, fluid characteristics, and production histories. Developing tailored EOR strategies that account for these variables requires extensive research, modeling, and testing, which can be time-consuming and resource-intensive.

Furthermore, the efficiency of EOR methods in different reservoir conditions varies widely. Techniques that work well in one field may prove ineffective in another due to differences in rock properties, oil viscosity, or reservoir pressure. This variability makes it difficult to standardize EOR approaches and necessitates continuous adaptation and optimization.

The technical limitations of current EOR technologies also present challenges. For example, polymer flooding can face issues with injectivity and polymer degradation at high temperatures, while thermal methods may be inefficient in thin or deep reservoirs. Overcoming these technical constraints requires ongoing research and development efforts.

Additionally, the industry faces challenges related to the scalability of EOR projects. Pilot tests that show promising results in small-scale applications may not always translate successfully to full-field implementation. Scaling up EOR operations often reveals unforeseen complications and requires significant adjustments to maintain effectiveness.

Lastly, the fluctuating oil prices and market uncertainties add another layer of complexity to EOR implementation. The economic viability of EOR projects is closely tied to oil prices, and sudden market downturns can render previously feasible projects uneconomical. This volatility makes long-term planning and investment in EOR technologies particularly challenging for oil companies.

One of the primary challenges is the high cost associated with implementing EOR technologies. Many EOR techniques require substantial capital investment in infrastructure, chemicals, and specialized equipment. This financial barrier often deters smaller operators from adopting these advanced recovery methods, limiting their application to larger, well-funded projects.

Another major hurdle is the environmental impact of certain EOR techniques. Chemical flooding methods, for instance, can introduce potentially harmful substances into reservoirs, raising concerns about groundwater contamination and long-term ecological effects. Balancing the need for increased oil recovery with environmental stewardship remains a significant challenge for the industry.

The complexity of reservoir characterization also poses a substantial obstacle. Each oil reservoir has unique geological properties, fluid characteristics, and production histories. Developing tailored EOR strategies that account for these variables requires extensive research, modeling, and testing, which can be time-consuming and resource-intensive.

Furthermore, the efficiency of EOR methods in different reservoir conditions varies widely. Techniques that work well in one field may prove ineffective in another due to differences in rock properties, oil viscosity, or reservoir pressure. This variability makes it difficult to standardize EOR approaches and necessitates continuous adaptation and optimization.

The technical limitations of current EOR technologies also present challenges. For example, polymer flooding can face issues with injectivity and polymer degradation at high temperatures, while thermal methods may be inefficient in thin or deep reservoirs. Overcoming these technical constraints requires ongoing research and development efforts.

Additionally, the industry faces challenges related to the scalability of EOR projects. Pilot tests that show promising results in small-scale applications may not always translate successfully to full-field implementation. Scaling up EOR operations often reveals unforeseen complications and requires significant adjustments to maintain effectiveness.

Lastly, the fluctuating oil prices and market uncertainties add another layer of complexity to EOR implementation. The economic viability of EOR projects is closely tied to oil prices, and sudden market downturns can render previously feasible projects uneconomical. This volatility makes long-term planning and investment in EOR technologies particularly challenging for oil companies.

Ammonium Hydroxide Solutions

01 Enhanced oil recovery using ammonium hydroxide

Ammonium hydroxide is used in enhanced oil recovery processes to improve the extraction of oil from reservoirs. It can be injected into the reservoir to alter the pH, reduce interfacial tension, and mobilize trapped oil. This method can increase oil recovery rates and efficiency in various types of oil fields.- Enhanced oil recovery using ammonium hydroxide: Ammonium hydroxide is used in enhanced oil recovery processes to improve the extraction of oil from reservoirs. It can alter the pH of the reservoir, reduce interfacial tension, and modify rock wettability, leading to increased oil recovery efficiency.

- Ammonium hydroxide in surfactant formulations: Ammonium hydroxide is incorporated into surfactant formulations for oil recovery. These formulations can include other components such as polymers or co-solvents to create effective microemulsions that mobilize trapped oil in reservoirs.

- Steam injection with ammonium hydroxide: The combination of steam injection and ammonium hydroxide is used to enhance heavy oil recovery. This method can reduce oil viscosity, improve sweep efficiency, and increase overall oil production from challenging reservoirs.

- Ammonium hydroxide for tar sand oil extraction: Ammonium hydroxide is utilized in processes specifically designed for extracting oil from tar sands. It can help separate bitumen from sand particles and improve the overall efficiency of tar sand oil recovery operations.

- Environmental considerations in ammonium hydroxide oil recovery: Research focuses on developing environmentally friendly methods for using ammonium hydroxide in oil recovery. This includes optimizing concentrations, minimizing waste, and exploring potential recycling or treatment of ammonium hydroxide after use in oil recovery processes.

02 Ammonium hydroxide in surfactant formulations

Ammonium hydroxide is incorporated into surfactant formulations for oil recovery applications. These formulations can include other components such as co-solvents, polymers, or additional surfactants. The combination enhances the effectiveness of the surfactant system in mobilizing and recovering oil from reservoirs.Expand Specific Solutions03 pH adjustment in oil recovery processes

Ammonium hydroxide is utilized for pH adjustment in various oil recovery processes. Controlling the pH of the injection fluid or reservoir can improve the performance of other chemicals used in the recovery process, such as polymers or surfactants. This pH adjustment can lead to better oil mobilization and increased recovery rates.Expand Specific Solutions04 Ammonium hydroxide in emulsion breaking

Ammonium hydroxide is employed in breaking oil-water emulsions during the oil recovery process. It can help separate oil from water more effectively, improving the quality of the recovered oil and reducing processing costs. This application is particularly useful in handling produced water and treating oil-water mixtures.Expand Specific Solutions05 Combination with other chemicals for synergistic effects

Ammonium hydroxide is combined with other chemicals to create synergistic effects in oil recovery. These combinations can include organic solvents, chelating agents, or specific ionic compounds. The resulting formulations can enhance oil mobilization, reduce formation damage, and improve overall recovery efficiency.Expand Specific Solutions

Key EOR Industry Players

The competitive landscape for ammonium hydroxide in surfactant-based oil recovery is evolving as the industry enters a growth phase. The market size is expanding due to increased demand for enhanced oil recovery techniques. Technological maturity varies among key players, with major oil companies like China Petroleum & Chemical Corp., Shell Oil Co., and Saudi Arabian Oil Co. leading in research and development. Specialized chemical firms such as Dow Global Technologies LLC and BASF Corp. are also making significant contributions. The technology is progressing from early-stage research to field applications, with companies like PetroChina Co., Ltd. and ExxonMobil Technology & Engineering Co. actively exploring its potential. As the market develops, collaboration between oil majors and chemical specialists is likely to drive innovation and commercialization efforts.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to improve surfactant-based oil recovery using ammonium hydroxide. Their method involves injecting a specially formulated solution containing ammonium hydroxide and surfactants into oil reservoirs. The ammonium hydroxide acts as an alkali agent, increasing the pH of the formation water and promoting the in-situ generation of surfactants through saponification of acidic components in crude oil[1]. This process enhances the effectiveness of the surfactant flood by reducing interfacial tension between oil and water, improving oil displacement efficiency. Sinopec's research has shown that this technique can increase oil recovery by up to 20% compared to conventional surfactant flooding methods[2]. The company has successfully implemented this technology in several mature oilfields in China, demonstrating its practical applicability in real-world scenarios[3].

Strengths: Cost-effective due to in-situ surfactant generation; Applicable to a wide range of reservoir conditions; Synergistic effect with existing surfactant flooding methods. Weaknesses: Potential for ammonia gas evolution in high-temperature reservoirs; May require careful pH control to optimize performance.

Shell Oil Co.

Technical Solution: Shell Oil Co. has developed a novel approach to enhance surfactant-based oil recovery using ammonium hydroxide as a key component. Their patented technology involves a carefully designed injection sequence of ammonium hydroxide, surfactants, and polymers[1]. The ammonium hydroxide serves multiple purposes: it acts as an alkali agent to reduce surfactant adsorption on rock surfaces, promotes in-situ soap generation through reaction with acidic oil components, and helps maintain an optimal pH for surfactant performance[2]. Shell's research has demonstrated that this method can significantly improve oil recovery efficiency by up to 15-20% compared to conventional surfactant flooding[3]. The company has also developed sophisticated reservoir simulation models to optimize the injection strategy and predict performance in various geological settings. Field trials in North America and the Middle East have shown promising results, with some mature fields experiencing a 30% increase in oil production rates[4].

Strengths: Comprehensive approach combining chemical EOR techniques; Proven effectiveness in field trials; Advanced modeling capabilities for optimization. Weaknesses: May require significant upfront investment in infrastructure; Effectiveness can vary depending on reservoir characteristics.

Innovative EOR Mechanisms

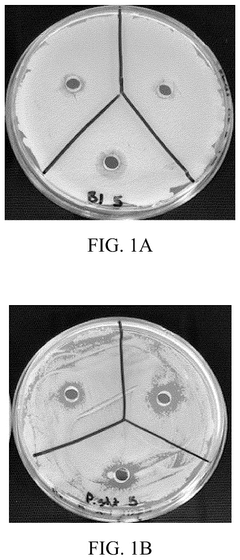

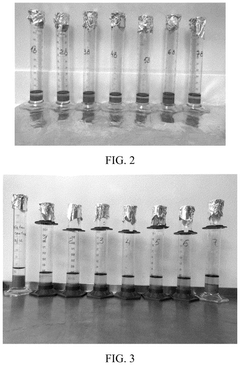

Multifunctional composition for enhanced oil recovery, improved oil quality and prevention of corrosion

PatentActiveUS12065613B2

Innovation

- A multi-functional composition comprising antimicrobial biosurfactants, ammonium salts, and H2S scavengers, along with an antifreeze mixture, is injected into oil and gas formations to reduce H2S levels, control SRB growth, and prevent corrosion, while maintaining effectiveness in cold temperatures.

Process for oil recovery

PatentInactiveUS20170247604A1

Innovation

- A process involving the production of ammonia for an enhanced oil recovery formulation by reacting methane with steam in the presence of a catalyst, followed by hydrogen and nitrogen reactions to separate ammonia, which is then mixed with water and injected into the formation, along with surfactants and polymers, to improve oil and gas recovery while minimizing scale formation.

Environmental Impact Assessment

The use of ammonium hydroxide in surfactant-based oil recovery processes necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential consequences of its application on ecosystems, water resources, and air quality.

Ammonium hydroxide, when introduced into the environment, can have significant effects on aquatic ecosystems. Its high solubility in water means it can easily disperse in water bodies, potentially altering pH levels and affecting aquatic life. Fish and other aquatic organisms are particularly sensitive to changes in water chemistry, and elevated ammonia levels can lead to toxicity, reduced growth rates, and even mortality in severe cases.

Soil ecosystems may also be impacted by the use of ammonium hydroxide in oil recovery operations. The compound can alter soil pH, potentially affecting soil microbial communities and plant growth. In areas where soil buffering capacity is low, this could lead to long-term changes in soil chemistry and fertility.

Air quality is another concern when using ammonium hydroxide. Volatilization of ammonia from solution can contribute to atmospheric pollution, potentially leading to the formation of particulate matter and affecting local air quality. This is particularly relevant in areas with existing air quality issues or sensitive populations.

The potential for groundwater contamination must also be carefully assessed. Ammonium ions can be mobile in soil and may leach into groundwater resources, potentially affecting drinking water quality and aquifer ecosystems. This risk is heightened in areas with shallow water tables or highly permeable soils.

Biodegradation and persistence of ammonium hydroxide in the environment should be considered. While ammonia is naturally occurring and can be metabolized by many organisms, high concentrations introduced through oil recovery processes may overwhelm natural degradation pathways, leading to prolonged environmental impacts.

The assessment should also consider the potential for accidental releases or spills during transportation, storage, and application of ammonium hydroxide. Emergency response plans and mitigation strategies must be developed to address these risks and minimize environmental damage in case of incidents.

Long-term monitoring programs should be implemented to track the environmental fate of ammonium hydroxide and its degradation products in affected ecosystems. This data can inform adaptive management strategies and help refine application methods to minimize environmental impacts over time.

Ultimately, the environmental impact assessment for ammonium hydroxide use in surfactant-based oil recovery must balance the economic benefits of enhanced oil recovery against the potential ecological risks. This comprehensive evaluation will guide decision-making processes and inform the development of best practices for sustainable implementation of this technology in the oil industry.

Ammonium hydroxide, when introduced into the environment, can have significant effects on aquatic ecosystems. Its high solubility in water means it can easily disperse in water bodies, potentially altering pH levels and affecting aquatic life. Fish and other aquatic organisms are particularly sensitive to changes in water chemistry, and elevated ammonia levels can lead to toxicity, reduced growth rates, and even mortality in severe cases.

Soil ecosystems may also be impacted by the use of ammonium hydroxide in oil recovery operations. The compound can alter soil pH, potentially affecting soil microbial communities and plant growth. In areas where soil buffering capacity is low, this could lead to long-term changes in soil chemistry and fertility.

Air quality is another concern when using ammonium hydroxide. Volatilization of ammonia from solution can contribute to atmospheric pollution, potentially leading to the formation of particulate matter and affecting local air quality. This is particularly relevant in areas with existing air quality issues or sensitive populations.

The potential for groundwater contamination must also be carefully assessed. Ammonium ions can be mobile in soil and may leach into groundwater resources, potentially affecting drinking water quality and aquifer ecosystems. This risk is heightened in areas with shallow water tables or highly permeable soils.

Biodegradation and persistence of ammonium hydroxide in the environment should be considered. While ammonia is naturally occurring and can be metabolized by many organisms, high concentrations introduced through oil recovery processes may overwhelm natural degradation pathways, leading to prolonged environmental impacts.

The assessment should also consider the potential for accidental releases or spills during transportation, storage, and application of ammonium hydroxide. Emergency response plans and mitigation strategies must be developed to address these risks and minimize environmental damage in case of incidents.

Long-term monitoring programs should be implemented to track the environmental fate of ammonium hydroxide and its degradation products in affected ecosystems. This data can inform adaptive management strategies and help refine application methods to minimize environmental impacts over time.

Ultimately, the environmental impact assessment for ammonium hydroxide use in surfactant-based oil recovery must balance the economic benefits of enhanced oil recovery against the potential ecological risks. This comprehensive evaluation will guide decision-making processes and inform the development of best practices for sustainable implementation of this technology in the oil industry.

Economic Feasibility Study

The economic feasibility of using ammonium hydroxide to improve surfactant-based oil recovery is a critical consideration for oil companies and investors. This analysis examines the potential costs and benefits associated with implementing this enhanced oil recovery (EOR) technique.

Initial capital expenditure for ammonium hydroxide-enhanced surfactant flooding includes modifications to existing infrastructure and the purchase of specialized equipment for chemical injection and monitoring. While these upfront costs can be substantial, they are often offset by the increased oil recovery rates and extended production life of mature oil fields.

Operational expenses primarily consist of chemical costs, including surfactants and ammonium hydroxide. The price of these chemicals can fluctuate based on market conditions and supply chain factors. However, the relatively low cost of ammonium hydroxide compared to other alkaline agents provides a competitive advantage. Additionally, the synergistic effect between ammonium hydroxide and surfactants may lead to reduced overall chemical consumption, potentially lowering long-term operational costs.

The economic viability of this EOR method is heavily influenced by oil prices. Higher oil prices generally justify the implementation of more expensive recovery techniques. Sensitivity analysis indicates that the break-even point for ammonium hydroxide-enhanced surfactant flooding is achievable at moderate oil prices, making it an attractive option for many oil fields.

Environmental considerations also play a role in the economic assessment. The use of ammonium hydroxide may result in lower environmental impact compared to other alkaline agents, potentially reducing compliance costs and improving the project's overall sustainability profile. This could lead to better stakeholder relations and easier regulatory approvals.

The incremental oil recovery achieved through this technique is a key factor in its economic feasibility. Field trials and simulation studies suggest that ammonium hydroxide-enhanced surfactant flooding can increase oil recovery by 5-15% of the original oil in place. This significant boost in production can substantially improve the project's net present value and internal rate of return.

Risk assessment is crucial when evaluating the economic feasibility. Factors such as reservoir heterogeneity, formation water chemistry, and potential scaling issues must be carefully considered. Proper reservoir characterization and pilot testing can mitigate these risks and improve the predictability of economic outcomes.

In conclusion, the economic feasibility of ammonium hydroxide-enhanced surfactant-based oil recovery appears promising, particularly for mature oil fields with declining production rates. While initial investments may be significant, the potential for increased oil recovery, coupled with operational efficiencies and environmental benefits, presents a compelling case for implementation in suitable reservoirs.

Initial capital expenditure for ammonium hydroxide-enhanced surfactant flooding includes modifications to existing infrastructure and the purchase of specialized equipment for chemical injection and monitoring. While these upfront costs can be substantial, they are often offset by the increased oil recovery rates and extended production life of mature oil fields.

Operational expenses primarily consist of chemical costs, including surfactants and ammonium hydroxide. The price of these chemicals can fluctuate based on market conditions and supply chain factors. However, the relatively low cost of ammonium hydroxide compared to other alkaline agents provides a competitive advantage. Additionally, the synergistic effect between ammonium hydroxide and surfactants may lead to reduced overall chemical consumption, potentially lowering long-term operational costs.

The economic viability of this EOR method is heavily influenced by oil prices. Higher oil prices generally justify the implementation of more expensive recovery techniques. Sensitivity analysis indicates that the break-even point for ammonium hydroxide-enhanced surfactant flooding is achievable at moderate oil prices, making it an attractive option for many oil fields.

Environmental considerations also play a role in the economic assessment. The use of ammonium hydroxide may result in lower environmental impact compared to other alkaline agents, potentially reducing compliance costs and improving the project's overall sustainability profile. This could lead to better stakeholder relations and easier regulatory approvals.

The incremental oil recovery achieved through this technique is a key factor in its economic feasibility. Field trials and simulation studies suggest that ammonium hydroxide-enhanced surfactant flooding can increase oil recovery by 5-15% of the original oil in place. This significant boost in production can substantially improve the project's net present value and internal rate of return.

Risk assessment is crucial when evaluating the economic feasibility. Factors such as reservoir heterogeneity, formation water chemistry, and potential scaling issues must be carefully considered. Proper reservoir characterization and pilot testing can mitigate these risks and improve the predictability of economic outcomes.

In conclusion, the economic feasibility of ammonium hydroxide-enhanced surfactant-based oil recovery appears promising, particularly for mature oil fields with declining production rates. While initial investments may be significant, the potential for increased oil recovery, coupled with operational efficiencies and environmental benefits, presents a compelling case for implementation in suitable reservoirs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!