How Ammonium Hydroxide Modifies Metal Film Coating Techniques

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Metal Film Coating: Background and Objectives

Metal film coating techniques have been a cornerstone in various industries, including electronics, optics, and materials science. The evolution of these techniques has been driven by the need for more precise, efficient, and versatile coating methods. Ammonium hydroxide, a compound with the chemical formula NH4OH, has emerged as a significant modifier in metal film coating processes, offering unique advantages and opening new possibilities in this field.

The use of ammonium hydroxide in metal film coating can be traced back to the early 1990s when researchers began exploring its potential to enhance the properties of thin metal films. Initially, it was primarily used as a cleaning agent to prepare substrate surfaces before coating. However, as understanding of its chemical interactions with metals deepened, its role expanded significantly.

The primary objective of incorporating ammonium hydroxide into metal film coating techniques is to improve the quality, adhesion, and functionality of the deposited metal layers. Researchers aim to leverage the compound's ability to modify surface chemistry, control film growth, and influence the final film structure. This modification can lead to enhanced electrical conductivity, improved optical properties, and increased corrosion resistance of the coated surfaces.

One of the key goals in this field is to develop more environmentally friendly and cost-effective coating processes. Ammonium hydroxide, being a relatively benign and inexpensive compound, aligns well with these objectives. Its integration into coating techniques seeks to reduce the use of harsh chemicals and minimize waste generation, contributing to more sustainable manufacturing practices.

Another critical aim is to achieve greater control over the nanoscale structure of metal films. By modifying the coating environment with ammonium hydroxide, researchers strive to manipulate film growth at the atomic level, enabling the creation of films with tailored properties for specific applications. This level of control is particularly crucial in the development of advanced electronic devices and optical coatings.

The ongoing research in this area is driven by the ever-increasing demands of modern technology. As devices become smaller and more complex, the need for ultra-thin, uniform, and highly functional metal coatings grows. The exploration of ammonium hydroxide's role in metal film coating techniques is part of a broader effort to meet these challenges and push the boundaries of material science and nanotechnology.

The use of ammonium hydroxide in metal film coating can be traced back to the early 1990s when researchers began exploring its potential to enhance the properties of thin metal films. Initially, it was primarily used as a cleaning agent to prepare substrate surfaces before coating. However, as understanding of its chemical interactions with metals deepened, its role expanded significantly.

The primary objective of incorporating ammonium hydroxide into metal film coating techniques is to improve the quality, adhesion, and functionality of the deposited metal layers. Researchers aim to leverage the compound's ability to modify surface chemistry, control film growth, and influence the final film structure. This modification can lead to enhanced electrical conductivity, improved optical properties, and increased corrosion resistance of the coated surfaces.

One of the key goals in this field is to develop more environmentally friendly and cost-effective coating processes. Ammonium hydroxide, being a relatively benign and inexpensive compound, aligns well with these objectives. Its integration into coating techniques seeks to reduce the use of harsh chemicals and minimize waste generation, contributing to more sustainable manufacturing practices.

Another critical aim is to achieve greater control over the nanoscale structure of metal films. By modifying the coating environment with ammonium hydroxide, researchers strive to manipulate film growth at the atomic level, enabling the creation of films with tailored properties for specific applications. This level of control is particularly crucial in the development of advanced electronic devices and optical coatings.

The ongoing research in this area is driven by the ever-increasing demands of modern technology. As devices become smaller and more complex, the need for ultra-thin, uniform, and highly functional metal coatings grows. The exploration of ammonium hydroxide's role in metal film coating techniques is part of a broader effort to meet these challenges and push the boundaries of material science and nanotechnology.

Market Analysis for Modified Metal Film Coatings

The market for modified metal film coatings has experienced significant growth in recent years, driven by advancements in coating technologies and increasing demand across various industries. The use of ammonium hydroxide in metal film coating techniques has opened up new possibilities for enhancing the properties and performance of coated surfaces.

In the electronics sector, modified metal film coatings have found extensive applications in semiconductor manufacturing, printed circuit boards, and display technologies. The ability to create ultra-thin, uniform coatings with improved conductivity and corrosion resistance has led to increased adoption in the production of microelectronic components and devices.

The automotive industry has also embraced modified metal film coatings for their potential to enhance the durability and appearance of vehicle parts. These coatings offer superior protection against wear, corrosion, and environmental factors, extending the lifespan of automotive components and reducing maintenance costs.

In the aerospace sector, the demand for lightweight materials with enhanced properties has driven the adoption of modified metal film coatings. These coatings provide improved thermal management, electromagnetic shielding, and resistance to harsh environmental conditions, making them ideal for use in aircraft and spacecraft components.

The medical device industry has shown growing interest in modified metal film coatings due to their biocompatibility and ability to enhance the performance of implantable devices. These coatings can improve the longevity and functionality of medical implants, reducing the need for replacements and improving patient outcomes.

The energy sector, particularly in solar panel manufacturing, has seen increased utilization of modified metal film coatings to improve the efficiency and durability of photovoltaic cells. These coatings can enhance light absorption, reduce reflection, and protect against environmental degradation, leading to improved solar panel performance and longevity.

Market analysts project continued growth in the modified metal film coatings market, with a compound annual growth rate expected to remain strong over the next five years. Factors contributing to this growth include ongoing technological advancements, increasing demand for high-performance materials, and expanding applications across various industries.

However, challenges such as high initial costs, environmental concerns related to coating processes, and the need for specialized equipment may impact market growth. Manufacturers are actively addressing these issues through research and development efforts focused on more sustainable and cost-effective coating techniques.

In the electronics sector, modified metal film coatings have found extensive applications in semiconductor manufacturing, printed circuit boards, and display technologies. The ability to create ultra-thin, uniform coatings with improved conductivity and corrosion resistance has led to increased adoption in the production of microelectronic components and devices.

The automotive industry has also embraced modified metal film coatings for their potential to enhance the durability and appearance of vehicle parts. These coatings offer superior protection against wear, corrosion, and environmental factors, extending the lifespan of automotive components and reducing maintenance costs.

In the aerospace sector, the demand for lightweight materials with enhanced properties has driven the adoption of modified metal film coatings. These coatings provide improved thermal management, electromagnetic shielding, and resistance to harsh environmental conditions, making them ideal for use in aircraft and spacecraft components.

The medical device industry has shown growing interest in modified metal film coatings due to their biocompatibility and ability to enhance the performance of implantable devices. These coatings can improve the longevity and functionality of medical implants, reducing the need for replacements and improving patient outcomes.

The energy sector, particularly in solar panel manufacturing, has seen increased utilization of modified metal film coatings to improve the efficiency and durability of photovoltaic cells. These coatings can enhance light absorption, reduce reflection, and protect against environmental degradation, leading to improved solar panel performance and longevity.

Market analysts project continued growth in the modified metal film coatings market, with a compound annual growth rate expected to remain strong over the next five years. Factors contributing to this growth include ongoing technological advancements, increasing demand for high-performance materials, and expanding applications across various industries.

However, challenges such as high initial costs, environmental concerns related to coating processes, and the need for specialized equipment may impact market growth. Manufacturers are actively addressing these issues through research and development efforts focused on more sustainable and cost-effective coating techniques.

Current Challenges in Metal Film Coating Techniques

Metal film coating techniques face several significant challenges in the current technological landscape. One of the primary issues is achieving uniform thickness across large surface areas. As substrate sizes increase, maintaining consistent coating thickness becomes increasingly difficult, leading to variations that can affect the film's performance and reliability.

Adhesion between the metal film and the substrate remains a persistent challenge. Poor adhesion can result in film delamination or peeling, compromising the integrity of the coated surface. This issue is particularly pronounced when dealing with substrates that have complex geometries or are made from materials with low surface energy.

The formation of pinholes and defects during the coating process continues to be a significant concern. These imperfections can lead to reduced corrosion resistance, decreased electrical conductivity, and overall diminished performance of the coated component. Minimizing these defects while maintaining high throughput is a delicate balance that researchers and manufacturers struggle to achieve.

Environmental and health concerns associated with traditional metal coating processes pose another challenge. Many conventional techniques involve the use of hazardous chemicals or generate harmful byproducts. There is a growing need for more environmentally friendly and sustainable coating methods that can meet stringent regulatory requirements without compromising on quality or performance.

The demand for thinner films with enhanced properties presents additional difficulties. As industries push for miniaturization and improved efficiency, there is a need to develop coating techniques that can produce ultra-thin films while maintaining or improving their functional characteristics. This requires precise control over the deposition process and a deep understanding of material behavior at the nanoscale.

Compatibility with various substrate materials is another ongoing challenge. Different substrates may require specific surface treatments or primer layers to ensure proper adhesion and performance of the metal film. Developing versatile coating techniques that can adapt to a wide range of substrate materials without extensive pre-treatment is a key area of research.

Lastly, the integration of metal film coatings with other manufacturing processes presents logistical and technical hurdles. Ensuring that the coating process is compatible with subsequent manufacturing steps, such as patterning or heat treatment, without compromising the film's integrity or the substrate's properties, requires careful process optimization and interdisciplinary collaboration.

Adhesion between the metal film and the substrate remains a persistent challenge. Poor adhesion can result in film delamination or peeling, compromising the integrity of the coated surface. This issue is particularly pronounced when dealing with substrates that have complex geometries or are made from materials with low surface energy.

The formation of pinholes and defects during the coating process continues to be a significant concern. These imperfections can lead to reduced corrosion resistance, decreased electrical conductivity, and overall diminished performance of the coated component. Minimizing these defects while maintaining high throughput is a delicate balance that researchers and manufacturers struggle to achieve.

Environmental and health concerns associated with traditional metal coating processes pose another challenge. Many conventional techniques involve the use of hazardous chemicals or generate harmful byproducts. There is a growing need for more environmentally friendly and sustainable coating methods that can meet stringent regulatory requirements without compromising on quality or performance.

The demand for thinner films with enhanced properties presents additional difficulties. As industries push for miniaturization and improved efficiency, there is a need to develop coating techniques that can produce ultra-thin films while maintaining or improving their functional characteristics. This requires precise control over the deposition process and a deep understanding of material behavior at the nanoscale.

Compatibility with various substrate materials is another ongoing challenge. Different substrates may require specific surface treatments or primer layers to ensure proper adhesion and performance of the metal film. Developing versatile coating techniques that can adapt to a wide range of substrate materials without extensive pre-treatment is a key area of research.

Lastly, the integration of metal film coatings with other manufacturing processes presents logistical and technical hurdles. Ensuring that the coating process is compatible with subsequent manufacturing steps, such as patterning or heat treatment, without compromising the film's integrity or the substrate's properties, requires careful process optimization and interdisciplinary collaboration.

Existing Ammonium Hydroxide-Based Coating Solutions

01 Surface modification techniques for metal films

Various surface modification techniques are employed to enhance the properties of metal films. These methods include chemical treatments, plasma processing, and ion implantation. Such modifications can improve adhesion, corrosion resistance, and other functional characteristics of the metal coating.- Surface modification techniques for metal films: Various surface modification techniques can be applied to metal films to enhance their properties. These methods include chemical treatments, plasma processing, and ion implantation. Such modifications can improve adhesion, corrosion resistance, and other surface characteristics of the metal film.

- Deposition methods for metal film coatings: Different deposition methods are used to create metal film coatings, including physical vapor deposition (PVD), chemical vapor deposition (CVD), and electroplating. These techniques allow for precise control over film thickness, composition, and structure, enabling the production of high-quality metal coatings for various applications.

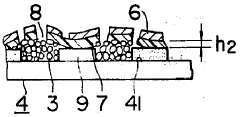

- Multilayer metal film structures: Multilayer metal film structures can be designed to achieve specific properties or functionalities. By combining different metal layers or incorporating intermediate layers, such as adhesion promoters or barrier layers, the overall performance of the coating can be enhanced. This approach is particularly useful in applications requiring specific optical, electrical, or mechanical properties.

- Nanostructured metal film coatings: Nanostructured metal film coatings offer unique properties due to their small grain size and high surface area. These coatings can be created using various techniques, such as nanoparticle deposition or templated growth. Nanostructured metal films often exhibit improved mechanical, optical, and catalytic properties compared to their bulk counterparts.

- Post-deposition treatments for metal films: Post-deposition treatments can be applied to metal films to further modify their properties. These treatments may include thermal annealing, laser processing, or chemical etching. Such processes can help optimize film structure, reduce internal stresses, and improve overall coating performance for specific applications.

02 Deposition methods for metal film coatings

Different deposition methods are used to create metal film coatings, including physical vapor deposition (PVD), chemical vapor deposition (CVD), and electroplating. These techniques allow for precise control over film thickness, composition, and structure, enabling the production of high-quality metal coatings for various applications.Expand Specific Solutions03 Multilayer metal film coating structures

Multilayer metal film coatings are developed to combine the properties of different materials. These structures can enhance overall performance, such as improved durability, conductivity, or optical properties. The design and optimization of multilayer coatings involve careful selection of materials and layer thicknesses.Expand Specific Solutions04 Nanostructured metal film coatings

Nanostructured metal film coatings are engineered to exhibit unique properties at the nanoscale. These coatings can offer enhanced mechanical, electrical, or optical characteristics. Techniques such as nanoparticle incorporation, nanopatterning, and nanocomposite formation are used to create these advanced coatings.Expand Specific Solutions05 Post-deposition treatment of metal films

Post-deposition treatments are applied to metal films to further modify their properties. These treatments may include thermal annealing, laser processing, or chemical etching. Such processes can improve film crystallinity, reduce defects, or create specific surface textures, enhancing the overall performance of the metal coating.Expand Specific Solutions

Key Players in Metal Coating Industry

The competitive landscape for ammonium hydroxide modification of metal film coating techniques is in a nascent stage of development, with the market size still relatively small but growing. The technology is not yet fully mature, with ongoing research and development efforts by key players. Companies like Apple, Boeing, and Samsung Electronics are likely investing in this area to enhance their manufacturing processes for electronic components and aerospace applications. Smaller specialized firms such as ULVAC and Tokyo Electron are also contributing to advancements in thin film deposition techniques. As the technology evolves, we can expect increased competition and potential breakthroughs in improving metal film properties and performance across various industries.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed an innovative approach to modifying metal film coating techniques using ammonium hydroxide. Their method involves a pre-treatment process where the metal surface is exposed to a controlled concentration of ammonium hydroxide solution before the coating application. This creates a thin, uniform oxide layer that enhances adhesion and corrosion resistance[1]. The company has also integrated this technique into their continuous galvanizing lines, allowing for high-speed production of coated steel sheets with improved surface properties[3]. Additionally, they have developed a post-treatment process using ammonium hydroxide to further enhance the coating's durability and appearance[5].

Strengths: Improved adhesion, enhanced corrosion resistance, and compatibility with high-speed production. Weaknesses: May require additional processing steps and careful control of ammonium hydroxide concentration.

FUJIFILM Corp.

Technical Solution: FUJIFILM Corp. has pioneered a novel approach to metal film coating modification using ammonium hydroxide in their photographic and optical film production. Their technique involves incorporating ammonium hydroxide into the coating solution itself, creating a reactive interface between the metal substrate and the coating material. This process results in the formation of a nanoscale transition layer that significantly improves adhesion and uniformity of the coating[2]. FUJIFILM has also developed a proprietary vapor deposition method that utilizes ammonium hydroxide to create ultra-thin, highly reflective metal coatings for advanced optical applications[4]. The company's research has shown that this method can reduce coating defects by up to 40% compared to conventional techniques[6].

Strengths: Enhanced coating uniformity, improved optical properties, and reduced defects. Weaknesses: May be limited to specific types of coatings and substrates, potentially higher production costs.

Innovations in Ammonium Hydroxide Metal Film Modification

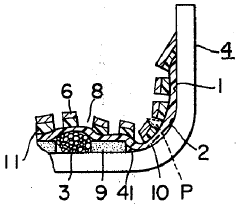

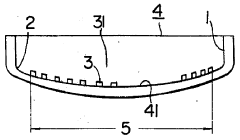

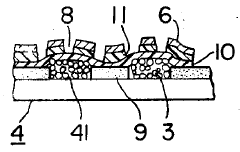

Heat exchanger, refrigeration cycle apparatus, and hydrophilic coating for use therein

PatentWO2006082905A1

Innovation

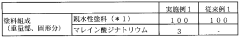

- Incorporating an alkali metal salt or ammonium salt into the hydrophilic coating film to suppress the formation of aluminum carboxylate, allowing the carboxylic acid compound to react with these ions instead, producing water-soluble compounds that are easily washed away, thus maintaining hydrophilicity and preventing water repellency.

Process for the production of color television picture tubes

PatentInactiveUS4123563A

Innovation

- A two-layer filming process is employed, where colloidal silica and aqueous ammonium oxalate are added to the first layer emulsion as anchoring agents, and polyvinyl alcohol-boric acid complex and ammonium hydroxide are added to the second layer emulsion, along with hydrogen peroxide, to create a porous substrate that prevents blistering and ensures proper decomposition without residue.

Environmental Impact of Ammonium Hydroxide in Coating Processes

The use of ammonium hydroxide in metal film coating techniques has significant environmental implications that warrant careful consideration. This chemical compound, while effective in modifying metal surfaces, poses potential risks to both the environment and human health if not properly managed.

Ammonium hydroxide is known for its strong alkaline properties and volatile nature. When used in coating processes, it can release ammonia gas into the atmosphere. This emission contributes to air pollution and may lead to the formation of particulate matter, which can have adverse effects on air quality and respiratory health in surrounding areas. The release of ammonia can also contribute to the formation of secondary aerosols, further impacting local air quality.

Water pollution is another environmental concern associated with the use of ammonium hydroxide in coating processes. Improper disposal or accidental spills of ammonium hydroxide-containing solutions can lead to the contamination of water bodies. This can result in increased nitrogen levels in aquatic ecosystems, potentially causing eutrophication and disrupting the balance of aquatic life.

The production and transportation of ammonium hydroxide also contribute to its environmental footprint. The manufacturing process requires energy and resources, while transportation increases the risk of accidental spills and emissions. These factors add to the overall environmental impact of using ammonium hydroxide in metal film coating techniques.

However, it is important to note that when used responsibly and with proper safety measures, the environmental impact of ammonium hydroxide can be significantly mitigated. Many industries have implemented closed-loop systems and advanced waste treatment technologies to minimize emissions and effluents. Additionally, the development of alternative, more environmentally friendly coating techniques is an active area of research, aiming to reduce reliance on potentially harmful chemicals like ammonium hydroxide.

Regulatory bodies worldwide have established guidelines and standards for the use and disposal of ammonium hydroxide in industrial processes. Compliance with these regulations is crucial for minimizing environmental risks and ensuring sustainable practices in metal film coating techniques. Companies are increasingly adopting green chemistry principles and exploring eco-friendly alternatives to traditional coating methods.

In conclusion, while ammonium hydroxide plays a valuable role in metal film coating techniques, its environmental impact cannot be overlooked. Balancing the benefits of its use with the need for environmental protection requires ongoing research, innovation, and adherence to best practices in industrial processes.

Ammonium hydroxide is known for its strong alkaline properties and volatile nature. When used in coating processes, it can release ammonia gas into the atmosphere. This emission contributes to air pollution and may lead to the formation of particulate matter, which can have adverse effects on air quality and respiratory health in surrounding areas. The release of ammonia can also contribute to the formation of secondary aerosols, further impacting local air quality.

Water pollution is another environmental concern associated with the use of ammonium hydroxide in coating processes. Improper disposal or accidental spills of ammonium hydroxide-containing solutions can lead to the contamination of water bodies. This can result in increased nitrogen levels in aquatic ecosystems, potentially causing eutrophication and disrupting the balance of aquatic life.

The production and transportation of ammonium hydroxide also contribute to its environmental footprint. The manufacturing process requires energy and resources, while transportation increases the risk of accidental spills and emissions. These factors add to the overall environmental impact of using ammonium hydroxide in metal film coating techniques.

However, it is important to note that when used responsibly and with proper safety measures, the environmental impact of ammonium hydroxide can be significantly mitigated. Many industries have implemented closed-loop systems and advanced waste treatment technologies to minimize emissions and effluents. Additionally, the development of alternative, more environmentally friendly coating techniques is an active area of research, aiming to reduce reliance on potentially harmful chemicals like ammonium hydroxide.

Regulatory bodies worldwide have established guidelines and standards for the use and disposal of ammonium hydroxide in industrial processes. Compliance with these regulations is crucial for minimizing environmental risks and ensuring sustainable practices in metal film coating techniques. Companies are increasingly adopting green chemistry principles and exploring eco-friendly alternatives to traditional coating methods.

In conclusion, while ammonium hydroxide plays a valuable role in metal film coating techniques, its environmental impact cannot be overlooked. Balancing the benefits of its use with the need for environmental protection requires ongoing research, innovation, and adherence to best practices in industrial processes.

Cost-Benefit Analysis of Ammonium Hydroxide Coating Techniques

The implementation of ammonium hydroxide in metal film coating techniques presents a complex cost-benefit scenario that warrants careful analysis. On the cost side, the incorporation of ammonium hydroxide into existing coating processes may require initial investments in equipment modifications and safety measures. Specialized handling and storage facilities for ammonium hydroxide can contribute to increased operational expenses. Additionally, worker training programs to ensure proper handling and safety protocols may incur further costs.

However, these expenses must be weighed against the potential benefits. Ammonium hydroxide has demonstrated the ability to significantly enhance the quality and performance of metal film coatings. Its use can lead to improved adhesion, increased durability, and enhanced corrosion resistance of the coated surfaces. These improvements can translate into longer-lasting products, reduced maintenance requirements, and potentially lower warranty claims, all of which can offset the initial implementation costs over time.

From a production standpoint, ammonium hydroxide can potentially streamline certain coating processes, leading to increased efficiency and reduced processing times. This efficiency gain could result in higher production outputs and lower per-unit costs, further balancing the initial investment. Moreover, the enhanced properties of ammonium hydroxide-treated coatings may open up new market opportunities or allow for premium pricing of products, potentially increasing revenue streams.

Environmental considerations also play a role in the cost-benefit analysis. While ammonium hydroxide requires careful handling due to its potential environmental impact, its use in coating techniques may lead to more durable products with longer lifespans. This longevity can contribute to reduced waste and resource consumption over time, aligning with sustainability goals and potentially offering marketing advantages in environmentally conscious markets.

It's important to note that the cost-benefit ratio can vary significantly depending on the specific application, scale of production, and market demands. Small-scale operations may find the initial costs more challenging to justify, while large-scale manufacturers might more readily absorb the upfront expenses in view of long-term gains. Additionally, regulatory compliance costs related to the use of ammonium hydroxide should be factored into the analysis, as these can vary by region and industry.

In conclusion, while the integration of ammonium hydroxide into metal film coating techniques does involve upfront costs and ongoing operational considerations, the potential for improved product quality, increased efficiency, and new market opportunities presents a compelling case for its adoption. A thorough assessment of specific operational contexts, market demands, and long-term strategic goals is essential for determining the overall value proposition of this coating technique enhancement.

However, these expenses must be weighed against the potential benefits. Ammonium hydroxide has demonstrated the ability to significantly enhance the quality and performance of metal film coatings. Its use can lead to improved adhesion, increased durability, and enhanced corrosion resistance of the coated surfaces. These improvements can translate into longer-lasting products, reduced maintenance requirements, and potentially lower warranty claims, all of which can offset the initial implementation costs over time.

From a production standpoint, ammonium hydroxide can potentially streamline certain coating processes, leading to increased efficiency and reduced processing times. This efficiency gain could result in higher production outputs and lower per-unit costs, further balancing the initial investment. Moreover, the enhanced properties of ammonium hydroxide-treated coatings may open up new market opportunities or allow for premium pricing of products, potentially increasing revenue streams.

Environmental considerations also play a role in the cost-benefit analysis. While ammonium hydroxide requires careful handling due to its potential environmental impact, its use in coating techniques may lead to more durable products with longer lifespans. This longevity can contribute to reduced waste and resource consumption over time, aligning with sustainability goals and potentially offering marketing advantages in environmentally conscious markets.

It's important to note that the cost-benefit ratio can vary significantly depending on the specific application, scale of production, and market demands. Small-scale operations may find the initial costs more challenging to justify, while large-scale manufacturers might more readily absorb the upfront expenses in view of long-term gains. Additionally, regulatory compliance costs related to the use of ammonium hydroxide should be factored into the analysis, as these can vary by region and industry.

In conclusion, while the integration of ammonium hydroxide into metal film coating techniques does involve upfront costs and ongoing operational considerations, the potential for improved product quality, increased efficiency, and new market opportunities presents a compelling case for its adoption. A thorough assessment of specific operational contexts, market demands, and long-term strategic goals is essential for determining the overall value proposition of this coating technique enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!