How AMOLED adapts to various touch-screen technologies?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Touch Integration Evolution

The evolution of AMOLED touch integration has been a journey of continuous innovation and technological advancement. Initially, AMOLED displays and touch sensors were separate components, with the touch layer placed on top of the display. This approach, while functional, resulted in thicker devices and reduced optical performance due to the additional layer.

As consumer demand for thinner, more responsive devices grew, manufacturers began exploring ways to integrate touch functionality directly into AMOLED displays. The first significant breakthrough came with the introduction of in-cell touch technology. This method embedded touch sensors within the display structure itself, eliminating the need for a separate touch layer. In-cell touch integration not only reduced device thickness but also improved optical performance by removing the air gap between the display and touch layer.

The next major advancement was the development of on-cell touch technology. This approach placed touch sensors on top of the AMOLED encapsulation layer but still within the display module. On-cell touch offered improved sensitivity and reduced production costs compared to in-cell solutions, while maintaining the benefits of a thinner overall structure.

More recently, the industry has seen the emergence of Y-OCTA (Youm On-Cell Touch AMOLED) technology. Y-OCTA represents a further refinement of on-cell touch, where the touch sensors are directly patterned on the AMOLED panel's encapsulation layer. This integration results in an even thinner display assembly and enhanced touch sensitivity.

The latest frontier in AMOLED touch integration is the development of under-display touch sensors. This technology aims to place touch-sensing elements beneath the AMOLED pixels, potentially offering the ultimate in display-touch integration. While still in its early stages, under-display touch holds promise for enabling new form factors and improving overall device aesthetics.

Throughout this evolution, AMOLED displays have had to adapt to various challenges posed by different touch technologies. These adaptations include modifications to pixel structures, changes in display driver circuitry, and innovations in materials science to ensure compatibility with touch sensors while maintaining the superior color reproduction and contrast ratios that AMOLED is known for.

The integration of touch functionality into AMOLED displays has not only driven advancements in display technology but has also influenced the broader smartphone and consumer electronics industries. As AMOLED touch integration continues to evolve, we can expect to see further innovations that push the boundaries of device design and user interaction.

As consumer demand for thinner, more responsive devices grew, manufacturers began exploring ways to integrate touch functionality directly into AMOLED displays. The first significant breakthrough came with the introduction of in-cell touch technology. This method embedded touch sensors within the display structure itself, eliminating the need for a separate touch layer. In-cell touch integration not only reduced device thickness but also improved optical performance by removing the air gap between the display and touch layer.

The next major advancement was the development of on-cell touch technology. This approach placed touch sensors on top of the AMOLED encapsulation layer but still within the display module. On-cell touch offered improved sensitivity and reduced production costs compared to in-cell solutions, while maintaining the benefits of a thinner overall structure.

More recently, the industry has seen the emergence of Y-OCTA (Youm On-Cell Touch AMOLED) technology. Y-OCTA represents a further refinement of on-cell touch, where the touch sensors are directly patterned on the AMOLED panel's encapsulation layer. This integration results in an even thinner display assembly and enhanced touch sensitivity.

The latest frontier in AMOLED touch integration is the development of under-display touch sensors. This technology aims to place touch-sensing elements beneath the AMOLED pixels, potentially offering the ultimate in display-touch integration. While still in its early stages, under-display touch holds promise for enabling new form factors and improving overall device aesthetics.

Throughout this evolution, AMOLED displays have had to adapt to various challenges posed by different touch technologies. These adaptations include modifications to pixel structures, changes in display driver circuitry, and innovations in materials science to ensure compatibility with touch sensors while maintaining the superior color reproduction and contrast ratios that AMOLED is known for.

The integration of touch functionality into AMOLED displays has not only driven advancements in display technology but has also influenced the broader smartphone and consumer electronics industries. As AMOLED touch integration continues to evolve, we can expect to see further innovations that push the boundaries of device design and user interaction.

Touch-Enabled AMOLED Market Analysis

The AMOLED touch-screen market has experienced significant growth in recent years, driven by the increasing demand for high-quality displays in smartphones, tablets, and other consumer electronics. This market segment combines the advanced display technology of Active-Matrix Organic Light-Emitting Diodes (AMOLED) with various touch-screen technologies to create responsive and visually appealing user interfaces.

The global AMOLED touch-screen market has been expanding rapidly, with major players like Samsung Display, LG Display, and BOE Technology Group leading the charge. These companies have invested heavily in research and development to improve AMOLED technology and its integration with touch-screen capabilities. The market has seen a steady increase in adoption across multiple industries, including mobile devices, automotive displays, and wearable technology.

Consumer demand for AMOLED touch-screens has been fueled by several key factors. Firstly, AMOLED displays offer superior color reproduction, contrast ratios, and energy efficiency compared to traditional LCD screens. When combined with touch-screen functionality, these displays provide an immersive and interactive user experience. Secondly, the flexibility of AMOLED panels has opened up new design possibilities for curved and foldable devices, creating unique product offerings that have captured consumer interest.

The automotive industry has emerged as a significant growth sector for AMOLED touch-screens. As vehicles become more technologically advanced, manufacturers are incorporating larger, more sophisticated displays into their dashboards and infotainment systems. AMOLED touch-screens offer improved visibility in varying light conditions and can be seamlessly integrated into modern vehicle interiors, making them an attractive option for automakers.

In the wearable technology market, AMOLED touch-screens have become increasingly popular in smartwatches and fitness trackers. The technology's ability to produce vibrant colors and deep blacks while consuming less power has made it ideal for small, battery-powered devices. As the wearable market continues to expand, the demand for AMOLED touch-screens in this sector is expected to grow substantially.

Looking ahead, the AMOLED touch-screen market is poised for continued growth. Technological advancements are focusing on improving touch sensitivity, reducing power consumption, and enhancing durability. Additionally, the development of flexible and foldable AMOLED displays is opening up new possibilities for innovative device designs, which is likely to drive further market expansion in the coming years.

The global AMOLED touch-screen market has been expanding rapidly, with major players like Samsung Display, LG Display, and BOE Technology Group leading the charge. These companies have invested heavily in research and development to improve AMOLED technology and its integration with touch-screen capabilities. The market has seen a steady increase in adoption across multiple industries, including mobile devices, automotive displays, and wearable technology.

Consumer demand for AMOLED touch-screens has been fueled by several key factors. Firstly, AMOLED displays offer superior color reproduction, contrast ratios, and energy efficiency compared to traditional LCD screens. When combined with touch-screen functionality, these displays provide an immersive and interactive user experience. Secondly, the flexibility of AMOLED panels has opened up new design possibilities for curved and foldable devices, creating unique product offerings that have captured consumer interest.

The automotive industry has emerged as a significant growth sector for AMOLED touch-screens. As vehicles become more technologically advanced, manufacturers are incorporating larger, more sophisticated displays into their dashboards and infotainment systems. AMOLED touch-screens offer improved visibility in varying light conditions and can be seamlessly integrated into modern vehicle interiors, making them an attractive option for automakers.

In the wearable technology market, AMOLED touch-screens have become increasingly popular in smartwatches and fitness trackers. The technology's ability to produce vibrant colors and deep blacks while consuming less power has made it ideal for small, battery-powered devices. As the wearable market continues to expand, the demand for AMOLED touch-screens in this sector is expected to grow substantially.

Looking ahead, the AMOLED touch-screen market is poised for continued growth. Technological advancements are focusing on improving touch sensitivity, reducing power consumption, and enhancing durability. Additionally, the development of flexible and foldable AMOLED displays is opening up new possibilities for innovative device designs, which is likely to drive further market expansion in the coming years.

AMOLED Touch Challenges

AMOLED displays face several challenges when integrating with touch-screen technologies. One of the primary issues is the potential interference between the touch sensors and the OLED pixels. The close proximity of these components can lead to signal crosstalk, affecting both display quality and touch accuracy. This challenge is particularly pronounced in high-resolution displays where pixel density is extremely high.

Another significant hurdle is the impact of touch layers on the overall optical performance of AMOLED displays. Traditional touch sensors, such as indium tin oxide (ITO) layers, can reduce light transmission and increase reflectivity, compromising the inherent advantages of AMOLED's high contrast and deep blacks. This necessitates the development of more transparent and thinner touch sensor materials that maintain optimal display characteristics.

The flexibility of AMOLED displays, while a key advantage, also presents challenges for touch integration. As AMOLED panels become increasingly flexible and even foldable, touch sensors must adapt to these form factors without compromising functionality or durability. This requires the development of equally flexible touch technologies that can withstand repeated bending and folding without degradation in performance.

Power consumption is another critical concern. AMOLED displays are known for their energy efficiency, particularly when displaying dark content. However, the addition of touch functionality can increase overall power draw. Balancing the power requirements of both the display and touch components while maintaining the energy advantages of AMOLED technology is a complex engineering challenge.

Durability and longevity pose additional challenges. AMOLED displays are sensitive to environmental factors such as moisture and oxygen. Integrating touch technology without compromising the display's protective layers or introducing new vulnerabilities is crucial for ensuring long-term reliability, especially in devices exposed to varied environmental conditions.

Manufacturing complexity and cost are also significant hurdles. The integration of touch technology with AMOLED displays often requires additional processing steps and materials, potentially increasing production costs and complexity. Streamlining these processes while maintaining high yield rates is essential for widespread adoption, particularly in cost-sensitive market segments.

Lastly, the challenge of achieving uniform touch sensitivity across the entire display surface, including curved or flexible areas, remains a significant technical hurdle. Ensuring consistent touch response regardless of display curvature or flexibility requires advanced sensor designs and sophisticated signal processing algorithms.

Another significant hurdle is the impact of touch layers on the overall optical performance of AMOLED displays. Traditional touch sensors, such as indium tin oxide (ITO) layers, can reduce light transmission and increase reflectivity, compromising the inherent advantages of AMOLED's high contrast and deep blacks. This necessitates the development of more transparent and thinner touch sensor materials that maintain optimal display characteristics.

The flexibility of AMOLED displays, while a key advantage, also presents challenges for touch integration. As AMOLED panels become increasingly flexible and even foldable, touch sensors must adapt to these form factors without compromising functionality or durability. This requires the development of equally flexible touch technologies that can withstand repeated bending and folding without degradation in performance.

Power consumption is another critical concern. AMOLED displays are known for their energy efficiency, particularly when displaying dark content. However, the addition of touch functionality can increase overall power draw. Balancing the power requirements of both the display and touch components while maintaining the energy advantages of AMOLED technology is a complex engineering challenge.

Durability and longevity pose additional challenges. AMOLED displays are sensitive to environmental factors such as moisture and oxygen. Integrating touch technology without compromising the display's protective layers or introducing new vulnerabilities is crucial for ensuring long-term reliability, especially in devices exposed to varied environmental conditions.

Manufacturing complexity and cost are also significant hurdles. The integration of touch technology with AMOLED displays often requires additional processing steps and materials, potentially increasing production costs and complexity. Streamlining these processes while maintaining high yield rates is essential for widespread adoption, particularly in cost-sensitive market segments.

Lastly, the challenge of achieving uniform touch sensitivity across the entire display surface, including curved or flexible areas, remains a significant technical hurdle. Ensuring consistent touch response regardless of display curvature or flexibility requires advanced sensor designs and sophisticated signal processing algorithms.

Current AMOLED Touch Solutions

01 AMOLED display driving techniques

Various methods for driving AMOLED displays are developed to improve performance and efficiency. These techniques include advanced pixel circuits, compensation algorithms, and timing control methods to address issues such as non-uniformity, image retention, and power consumption in AMOLED panels.- AMOLED display panel structure and manufacturing: This category focuses on the structure and manufacturing processes of AMOLED display panels. It includes innovations in pixel arrangements, thin-film transistor (TFT) designs, and layer compositions to improve display performance, efficiency, and durability. Advanced manufacturing techniques are employed to enhance the overall quality and yield of AMOLED panels.

- Driving and control methods for AMOLED displays: This category covers various driving and control methods for AMOLED displays. It includes techniques for pixel compensation, current control, and voltage management to improve display uniformity, reduce power consumption, and extend the lifespan of AMOLED panels. Advanced algorithms and circuit designs are implemented to optimize display performance and image quality.

- AMOLED display integration with touch and biometric sensors: This category focuses on integrating touch and biometric sensors into AMOLED displays. It includes innovations in in-display fingerprint sensors, under-display cameras, and touch-sensitive OLED panels. These advancements aim to improve device functionality, user experience, and design aesthetics by seamlessly incorporating multiple features into the display.

- Power management and efficiency in AMOLED displays: This category addresses power management and efficiency improvements in AMOLED displays. It includes techniques for reducing power consumption, optimizing brightness control, and implementing energy-saving modes. These innovations aim to extend battery life in devices using AMOLED displays while maintaining high image quality and performance.

- Color management and image quality enhancement in AMOLED displays: This category focuses on color management and image quality enhancement techniques for AMOLED displays. It includes innovations in color gamut expansion, contrast improvement, and high dynamic range (HDR) implementation. These advancements aim to deliver more vibrant, accurate, and lifelike images on AMOLED screens across various devices and applications.

02 AMOLED panel structure and fabrication

Innovations in AMOLED panel structure and fabrication processes aim to enhance display quality, durability, and manufacturing efficiency. These advancements include novel pixel layouts, thin-film transistor designs, and encapsulation techniques to improve color accuracy, brightness, and lifespan of AMOLED displays.Expand Specific Solutions03 Power management in AMOLED displays

Power management strategies for AMOLED displays focus on reducing energy consumption while maintaining image quality. These methods include adaptive brightness control, selective pixel dimming, and optimized voltage regulation to extend battery life in mobile devices and improve overall display efficiency.Expand Specific Solutions04 Touch integration in AMOLED panels

Integration of touch functionality directly into AMOLED panels enables thinner device profiles and improved touch sensitivity. These technologies include in-cell and on-cell touch solutions, as well as advanced sensing algorithms to enhance user interaction with AMOLED displays.Expand Specific Solutions05 AMOLED display color management

Color management techniques for AMOLED displays aim to improve color accuracy, gamut, and consistency across different viewing conditions. These methods include advanced color calibration algorithms, dynamic color adjustment, and compensation for color shift due to viewing angle or aging effects.Expand Specific Solutions

AMOLED Touch Industry Leaders

The AMOLED adaptation to various touch-screen technologies is in a mature stage of development, with a growing market size driven by increasing demand for high-quality displays in smartphones, wearables, and other devices. The technology's maturity is evident in the diverse range of companies involved, including major players like Samsung Electronics, BOE Technology Group, and Tianma Microelectronics. These firms have established production capabilities and continue to innovate in AMOLED technology. The competitive landscape is characterized by a mix of large, established corporations and specialized display manufacturers, indicating a robust and evolving market with potential for further technological advancements and market expansion.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in adapting AMOLED to touch-screen technologies. Their flexible AMOLED displays incorporate in-cell touch solutions, where touch sensors are embedded within the display stack[4]. This approach reduces display thickness and improves touch responsiveness. BOE has also developed on-cell touch AMOLED panels, which place the touch layer on top of the encapsulation layer, offering a good balance between performance and cost[5]. Additionally, BOE's AMOLED displays support advanced features like force touch and in-display fingerprint sensing, enhancing user interaction capabilities[6].

Strengths: Cost-effective solutions, wide range of touch integration options. Weaknesses: Slightly behind Samsung in terms of cutting-edge technology implementation.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced AMOLED displays that seamlessly integrate with various touch-screen technologies. Their Y-OCTA (Youm On-Cell Touch AMOLED) technology directly integrates the touch sensor into the AMOLED panel, eliminating the need for a separate touch layer[1]. This results in thinner displays with improved touch sensitivity and reduced power consumption. Samsung's latest displays also incorporate ultrasonic fingerprint sensors beneath the AMOLED screen, allowing for secure biometric authentication without compromising display quality[2]. The company has also introduced S-Stripe subpixel layout, which enhances color accuracy and energy efficiency in AMOLED panels used with touch interfaces[3].

Strengths: Industry-leading integration of touch and display technologies, thinner device profiles, improved touch sensitivity. Weaknesses: Higher production costs, potential for increased complexity in manufacturing processes.

Key AMOLED Touch Patents

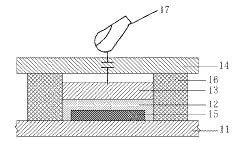

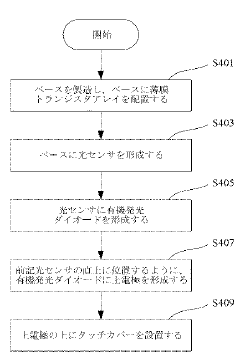

Touch device integrated with amoled panel, and method of manufacturing the same

PatentActiveJP2016053934A

Innovation

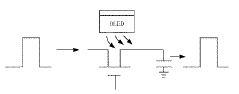

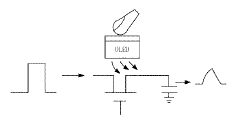

- A touch device integrated with an AMOLED panel that includes a thin film transistor array, organic light emitting diodes, a touch cover, and a light sensor positioned between the diode and the base, utilizing In-Cell optical touch technology to eliminate errors and enhance accuracy.

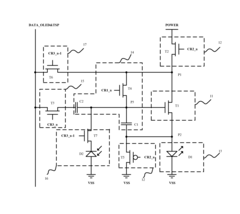

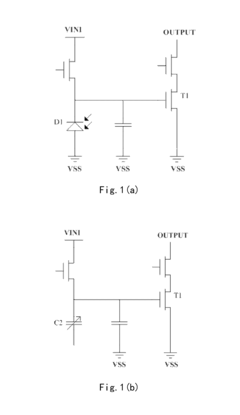

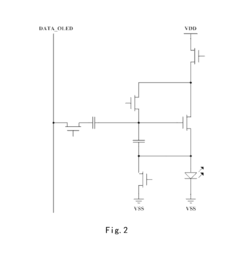

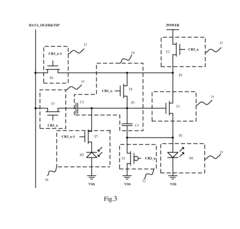

Active matrix organic light emitting diode pixel unit circuit and display panel

PatentActiveUS9530354B2

Innovation

- An active matrix organic light emitting diode pixel unit circuit is designed with specific modules such as a light emitting module, driving module, threshold compensation module, light emitting control module, touch sensing module, and sensing signal output module, utilizing common data lines and control signals to integrate the TSP in Cell circuit, including additional TFTs and capacitors, while optimizing circuit components and signal operations.

AMOLED Touch Performance Metrics

AMOLED touch performance metrics are crucial for evaluating the effectiveness of touch-screen technologies integrated with AMOLED displays. These metrics provide quantitative measures to assess the responsiveness, accuracy, and overall user experience of touch interactions on AMOLED screens.

One key metric is touch response time, which measures the delay between a user's touch input and the display's visual response. For AMOLED displays, this metric is particularly important due to the technology's inherently fast pixel response times. Manufacturers aim to minimize touch response times to create a more immediate and fluid user experience, typically targeting sub-10 millisecond latencies.

Touch accuracy is another critical metric, quantifying the precision with which the touch system can detect and interpret user inputs. This is measured in terms of spatial resolution, often expressed in dots per inch (DPI) or pixels per inch (PPI). Higher accuracy allows for more precise interactions, especially important for applications requiring fine motor control, such as digital art or precise UI navigation.

Multi-touch capability is an essential performance metric for modern AMOLED touch screens. This metric evaluates the display's ability to recognize and process multiple simultaneous touch points. Advanced AMOLED touch systems can typically detect 10 or more touch points concurrently, enabling complex gestures and multi-finger interactions.

Touch sensitivity is a metric that assesses the screen's ability to detect light touches. AMOLED displays, when combined with capacitive touch technology, can offer high sensitivity, allowing for interactions with minimal pressure. This metric is often measured by the minimum force required to register a touch, typically expressed in grams-force (gf).

Palm rejection performance is an increasingly important metric, especially for larger AMOLED displays used in tablets or foldable devices. This metric evaluates the system's ability to distinguish between intentional touch inputs and accidental contact from palms or other body parts resting on the screen.

Durability and reliability metrics are also crucial for AMOLED touch screens. These include measures such as the number of touch cycles a screen can endure before degradation, resistance to environmental factors like humidity and temperature, and consistency of touch performance over time.

Finally, power consumption related to touch functionality is a key metric, particularly for mobile devices with AMOLED displays. This metric assesses the additional energy draw of the touch system, which can impact overall device battery life. Efficient touch controllers and integration techniques are employed to minimize this power overhead while maintaining high performance.

One key metric is touch response time, which measures the delay between a user's touch input and the display's visual response. For AMOLED displays, this metric is particularly important due to the technology's inherently fast pixel response times. Manufacturers aim to minimize touch response times to create a more immediate and fluid user experience, typically targeting sub-10 millisecond latencies.

Touch accuracy is another critical metric, quantifying the precision with which the touch system can detect and interpret user inputs. This is measured in terms of spatial resolution, often expressed in dots per inch (DPI) or pixels per inch (PPI). Higher accuracy allows for more precise interactions, especially important for applications requiring fine motor control, such as digital art or precise UI navigation.

Multi-touch capability is an essential performance metric for modern AMOLED touch screens. This metric evaluates the display's ability to recognize and process multiple simultaneous touch points. Advanced AMOLED touch systems can typically detect 10 or more touch points concurrently, enabling complex gestures and multi-finger interactions.

Touch sensitivity is a metric that assesses the screen's ability to detect light touches. AMOLED displays, when combined with capacitive touch technology, can offer high sensitivity, allowing for interactions with minimal pressure. This metric is often measured by the minimum force required to register a touch, typically expressed in grams-force (gf).

Palm rejection performance is an increasingly important metric, especially for larger AMOLED displays used in tablets or foldable devices. This metric evaluates the system's ability to distinguish between intentional touch inputs and accidental contact from palms or other body parts resting on the screen.

Durability and reliability metrics are also crucial for AMOLED touch screens. These include measures such as the number of touch cycles a screen can endure before degradation, resistance to environmental factors like humidity and temperature, and consistency of touch performance over time.

Finally, power consumption related to touch functionality is a key metric, particularly for mobile devices with AMOLED displays. This metric assesses the additional energy draw of the touch system, which can impact overall device battery life. Efficient touch controllers and integration techniques are employed to minimize this power overhead while maintaining high performance.

AMOLED Touch Manufacturing Process

The AMOLED touch manufacturing process involves a complex integration of display and touch technologies. AMOLED (Active-Matrix Organic Light-Emitting Diode) displays are known for their superior image quality, high contrast ratios, and energy efficiency. To adapt these displays to touch functionality, manufacturers employ various techniques that ensure seamless touch responsiveness without compromising display performance.

One of the primary methods used in AMOLED touch manufacturing is the on-cell touch technology. This approach integrates the touch sensors directly onto the display panel, reducing the overall thickness of the device and improving optical performance. The process begins with the fabrication of the AMOLED display layers, including the TFT (Thin-Film Transistor) backplane, organic light-emitting materials, and encapsulation layers.

Once the basic AMOLED structure is in place, touch sensors are deposited directly onto the encapsulation layer. These sensors are typically made of transparent conductive materials such as indium tin oxide (ITO) or more advanced alternatives like silver nanowires. The deposition is carried out using techniques like sputtering or photolithography to create a precise pattern of touch-sensitive electrodes.

Another approach in AMOLED touch manufacturing is the in-cell touch technology. This method integrates touch sensors within the display's pixel structure, further reducing the thickness and improving optical clarity. The manufacturing process for in-cell touch AMOLEDs involves modifying the TFT backplane to incorporate touch-sensing capabilities alongside display driving functions.

To achieve this, additional circuitry is integrated into the TFT layer, allowing it to perform both display and touch functions. This dual-purpose design requires careful optimization of the manufacturing process to ensure that touch sensitivity does not interfere with display performance and vice versa. Advanced lithography and etching techniques are employed to create the intricate patterns necessary for this integration.

The final stages of AMOLED touch manufacturing involve the application of protective layers and the integration of touch processing circuitry. A thin layer of optically clear adhesive is often applied to bond the touch layer with the display, followed by a protective cover glass. The touch controller IC is then connected to the touch sensors, completing the touch-enabled AMOLED module.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the uniformity of both display and touch performance. This includes testing for defects in the OLED pixels, verifying the accuracy and responsiveness of touch sensors, and calibrating the overall system for optimal user experience.

One of the primary methods used in AMOLED touch manufacturing is the on-cell touch technology. This approach integrates the touch sensors directly onto the display panel, reducing the overall thickness of the device and improving optical performance. The process begins with the fabrication of the AMOLED display layers, including the TFT (Thin-Film Transistor) backplane, organic light-emitting materials, and encapsulation layers.

Once the basic AMOLED structure is in place, touch sensors are deposited directly onto the encapsulation layer. These sensors are typically made of transparent conductive materials such as indium tin oxide (ITO) or more advanced alternatives like silver nanowires. The deposition is carried out using techniques like sputtering or photolithography to create a precise pattern of touch-sensitive electrodes.

Another approach in AMOLED touch manufacturing is the in-cell touch technology. This method integrates touch sensors within the display's pixel structure, further reducing the thickness and improving optical clarity. The manufacturing process for in-cell touch AMOLEDs involves modifying the TFT backplane to incorporate touch-sensing capabilities alongside display driving functions.

To achieve this, additional circuitry is integrated into the TFT layer, allowing it to perform both display and touch functions. This dual-purpose design requires careful optimization of the manufacturing process to ensure that touch sensitivity does not interfere with display performance and vice versa. Advanced lithography and etching techniques are employed to create the intricate patterns necessary for this integration.

The final stages of AMOLED touch manufacturing involve the application of protective layers and the integration of touch processing circuitry. A thin layer of optically clear adhesive is often applied to bond the touch layer with the display, followed by a protective cover glass. The touch controller IC is then connected to the touch sensors, completing the touch-enabled AMOLED module.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the uniformity of both display and touch performance. This includes testing for defects in the OLED pixels, verifying the accuracy and responsiveness of touch sensors, and calibrating the overall system for optimal user experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!