The importance of color consistency in AMOLED applications.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Color Consistency Background and Objectives

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has revolutionized the display industry, offering superior image quality, energy efficiency, and design flexibility. As this technology continues to evolve and penetrate various markets, the importance of color consistency in AMOLED applications has become increasingly critical.

Color consistency refers to the ability of a display to maintain uniform and accurate color reproduction across its entire surface and throughout its lifespan. In AMOLED displays, achieving and maintaining color consistency presents unique challenges due to the organic nature of the light-emitting materials and the complexity of the manufacturing process.

The evolution of AMOLED technology can be traced back to the late 1980s when the first organic electroluminescent devices were developed. However, it wasn't until the early 2000s that AMOLED displays began to gain traction in commercial applications. As the technology matured, the focus shifted from basic functionality to enhancing display performance, with color consistency emerging as a key differentiator in the competitive display market.

The growing demand for high-quality displays in smartphones, televisions, and other consumer electronics has further emphasized the need for excellent color consistency. Users expect vibrant, accurate, and uniform colors across their devices, regardless of viewing angle or ambient lighting conditions. This expectation has driven manufacturers to invest heavily in research and development to improve color consistency in AMOLED applications.

From a technical perspective, achieving color consistency in AMOLED displays involves addressing several challenges. These include variations in organic material degradation rates, non-uniform current distribution across the display, and temperature-induced color shifts. Additionally, the manufacturing process itself can introduce inconsistencies, requiring precise control and advanced compensation techniques.

The objectives of improving color consistency in AMOLED applications are multifaceted. Firstly, there is a need to develop more stable and uniform organic materials that can maintain consistent light emission properties over time. Secondly, advanced driving schemes and compensation algorithms are required to counteract the effects of aging and environmental factors on color reproduction. Thirdly, manufacturing processes must be refined to minimize panel-to-panel variations and ensure consistent quality across large production volumes.

As the AMOLED market continues to expand into new application areas such as automotive displays, augmented reality (AR) and virtual reality (VR) headsets, and flexible or foldable devices, the importance of color consistency becomes even more pronounced. These emerging applications often have stringent requirements for color accuracy and uniformity, pushing the boundaries of what current AMOLED technology can achieve.

In conclusion, the pursuit of superior color consistency in AMOLED applications represents a critical technological goal that drives innovation in the display industry. It encompasses a wide range of technical challenges and objectives, from material science to manufacturing processes, and has far-reaching implications for the future of display technology and user experience.

Color consistency refers to the ability of a display to maintain uniform and accurate color reproduction across its entire surface and throughout its lifespan. In AMOLED displays, achieving and maintaining color consistency presents unique challenges due to the organic nature of the light-emitting materials and the complexity of the manufacturing process.

The evolution of AMOLED technology can be traced back to the late 1980s when the first organic electroluminescent devices were developed. However, it wasn't until the early 2000s that AMOLED displays began to gain traction in commercial applications. As the technology matured, the focus shifted from basic functionality to enhancing display performance, with color consistency emerging as a key differentiator in the competitive display market.

The growing demand for high-quality displays in smartphones, televisions, and other consumer electronics has further emphasized the need for excellent color consistency. Users expect vibrant, accurate, and uniform colors across their devices, regardless of viewing angle or ambient lighting conditions. This expectation has driven manufacturers to invest heavily in research and development to improve color consistency in AMOLED applications.

From a technical perspective, achieving color consistency in AMOLED displays involves addressing several challenges. These include variations in organic material degradation rates, non-uniform current distribution across the display, and temperature-induced color shifts. Additionally, the manufacturing process itself can introduce inconsistencies, requiring precise control and advanced compensation techniques.

The objectives of improving color consistency in AMOLED applications are multifaceted. Firstly, there is a need to develop more stable and uniform organic materials that can maintain consistent light emission properties over time. Secondly, advanced driving schemes and compensation algorithms are required to counteract the effects of aging and environmental factors on color reproduction. Thirdly, manufacturing processes must be refined to minimize panel-to-panel variations and ensure consistent quality across large production volumes.

As the AMOLED market continues to expand into new application areas such as automotive displays, augmented reality (AR) and virtual reality (VR) headsets, and flexible or foldable devices, the importance of color consistency becomes even more pronounced. These emerging applications often have stringent requirements for color accuracy and uniformity, pushing the boundaries of what current AMOLED technology can achieve.

In conclusion, the pursuit of superior color consistency in AMOLED applications represents a critical technological goal that drives innovation in the display industry. It encompasses a wide range of technical challenges and objectives, from material science to manufacturing processes, and has far-reaching implications for the future of display technology and user experience.

Market Demand for High-Quality AMOLED Displays

The demand for high-quality AMOLED displays has been steadily increasing across various industries, driven by the growing consumer preference for vibrant, energy-efficient, and visually appealing screens. This trend is particularly evident in the smartphone market, where AMOLED technology has become a key differentiator for premium devices. The superior color reproduction, deep blacks, and high contrast ratios offered by AMOLED displays have set new standards for visual quality, making them highly sought after by consumers.

In the automotive sector, there is a rising demand for AMOLED displays in infotainment systems and digital dashboards. The automotive industry values the technology's ability to deliver clear, vivid visuals even in bright sunlight, enhancing the overall driving experience and safety. Additionally, the flexibility of AMOLED panels allows for curved and uniquely shaped displays, opening up new design possibilities for vehicle interiors.

The wearable technology market has also embraced AMOLED displays, particularly in smartwatches and fitness trackers. The technology's energy efficiency and ability to produce vibrant colors on small screens make it ideal for these compact devices. As the wearable market continues to expand, the demand for high-quality AMOLED displays is expected to grow in tandem.

In the television industry, AMOLED technology, often marketed as OLED, has gained significant traction in the high-end segment. Consumers are increasingly willing to pay a premium for the superior picture quality, perfect blacks, and wide viewing angles offered by AMOLED TVs. This trend is driving manufacturers to invest more in AMOLED production capabilities to meet the growing demand.

The gaming industry represents another significant market for high-quality AMOLED displays. Gamers value the technology's fast response times, high refresh rates, and excellent color reproduction, which contribute to a more immersive gaming experience. As competitive gaming and e-sports continue to gain popularity, the demand for AMOLED displays in gaming monitors and laptops is expected to rise.

The commercial signage and advertising sector is also showing increased interest in AMOLED technology. The vibrant colors and high contrast ratios make AMOLED displays particularly effective for digital signage in retail environments, airports, and other public spaces. The ability to produce flexible and transparent AMOLED panels opens up new possibilities for innovative advertising displays.

As the market for AMOLED displays expands, there is a growing emphasis on color consistency across different applications and devices. Consumers and industries alike are demanding displays that can accurately reproduce colors and maintain consistency across various viewing conditions. This focus on color consistency is driving research and development efforts in AMOLED technology, aiming to improve color calibration, reduce color shift, and enhance overall display performance.

In the automotive sector, there is a rising demand for AMOLED displays in infotainment systems and digital dashboards. The automotive industry values the technology's ability to deliver clear, vivid visuals even in bright sunlight, enhancing the overall driving experience and safety. Additionally, the flexibility of AMOLED panels allows for curved and uniquely shaped displays, opening up new design possibilities for vehicle interiors.

The wearable technology market has also embraced AMOLED displays, particularly in smartwatches and fitness trackers. The technology's energy efficiency and ability to produce vibrant colors on small screens make it ideal for these compact devices. As the wearable market continues to expand, the demand for high-quality AMOLED displays is expected to grow in tandem.

In the television industry, AMOLED technology, often marketed as OLED, has gained significant traction in the high-end segment. Consumers are increasingly willing to pay a premium for the superior picture quality, perfect blacks, and wide viewing angles offered by AMOLED TVs. This trend is driving manufacturers to invest more in AMOLED production capabilities to meet the growing demand.

The gaming industry represents another significant market for high-quality AMOLED displays. Gamers value the technology's fast response times, high refresh rates, and excellent color reproduction, which contribute to a more immersive gaming experience. As competitive gaming and e-sports continue to gain popularity, the demand for AMOLED displays in gaming monitors and laptops is expected to rise.

The commercial signage and advertising sector is also showing increased interest in AMOLED technology. The vibrant colors and high contrast ratios make AMOLED displays particularly effective for digital signage in retail environments, airports, and other public spaces. The ability to produce flexible and transparent AMOLED panels opens up new possibilities for innovative advertising displays.

As the market for AMOLED displays expands, there is a growing emphasis on color consistency across different applications and devices. Consumers and industries alike are demanding displays that can accurately reproduce colors and maintain consistency across various viewing conditions. This focus on color consistency is driving research and development efforts in AMOLED technology, aiming to improve color calibration, reduce color shift, and enhance overall display performance.

Current Challenges in AMOLED Color Consistency

AMOLED displays have revolutionized the mobile device industry with their vibrant colors and energy efficiency. However, maintaining color consistency across these displays remains a significant challenge. One of the primary issues is the inherent variability in OLED materials and manufacturing processes, which can lead to inconsistencies in color reproduction between different panels and even within the same panel over time.

The organic nature of OMOLED materials makes them susceptible to degradation, particularly when exposed to heat, light, and electrical current. This degradation is not uniform across all color components, resulting in shifts in color balance as the display ages. Blue OLEDs, in particular, tend to degrade faster than red and green, leading to a yellowish tint in older displays.

Another challenge is the variation in color performance due to viewing angles. AMOLED displays can exhibit significant color shifts when viewed off-axis, which is particularly problematic for devices that are frequently used in various orientations, such as smartphones and tablets. This phenomenon, known as angular color shift, can result in inconsistent color perception depending on how the user holds or views the device.

Temperature fluctuations also play a crucial role in color consistency challenges. AMOLED displays are sensitive to temperature changes, which can affect the emission characteristics of the organic materials. This sensitivity can lead to noticeable color shifts in different ambient temperatures or during extended use when the device heats up.

The manufacturing process itself introduces variability that impacts color consistency. Slight differences in the deposition of organic materials or variations in the thin-film transistor (TFT) backplane can result in panel-to-panel color discrepancies. This makes it challenging to ensure uniform color reproduction across a production run of devices.

Calibration and compensation techniques have been developed to address these issues, but they come with their own set of challenges. While factory calibration can improve initial color accuracy, it doesn't account for long-term changes due to aging. Dynamic compensation algorithms can help mitigate some effects of degradation, but they require sophisticated sensors and processing power, which can increase device cost and complexity.

The pursuit of higher resolutions and pixel densities in AMOLED displays also exacerbates color consistency challenges. As pixel sizes shrink, the precision required in manufacturing and the sensitivity to material variations increase, making it more difficult to maintain uniform color across the entire display area.

The organic nature of OMOLED materials makes them susceptible to degradation, particularly when exposed to heat, light, and electrical current. This degradation is not uniform across all color components, resulting in shifts in color balance as the display ages. Blue OLEDs, in particular, tend to degrade faster than red and green, leading to a yellowish tint in older displays.

Another challenge is the variation in color performance due to viewing angles. AMOLED displays can exhibit significant color shifts when viewed off-axis, which is particularly problematic for devices that are frequently used in various orientations, such as smartphones and tablets. This phenomenon, known as angular color shift, can result in inconsistent color perception depending on how the user holds or views the device.

Temperature fluctuations also play a crucial role in color consistency challenges. AMOLED displays are sensitive to temperature changes, which can affect the emission characteristics of the organic materials. This sensitivity can lead to noticeable color shifts in different ambient temperatures or during extended use when the device heats up.

The manufacturing process itself introduces variability that impacts color consistency. Slight differences in the deposition of organic materials or variations in the thin-film transistor (TFT) backplane can result in panel-to-panel color discrepancies. This makes it challenging to ensure uniform color reproduction across a production run of devices.

Calibration and compensation techniques have been developed to address these issues, but they come with their own set of challenges. While factory calibration can improve initial color accuracy, it doesn't account for long-term changes due to aging. Dynamic compensation algorithms can help mitigate some effects of degradation, but they require sophisticated sensors and processing power, which can increase device cost and complexity.

The pursuit of higher resolutions and pixel densities in AMOLED displays also exacerbates color consistency challenges. As pixel sizes shrink, the precision required in manufacturing and the sensitivity to material variations increase, making it more difficult to maintain uniform color across the entire display area.

Existing Color Consistency Solutions for AMOLED

01 Compensation techniques for color consistency

Various compensation techniques are employed to maintain color consistency in AMOLED displays. These methods include pixel-level compensation, temperature-based compensation, and aging compensation. By adjusting individual pixel characteristics and accounting for environmental factors, these techniques help ensure uniform color reproduction across the display.- Compensation techniques for color consistency: Various compensation techniques are employed to maintain color consistency in AMOLED displays. These methods include pixel-level compensation, temperature-based compensation, and aging compensation. By adjusting the driving signals or voltage levels for individual pixels, these techniques help to mitigate color variations caused by manufacturing inconsistencies, temperature fluctuations, and device aging.

- Color management and calibration systems: Advanced color management and calibration systems are implemented to ensure consistent color reproduction across AMOLED displays. These systems involve measuring and adjusting color parameters, such as gamma curves and color gamut, to achieve uniform color performance. Real-time color correction algorithms and feedback mechanisms are used to maintain color accuracy throughout the display's lifetime.

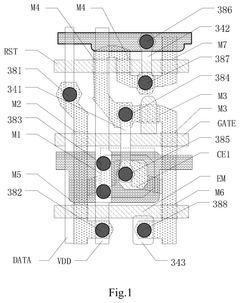

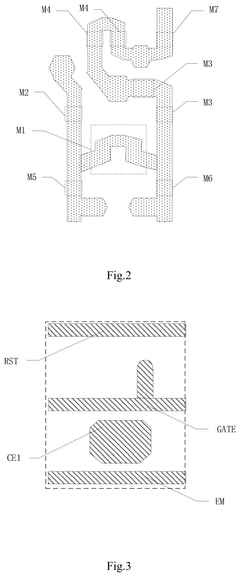

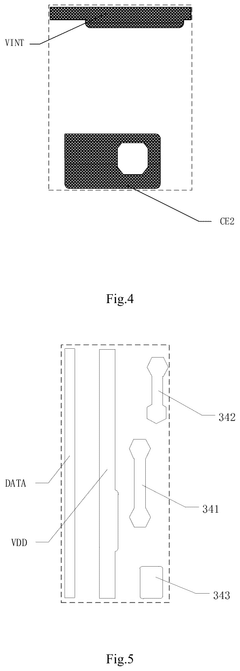

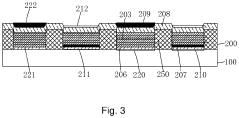

- Pixel structure and materials optimization: Improvements in pixel structure and materials contribute to enhanced color consistency in AMOLED displays. This includes developing new organic light-emitting materials, optimizing pixel layouts, and implementing advanced thin-film transistor (TFT) designs. These advancements help to reduce color variations caused by manufacturing tolerances and improve overall display uniformity.

- Sensing and feedback mechanisms: Integrated sensing and feedback mechanisms are utilized to monitor and adjust color performance in real-time. These systems may include on-panel sensors, external optical sensors, or electrical characteristic measurements to detect color shifts and variations. The collected data is used to dynamically adjust display parameters, ensuring consistent color reproduction across the entire panel.

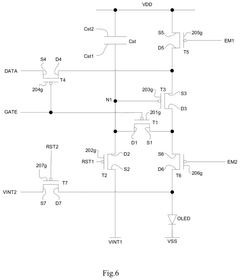

- Driving schemes and circuit designs: Novel driving schemes and circuit designs are developed to improve color consistency in AMOLED displays. These include advanced pixel driving circuits, voltage compensation techniques, and current programming methods. By precisely controlling the current flow through each OLED pixel, these approaches help to maintain uniform brightness and color across the display, even as individual pixels age or degrade over time.

02 Pixel structure optimization for color uniformity

Improving the pixel structure of AMOLED displays contributes to better color consistency. This includes optimizing subpixel layouts, implementing advanced driving schemes, and enhancing light-emitting layer designs. These structural improvements help reduce color variations and maintain uniform brightness across the display.Expand Specific Solutions03 Color management systems for AMOLED displays

Sophisticated color management systems are implemented to ensure consistent color reproduction in AMOLED displays. These systems involve color calibration, gamut mapping, and dynamic color adjustment algorithms. By continuously monitoring and adjusting color parameters, these systems maintain color accuracy and consistency under various viewing conditions.Expand Specific Solutions04 Sensing and feedback mechanisms for color consistency

AMOLED displays incorporate various sensing and feedback mechanisms to maintain color consistency. These include integrated color sensors, temperature sensors, and real-time monitoring of pixel performance. The feedback from these sensors is used to dynamically adjust display parameters, ensuring consistent color output over time and under different operating conditions.Expand Specific Solutions05 Manufacturing process improvements for color uniformity

Advancements in manufacturing processes contribute to improved color consistency in AMOLED displays. These include refined deposition techniques for organic materials, enhanced quality control measures, and improved encapsulation methods. By minimizing variations in the production process, these improvements lead to more uniform color characteristics across the display panel.Expand Specific Solutions

Key Players in AMOLED Display Industry

The color consistency in AMOLED applications has become a critical focus in the display industry, with the market entering a mature phase characterized by intense competition and technological refinement. Major players like BOE Technology, Universal Display Corp, and Samsung Display are driving innovation in this field. The market size for AMOLED displays is expanding rapidly, driven by increasing adoption in smartphones, wearables, and automotive applications. Technological maturity varies among companies, with industry leaders like Universal Display and Samsung Display demonstrating advanced capabilities in color consistency and uniformity. Emerging players such as Everdisplay Optronics and Visionox are also making significant strides, narrowing the gap with established manufacturers.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced color management technologies for AMOLED displays, including their proprietary ADSDS (Advanced Super Dimension Switch) technology. This technology enhances color consistency across viewing angles and reduces color shift[1]. BOE also employs AI-driven color calibration algorithms to optimize each pixel's color output, ensuring uniform color representation across the entire display[2]. Their latest AMOLED panels incorporate a novel pixel compensation circuit that mitigates the effects of OLED degradation over time, maintaining color consistency throughout the display's lifespan[3].

Strengths: Industry-leading AMOLED technology, large-scale production capabilities, and continuous innovation in color management. Weaknesses: Potential higher production costs due to advanced technologies, which may impact pricing competitiveness in some market segments.

Universal Display Corp.

Technical Solution: Universal Display Corporation (UDC) focuses on developing and commercializing phosphorescent OLED (PHOLED) technologies and materials. Their PHOLED technology significantly improves color consistency in AMOLED applications by offering more stable and efficient emitters[4]. UDC's latest generation of emitter materials provides enhanced color point accuracy and reduced color shift over the operational lifetime of AMOLED displays[5]. The company has also developed a novel blue PHOLED system that addresses one of the most challenging aspects of AMOLED color consistency - the differential aging of blue subpixels compared to red and green[6].

Strengths: Pioneering PHOLED technology, extensive patent portfolio, and strong partnerships with major display manufacturers. Weaknesses: Reliance on OLED market growth and potential vulnerability to alternative display technologies.

Core Innovations in AMOLED Color Management

Display panel, method for manufacturing display panel, and display device

PatentPendingUS20240324370A1

Innovation

- A display panel design featuring a functional film layer with a power source signal line layer, data line layer, and compensation functional layer, where the first light-emitting elements have an anode structure that overlaps with these layers to compensate for segment differences, ensuring flatness and preventing color cast.

Amoled double-side display

PatentActiveUS20200219957A1

Innovation

- An AMOLED double-sided display design featuring a substrate with alternating top-emitting and bottom-emitting OLED units, where the anode of top-emitting units is thicker and reflective, and the cathode of bottom-emitting units is thicker and light-transmissive, allowing for single IC control and eliminating mirrored images.

Environmental Impact of AMOLED Manufacturing

The manufacturing process of AMOLED displays has significant environmental implications that warrant careful consideration. The production of these advanced displays involves complex processes and materials that can have both direct and indirect environmental impacts.

One of the primary environmental concerns in AMOLED manufacturing is the use of organic materials. These materials, while essential for the display's functionality, often require energy-intensive synthesis processes and may involve the use of potentially hazardous chemicals. The disposal of waste materials from these processes must be carefully managed to prevent soil and water contamination.

Energy consumption is another critical factor in the environmental impact of AMOLED production. The manufacturing process, particularly the deposition of organic layers and the creation of thin-film transistors, requires substantial amounts of electricity. This high energy demand contributes to increased carbon emissions if the energy source is not renewable.

Water usage in AMOLED manufacturing is also a significant environmental consideration. The production process requires ultra-pure water for cleaning and processing, which can strain local water resources, especially in water-scarce regions. The treatment and disposal of wastewater from these processes must be carefully managed to prevent pollution.

The use of rare earth elements in AMOLED displays presents another environmental challenge. The extraction and processing of these materials can have severe environmental consequences, including habitat destruction and the generation of toxic waste. As demand for AMOLED displays grows, the pressure on these limited resources intensifies.

However, it's important to note that AMOLED technology also offers some environmental benefits. These displays are generally more energy-efficient in operation compared to traditional LCD screens, potentially reducing the overall energy consumption of devices over their lifetime. Additionally, the thin and flexible nature of AMOLED displays can lead to more compact device designs, potentially reducing material usage in the final products.

Manufacturers are increasingly aware of these environmental challenges and are implementing strategies to mitigate their impact. This includes investing in more efficient production processes, developing recycling programs for AMOLED displays, and researching alternative materials that could reduce the environmental footprint of production.

As the demand for AMOLED displays continues to grow, balancing technological advancement with environmental responsibility will be crucial. Ongoing research and development efforts are focused on finding more sustainable manufacturing methods and materials, aiming to reduce the environmental impact while maintaining the high performance and color consistency that AMOLED displays are known for.

One of the primary environmental concerns in AMOLED manufacturing is the use of organic materials. These materials, while essential for the display's functionality, often require energy-intensive synthesis processes and may involve the use of potentially hazardous chemicals. The disposal of waste materials from these processes must be carefully managed to prevent soil and water contamination.

Energy consumption is another critical factor in the environmental impact of AMOLED production. The manufacturing process, particularly the deposition of organic layers and the creation of thin-film transistors, requires substantial amounts of electricity. This high energy demand contributes to increased carbon emissions if the energy source is not renewable.

Water usage in AMOLED manufacturing is also a significant environmental consideration. The production process requires ultra-pure water for cleaning and processing, which can strain local water resources, especially in water-scarce regions. The treatment and disposal of wastewater from these processes must be carefully managed to prevent pollution.

The use of rare earth elements in AMOLED displays presents another environmental challenge. The extraction and processing of these materials can have severe environmental consequences, including habitat destruction and the generation of toxic waste. As demand for AMOLED displays grows, the pressure on these limited resources intensifies.

However, it's important to note that AMOLED technology also offers some environmental benefits. These displays are generally more energy-efficient in operation compared to traditional LCD screens, potentially reducing the overall energy consumption of devices over their lifetime. Additionally, the thin and flexible nature of AMOLED displays can lead to more compact device designs, potentially reducing material usage in the final products.

Manufacturers are increasingly aware of these environmental challenges and are implementing strategies to mitigate their impact. This includes investing in more efficient production processes, developing recycling programs for AMOLED displays, and researching alternative materials that could reduce the environmental footprint of production.

As the demand for AMOLED displays continues to grow, balancing technological advancement with environmental responsibility will be crucial. Ongoing research and development efforts are focused on finding more sustainable manufacturing methods and materials, aiming to reduce the environmental impact while maintaining the high performance and color consistency that AMOLED displays are known for.

User Experience and Color Perception in AMOLED

Color consistency plays a crucial role in shaping user experience and perception in AMOLED applications. The human visual system is highly sensitive to color variations, and inconsistencies can significantly impact the overall quality of displayed content. AMOLED displays, known for their vibrant colors and deep blacks, require careful calibration to ensure uniform color reproduction across the entire screen.

Users interact with AMOLED displays in various lighting conditions, from bright outdoor environments to dimly lit rooms. Color consistency becomes particularly important in these diverse scenarios, as it affects the legibility of text, the accuracy of image representation, and the overall aesthetic appeal of the interface. Inconsistent colors can lead to eye strain, reduced readability, and a diminished sense of product quality.

In the context of mobile devices, where AMOLED displays are commonly used, color consistency is essential for maintaining brand identity and user trust. Applications and user interfaces rely on specific color schemes to convey information and evoke emotional responses. Any deviation from the intended colors can disrupt the user's expectations and potentially lead to misinterpretation of visual cues.

The perception of color on AMOLED displays is influenced by various factors, including the display's color gamut, white point, and gamma curve. These parameters must be carefully calibrated to ensure accurate color reproduction across different devices and viewing conditions. Additionally, the organic nature of AMOLED pixels makes them susceptible to aging and burn-in effects, which can further impact color consistency over time.

To address these challenges, manufacturers and developers employ various techniques to maintain color consistency. These include factory calibration, software-based color management systems, and adaptive display technologies that adjust color parameters based on ambient lighting conditions. User-facing features, such as color temperature adjustments and display modes, also allow individuals to customize their viewing experience and compensate for any perceived inconsistencies.

The importance of color consistency extends beyond individual applications to the entire device ecosystem. Operating systems and system-wide UI elements must maintain consistent colors across different screens and applications to provide a cohesive user experience. This requires collaboration between hardware manufacturers, software developers, and content creators to establish and adhere to color standards that ensure uniformity across the AMOLED display ecosystem.

Users interact with AMOLED displays in various lighting conditions, from bright outdoor environments to dimly lit rooms. Color consistency becomes particularly important in these diverse scenarios, as it affects the legibility of text, the accuracy of image representation, and the overall aesthetic appeal of the interface. Inconsistent colors can lead to eye strain, reduced readability, and a diminished sense of product quality.

In the context of mobile devices, where AMOLED displays are commonly used, color consistency is essential for maintaining brand identity and user trust. Applications and user interfaces rely on specific color schemes to convey information and evoke emotional responses. Any deviation from the intended colors can disrupt the user's expectations and potentially lead to misinterpretation of visual cues.

The perception of color on AMOLED displays is influenced by various factors, including the display's color gamut, white point, and gamma curve. These parameters must be carefully calibrated to ensure accurate color reproduction across different devices and viewing conditions. Additionally, the organic nature of AMOLED pixels makes them susceptible to aging and burn-in effects, which can further impact color consistency over time.

To address these challenges, manufacturers and developers employ various techniques to maintain color consistency. These include factory calibration, software-based color management systems, and adaptive display technologies that adjust color parameters based on ambient lighting conditions. User-facing features, such as color temperature adjustments and display modes, also allow individuals to customize their viewing experience and compensate for any perceived inconsistencies.

The importance of color consistency extends beyond individual applications to the entire device ecosystem. Operating systems and system-wide UI elements must maintain consistent colors across different screens and applications to provide a cohesive user experience. This requires collaboration between hardware manufacturers, software developers, and content creators to establish and adhere to color standards that ensure uniformity across the AMOLED display ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!