How AMOLED improves energy efficiency in flexible screens?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Flexible Screen Evolution

The evolution of AMOLED flexible screens represents a significant leap in display technology, particularly in terms of energy efficiency. This progression can be traced through several key developmental stages, each marked by notable technological advancements and innovative solutions.

In the early 2000s, the first generation of AMOLED displays emerged, primarily focusing on rigid screens. These initial iterations demonstrated the potential for improved color reproduction and contrast compared to traditional LCD technology. However, they were limited by high production costs and energy consumption issues.

The mid-2000s saw the introduction of more efficient AMOLED designs, incorporating better organic materials and refined manufacturing processes. This period marked the beginning of serious research into flexible AMOLED technology, with prototypes showcasing the possibility of bendable displays.

By the early 2010s, the first commercially viable flexible AMOLED screens were introduced. These displays utilized plastic substrates instead of glass, allowing for a degree of flexibility while maintaining the superior visual qualities of AMOLED technology. However, energy efficiency remained a challenge, with these early flexible screens often consuming more power than their rigid counterparts.

The mid-2010s brought about a significant breakthrough in energy efficiency for flexible AMOLED screens. Manufacturers developed new pixel architectures and implemented advanced power management systems. These innovations allowed for more precise control over individual pixels, reducing overall power consumption without compromising display quality.

Recent years have seen the integration of AI-driven algorithms and advanced materials science in flexible AMOLED technology. These developments have further enhanced energy efficiency by optimizing pixel usage based on displayed content and ambient lighting conditions. Additionally, the introduction of more efficient organic compounds has reduced the power required for light emission.

The latest generation of flexible AMOLED screens, emerging in the late 2010s and early 2020s, has achieved remarkable improvements in energy efficiency. These displays incorporate ultra-thin film transistors and advanced OLED materials that operate at lower voltages. Combined with sophisticated power management circuits, these innovations have resulted in flexible screens that consume significantly less energy than their predecessors while offering enhanced flexibility and durability.

Looking forward, the evolution of AMOLED flexible screens continues to focus on pushing the boundaries of energy efficiency. Research is ongoing into new organic materials with higher luminous efficacy, as well as more advanced pixel structures that can further reduce power consumption. The integration of energy harvesting technologies and the development of self-powered flexible displays represent exciting frontiers in this evolving field.

In the early 2000s, the first generation of AMOLED displays emerged, primarily focusing on rigid screens. These initial iterations demonstrated the potential for improved color reproduction and contrast compared to traditional LCD technology. However, they were limited by high production costs and energy consumption issues.

The mid-2000s saw the introduction of more efficient AMOLED designs, incorporating better organic materials and refined manufacturing processes. This period marked the beginning of serious research into flexible AMOLED technology, with prototypes showcasing the possibility of bendable displays.

By the early 2010s, the first commercially viable flexible AMOLED screens were introduced. These displays utilized plastic substrates instead of glass, allowing for a degree of flexibility while maintaining the superior visual qualities of AMOLED technology. However, energy efficiency remained a challenge, with these early flexible screens often consuming more power than their rigid counterparts.

The mid-2010s brought about a significant breakthrough in energy efficiency for flexible AMOLED screens. Manufacturers developed new pixel architectures and implemented advanced power management systems. These innovations allowed for more precise control over individual pixels, reducing overall power consumption without compromising display quality.

Recent years have seen the integration of AI-driven algorithms and advanced materials science in flexible AMOLED technology. These developments have further enhanced energy efficiency by optimizing pixel usage based on displayed content and ambient lighting conditions. Additionally, the introduction of more efficient organic compounds has reduced the power required for light emission.

The latest generation of flexible AMOLED screens, emerging in the late 2010s and early 2020s, has achieved remarkable improvements in energy efficiency. These displays incorporate ultra-thin film transistors and advanced OLED materials that operate at lower voltages. Combined with sophisticated power management circuits, these innovations have resulted in flexible screens that consume significantly less energy than their predecessors while offering enhanced flexibility and durability.

Looking forward, the evolution of AMOLED flexible screens continues to focus on pushing the boundaries of energy efficiency. Research is ongoing into new organic materials with higher luminous efficacy, as well as more advanced pixel structures that can further reduce power consumption. The integration of energy harvesting technologies and the development of self-powered flexible displays represent exciting frontiers in this evolving field.

Energy Efficiency Market Demand

The demand for energy-efficient flexible screens has been steadily increasing in recent years, driven by the growing market for mobile devices, wearables, and emerging applications in automotive and smart home sectors. Consumers are increasingly prioritizing devices with longer battery life and improved power management, making energy efficiency a critical factor in product development and market competitiveness.

AMOLED technology has emerged as a key player in addressing this market demand, offering significant advantages in energy efficiency for flexible displays. The self-emissive nature of AMOLED pixels allows for selective pixel illumination, resulting in substantial power savings compared to traditional LCD screens that require constant backlighting. This feature is particularly beneficial for mobile devices and wearables, where battery life is a crucial selling point.

The automotive industry has also shown increasing interest in energy-efficient flexible AMOLED displays for in-vehicle infotainment systems and digital dashboards. As vehicles become more electrified and autonomous, the need for power-efficient, adaptable displays that can conform to various interior surfaces has grown substantially. AMOLED technology's ability to deliver high contrast ratios and deep blacks while consuming less power aligns well with the automotive sector's requirements for both aesthetics and energy conservation.

In the smart home market, energy-efficient flexible AMOLED displays are gaining traction for applications such as smart mirrors, curved televisions, and interactive home control panels. Consumers are increasingly conscious of their overall energy consumption, and the adoption of power-efficient display technologies contributes to the broader trend of creating more sustainable and eco-friendly living spaces.

The wearable technology sector, including smartwatches and fitness trackers, has been a significant driver of demand for energy-efficient flexible displays. These devices often have limited battery capacity due to their compact form factors, making power efficiency a critical consideration. AMOLED's ability to provide vibrant, always-on displays while minimizing power consumption has made it a preferred choice for many wearable device manufacturers.

As the Internet of Things (IoT) continues to expand, the demand for energy-efficient flexible displays in various connected devices is expected to grow. From smart appliances to industrial control panels, the need for displays that can provide clear information while minimizing power draw is becoming increasingly important across multiple sectors.

The market demand for energy-efficient flexible screens is also influenced by regulatory pressures and environmental concerns. Governments worldwide are implementing stricter energy efficiency standards for electronic devices, encouraging manufacturers to adopt technologies like AMOLED that can help meet these requirements while delivering superior performance.

AMOLED technology has emerged as a key player in addressing this market demand, offering significant advantages in energy efficiency for flexible displays. The self-emissive nature of AMOLED pixels allows for selective pixel illumination, resulting in substantial power savings compared to traditional LCD screens that require constant backlighting. This feature is particularly beneficial for mobile devices and wearables, where battery life is a crucial selling point.

The automotive industry has also shown increasing interest in energy-efficient flexible AMOLED displays for in-vehicle infotainment systems and digital dashboards. As vehicles become more electrified and autonomous, the need for power-efficient, adaptable displays that can conform to various interior surfaces has grown substantially. AMOLED technology's ability to deliver high contrast ratios and deep blacks while consuming less power aligns well with the automotive sector's requirements for both aesthetics and energy conservation.

In the smart home market, energy-efficient flexible AMOLED displays are gaining traction for applications such as smart mirrors, curved televisions, and interactive home control panels. Consumers are increasingly conscious of their overall energy consumption, and the adoption of power-efficient display technologies contributes to the broader trend of creating more sustainable and eco-friendly living spaces.

The wearable technology sector, including smartwatches and fitness trackers, has been a significant driver of demand for energy-efficient flexible displays. These devices often have limited battery capacity due to their compact form factors, making power efficiency a critical consideration. AMOLED's ability to provide vibrant, always-on displays while minimizing power consumption has made it a preferred choice for many wearable device manufacturers.

As the Internet of Things (IoT) continues to expand, the demand for energy-efficient flexible displays in various connected devices is expected to grow. From smart appliances to industrial control panels, the need for displays that can provide clear information while minimizing power draw is becoming increasingly important across multiple sectors.

The market demand for energy-efficient flexible screens is also influenced by regulatory pressures and environmental concerns. Governments worldwide are implementing stricter energy efficiency standards for electronic devices, encouraging manufacturers to adopt technologies like AMOLED that can help meet these requirements while delivering superior performance.

AMOLED Tech Challenges

AMOLED technology, while offering significant advantages in display quality and energy efficiency, faces several technical challenges in its implementation for flexible screens. One of the primary hurdles is the development of flexible substrates that can withstand repeated bending without compromising the integrity of the OLED layers. Traditional glass substrates are rigid and brittle, necessitating the use of plastic or metal foils that must maintain their flexibility while providing a smooth surface for OLED deposition.

Another significant challenge lies in the encapsulation of OLED devices on flexible substrates. OLEDs are highly sensitive to moisture and oxygen, which can rapidly degrade their performance and lifespan. Conventional rigid glass encapsulation techniques are not suitable for flexible displays, requiring the development of new thin-film encapsulation methods that can provide adequate protection while maintaining flexibility.

The fabrication of thin-film transistors (TFTs) on flexible substrates presents additional complications. These TFTs are crucial for driving the OLED pixels, but their performance can be affected by mechanical stress during bending. Researchers are exploring low-temperature polycrystalline silicon (LTPS) and oxide semiconductor technologies to create TFTs that can maintain stable electrical characteristics under flexing conditions.

Thermal management is another critical issue in flexible AMOLED displays. The heat generated during operation can cause localized expansion and contraction, potentially leading to delamination or cracking of the OLED layers. Developing efficient heat dissipation mechanisms that work within the constraints of a flexible form factor is essential for ensuring long-term reliability.

The uniformity of OLED emission across a flexible surface poses yet another challenge. Bending the display can cause variations in the electrical and optical properties of the OLEDs, resulting in non-uniform brightness and color. Compensation algorithms and advanced pixel designs are being investigated to mitigate these effects and maintain consistent image quality regardless of the display's curvature.

Lastly, scaling up the manufacturing process for flexible AMOLED displays presents significant hurdles. Current production methods for rigid OLED panels must be adapted to handle flexible substrates without compromising yield or increasing costs prohibitively. This requires innovations in handling equipment, deposition techniques, and quality control processes throughout the manufacturing line.

Another significant challenge lies in the encapsulation of OLED devices on flexible substrates. OLEDs are highly sensitive to moisture and oxygen, which can rapidly degrade their performance and lifespan. Conventional rigid glass encapsulation techniques are not suitable for flexible displays, requiring the development of new thin-film encapsulation methods that can provide adequate protection while maintaining flexibility.

The fabrication of thin-film transistors (TFTs) on flexible substrates presents additional complications. These TFTs are crucial for driving the OLED pixels, but their performance can be affected by mechanical stress during bending. Researchers are exploring low-temperature polycrystalline silicon (LTPS) and oxide semiconductor technologies to create TFTs that can maintain stable electrical characteristics under flexing conditions.

Thermal management is another critical issue in flexible AMOLED displays. The heat generated during operation can cause localized expansion and contraction, potentially leading to delamination or cracking of the OLED layers. Developing efficient heat dissipation mechanisms that work within the constraints of a flexible form factor is essential for ensuring long-term reliability.

The uniformity of OLED emission across a flexible surface poses yet another challenge. Bending the display can cause variations in the electrical and optical properties of the OLEDs, resulting in non-uniform brightness and color. Compensation algorithms and advanced pixel designs are being investigated to mitigate these effects and maintain consistent image quality regardless of the display's curvature.

Lastly, scaling up the manufacturing process for flexible AMOLED displays presents significant hurdles. Current production methods for rigid OLED panels must be adapted to handle flexible substrates without compromising yield or increasing costs prohibitively. This requires innovations in handling equipment, deposition techniques, and quality control processes throughout the manufacturing line.

Current AMOLED Energy Solutions

01 Pixel circuit optimization for energy efficiency

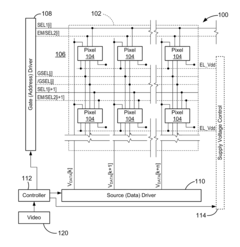

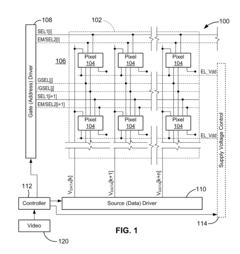

AMOLED displays can achieve improved energy efficiency through optimized pixel circuit designs. These designs may include advanced compensation techniques, reduced power consumption during operation, and enhanced control of pixel current. Such optimizations can lead to better overall display performance while minimizing power usage.- Pixel circuit optimization for energy efficiency: AMOLED displays can achieve improved energy efficiency through optimized pixel circuit designs. These designs may include advanced driving schemes, compensation circuits, and voltage control mechanisms that reduce power consumption while maintaining display quality.

- Power management techniques: Various power management techniques are employed to enhance AMOLED energy efficiency. These may include adaptive brightness control, selective pixel activation, and intelligent power distribution systems that minimize energy waste during display operation.

- OLED material improvements: Advancements in OLED materials contribute to increased energy efficiency in AMOLED displays. This includes the development of high-efficiency emitters, improved charge transport layers, and novel electrode materials that enhance light output while reducing power consumption.

- Display driving and timing control: Efficient display driving and timing control methods are implemented to reduce power consumption in AMOLED displays. These techniques may involve optimized refresh rates, dynamic frame rate adjustment, and advanced scanning methods that minimize unnecessary pixel activations.

- Thermal management for efficiency: Thermal management strategies are employed to maintain optimal operating temperatures in AMOLED displays, which in turn improves energy efficiency. This may include heat dissipation techniques, temperature-sensitive driving schemes, and thermal feedback systems that prevent performance degradation due to overheating.

02 Power management techniques

Various power management techniques are employed to enhance AMOLED energy efficiency. These may include adaptive brightness control, selective pixel activation, and intelligent power distribution systems. By implementing these techniques, AMOLED displays can significantly reduce energy consumption without compromising image quality.Expand Specific Solutions03 OLED material improvements

Advancements in OLED materials contribute to increased energy efficiency in AMOLED displays. This includes the development of more efficient emissive materials, improved electron transport layers, and enhanced hole injection layers. These material improvements result in higher luminous efficacy and lower power consumption.Expand Specific Solutions04 Driving scheme optimization

Innovative driving schemes are implemented to improve AMOLED energy efficiency. These may include advanced voltage programming methods, current-based driving techniques, and optimized refresh rates. By refining the way pixels are driven, power consumption can be reduced while maintaining or enhancing display performance.Expand Specific Solutions05 Thermal management for efficiency

Effective thermal management strategies are crucial for maintaining AMOLED energy efficiency. This includes implementing heat dissipation techniques, temperature-compensated driving methods, and thermal feedback systems. By managing heat generation and dissipation, AMOLED displays can operate more efficiently and with improved longevity.Expand Specific Solutions

Key AMOLED Manufacturers

The AMOLED technology for flexible screens is in a mature growth stage, with significant market adoption and ongoing innovation. The global flexible display market is projected to reach substantial size, driven by increasing demand for smartphones, wearables, and automotive applications. Technologically, AMOLED has reached a high level of maturity, with key players like Samsung Display, LG Display, and BOE Technology leading in production capabilities and efficiency improvements. Companies such as Visionox, Tianma, and Everdisplay Optronics are also making strides in AMOLED development, focusing on energy efficiency enhancements. The competitive landscape is characterized by intense R&D efforts to further improve power consumption and display quality in flexible AMOLED screens.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in AMOLED technology for flexible screens, focusing on energy efficiency. They have developed a proprietary OLED light-emitting layer material that improves luminous efficiency by up to 20%[4]. BOE's flexible AMOLED displays incorporate advanced pixel circuits that reduce power consumption during both active and standby modes. They have also implemented a dynamic power management system that adjusts pixel brightness based on ambient light and displayed content, further optimizing energy usage[5]. Additionally, BOE has introduced a novel electrode structure that enhances charge carrier mobility, reducing the voltage required for display operation and thus improving overall energy efficiency[6].

Strengths: Large-scale production capabilities, strong presence in the Chinese market, and growing international partnerships. Weaknesses: Relatively newer to AMOLED technology compared to some competitors, potentially playing catch-up in some advanced features.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered AMOLED technology for flexible screens, focusing on energy efficiency improvements. Their latest AMOLED displays utilize advanced pixel structures and materials to reduce power consumption. They've implemented a variable refresh rate technology, allowing screens to adjust from 1Hz to 120Hz based on content, significantly reducing energy usage[1]. Samsung has also developed eco-OLED technology, which reduces power consumption by up to 25% compared to conventional OLED displays[2]. Their displays incorporate advanced organic materials and thin-film transistor (TFT) designs that minimize current leakage and improve electron mobility, further enhancing energy efficiency[3].

Strengths: Industry-leading AMOLED technology, extensive R&D capabilities, and a strong patent portfolio. Weaknesses: High production costs and potential supply chain dependencies for rare materials.

AMOLED Efficiency Innovations

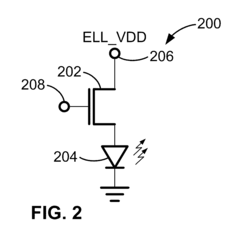

Lifetime uniformity parameter extraction methods

PatentActiveUS20110227964A1

Innovation

- A method and apparatus for evaluating OLED display pixel status by generating a sequence of patterns using discrete cosine transformations, wavelet transformations, or principal component analysis, sensing responses, and deriving a matrix of status values to apply correction signals, allowing for real-time diagnostic tools to improve display uniformity and lifetime.

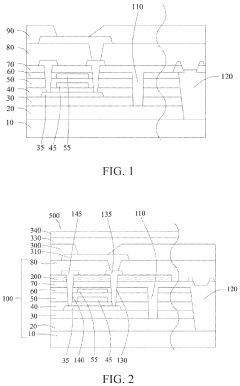

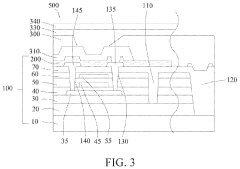

Array substrate and display panel

PatentInactiveUS20210391399A1

Innovation

- Incorporating a hydrophilicity-hydrophobicity matching layer, made of inorganic materials like silicon oxide or silicon nitride, between the organic filling layer and the sources and drains to prevent the formation of fluorine-carbon bonds, thereby enhancing the adhesion between the organic filling layer and the planarization layer.

Environmental Impact

The environmental impact of AMOLED technology in flexible screens is a crucial consideration in the context of energy efficiency improvements. AMOLED displays offer significant advantages in reducing power consumption, which directly translates to lower energy usage and, consequently, a reduced carbon footprint. This technology's ability to selectively illuminate individual pixels results in substantial energy savings, particularly when displaying darker content or using dark mode interfaces.

The manufacturing process of AMOLED displays has also seen advancements that contribute to environmental sustainability. Compared to traditional LCD screens, AMOLED production typically requires fewer materials and chemicals, potentially reducing the overall environmental impact of screen manufacturing. Additionally, the thin and flexible nature of AMOLED displays allows for more efficient use of materials, potentially decreasing waste in the production process.

The longevity and durability of AMOLED screens in flexible devices can also contribute to reduced electronic waste. As these displays are less prone to damage from bending and folding, they may have a longer lifespan, reducing the frequency of device replacements and subsequently minimizing e-waste generation. This aspect is particularly important given the growing concern over electronic waste and its environmental consequences.

Furthermore, the energy efficiency of AMOLED technology in flexible screens can lead to extended battery life in mobile devices. This improvement not only enhances user experience but also has potential environmental benefits. Longer-lasting batteries mean less frequent charging, which can result in reduced overall energy consumption. Additionally, it may lead to a decrease in battery replacements, further minimizing electronic waste.

However, it is important to note that the environmental impact of AMOLED technology is not entirely positive. The production of AMOLED displays involves the use of rare earth elements and other precious materials, which can have significant environmental implications in terms of mining and processing. The challenge lies in balancing the energy efficiency gains with the environmental costs associated with material extraction and manufacturing processes.

In conclusion, while AMOLED technology in flexible screens offers substantial improvements in energy efficiency and potential reductions in electronic waste, a holistic approach is necessary to fully assess its environmental impact. Future developments in this technology should focus not only on enhancing energy efficiency but also on improving the sustainability of the entire lifecycle, from production to disposal.

The manufacturing process of AMOLED displays has also seen advancements that contribute to environmental sustainability. Compared to traditional LCD screens, AMOLED production typically requires fewer materials and chemicals, potentially reducing the overall environmental impact of screen manufacturing. Additionally, the thin and flexible nature of AMOLED displays allows for more efficient use of materials, potentially decreasing waste in the production process.

The longevity and durability of AMOLED screens in flexible devices can also contribute to reduced electronic waste. As these displays are less prone to damage from bending and folding, they may have a longer lifespan, reducing the frequency of device replacements and subsequently minimizing e-waste generation. This aspect is particularly important given the growing concern over electronic waste and its environmental consequences.

Furthermore, the energy efficiency of AMOLED technology in flexible screens can lead to extended battery life in mobile devices. This improvement not only enhances user experience but also has potential environmental benefits. Longer-lasting batteries mean less frequent charging, which can result in reduced overall energy consumption. Additionally, it may lead to a decrease in battery replacements, further minimizing electronic waste.

However, it is important to note that the environmental impact of AMOLED technology is not entirely positive. The production of AMOLED displays involves the use of rare earth elements and other precious materials, which can have significant environmental implications in terms of mining and processing. The challenge lies in balancing the energy efficiency gains with the environmental costs associated with material extraction and manufacturing processes.

In conclusion, while AMOLED technology in flexible screens offers substantial improvements in energy efficiency and potential reductions in electronic waste, a holistic approach is necessary to fully assess its environmental impact. Future developments in this technology should focus not only on enhancing energy efficiency but also on improving the sustainability of the entire lifecycle, from production to disposal.

AMOLED Manufacturing Process

The AMOLED manufacturing process is a complex and highly sophisticated procedure that involves multiple stages and cutting-edge technologies. The process begins with the preparation of a substrate, typically made of flexible plastic or ultra-thin glass, which forms the base of the display. This substrate is carefully cleaned and treated to ensure optimal adhesion of subsequent layers.

Next, a thin-film transistor (TFT) backplane is deposited onto the substrate. This layer consists of numerous transistors that control individual pixels, allowing for precise management of each OLED element. The TFT layer is created using low-temperature polycrystalline silicon (LTPS) or indium gallium zinc oxide (IGZO) technologies, which offer high electron mobility and low power consumption.

Following the TFT backplane, a planarization layer is applied to create a smooth surface for the subsequent OLED layers. This step is crucial for ensuring uniform light emission and preventing defects in the final display. The OLED layers are then deposited using a technique called vacuum thermal evaporation. This process involves heating organic materials in a vacuum chamber until they vaporize and condense onto the substrate, forming ultra-thin layers of hole transport, emission, and electron transport materials.

The cathode layer, typically made of a reflective metal such as aluminum, is then deposited on top of the OLED stack. This layer serves as the negative electrode and helps to enhance light output. To protect the sensitive organic materials from moisture and oxygen, which can degrade OLED performance, a thin-film encapsulation (TFE) layer is applied. This layer consists of alternating organic and inorganic materials that provide an effective barrier against environmental factors.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the highest standards of performance and reliability. Advanced inspection systems are used to detect defects at each stage, allowing for immediate corrections and minimizing waste. The entire process is carried out in cleanroom environments to prevent contamination that could compromise the display's functionality.

To enhance energy efficiency in flexible screens, AMOLED manufacturers have developed innovative techniques such as the use of phosphorescent materials, which offer higher internal quantum efficiency compared to fluorescent OLEDs. Additionally, the implementation of advanced pixel designs, such as pentile arrangements, allows for reduced power consumption while maintaining high display quality.

Next, a thin-film transistor (TFT) backplane is deposited onto the substrate. This layer consists of numerous transistors that control individual pixels, allowing for precise management of each OLED element. The TFT layer is created using low-temperature polycrystalline silicon (LTPS) or indium gallium zinc oxide (IGZO) technologies, which offer high electron mobility and low power consumption.

Following the TFT backplane, a planarization layer is applied to create a smooth surface for the subsequent OLED layers. This step is crucial for ensuring uniform light emission and preventing defects in the final display. The OLED layers are then deposited using a technique called vacuum thermal evaporation. This process involves heating organic materials in a vacuum chamber until they vaporize and condense onto the substrate, forming ultra-thin layers of hole transport, emission, and electron transport materials.

The cathode layer, typically made of a reflective metal such as aluminum, is then deposited on top of the OLED stack. This layer serves as the negative electrode and helps to enhance light output. To protect the sensitive organic materials from moisture and oxygen, which can degrade OLED performance, a thin-film encapsulation (TFE) layer is applied. This layer consists of alternating organic and inorganic materials that provide an effective barrier against environmental factors.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the highest standards of performance and reliability. Advanced inspection systems are used to detect defects at each stage, allowing for immediate corrections and minimizing waste. The entire process is carried out in cleanroom environments to prevent contamination that could compromise the display's functionality.

To enhance energy efficiency in flexible screens, AMOLED manufacturers have developed innovative techniques such as the use of phosphorescent materials, which offer higher internal quantum efficiency compared to fluorescent OLEDs. Additionally, the implementation of advanced pixel designs, such as pentile arrangements, allows for reduced power consumption while maintaining high display quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!