How Battery Acid Catalyzes the Formation of Lead Sulfate

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lead-Acid Battery Fundamentals and Objectives

Lead-acid batteries have been a cornerstone of energy storage technology for over 150 years, playing a crucial role in various applications from automotive to backup power systems. The fundamental principle behind these batteries lies in the reversible chemical reaction between lead, lead dioxide, and sulfuric acid. Understanding this process is essential for improving battery performance and longevity.

The primary objective of studying how battery acid catalyzes the formation of lead sulfate is to optimize the efficiency and lifespan of lead-acid batteries. By comprehending the intricacies of this reaction, researchers and engineers can develop strategies to mitigate sulfation, a common cause of battery failure. This knowledge is particularly valuable as the demand for reliable energy storage solutions continues to grow in sectors such as renewable energy and electric vehicles.

The evolution of lead-acid battery technology has been marked by incremental improvements in electrode design, electrolyte composition, and manufacturing processes. Recent advancements have focused on enhancing charge acceptance, reducing water loss, and improving cycle life. These developments aim to address the limitations of traditional lead-acid batteries while leveraging their established manufacturing infrastructure and recyclability.

As we delve into the catalytic role of battery acid in lead sulfate formation, it is important to consider the broader context of electrochemical energy storage. The insights gained from this study can potentially inform the development of next-generation battery technologies, bridging the gap between conventional lead-acid systems and emerging alternatives such as lithium-ion batteries.

The technical goals of this investigation include elucidating the kinetics of lead sulfate formation, identifying factors that influence the rate and reversibility of the reaction, and exploring methods to control the morphology of lead sulfate crystals. By achieving these objectives, we can pave the way for innovative approaches to battery management and design, ultimately leading to more efficient and durable energy storage solutions.

The primary objective of studying how battery acid catalyzes the formation of lead sulfate is to optimize the efficiency and lifespan of lead-acid batteries. By comprehending the intricacies of this reaction, researchers and engineers can develop strategies to mitigate sulfation, a common cause of battery failure. This knowledge is particularly valuable as the demand for reliable energy storage solutions continues to grow in sectors such as renewable energy and electric vehicles.

The evolution of lead-acid battery technology has been marked by incremental improvements in electrode design, electrolyte composition, and manufacturing processes. Recent advancements have focused on enhancing charge acceptance, reducing water loss, and improving cycle life. These developments aim to address the limitations of traditional lead-acid batteries while leveraging their established manufacturing infrastructure and recyclability.

As we delve into the catalytic role of battery acid in lead sulfate formation, it is important to consider the broader context of electrochemical energy storage. The insights gained from this study can potentially inform the development of next-generation battery technologies, bridging the gap between conventional lead-acid systems and emerging alternatives such as lithium-ion batteries.

The technical goals of this investigation include elucidating the kinetics of lead sulfate formation, identifying factors that influence the rate and reversibility of the reaction, and exploring methods to control the morphology of lead sulfate crystals. By achieving these objectives, we can pave the way for innovative approaches to battery management and design, ultimately leading to more efficient and durable energy storage solutions.

Market Analysis of Lead-Acid Battery Industry

The lead-acid battery industry has experienced steady growth over the past decade, driven by increasing demand for automotive batteries and backup power systems. The global market size for lead-acid batteries reached $39.7 billion in 2020 and is projected to grow at a CAGR of 4.7% from 2021 to 2028. This growth is primarily attributed to the rising automotive production, especially in emerging economies, and the expanding telecommunications sector requiring reliable backup power solutions.

The automotive sector remains the largest consumer of lead-acid batteries, accounting for approximately 60% of the total market share. The increasing number of vehicles on the road, coupled with the growing trend of start-stop technology in modern vehicles, continues to drive demand for lead-acid batteries. Additionally, the industrial sector, including uninterruptible power supply (UPS) systems and material handling equipment, represents a significant market segment with steady growth potential.

Geographically, Asia Pacific dominates the lead-acid battery market, with China being the largest producer and consumer. The region's rapid industrialization, expanding automotive industry, and increasing investments in renewable energy projects contribute to its market leadership. North America and Europe follow, with mature markets focusing on technological advancements and environmental regulations.

Despite the emergence of alternative battery technologies, lead-acid batteries maintain their market position due to their cost-effectiveness, reliability, and established recycling infrastructure. The recycling rate for lead-acid batteries exceeds 99% in many developed countries, making them one of the most recycled consumer products. This circular economy aspect provides a significant advantage in terms of sustainability and resource efficiency.

However, the industry faces challenges from stringent environmental regulations and the growing adoption of lithium-ion batteries in certain applications. To address these challenges, manufacturers are investing in research and development to improve the performance and lifespan of lead-acid batteries. Innovations such as advanced grid designs, carbon additives, and valve-regulated lead-acid (VRLA) technologies are enhancing the competitiveness of lead-acid batteries in various applications.

The market landscape is characterized by a mix of large multinational corporations and regional players. Key market players include Johnson Controls, Exide Technologies, EnerSys, and GS Yuasa Corporation. These companies are focusing on strategic partnerships, mergers and acquisitions, and product innovations to maintain their market positions and expand their global footprint.

The automotive sector remains the largest consumer of lead-acid batteries, accounting for approximately 60% of the total market share. The increasing number of vehicles on the road, coupled with the growing trend of start-stop technology in modern vehicles, continues to drive demand for lead-acid batteries. Additionally, the industrial sector, including uninterruptible power supply (UPS) systems and material handling equipment, represents a significant market segment with steady growth potential.

Geographically, Asia Pacific dominates the lead-acid battery market, with China being the largest producer and consumer. The region's rapid industrialization, expanding automotive industry, and increasing investments in renewable energy projects contribute to its market leadership. North America and Europe follow, with mature markets focusing on technological advancements and environmental regulations.

Despite the emergence of alternative battery technologies, lead-acid batteries maintain their market position due to their cost-effectiveness, reliability, and established recycling infrastructure. The recycling rate for lead-acid batteries exceeds 99% in many developed countries, making them one of the most recycled consumer products. This circular economy aspect provides a significant advantage in terms of sustainability and resource efficiency.

However, the industry faces challenges from stringent environmental regulations and the growing adoption of lithium-ion batteries in certain applications. To address these challenges, manufacturers are investing in research and development to improve the performance and lifespan of lead-acid batteries. Innovations such as advanced grid designs, carbon additives, and valve-regulated lead-acid (VRLA) technologies are enhancing the competitiveness of lead-acid batteries in various applications.

The market landscape is characterized by a mix of large multinational corporations and regional players. Key market players include Johnson Controls, Exide Technologies, EnerSys, and GS Yuasa Corporation. These companies are focusing on strategic partnerships, mergers and acquisitions, and product innovations to maintain their market positions and expand their global footprint.

Current Challenges in Lead Sulfate Formation

The formation of lead sulfate in lead-acid batteries presents several significant challenges that impact battery performance, longevity, and efficiency. One of the primary issues is the irreversible sulfation process, which occurs when lead sulfate crystals grow and harden on battery plates. This phenomenon reduces the battery's capacity and ability to accept a charge, ultimately leading to premature battery failure.

Another challenge lies in controlling the rate and uniformity of lead sulfate formation. Uneven distribution of lead sulfate across battery plates can result in localized areas of high resistance, causing hotspots and accelerated degradation. This non-uniform formation also contributes to reduced overall battery capacity and shortened lifespan.

The conversion of active material (lead and lead dioxide) to lead sulfate during discharge is accompanied by volume changes, which can lead to mechanical stress on battery components. Over time, this stress may cause plate warping, shedding of active material, and internal short circuits, further compromising battery performance and safety.

Temperature fluctuations pose an additional challenge in lead sulfate formation. At lower temperatures, the reaction kinetics slow down, potentially leading to incomplete conversion and reduced battery efficiency. Conversely, high temperatures can accelerate sulfation and other degradation processes, exacerbating the aforementioned issues.

The reversibility of the lead sulfate formation process is crucial for battery cycling. However, achieving complete reversibility during charging remains a challenge, particularly in deep-cycle applications or when batteries are left in a discharged state for extended periods. Incomplete reconversion of lead sulfate back to active materials results in capacity loss and decreased cycle life.

Electrolyte stratification is another concern related to lead sulfate formation. As the battery cycles, the electrolyte can become unevenly distributed, with higher concentrations of sulfuric acid settling at the bottom of the battery. This stratification affects the uniformity of the lead sulfate formation process and can lead to localized areas of accelerated corrosion and degradation.

Addressing these challenges requires innovative approaches in battery design, materials science, and charging strategies. Researchers are exploring advanced electrode materials, electrolyte additives, and novel cell architectures to mitigate sulfation and improve the overall performance of lead-acid batteries. Additionally, the development of smart charging algorithms and battery management systems aims to optimize the charging process and minimize the negative impacts of lead sulfate formation.

Another challenge lies in controlling the rate and uniformity of lead sulfate formation. Uneven distribution of lead sulfate across battery plates can result in localized areas of high resistance, causing hotspots and accelerated degradation. This non-uniform formation also contributes to reduced overall battery capacity and shortened lifespan.

The conversion of active material (lead and lead dioxide) to lead sulfate during discharge is accompanied by volume changes, which can lead to mechanical stress on battery components. Over time, this stress may cause plate warping, shedding of active material, and internal short circuits, further compromising battery performance and safety.

Temperature fluctuations pose an additional challenge in lead sulfate formation. At lower temperatures, the reaction kinetics slow down, potentially leading to incomplete conversion and reduced battery efficiency. Conversely, high temperatures can accelerate sulfation and other degradation processes, exacerbating the aforementioned issues.

The reversibility of the lead sulfate formation process is crucial for battery cycling. However, achieving complete reversibility during charging remains a challenge, particularly in deep-cycle applications or when batteries are left in a discharged state for extended periods. Incomplete reconversion of lead sulfate back to active materials results in capacity loss and decreased cycle life.

Electrolyte stratification is another concern related to lead sulfate formation. As the battery cycles, the electrolyte can become unevenly distributed, with higher concentrations of sulfuric acid settling at the bottom of the battery. This stratification affects the uniformity of the lead sulfate formation process and can lead to localized areas of accelerated corrosion and degradation.

Addressing these challenges requires innovative approaches in battery design, materials science, and charging strategies. Researchers are exploring advanced electrode materials, electrolyte additives, and novel cell architectures to mitigate sulfation and improve the overall performance of lead-acid batteries. Additionally, the development of smart charging algorithms and battery management systems aims to optimize the charging process and minimize the negative impacts of lead sulfate formation.

Existing Mechanisms of Lead Sulfate Formation

01 Formation of lead sulfate during battery discharge

During the discharge process of lead-acid batteries, lead sulfate is formed on both the positive and negative electrodes. This process involves the reaction of lead and lead dioxide with sulfuric acid, resulting in the formation of lead sulfate crystals. Understanding this mechanism is crucial for improving battery performance and longevity.- Formation of lead sulfate during battery discharge: During the discharge process of lead-acid batteries, lead sulfate is formed on the electrode plates. This process involves the reaction between the active materials (lead and lead dioxide) and the sulfuric acid electrolyte. Understanding this formation mechanism is crucial for improving battery performance and longevity.

- Prevention and control of lead sulfate formation: Various methods and additives are employed to prevent excessive lead sulfate formation and control its growth. These techniques aim to maintain battery capacity and extend its lifespan. Approaches include using specific electrolyte compositions, adding organic compounds, and implementing charging strategies to minimize sulfation.

- Recycling and regeneration of lead-acid batteries: Recycling processes have been developed to recover lead and other materials from spent lead-acid batteries. These methods often involve breaking down lead sulfate formations and converting them back into usable lead compounds. Advanced regeneration techniques aim to restore capacity in sulfated batteries by dissolving and redistributing lead sulfate crystals.

- Advanced electrode materials to mitigate sulfation: Research focuses on developing new electrode materials and coatings that can reduce lead sulfate formation or improve its reversibility. These materials aim to enhance the overall performance and cycle life of lead-acid batteries by addressing the sulfation issue at the electrode level.

- Monitoring and analysis of lead sulfate formation: Various techniques and devices have been developed to monitor and analyze the formation of lead sulfate in batteries. These methods help in understanding the sulfation process, assessing battery health, and optimizing charging strategies. Advanced sensors and analytical tools are employed to study the morphology and distribution of lead sulfate crystals.

02 Prevention and control of lead sulfate formation

Various methods and additives are employed to prevent or control excessive lead sulfate formation in batteries. These techniques aim to maintain battery capacity, extend cycle life, and improve overall performance. Strategies may include the use of specific electrolyte compositions, electrode treatments, or the addition of organic compounds to inhibit sulfation.Expand Specific Solutions03 Recycling and regeneration of lead-acid batteries

Recycling and regeneration processes for lead-acid batteries often involve addressing the issue of lead sulfate formation. These methods aim to convert lead sulfate back into active materials, thereby restoring battery capacity. Techniques may include chemical treatments, electrolytic processes, or the use of specialized equipment to break down sulfate crystals.Expand Specific Solutions04 Advanced electrode materials to mitigate sulfation

Research into advanced electrode materials focuses on developing compositions that are more resistant to lead sulfate formation or can better accommodate the sulfation process. These materials may include modified lead alloys, carbon-based additives, or nanostructured surfaces that aim to improve the reversibility of the sulfation reaction and maintain battery performance over time.Expand Specific Solutions05 Monitoring and analysis of lead sulfate formation

Techniques for monitoring and analyzing lead sulfate formation in batteries are essential for understanding battery health and predicting performance. These methods may include electrochemical impedance spectroscopy, X-ray diffraction, or advanced imaging techniques to assess the extent and nature of sulfation. Such analyses help in developing better maintenance strategies and improving battery design.Expand Specific Solutions

Key Players in Lead-Acid Battery Manufacturing

The battery acid catalysis of lead sulfate formation is a mature technology in the lead-acid battery industry, which is currently in a stable growth phase. The global lead-acid battery market size is projected to reach $52.5 billion by 2024, with a CAGR of 4.7%. Key players like Johnson Controls, GS Yuasa, and Chaowei Power Group dominate the market, leveraging their advanced research capabilities and extensive manufacturing experience. Emerging companies such as ArcActive and EVOQ Nano are introducing innovative technologies to enhance battery performance and lifespan. The technology's maturity is evident in its widespread application across automotive, industrial, and energy storage sectors, with ongoing research focused on improving efficiency and sustainability.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed advanced lead-acid battery technology that optimizes the formation of lead sulfate during discharge. Their approach involves using proprietary additives and electrode designs to control the size and distribution of lead sulfate crystals[1]. This results in improved charge acceptance and cycle life. The company has also implemented a micro-hybrid battery system that utilizes a start-stop functionality, reducing fuel consumption and CO2 emissions by up to 5%[2]. Additionally, Johnson Controls has invested in research on carbon additives to enhance the negative electrode, which helps in minimizing sulfation and improving battery performance[3].

Strengths: Extensive experience in lead-acid battery technology, large-scale manufacturing capabilities, and ongoing research in battery chemistry improvements. Weaknesses: Potential limitations in energy density compared to newer battery technologies, and environmental concerns associated with lead usage.

Chaowei Power Group Co., Ltd.

Technical Solution: Chaowei Power Group has made significant advancements in lead-acid battery technology, particularly in addressing the formation of lead sulfate. Their approach involves using nano-scale carbon additives to enhance the negative electrode's conductivity and surface area[7]. This helps in reducing sulfation and improving charge acceptance. The company has also developed a proprietary electrolyte formulation that includes organic compounds to modify the lead sulfate crystal structure, resulting in easier conversion back to lead during charging[8]. Chaowei's batteries feature a unique plate design that optimizes current distribution and minimizes areas prone to sulfation. Additionally, they have implemented advanced formation techniques that ensure uniform initial lead sulfate distribution, leading to improved battery performance and longevity[9].

Strengths: Strong focus on nano-technology applications in lead-acid batteries, large-scale production capabilities, and significant market presence in Asia. Weaknesses: Potential challenges in global market expansion and competition from established international brands.

Catalytic Role of Battery Acid in Lead Sulfate Formation

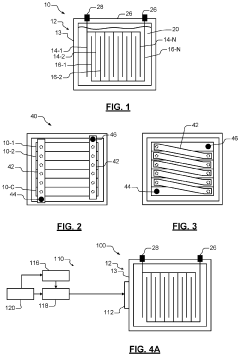

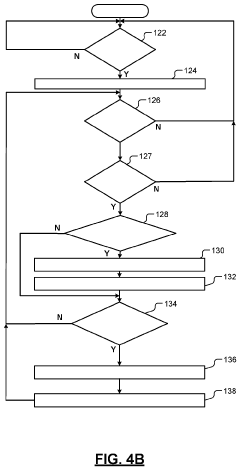

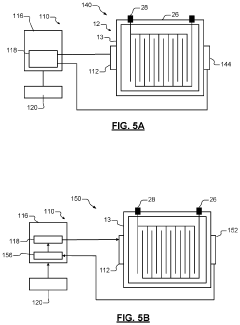

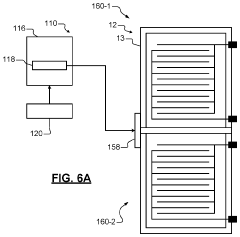

Desulfation of lead acid batteries using electrolyte agitator

PatentActiveUS20210399354A1

Innovation

- A battery maintenance system with an electrolyte agitator, utilizing a piezoelectric device and a controller to selectively agitate the electrolyte, either when the vehicle is parked or before starting, to prevent stratification and promote desulfation, combined with optional high voltage pulses and heating.

Desulfation of lead acid batteries using electrolyte agitator

PatentWO2020093359A1

Innovation

- The system addresses sulfation by preventing crystallization of lead sulfate, which is a major cause of battery capacity loss.

- The system tackles electrolyte stratification, which can reduce battery capacity and performance.

- An enclosure with multiple walls is used to house the battery maintenance system, potentially allowing for better control of the desulfation process.

Environmental Impact of Lead-Acid Batteries

The environmental impact of lead-acid batteries is a significant concern due to their widespread use and potential hazards. These batteries contain toxic materials, primarily lead and sulfuric acid, which can pose serious risks to ecosystems and human health if not properly managed throughout their lifecycle.

During the manufacturing process of lead-acid batteries, the production and handling of lead and sulfuric acid can result in emissions and waste that may contaminate air, water, and soil. Strict regulations and advanced manufacturing techniques have helped mitigate these risks, but the potential for environmental pollution remains a constant challenge for the industry.

The use phase of lead-acid batteries generally has minimal direct environmental impact when properly maintained. However, improper handling, accidental spills, or damage to the battery casing can release harmful substances into the environment. This is particularly concerning in automotive applications, where batteries may be exposed to harsh conditions or accidents.

The most significant environmental concerns arise at the end of a lead-acid battery's life cycle. Improper disposal can lead to severe contamination of soil and water resources. When batteries are discarded in landfills or incinerated, lead and other toxic components can leach into the surrounding environment, potentially entering the food chain and causing long-term ecological damage.

Recycling of lead-acid batteries is crucial for minimizing their environmental impact. Fortunately, lead-acid batteries are among the most recycled consumer products, with recycling rates exceeding 99% in many developed countries. The recycling process involves breaking down the batteries, separating the components, and recovering the lead and plastic for reuse. While this process significantly reduces the need for new raw materials, it still requires careful management to prevent environmental contamination during the recycling operations.

The sulfuric acid in lead-acid batteries also poses environmental challenges. When batteries are improperly disposed of or damaged, the acid can contaminate soil and water, altering pH levels and potentially harming aquatic life and vegetation. Proper neutralization and treatment of the acid are essential steps in the recycling and disposal processes to mitigate these risks.

Despite the environmental concerns, ongoing research and development in battery technology are focused on improving the sustainability of lead-acid batteries. This includes efforts to reduce the amount of lead used, enhance battery lifespan, and develop more efficient recycling processes. Additionally, the emergence of alternative battery technologies, such as lithium-ion batteries, is gradually reducing reliance on lead-acid batteries in some applications, potentially lessening their overall environmental impact in the long term.

During the manufacturing process of lead-acid batteries, the production and handling of lead and sulfuric acid can result in emissions and waste that may contaminate air, water, and soil. Strict regulations and advanced manufacturing techniques have helped mitigate these risks, but the potential for environmental pollution remains a constant challenge for the industry.

The use phase of lead-acid batteries generally has minimal direct environmental impact when properly maintained. However, improper handling, accidental spills, or damage to the battery casing can release harmful substances into the environment. This is particularly concerning in automotive applications, where batteries may be exposed to harsh conditions or accidents.

The most significant environmental concerns arise at the end of a lead-acid battery's life cycle. Improper disposal can lead to severe contamination of soil and water resources. When batteries are discarded in landfills or incinerated, lead and other toxic components can leach into the surrounding environment, potentially entering the food chain and causing long-term ecological damage.

Recycling of lead-acid batteries is crucial for minimizing their environmental impact. Fortunately, lead-acid batteries are among the most recycled consumer products, with recycling rates exceeding 99% in many developed countries. The recycling process involves breaking down the batteries, separating the components, and recovering the lead and plastic for reuse. While this process significantly reduces the need for new raw materials, it still requires careful management to prevent environmental contamination during the recycling operations.

The sulfuric acid in lead-acid batteries also poses environmental challenges. When batteries are improperly disposed of or damaged, the acid can contaminate soil and water, altering pH levels and potentially harming aquatic life and vegetation. Proper neutralization and treatment of the acid are essential steps in the recycling and disposal processes to mitigate these risks.

Despite the environmental concerns, ongoing research and development in battery technology are focused on improving the sustainability of lead-acid batteries. This includes efforts to reduce the amount of lead used, enhance battery lifespan, and develop more efficient recycling processes. Additionally, the emergence of alternative battery technologies, such as lithium-ion batteries, is gradually reducing reliance on lead-acid batteries in some applications, potentially lessening their overall environmental impact in the long term.

Recycling and Sustainability Strategies

The recycling and sustainability strategies for lead-acid batteries are crucial in addressing environmental concerns and resource conservation. The formation of lead sulfate during battery discharge presents both challenges and opportunities in this context. Recycling lead-acid batteries has become increasingly important due to the growing demand for energy storage solutions and the need to reduce the environmental impact of battery disposal.

One of the primary recycling strategies involves the collection and proper handling of used lead-acid batteries. This process typically begins with the segregation of batteries from other waste streams, followed by their transportation to specialized recycling facilities. These facilities employ advanced technologies to break down the batteries into their constituent components, including lead, plastic, and electrolyte solutions.

The lead components, including lead sulfate, are processed through smelting operations to recover pure lead. This recovered lead can then be used in the production of new batteries or other lead-based products, significantly reducing the need for primary lead mining. The plastic components, primarily polypropylene, are also recycled and repurposed for various applications, including new battery casings.

The sulfuric acid electrolyte presents a unique challenge in the recycling process. However, innovative techniques have been developed to neutralize and treat this acid, converting it into gypsum or sodium sulfate, which can be used in construction materials or other industrial processes. This approach not only eliminates a potential environmental hazard but also creates value from what was once considered waste.

Sustainability strategies in lead-acid battery production and use focus on extending battery life and improving overall efficiency. This includes the development of advanced grid designs and active material formulations that resist sulfation, the primary cause of battery degradation. By minimizing sulfation, batteries can maintain their capacity for longer periods, reducing the frequency of replacement and, consequently, the demand for new batteries.

Furthermore, research is ongoing to develop more environmentally friendly alternatives to traditional lead-acid batteries. These include the exploration of less toxic materials for electrodes and electrolytes, as well as the integration of smart charging technologies to optimize battery performance and longevity. Such innovations aim to reduce the environmental footprint of battery production and use while maintaining or improving energy storage capabilities.

The implementation of closed-loop manufacturing processes in battery production represents another significant sustainability strategy. This approach aims to minimize waste and maximize resource efficiency by incorporating recycled materials into new battery production. By doing so, manufacturers can reduce their reliance on raw materials and decrease the overall environmental impact of battery manufacturing.

One of the primary recycling strategies involves the collection and proper handling of used lead-acid batteries. This process typically begins with the segregation of batteries from other waste streams, followed by their transportation to specialized recycling facilities. These facilities employ advanced technologies to break down the batteries into their constituent components, including lead, plastic, and electrolyte solutions.

The lead components, including lead sulfate, are processed through smelting operations to recover pure lead. This recovered lead can then be used in the production of new batteries or other lead-based products, significantly reducing the need for primary lead mining. The plastic components, primarily polypropylene, are also recycled and repurposed for various applications, including new battery casings.

The sulfuric acid electrolyte presents a unique challenge in the recycling process. However, innovative techniques have been developed to neutralize and treat this acid, converting it into gypsum or sodium sulfate, which can be used in construction materials or other industrial processes. This approach not only eliminates a potential environmental hazard but also creates value from what was once considered waste.

Sustainability strategies in lead-acid battery production and use focus on extending battery life and improving overall efficiency. This includes the development of advanced grid designs and active material formulations that resist sulfation, the primary cause of battery degradation. By minimizing sulfation, batteries can maintain their capacity for longer periods, reducing the frequency of replacement and, consequently, the demand for new batteries.

Furthermore, research is ongoing to develop more environmentally friendly alternatives to traditional lead-acid batteries. These include the exploration of less toxic materials for electrodes and electrolytes, as well as the integration of smart charging technologies to optimize battery performance and longevity. Such innovations aim to reduce the environmental footprint of battery production and use while maintaining or improving energy storage capabilities.

The implementation of closed-loop manufacturing processes in battery production represents another significant sustainability strategy. This approach aims to minimize waste and maximize resource efficiency by incorporating recycled materials into new battery production. By doing so, manufacturers can reduce their reliance on raw materials and decrease the overall environmental impact of battery manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!