How Butane Contributes to the Enhancement of Blend Fuels

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Blend Fuels: Background and Objectives

Butane, a hydrocarbon with the formula C4H10, has played a significant role in the evolution of blend fuels. The journey of butane in fuel blending can be traced back to the early 20th century when the petroleum industry began exploring ways to improve fuel performance and efficiency. As automotive technologies advanced, the demand for higher-quality fuels grew, leading to the development of more sophisticated blending techniques.

The primary objective of incorporating butane into blend fuels is to enhance the overall performance and characteristics of the fuel mixture. Butane contributes to several key aspects of fuel quality, including octane rating, vapor pressure, and energy content. These properties directly impact engine performance, fuel economy, and emissions, making butane an essential component in modern fuel formulations.

Over the years, the role of butane in blend fuels has evolved in response to changing environmental regulations and automotive technologies. Stricter emission standards have necessitated the development of cleaner-burning fuels, while advancements in engine design have created a demand for fuels with specific performance characteristics. This has led to a more nuanced approach to fuel blending, with butane playing a crucial role in achieving the desired balance of properties.

The technology behind butane blending has also progressed significantly. From simple mixing techniques to sophisticated computer-controlled blending systems, the industry has continually refined its methods to optimize fuel composition. This technological evolution has enabled more precise control over fuel properties, allowing for the creation of tailored fuel blends that meet specific regional, seasonal, and regulatory requirements.

Looking ahead, the future of butane in blend fuels is closely tied to broader trends in the energy sector. As the world moves towards cleaner and more sustainable energy sources, the role of traditional hydrocarbon fuels is being reevaluated. However, butane's unique properties continue to make it a valuable component in the transition to cleaner fuels, particularly in the development of high-performance, low-emission blends.

The ongoing research and development in this field aim to further optimize the use of butane in fuel blends, focusing on maximizing its benefits while minimizing environmental impact. This includes exploring new blending techniques, investigating alternative additives that can work synergistically with butane, and developing advanced fuel formulations that can meet increasingly stringent performance and environmental standards.

The primary objective of incorporating butane into blend fuels is to enhance the overall performance and characteristics of the fuel mixture. Butane contributes to several key aspects of fuel quality, including octane rating, vapor pressure, and energy content. These properties directly impact engine performance, fuel economy, and emissions, making butane an essential component in modern fuel formulations.

Over the years, the role of butane in blend fuels has evolved in response to changing environmental regulations and automotive technologies. Stricter emission standards have necessitated the development of cleaner-burning fuels, while advancements in engine design have created a demand for fuels with specific performance characteristics. This has led to a more nuanced approach to fuel blending, with butane playing a crucial role in achieving the desired balance of properties.

The technology behind butane blending has also progressed significantly. From simple mixing techniques to sophisticated computer-controlled blending systems, the industry has continually refined its methods to optimize fuel composition. This technological evolution has enabled more precise control over fuel properties, allowing for the creation of tailored fuel blends that meet specific regional, seasonal, and regulatory requirements.

Looking ahead, the future of butane in blend fuels is closely tied to broader trends in the energy sector. As the world moves towards cleaner and more sustainable energy sources, the role of traditional hydrocarbon fuels is being reevaluated. However, butane's unique properties continue to make it a valuable component in the transition to cleaner fuels, particularly in the development of high-performance, low-emission blends.

The ongoing research and development in this field aim to further optimize the use of butane in fuel blends, focusing on maximizing its benefits while minimizing environmental impact. This includes exploring new blending techniques, investigating alternative additives that can work synergistically with butane, and developing advanced fuel formulations that can meet increasingly stringent performance and environmental standards.

Market Analysis of Butane-Enhanced Fuel Blends

The market for butane-enhanced fuel blends has shown significant growth in recent years, driven by increasing demand for high-performance and cost-effective fuel options. Butane, as a key component in these blends, contributes to improved engine performance, enhanced fuel efficiency, and reduced emissions, making it an attractive option for both consumers and manufacturers.

The global market for butane-enhanced fuel blends is projected to expand at a steady rate, with North America and Europe leading in adoption. These regions have well-established automotive industries and stringent environmental regulations, which have accelerated the development and implementation of advanced fuel technologies. Asia-Pacific is emerging as a rapidly growing market, particularly in countries like China and India, where increasing vehicle ownership and urbanization are driving demand for more efficient fuel options.

Consumer preferences play a crucial role in shaping the market landscape. There is a growing awareness among consumers about the benefits of butane-enhanced fuels, including improved engine performance and potential cost savings. This awareness has led to increased demand for premium fuel blends that incorporate butane as a key component.

The automotive industry's shift towards more fuel-efficient vehicles has also contributed to the market growth of butane-enhanced fuel blends. Manufacturers are increasingly focusing on developing engines that can optimize the use of these blends, further driving market expansion. Additionally, the rising popularity of high-performance vehicles in both developed and emerging markets has created a niche demand for premium fuel blends that offer enhanced power and efficiency.

Government regulations and environmental policies have had a significant impact on the market. Many countries have implemented stricter emissions standards, prompting fuel manufacturers to develop cleaner-burning fuel options. Butane-enhanced blends have emerged as a viable solution to meet these regulatory requirements while maintaining or improving vehicle performance.

The market is characterized by intense competition among major oil and gas companies, as well as specialized fuel blend manufacturers. These players are investing heavily in research and development to create innovative fuel formulations that maximize the benefits of butane addition. Collaborations between fuel manufacturers and automotive companies are becoming more common, aimed at developing optimized fuel-engine combinations.

Looking ahead, the market for butane-enhanced fuel blends is expected to continue its growth trajectory. Factors such as ongoing technological advancements, increasing environmental concerns, and the push for energy efficiency are likely to drive further innovation and adoption in this sector. However, challenges such as price volatility of butane and the gradual shift towards electric vehicles may impact the long-term market dynamics, necessitating continuous adaptation and innovation from industry players.

The global market for butane-enhanced fuel blends is projected to expand at a steady rate, with North America and Europe leading in adoption. These regions have well-established automotive industries and stringent environmental regulations, which have accelerated the development and implementation of advanced fuel technologies. Asia-Pacific is emerging as a rapidly growing market, particularly in countries like China and India, where increasing vehicle ownership and urbanization are driving demand for more efficient fuel options.

Consumer preferences play a crucial role in shaping the market landscape. There is a growing awareness among consumers about the benefits of butane-enhanced fuels, including improved engine performance and potential cost savings. This awareness has led to increased demand for premium fuel blends that incorporate butane as a key component.

The automotive industry's shift towards more fuel-efficient vehicles has also contributed to the market growth of butane-enhanced fuel blends. Manufacturers are increasingly focusing on developing engines that can optimize the use of these blends, further driving market expansion. Additionally, the rising popularity of high-performance vehicles in both developed and emerging markets has created a niche demand for premium fuel blends that offer enhanced power and efficiency.

Government regulations and environmental policies have had a significant impact on the market. Many countries have implemented stricter emissions standards, prompting fuel manufacturers to develop cleaner-burning fuel options. Butane-enhanced blends have emerged as a viable solution to meet these regulatory requirements while maintaining or improving vehicle performance.

The market is characterized by intense competition among major oil and gas companies, as well as specialized fuel blend manufacturers. These players are investing heavily in research and development to create innovative fuel formulations that maximize the benefits of butane addition. Collaborations between fuel manufacturers and automotive companies are becoming more common, aimed at developing optimized fuel-engine combinations.

Looking ahead, the market for butane-enhanced fuel blends is expected to continue its growth trajectory. Factors such as ongoing technological advancements, increasing environmental concerns, and the push for energy efficiency are likely to drive further innovation and adoption in this sector. However, challenges such as price volatility of butane and the gradual shift towards electric vehicles may impact the long-term market dynamics, necessitating continuous adaptation and innovation from industry players.

Current Challenges in Butane Blending Technology

The integration of butane into blend fuels presents several significant challenges that require careful consideration and innovative solutions. One of the primary issues is the volatility of butane, which can lead to vapor lock in fuel systems, especially in warmer climates or at higher altitudes. This volatility also contributes to increased evaporative emissions, posing environmental concerns and regulatory compliance challenges.

Another critical challenge lies in maintaining consistent fuel quality across different batches and seasons. Butane's properties can vary significantly based on its source and production method, making it difficult to achieve uniform blending results. This variability can affect the overall performance and efficiency of the blended fuel, potentially leading to engine issues and customer dissatisfaction.

The blending process itself presents technical hurdles. Achieving the optimal butane-to-gasoline ratio requires sophisticated blending equipment and precise control systems. Many existing refineries and blending facilities may need substantial upgrades to handle butane blending effectively, incurring significant capital expenditures.

Storage and transportation of butane for blending purposes also pose challenges. Butane's high vapor pressure necessitates specialized storage tanks and transportation methods to prevent leaks and ensure safety. This infrastructure requirement can be a barrier to entry for smaller fuel producers and distributors.

Regulatory compliance adds another layer of complexity to butane blending. Different regions have varying regulations regarding fuel composition, vapor pressure limits, and emissions standards. Blenders must navigate these regulatory landscapes while still maintaining fuel performance and cost-effectiveness, often requiring complex formulation adjustments based on geographic location and season.

The economic aspects of butane blending also present challenges. The price volatility of butane in the market can significantly impact the cost-effectiveness of blending operations. Blenders must constantly adjust their formulations and pricing strategies to maintain profitability while meeting quality standards.

Lastly, there are technical challenges related to the measurement and quality control of butane content in blended fuels. Accurate and reliable testing methods are crucial for ensuring compliance with specifications and regulations. However, existing testing methodologies may not always provide the level of precision required for optimal blending control, necessitating ongoing research and development in analytical techniques.

Addressing these challenges requires a multifaceted approach, combining advances in blending technology, improvements in infrastructure, and innovative regulatory strategies. As the demand for more efficient and environmentally friendly fuels continues to grow, overcoming these hurdles in butane blending technology will be crucial for the future of the fuel industry.

Another critical challenge lies in maintaining consistent fuel quality across different batches and seasons. Butane's properties can vary significantly based on its source and production method, making it difficult to achieve uniform blending results. This variability can affect the overall performance and efficiency of the blended fuel, potentially leading to engine issues and customer dissatisfaction.

The blending process itself presents technical hurdles. Achieving the optimal butane-to-gasoline ratio requires sophisticated blending equipment and precise control systems. Many existing refineries and blending facilities may need substantial upgrades to handle butane blending effectively, incurring significant capital expenditures.

Storage and transportation of butane for blending purposes also pose challenges. Butane's high vapor pressure necessitates specialized storage tanks and transportation methods to prevent leaks and ensure safety. This infrastructure requirement can be a barrier to entry for smaller fuel producers and distributors.

Regulatory compliance adds another layer of complexity to butane blending. Different regions have varying regulations regarding fuel composition, vapor pressure limits, and emissions standards. Blenders must navigate these regulatory landscapes while still maintaining fuel performance and cost-effectiveness, often requiring complex formulation adjustments based on geographic location and season.

The economic aspects of butane blending also present challenges. The price volatility of butane in the market can significantly impact the cost-effectiveness of blending operations. Blenders must constantly adjust their formulations and pricing strategies to maintain profitability while meeting quality standards.

Lastly, there are technical challenges related to the measurement and quality control of butane content in blended fuels. Accurate and reliable testing methods are crucial for ensuring compliance with specifications and regulations. However, existing testing methodologies may not always provide the level of precision required for optimal blending control, necessitating ongoing research and development in analytical techniques.

Addressing these challenges requires a multifaceted approach, combining advances in blending technology, improvements in infrastructure, and innovative regulatory strategies. As the demand for more efficient and environmentally friendly fuels continues to grow, overcoming these hurdles in butane blending technology will be crucial for the future of the fuel industry.

Existing Butane Blending Methodologies

01 Butane purification methods

Various techniques are employed to enhance the quality of butane through purification processes. These methods aim to remove impurities and improve the overall performance of butane for different applications. Purification can involve distillation, adsorption, or other separation techniques to achieve higher purity levels.- Butane purification methods: Various techniques are employed to enhance the quality of butane through purification processes. These methods aim to remove impurities and improve the overall performance of butane for different applications. Purification can involve distillation, adsorption, or other separation techniques to achieve higher purity levels.

- Butane fuel enhancement for lighters and torches: Innovations in butane fuel formulations and delivery systems for lighters and torches focus on improving ignition, flame stability, and overall performance. These enhancements may include adjusting the composition of the fuel mixture or modifying the design of the fuel release mechanism to optimize combustion efficiency.

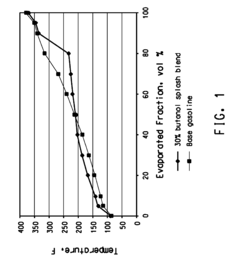

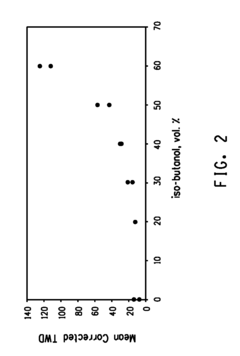

- Butane blending for improved fuel properties: Blending butane with other hydrocarbons or additives can enhance its properties as a fuel. This process aims to improve characteristics such as octane rating, volatility, or combustion efficiency. The resulting blends may offer better performance in various applications, including automotive fuels and industrial processes.

- Butane storage and dispensing systems: Advancements in butane storage and dispensing systems focus on improving safety, efficiency, and ease of use. These innovations may include enhanced valve designs, pressure regulation mechanisms, or smart dispensing technologies that optimize the handling and distribution of butane for various applications.

- Catalytic processes for butane conversion: Catalytic processes are developed to convert butane into higher-value products or to modify its properties. These processes may involve dehydrogenation, isomerization, or other chemical transformations that enhance the utility of butane in various industrial applications, potentially leading to more efficient use of this hydrocarbon resource.

02 Butane fuel enhancement for lighters and torches

Innovations in butane fuel formulations and delivery systems for lighters and torches focus on improving ignition, flame stability, and overall performance. These enhancements may include adjustments to fuel composition, nozzle design, or pressure regulation to optimize the burning characteristics of butane in portable flame devices.Expand Specific Solutions03 Butane blending for improved fuel properties

Blending butane with other hydrocarbons or additives can enhance its properties as a fuel. This process aims to improve characteristics such as octane rating, volatility, or combustion efficiency. The resulting blends may offer better performance in various applications, including automotive fuels and industrial processes.Expand Specific Solutions04 Butane storage and dispensing systems

Advancements in butane storage and dispensing systems focus on improving safety, efficiency, and ease of use. These innovations may include enhanced valve designs, pressure regulation mechanisms, or smart dispensing technologies that optimize the handling and distribution of butane for various applications.Expand Specific Solutions05 Butane as a refrigerant or propellant

Exploring the use of butane as an alternative refrigerant or propellant in various applications. This includes developing new formulations or systems that leverage butane's properties to enhance cooling efficiency or propellant performance while addressing environmental and safety concerns associated with traditional refrigerants and propellants.Expand Specific Solutions

Key Industry Players in Butane-Based Fuel Production

The market for butane-enhanced blend fuels is in a growth phase, driven by increasing demand for cleaner and more efficient fuel options. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with major players like DuPont de Nemours, Saudi Aramco, Shell, and Gevo leading innovation. These companies are investing heavily in research and development to improve butane blending techniques, optimize fuel performance, and reduce environmental impact. The involvement of energy giants and specialized biofuel firms indicates a maturing technology landscape, with ongoing efforts to enhance efficiency and scalability.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a proprietary technology called CONVERGE™ for enhancing blend fuels with butane. This process utilizes a novel catalytic system to convert butane into higher-value gasoline blending components. The technology enables the production of high-octane gasoline blendstocks from butane, improving fuel efficiency and reducing emissions. CONVERGE™ can increase gasoline pool octane by up to 3 numbers while maintaining fuel volatility within specifications[1]. The process also allows for the incorporation of up to 15% butane in the final gasoline blend, significantly higher than conventional blending limits[2].

Strengths: Increases octane rating without compromising fuel stability; Enables higher butane blending ratios; Improves refinery economics. Weaknesses: May require significant capital investment for implementation; Limited to gasoline blending applications.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an advanced butane blending technology called Shell Gasoline Efficiency Blend (GEB). This technology optimizes the use of butane in gasoline blends to enhance fuel efficiency and reduce emissions. The GEB process utilizes a proprietary algorithm that determines the optimal butane content based on various factors such as ambient temperature, fuel volatility requirements, and engine performance characteristics. Shell's research has shown that their GEB technology can improve fuel economy by up to 3% compared to standard gasoline blends[3]. Additionally, the process incorporates a unique additive package that works synergistically with butane to further enhance combustion efficiency and reduce deposit formation in engines[4].

Strengths: Improves fuel economy; Reduces emissions; Adaptable to varying environmental conditions. Weaknesses: May require specialized blending equipment; Effectiveness may vary depending on vehicle type and driving conditions.

Innovative Butane Incorporation Strategies

Butanol Compositions for Fuel Blending and Methods for the Production Thereof

PatentActiveUS20120247003A1

Innovation

- Development of butanol compositions that include an octane improving component and a vapor pressure adjustment component, allowing direct substitution for ethanol in fuel blends, which can be produced using existing equipment in ethanol production plants, enabling the creation of fuel blends that meet performance standards without modifying existing infrastructure.

Systems for decreasing excess octane during gasoline blending

PatentActiveUS11939210B1

Innovation

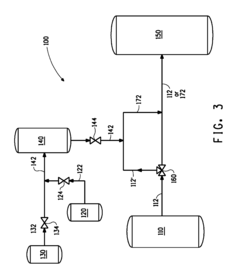

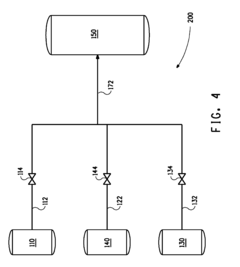

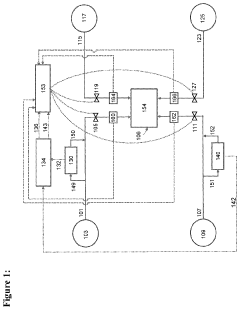

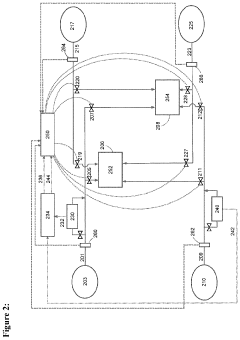

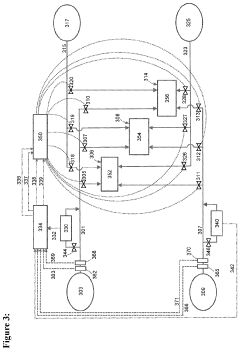

- A system comprising premium and regular octane pipes, butane and ethanol pipes, analyzer cells, and a programmable logic controller that continuously measures and calculates the blend ratios based on real-time octane and volatility data, using estimated values for ethanol and butane to optimize the blend and prevent excess octane, ensuring the produced gasoline meets specifications.

Environmental Impact of Butane in Fuel Blends

The environmental impact of butane in fuel blends is a critical consideration in the ongoing efforts to enhance blend fuels. Butane, as a component in fuel blends, contributes to both positive and negative environmental outcomes, necessitating a comprehensive analysis of its effects.

One of the primary environmental benefits of incorporating butane into fuel blends is its potential to reduce overall greenhouse gas emissions. When used in appropriate proportions, butane can improve the combustion efficiency of the fuel mixture, leading to more complete burning and fewer unburned hydrocarbons released into the atmosphere. This efficiency gain can result in a reduction of carbon dioxide emissions per unit of energy produced, contributing to climate change mitigation efforts.

However, the volatile nature of butane presents environmental challenges. Its high vapor pressure increases the likelihood of evaporative emissions, particularly during fuel storage and vehicle refueling processes. These emissions contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on air quality and human health in urban areas.

The use of butane in fuel blends also impacts the overall reactivity of vehicle exhaust emissions. While it can help reduce some pollutants, such as carbon monoxide, it may increase the formation of other harmful compounds, including certain types of particulate matter and nitrogen oxides. These pollutants are known to contribute to respiratory issues and can have long-term environmental consequences.

From a lifecycle perspective, the production and transportation of butane for fuel blending purposes also carry environmental implications. The extraction and processing of butane from natural gas or petroleum sources require energy inputs and can result in fugitive emissions. Additionally, the transportation of butane to blending facilities contributes to the overall carbon footprint of the fuel product.

It is important to note that the environmental impact of butane in fuel blends can vary significantly depending on factors such as blend composition, engine technology, and local environmental conditions. Regulatory frameworks play a crucial role in managing these impacts, with many jurisdictions implementing strict standards for fuel composition and emissions control.

As the automotive industry continues to evolve towards more sustainable solutions, the role of butane in fuel blends is likely to be reevaluated. Emerging technologies, such as advanced catalytic converters and fuel system designs, may help mitigate some of the negative environmental effects associated with butane use. Furthermore, the ongoing transition to electric vehicles and alternative fuel sources may gradually reduce the reliance on traditional fuel blends, potentially diminishing the environmental concerns related to butane usage in this context.

One of the primary environmental benefits of incorporating butane into fuel blends is its potential to reduce overall greenhouse gas emissions. When used in appropriate proportions, butane can improve the combustion efficiency of the fuel mixture, leading to more complete burning and fewer unburned hydrocarbons released into the atmosphere. This efficiency gain can result in a reduction of carbon dioxide emissions per unit of energy produced, contributing to climate change mitigation efforts.

However, the volatile nature of butane presents environmental challenges. Its high vapor pressure increases the likelihood of evaporative emissions, particularly during fuel storage and vehicle refueling processes. These emissions contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on air quality and human health in urban areas.

The use of butane in fuel blends also impacts the overall reactivity of vehicle exhaust emissions. While it can help reduce some pollutants, such as carbon monoxide, it may increase the formation of other harmful compounds, including certain types of particulate matter and nitrogen oxides. These pollutants are known to contribute to respiratory issues and can have long-term environmental consequences.

From a lifecycle perspective, the production and transportation of butane for fuel blending purposes also carry environmental implications. The extraction and processing of butane from natural gas or petroleum sources require energy inputs and can result in fugitive emissions. Additionally, the transportation of butane to blending facilities contributes to the overall carbon footprint of the fuel product.

It is important to note that the environmental impact of butane in fuel blends can vary significantly depending on factors such as blend composition, engine technology, and local environmental conditions. Regulatory frameworks play a crucial role in managing these impacts, with many jurisdictions implementing strict standards for fuel composition and emissions control.

As the automotive industry continues to evolve towards more sustainable solutions, the role of butane in fuel blends is likely to be reevaluated. Emerging technologies, such as advanced catalytic converters and fuel system designs, may help mitigate some of the negative environmental effects associated with butane use. Furthermore, the ongoing transition to electric vehicles and alternative fuel sources may gradually reduce the reliance on traditional fuel blends, potentially diminishing the environmental concerns related to butane usage in this context.

Regulatory Framework for Butane-Blended Fuels

The regulatory framework for butane-blended fuels plays a crucial role in shaping the industry's practices and ensuring the safe and efficient use of these fuel mixtures. Governments and regulatory bodies worldwide have established comprehensive guidelines and standards to govern the production, distribution, and use of butane-blended fuels.

In the United States, the Environmental Protection Agency (EPA) sets forth regulations under the Clean Air Act that directly impact the use of butane in fuel blending. These regulations specify the maximum allowable Reid Vapor Pressure (RVP) for gasoline during summer months to reduce evaporative emissions. Butane, being a highly volatile component, is subject to strict limitations during this period to maintain compliance with RVP standards.

The European Union has implemented its own set of regulations through the Fuel Quality Directive (FQD) and the Renewable Energy Directive (RED). These directives establish standards for fuel composition, including limits on butane content, to ensure environmental protection and promote the use of renewable energy sources in transportation fuels.

Many countries have adopted similar regulatory frameworks, often tailored to their specific environmental and economic needs. For instance, Canada's Renewable Fuels Regulations mandate minimum renewable fuel content in gasoline, which indirectly affects the use of butane in blending processes.

Safety regulations also form a significant part of the regulatory landscape for butane-blended fuels. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US provide guidelines for the safe handling and storage of butane and other volatile hydrocarbons used in fuel blending.

The International Maritime Organization (IMO) has implemented global sulfur limits for marine fuels, which has implications for butane blending in marine fuel applications. These regulations aim to reduce sulfur oxide emissions from ships, prompting the industry to explore new blending strategies that may involve butane.

Regulatory bodies also mandate specific testing and certification procedures for fuel blends. ASTM International, for example, provides standard test methods for determining the butane content in gasoline and other fuel blends. Compliance with these standards is often a legal requirement for fuel producers and distributors.

As environmental concerns continue to drive policy decisions, the regulatory framework for butane-blended fuels is likely to evolve. Future regulations may focus on further reducing emissions, improving fuel efficiency, and promoting the integration of renewable components in fuel blends. This dynamic regulatory landscape necessitates ongoing adaptation and innovation within the fuel blending industry to meet changing standards while maximizing the benefits of butane as a blending component.

In the United States, the Environmental Protection Agency (EPA) sets forth regulations under the Clean Air Act that directly impact the use of butane in fuel blending. These regulations specify the maximum allowable Reid Vapor Pressure (RVP) for gasoline during summer months to reduce evaporative emissions. Butane, being a highly volatile component, is subject to strict limitations during this period to maintain compliance with RVP standards.

The European Union has implemented its own set of regulations through the Fuel Quality Directive (FQD) and the Renewable Energy Directive (RED). These directives establish standards for fuel composition, including limits on butane content, to ensure environmental protection and promote the use of renewable energy sources in transportation fuels.

Many countries have adopted similar regulatory frameworks, often tailored to their specific environmental and economic needs. For instance, Canada's Renewable Fuels Regulations mandate minimum renewable fuel content in gasoline, which indirectly affects the use of butane in blending processes.

Safety regulations also form a significant part of the regulatory landscape for butane-blended fuels. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US provide guidelines for the safe handling and storage of butane and other volatile hydrocarbons used in fuel blending.

The International Maritime Organization (IMO) has implemented global sulfur limits for marine fuels, which has implications for butane blending in marine fuel applications. These regulations aim to reduce sulfur oxide emissions from ships, prompting the industry to explore new blending strategies that may involve butane.

Regulatory bodies also mandate specific testing and certification procedures for fuel blends. ASTM International, for example, provides standard test methods for determining the butane content in gasoline and other fuel blends. Compliance with these standards is often a legal requirement for fuel producers and distributors.

As environmental concerns continue to drive policy decisions, the regulatory framework for butane-blended fuels is likely to evolve. Future regulations may focus on further reducing emissions, improving fuel efficiency, and promoting the integration of renewable components in fuel blends. This dynamic regulatory landscape necessitates ongoing adaptation and innovation within the fuel blending industry to meet changing standards while maximizing the benefits of butane as a blending component.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!