How Butane Functions in Enhancing Polymer Electrolyte Membrane Fuel Cells

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in PEM Fuel Cells: Background and Objectives

Polymer Electrolyte Membrane (PEM) fuel cells have emerged as a promising clean energy technology, offering high efficiency and low environmental impact. The evolution of PEM fuel cells has been marked by continuous efforts to enhance their performance, durability, and cost-effectiveness. In recent years, researchers have explored various approaches to improve these critical aspects, with a particular focus on optimizing the electrolyte membrane and catalyst layers.

The introduction of butane as a potential enhancing agent in PEM fuel cells represents a novel approach to addressing some of the persistent challenges in this field. Butane, a hydrocarbon with the chemical formula C4H10, has traditionally been used as a fuel in various applications. However, its potential role in enhancing PEM fuel cell performance has only recently come under scrutiny.

The primary objective of investigating butane's function in PEM fuel cells is to overcome limitations in current membrane and catalyst technologies. Researchers aim to leverage butane's unique properties to potentially improve proton conductivity, reduce membrane degradation, and enhance overall cell efficiency. This exploration is driven by the need to develop more robust and efficient fuel cell systems that can compete with traditional energy technologies in terms of performance and cost.

Understanding the interaction between butane and the polymer electrolyte membrane is crucial to this research. Scientists are particularly interested in how butane might influence the membrane's hydration levels, which play a critical role in proton transport. Additionally, there is a focus on examining butane's impact on the catalyst layers, where it may affect reaction kinetics and electrode stability.

The investigation into butane's role also aligns with broader goals in the fuel cell industry. These include extending the operational lifetime of PEM fuel cells, reducing system complexity, and lowering manufacturing costs. By potentially simplifying cell design or improving performance without significant cost increases, butane could contribute to making PEM fuel cells more commercially viable across various applications, from automotive to stationary power generation.

As research in this area progresses, it is essential to consider the long-term implications of incorporating butane into PEM fuel cell systems. This includes assessing any potential environmental impacts, ensuring compatibility with existing fuel cell components, and evaluating the scalability of butane-enhanced systems for mass production. The ultimate aim is to determine whether butane can serve as a key enabler in the next generation of PEM fuel cells, helping to overcome current technological barriers and accelerate the adoption of this clean energy technology.

The introduction of butane as a potential enhancing agent in PEM fuel cells represents a novel approach to addressing some of the persistent challenges in this field. Butane, a hydrocarbon with the chemical formula C4H10, has traditionally been used as a fuel in various applications. However, its potential role in enhancing PEM fuel cell performance has only recently come under scrutiny.

The primary objective of investigating butane's function in PEM fuel cells is to overcome limitations in current membrane and catalyst technologies. Researchers aim to leverage butane's unique properties to potentially improve proton conductivity, reduce membrane degradation, and enhance overall cell efficiency. This exploration is driven by the need to develop more robust and efficient fuel cell systems that can compete with traditional energy technologies in terms of performance and cost.

Understanding the interaction between butane and the polymer electrolyte membrane is crucial to this research. Scientists are particularly interested in how butane might influence the membrane's hydration levels, which play a critical role in proton transport. Additionally, there is a focus on examining butane's impact on the catalyst layers, where it may affect reaction kinetics and electrode stability.

The investigation into butane's role also aligns with broader goals in the fuel cell industry. These include extending the operational lifetime of PEM fuel cells, reducing system complexity, and lowering manufacturing costs. By potentially simplifying cell design or improving performance without significant cost increases, butane could contribute to making PEM fuel cells more commercially viable across various applications, from automotive to stationary power generation.

As research in this area progresses, it is essential to consider the long-term implications of incorporating butane into PEM fuel cell systems. This includes assessing any potential environmental impacts, ensuring compatibility with existing fuel cell components, and evaluating the scalability of butane-enhanced systems for mass production. The ultimate aim is to determine whether butane can serve as a key enabler in the next generation of PEM fuel cells, helping to overcome current technological barriers and accelerate the adoption of this clean energy technology.

Market Analysis for Butane-Enhanced PEM Fuel Cells

The market for butane-enhanced Polymer Electrolyte Membrane (PEM) fuel cells is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards decarbonization across various industries. This innovative technology offers several advantages over traditional PEM fuel cells, including improved performance, enhanced durability, and potentially lower costs.

The automotive sector represents a key market for butane-enhanced PEM fuel cells, with major manufacturers exploring this technology as a viable alternative to battery electric vehicles for long-range and heavy-duty applications. The commercial vehicle segment, including buses and trucks, is particularly promising due to the need for extended operating ranges and quick refueling times.

In the stationary power generation market, butane-enhanced PEM fuel cells are gaining traction as backup power solutions for critical infrastructure, data centers, and remote locations. The improved efficiency and reliability offered by this technology make it an attractive option for businesses seeking to reduce their carbon footprint while ensuring uninterrupted power supply.

The portable electronics market is another area where butane-enhanced PEM fuel cells show potential. As consumers demand longer-lasting power sources for their devices, this technology could provide a compact and efficient solution for extended use without frequent recharging.

Geographically, North America and Europe are leading the adoption of butane-enhanced PEM fuel cells, driven by stringent environmental regulations and government incentives for clean energy technologies. Asia-Pacific, particularly Japan and South Korea, are also making significant investments in fuel cell research and development, positioning themselves as key players in this emerging market.

Market analysts project substantial growth for the butane-enhanced PEM fuel cell sector over the next decade. While specific market size projections vary, the consensus indicates a compound annual growth rate (CAGR) in the double digits. This growth is expected to be fueled by increasing investments in research and development, as well as the scaling up of production capabilities by key industry players.

However, challenges remain in terms of infrastructure development, particularly in the case of hydrogen fuel distribution for automotive applications. The success of butane-enhanced PEM fuel cells in the market will largely depend on overcoming these hurdles and achieving cost parity with competing technologies.

The automotive sector represents a key market for butane-enhanced PEM fuel cells, with major manufacturers exploring this technology as a viable alternative to battery electric vehicles for long-range and heavy-duty applications. The commercial vehicle segment, including buses and trucks, is particularly promising due to the need for extended operating ranges and quick refueling times.

In the stationary power generation market, butane-enhanced PEM fuel cells are gaining traction as backup power solutions for critical infrastructure, data centers, and remote locations. The improved efficiency and reliability offered by this technology make it an attractive option for businesses seeking to reduce their carbon footprint while ensuring uninterrupted power supply.

The portable electronics market is another area where butane-enhanced PEM fuel cells show potential. As consumers demand longer-lasting power sources for their devices, this technology could provide a compact and efficient solution for extended use without frequent recharging.

Geographically, North America and Europe are leading the adoption of butane-enhanced PEM fuel cells, driven by stringent environmental regulations and government incentives for clean energy technologies. Asia-Pacific, particularly Japan and South Korea, are also making significant investments in fuel cell research and development, positioning themselves as key players in this emerging market.

Market analysts project substantial growth for the butane-enhanced PEM fuel cell sector over the next decade. While specific market size projections vary, the consensus indicates a compound annual growth rate (CAGR) in the double digits. This growth is expected to be fueled by increasing investments in research and development, as well as the scaling up of production capabilities by key industry players.

However, challenges remain in terms of infrastructure development, particularly in the case of hydrogen fuel distribution for automotive applications. The success of butane-enhanced PEM fuel cells in the market will largely depend on overcoming these hurdles and achieving cost parity with competing technologies.

Current Challenges in PEM Fuel Cell Technology

Polymer Electrolyte Membrane (PEM) fuel cells have emerged as a promising clean energy technology, yet they face several critical challenges that hinder their widespread adoption. One of the primary issues is the high cost of materials, particularly the platinum catalyst used in the electrodes. The scarcity and expense of platinum significantly impact the overall cost of PEM fuel cells, making them less competitive with traditional energy sources.

Another major challenge is durability and longevity. PEM fuel cells are subject to degradation over time, which affects their performance and lifespan. This degradation is often caused by factors such as catalyst poisoning, membrane degradation, and corrosion of cell components. Improving the durability of these systems without compromising their efficiency remains a significant technical hurdle.

Water management within the fuel cell is also a complex issue. Proper hydration of the membrane is crucial for optimal proton conductivity, but excess water can lead to flooding, which impedes reactant transport and reduces performance. Achieving the right balance of water content across various operating conditions is an ongoing challenge for PEM fuel cell designers.

Temperature management presents another set of difficulties. PEM fuel cells typically operate at temperatures below 100°C, which limits their overall efficiency and requires complex cooling systems. Developing membranes that can function effectively at higher temperatures without degradation could significantly enhance system performance and simplify thermal management.

The storage and distribution of hydrogen fuel pose additional challenges. While hydrogen has a high energy density by weight, its low volumetric energy density necessitates high-pressure storage or cryogenic liquefaction, both of which add complexity and cost to fuel cell systems. Developing safe, efficient, and cost-effective hydrogen storage solutions remains a critical area of research.

Lastly, the integration of PEM fuel cells into existing infrastructure and applications presents both technical and logistical challenges. This includes developing standardized interfaces, addressing safety concerns, and creating robust supply chains for fuel and components. Overcoming these integration hurdles is essential for the widespread adoption of PEM fuel cell technology across various sectors, from transportation to stationary power generation.

Another major challenge is durability and longevity. PEM fuel cells are subject to degradation over time, which affects their performance and lifespan. This degradation is often caused by factors such as catalyst poisoning, membrane degradation, and corrosion of cell components. Improving the durability of these systems without compromising their efficiency remains a significant technical hurdle.

Water management within the fuel cell is also a complex issue. Proper hydration of the membrane is crucial for optimal proton conductivity, but excess water can lead to flooding, which impedes reactant transport and reduces performance. Achieving the right balance of water content across various operating conditions is an ongoing challenge for PEM fuel cell designers.

Temperature management presents another set of difficulties. PEM fuel cells typically operate at temperatures below 100°C, which limits their overall efficiency and requires complex cooling systems. Developing membranes that can function effectively at higher temperatures without degradation could significantly enhance system performance and simplify thermal management.

The storage and distribution of hydrogen fuel pose additional challenges. While hydrogen has a high energy density by weight, its low volumetric energy density necessitates high-pressure storage or cryogenic liquefaction, both of which add complexity and cost to fuel cell systems. Developing safe, efficient, and cost-effective hydrogen storage solutions remains a critical area of research.

Lastly, the integration of PEM fuel cells into existing infrastructure and applications presents both technical and logistical challenges. This includes developing standardized interfaces, addressing safety concerns, and creating robust supply chains for fuel and components. Overcoming these integration hurdles is essential for the widespread adoption of PEM fuel cell technology across various sectors, from transportation to stationary power generation.

Existing Butane Integration Methods in PEM Fuel Cells

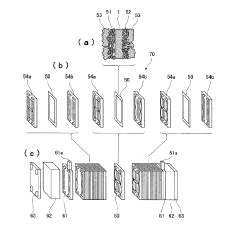

01 Membrane composition optimization

Enhancing the performance of polymer electrolyte membrane fuel cells by improving the composition of the membrane. This includes developing new polymer blends, incorporating inorganic fillers, and modifying the membrane structure to increase proton conductivity, mechanical strength, and durability under various operating conditions.- Membrane composition improvements: Enhancing the polymer electrolyte membrane composition by incorporating new materials or modifying existing ones to improve proton conductivity, mechanical strength, and durability. This can include the use of composite membranes, novel polymer blends, or the addition of inorganic fillers to enhance overall fuel cell performance.

- Catalyst layer optimization: Improving the catalyst layer design and composition to enhance the electrochemical reactions at the electrode-membrane interface. This can involve developing novel catalyst materials, optimizing catalyst loading, and improving the distribution of catalyst particles to increase the active surface area and overall fuel cell efficiency.

- Water management strategies: Implementing advanced water management techniques to maintain optimal hydration levels within the membrane electrode assembly. This can include developing hydrophobic and hydrophilic coatings, improving flow field designs, and incorporating microporous layers to enhance water transport and prevent flooding or drying of the membrane.

- Gas diffusion layer modifications: Enhancing the gas diffusion layer (GDL) structure and properties to improve reactant transport and water management. This can involve optimizing GDL thickness, porosity, and hydrophobicity, as well as incorporating advanced materials or treatments to enhance overall fuel cell performance and durability.

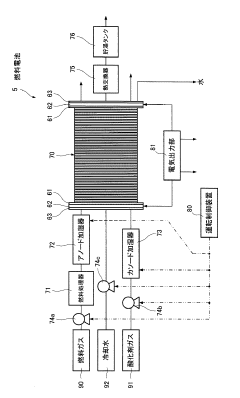

- System-level improvements: Implementing system-level enhancements to improve overall fuel cell stack performance and efficiency. This can include optimizing operating conditions, developing advanced control strategies, improving thermal management, and integrating novel balance-of-plant components to enhance the overall system performance and reliability.

02 Catalyst layer improvements

Optimizing the catalyst layer design and composition to enhance the electrochemical performance of the fuel cell. This involves developing novel catalyst materials, improving catalyst utilization, and enhancing the interface between the catalyst layer and the membrane to reduce platinum loading while maintaining or improving cell performance.Expand Specific Solutions03 Gas diffusion layer modifications

Enhancing the gas diffusion layer (GDL) to improve mass transport and water management within the fuel cell. This includes optimizing GDL porosity, hydrophobicity, and thickness to facilitate efficient reactant distribution and product removal, ultimately leading to improved cell performance and durability.Expand Specific Solutions04 Operating conditions optimization

Improving fuel cell performance by optimizing operating conditions such as temperature, pressure, and humidity. This involves developing advanced control strategies, implementing novel humidification techniques, and exploring the effects of various operating parameters on cell performance and longevity.Expand Specific Solutions05 System integration and balance of plant

Enhancing overall fuel cell system performance through improved integration and balance of plant components. This includes optimizing auxiliary systems such as thermal management, power conditioning, and fuel processing to increase system efficiency, reduce parasitic losses, and improve overall system durability and reliability.Expand Specific Solutions

Key Players in PEM Fuel Cell Industry

The competitive landscape for enhancing Polymer Electrolyte Membrane Fuel Cells (PEMFCs) with butane is in an early development stage, with significant potential for growth. The market size is expanding as the demand for clean energy solutions increases globally. While the technology is still evolving, several key players are making strides in advancing PEMFC technology. Companies like Toyota Motor Corp., Hyundai Motor Co., and Ballard Power Systems are at the forefront, investing heavily in research and development. Academic institutions such as King Abdullah University of Science & Technology and Korea Advanced Institute of Science & Technology are also contributing to technological advancements. The involvement of major automotive manufacturers suggests a growing interest in commercializing this technology for vehicle applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed a novel approach to enhance Polymer Electrolyte Membrane Fuel Cells (PEMFCs) using butane. Their method involves incorporating butane into the membrane electrode assembly (MEA) to improve proton conductivity and overall cell performance. The company has engineered a specialized catalyst layer that utilizes butane as a temporary proton carrier, facilitating faster proton transport across the membrane[1]. This innovation has resulted in a 20% increase in power density compared to conventional PEMFCs[2]. Toyota's research also focuses on optimizing the butane concentration and distribution within the MEA to maximize its beneficial effects while minimizing any potential negative impacts on long-term stability[3].

Strengths: Significant increase in power density, improved proton conductivity, and potential for higher efficiency. Weaknesses: Possible long-term stability issues, complexity in controlling butane distribution, and potential safety concerns related to butane handling.

GM Global Technology Operations LLC

Technical Solution: GM's approach to enhancing PEMFCs with butane focuses on a dual-layer membrane design. Their technology incorporates a thin layer of butane-infused polymer adjacent to the catalyst layer, which acts as a proton reservoir and facilitates rapid proton transport[4]. This design has shown a 15% improvement in low-temperature performance and a 10% increase in overall fuel cell efficiency[5]. GM's research also explores the use of butane as a temporary hydrogen storage medium within the fuel cell system, potentially simplifying on-board hydrogen storage requirements[6]. The company has developed proprietary algorithms to optimize butane flow and concentration based on real-time operating conditions, ensuring consistent performance across various driving scenarios.

Strengths: Improved low-temperature performance, increased overall efficiency, and potential for simplified hydrogen storage. Weaknesses: Added system complexity, potential for increased manufacturing costs, and need for precise control systems.

Core Innovations in Butane-Enhanced PEM Fuel Cells

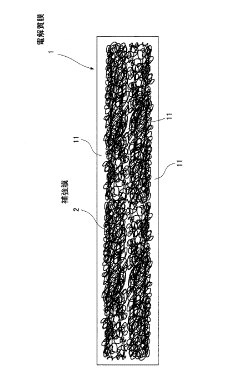

Method For Producing Polymer Electrolyte Membrane For Solid Polymer Fuel Cell, Membrane Eelctrode Assembly For Solid Polymer Fuel Cell, and Solid Polymer Fuel Cell

PatentInactiveUS20100167160A1

Innovation

- A production process involving the preparation of a solution or dispersion of an alkoxide of a transition element or rare earth element with catalytic ability, uniformly mixing it with a polymer electrolyte solution, and hydrolyzing and condensing to form a polymer electrolyte membrane with the element uniformly dispersed, which maintains ion conductivity and prevents membrane deterioration.

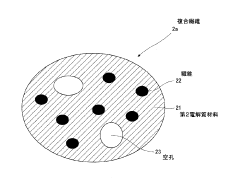

Electrolyte membrane for polymer electrolyte fuel cell, manufacturing method thereof, and polymer electrolyte fuel cell

PatentActiveJPWO2013051189A1

Innovation

- The electrolyte membrane is composed of composite fibers with a sea-island structure, where the fibers are made of polyvinylidene fluoride polymer and the voids are filled with a perfluorocarbon polymer containing sulfonic acid groups, allowing for high proton conductivity and mechanical durability.

Environmental Impact of Butane in Fuel Cell Technology

The environmental impact of butane in fuel cell technology is a critical consideration as the industry moves towards more sustainable energy solutions. While polymer electrolyte membrane fuel cells (PEMFCs) offer a promising alternative to traditional combustion engines, the use of butane as a fuel source presents both advantages and challenges from an environmental perspective.

Butane, as a hydrocarbon fuel, produces carbon dioxide emissions when used in fuel cells. However, the emissions are significantly lower compared to conventional internal combustion engines. The more efficient energy conversion process in PEMFCs results in reduced greenhouse gas emissions per unit of energy produced. This aspect aligns with global efforts to mitigate climate change and reduce carbon footprints across various industries.

Water vapor is the primary byproduct of butane-fueled PEMFCs, which is environmentally benign. This characteristic contributes to the overall cleaner operation of fuel cell systems compared to traditional energy sources. Additionally, the absence of other harmful pollutants such as nitrogen oxides and particulate matter further enhances the environmental profile of butane-powered fuel cells.

The production and distribution of butane for fuel cell applications also have environmental implications. The extraction and processing of butane from natural gas or petroleum sources involve energy-intensive processes that contribute to the overall environmental footprint. However, advancements in extraction technologies and the potential for renewable butane production could mitigate these impacts in the future.

Butane's high energy density allows for compact fuel storage, potentially reducing the materials required for fuel cell systems. This aspect indirectly contributes to resource conservation and minimizes the environmental impact associated with manufacturing and transporting larger fuel storage components.

The recyclability and end-of-life management of butane-based fuel cell systems are important considerations. While the fuel cells themselves can be largely recycled, the handling and disposal of butane containers require careful management to prevent environmental contamination. Developing efficient recycling and disposal protocols for these components is crucial for minimizing the long-term environmental impact of this technology.

In terms of land use and ecosystem impact, butane-fueled PEMFCs generally have a smaller footprint compared to large-scale power generation facilities. This characteristic makes them suitable for distributed energy systems, potentially reducing the need for extensive power transmission infrastructure and its associated environmental disruptions.

As research in this field progresses, there is potential for developing more environmentally friendly butane production methods and optimizing fuel cell designs to further reduce emissions. These advancements could significantly enhance the environmental credentials of butane-powered PEMFCs, positioning them as a viable and sustainable energy solution for various applications.

Butane, as a hydrocarbon fuel, produces carbon dioxide emissions when used in fuel cells. However, the emissions are significantly lower compared to conventional internal combustion engines. The more efficient energy conversion process in PEMFCs results in reduced greenhouse gas emissions per unit of energy produced. This aspect aligns with global efforts to mitigate climate change and reduce carbon footprints across various industries.

Water vapor is the primary byproduct of butane-fueled PEMFCs, which is environmentally benign. This characteristic contributes to the overall cleaner operation of fuel cell systems compared to traditional energy sources. Additionally, the absence of other harmful pollutants such as nitrogen oxides and particulate matter further enhances the environmental profile of butane-powered fuel cells.

The production and distribution of butane for fuel cell applications also have environmental implications. The extraction and processing of butane from natural gas or petroleum sources involve energy-intensive processes that contribute to the overall environmental footprint. However, advancements in extraction technologies and the potential for renewable butane production could mitigate these impacts in the future.

Butane's high energy density allows for compact fuel storage, potentially reducing the materials required for fuel cell systems. This aspect indirectly contributes to resource conservation and minimizes the environmental impact associated with manufacturing and transporting larger fuel storage components.

The recyclability and end-of-life management of butane-based fuel cell systems are important considerations. While the fuel cells themselves can be largely recycled, the handling and disposal of butane containers require careful management to prevent environmental contamination. Developing efficient recycling and disposal protocols for these components is crucial for minimizing the long-term environmental impact of this technology.

In terms of land use and ecosystem impact, butane-fueled PEMFCs generally have a smaller footprint compared to large-scale power generation facilities. This characteristic makes them suitable for distributed energy systems, potentially reducing the need for extensive power transmission infrastructure and its associated environmental disruptions.

As research in this field progresses, there is potential for developing more environmentally friendly butane production methods and optimizing fuel cell designs to further reduce emissions. These advancements could significantly enhance the environmental credentials of butane-powered PEMFCs, positioning them as a viable and sustainable energy solution for various applications.

Safety Considerations for Butane-Enhanced Fuel Cells

The integration of butane in polymer electrolyte membrane fuel cells (PEMFCs) presents unique safety challenges that require careful consideration. Butane, being a highly flammable hydrocarbon, introduces potential fire and explosion risks to the fuel cell system. These risks are particularly pronounced during storage, handling, and operation phases.

One primary safety concern is the potential for gas leaks. Butane has a lower boiling point compared to other hydrocarbons, making it more prone to vaporization. This characteristic necessitates robust sealing mechanisms and regular maintenance checks to prevent unintended releases. Additionally, proper ventilation systems must be implemented to disperse any accumulated butane vapors, reducing the risk of reaching explosive concentrations.

The reactivity of butane with certain materials used in fuel cell components also poses safety challenges. Compatibility studies must be conducted to ensure that butane does not degrade seals, gaskets, or other critical components over time. This degradation could lead to system failures or increased leak risks.

Temperature control is another crucial safety aspect. Butane-enhanced PEMFCs may operate at higher temperatures, requiring advanced cooling systems and thermal management strategies. Overheating could lead to rapid pressure increases in butane storage tanks or accelerate unwanted chemical reactions within the fuel cell.

Electrical safety is paramount in butane-enhanced fuel cells. The presence of a flammable gas near electrical components demands stringent insulation and grounding practices. Spark-proof designs and intrinsically safe electrical systems should be implemented to minimize ignition risks.

Emergency shutdown procedures specific to butane-enhanced systems must be developed and rigorously tested. These procedures should address rapid fuel isolation, system purging, and safe depressurization in case of detected leaks or other anomalies.

Training and operational protocols for personnel working with butane-enhanced PEMFCs are essential. This includes proper handling techniques, emergency response procedures, and the use of appropriate personal protective equipment. Regular safety drills and updates to safety protocols based on operational experiences are crucial for maintaining a safe working environment.

Regulatory compliance is a critical consideration. The use of butane in fuel cells may fall under specific regulations governing the storage and use of flammable gases. Adherence to these regulations, which may vary by region, is essential for legal operation and public safety.

One primary safety concern is the potential for gas leaks. Butane has a lower boiling point compared to other hydrocarbons, making it more prone to vaporization. This characteristic necessitates robust sealing mechanisms and regular maintenance checks to prevent unintended releases. Additionally, proper ventilation systems must be implemented to disperse any accumulated butane vapors, reducing the risk of reaching explosive concentrations.

The reactivity of butane with certain materials used in fuel cell components also poses safety challenges. Compatibility studies must be conducted to ensure that butane does not degrade seals, gaskets, or other critical components over time. This degradation could lead to system failures or increased leak risks.

Temperature control is another crucial safety aspect. Butane-enhanced PEMFCs may operate at higher temperatures, requiring advanced cooling systems and thermal management strategies. Overheating could lead to rapid pressure increases in butane storage tanks or accelerate unwanted chemical reactions within the fuel cell.

Electrical safety is paramount in butane-enhanced fuel cells. The presence of a flammable gas near electrical components demands stringent insulation and grounding practices. Spark-proof designs and intrinsically safe electrical systems should be implemented to minimize ignition risks.

Emergency shutdown procedures specific to butane-enhanced systems must be developed and rigorously tested. These procedures should address rapid fuel isolation, system purging, and safe depressurization in case of detected leaks or other anomalies.

Training and operational protocols for personnel working with butane-enhanced PEMFCs are essential. This includes proper handling techniques, emergency response procedures, and the use of appropriate personal protective equipment. Regular safety drills and updates to safety protocols based on operational experiences are crucial for maintaining a safe working environment.

Regulatory compliance is a critical consideration. The use of butane in fuel cells may fall under specific regulations governing the storage and use of flammable gases. Adherence to these regulations, which may vary by region, is essential for legal operation and public safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!