How Butane Resonates in the Progression of Gas-to-Liquids Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in GTL Evolution

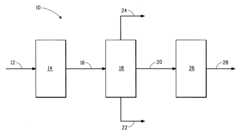

Butane has played a pivotal role in the evolution of Gas-to-Liquids (GTL) technologies, serving as a crucial component in the progression of this innovative process. The journey of butane in GTL began with its recognition as a valuable feedstock for the production of synthetic fuels and chemicals. Initially, GTL processes primarily focused on methane conversion, but researchers soon realized the potential of higher hydrocarbons like butane to enhance the efficiency and product slate of GTL operations.

In the early stages of GTL development, butane was primarily used as a supplementary feedstock to augment the carbon content of the synthesis gas. This approach allowed for better control of the hydrogen-to-carbon monoxide ratio, which is critical for optimizing the Fischer-Tropsch synthesis process. As GTL technologies advanced, the role of butane expanded beyond a mere supplement to become an integral part of the feedstock mix.

The incorporation of butane into GTL processes led to significant improvements in product yields and quality. By introducing butane into the reforming stage, operators could increase the production of longer-chain hydrocarbons, resulting in a higher proportion of valuable liquid fuels and specialty chemicals. This shift in feedstock composition also contributed to enhanced process flexibility, allowing GTL plants to adjust their product slate based on market demands and economic factors.

Butane's influence on GTL evolution extended to the development of novel catalysts and reactor designs. Researchers focused on creating catalysts that could efficiently handle mixed feedstocks, including butane, without compromising performance or selectivity. This led to the emergence of advanced reforming technologies and more robust Fischer-Tropsch catalysts capable of processing a wider range of hydrocarbon inputs.

The progression of butane utilization in GTL also drove advancements in process integration and heat management. Engineers developed innovative heat exchange systems and process configurations to maximize energy efficiency when dealing with mixed feedstocks. These improvements not only enhanced the overall economics of GTL operations but also reduced the environmental footprint of the technology.

As GTL technologies continued to mature, butane's role expanded into new areas of application. It became a key player in small-scale and modular GTL units, where its ease of transportation and storage made it an attractive feedstock option for remote or stranded gas valorization. This development opened up new markets and opportunities for GTL technology, particularly in regions with abundant natural gas liquids resources.

In the early stages of GTL development, butane was primarily used as a supplementary feedstock to augment the carbon content of the synthesis gas. This approach allowed for better control of the hydrogen-to-carbon monoxide ratio, which is critical for optimizing the Fischer-Tropsch synthesis process. As GTL technologies advanced, the role of butane expanded beyond a mere supplement to become an integral part of the feedstock mix.

The incorporation of butane into GTL processes led to significant improvements in product yields and quality. By introducing butane into the reforming stage, operators could increase the production of longer-chain hydrocarbons, resulting in a higher proportion of valuable liquid fuels and specialty chemicals. This shift in feedstock composition also contributed to enhanced process flexibility, allowing GTL plants to adjust their product slate based on market demands and economic factors.

Butane's influence on GTL evolution extended to the development of novel catalysts and reactor designs. Researchers focused on creating catalysts that could efficiently handle mixed feedstocks, including butane, without compromising performance or selectivity. This led to the emergence of advanced reforming technologies and more robust Fischer-Tropsch catalysts capable of processing a wider range of hydrocarbon inputs.

The progression of butane utilization in GTL also drove advancements in process integration and heat management. Engineers developed innovative heat exchange systems and process configurations to maximize energy efficiency when dealing with mixed feedstocks. These improvements not only enhanced the overall economics of GTL operations but also reduced the environmental footprint of the technology.

As GTL technologies continued to mature, butane's role expanded into new areas of application. It became a key player in small-scale and modular GTL units, where its ease of transportation and storage made it an attractive feedstock option for remote or stranded gas valorization. This development opened up new markets and opportunities for GTL technology, particularly in regions with abundant natural gas liquids resources.

GTL Market Dynamics

The Gas-to-Liquids (GTL) market has experienced significant growth and transformation in recent years, driven by the increasing demand for cleaner fuels and the need to monetize stranded gas reserves. The global GTL market size was valued at approximately $12 billion in 2020 and is projected to reach $20 billion by 2027, growing at a CAGR of around 6% during the forecast period.

The market dynamics of GTL technologies are heavily influenced by several factors, including fluctuating oil prices, environmental regulations, and technological advancements. As countries worldwide strive to reduce their carbon footprint and diversify their energy sources, GTL products have gained traction due to their lower emissions and higher purity compared to conventional petroleum-derived fuels.

Butane plays a crucial role in the GTL market dynamics, particularly in the progression of GTL technologies. As a component of natural gas and a byproduct of petroleum refining, butane serves as a valuable feedstock for GTL processes. The abundance and relatively low cost of butane make it an attractive option for GTL production, especially in regions with significant natural gas reserves.

The market for GTL products derived from butane has shown promising growth potential, particularly in the transportation and petrochemical sectors. GTL diesel, for instance, offers superior performance and lower emissions compared to conventional diesel, making it an attractive option for fleet operators and environmentally conscious consumers.

Geographically, the Middle East and North America dominate the GTL market, owing to their vast natural gas reserves and well-established energy infrastructure. However, emerging economies in Asia-Pacific and Africa are increasingly investing in GTL technologies to monetize their gas resources and reduce dependence on imported fuels.

The competitive landscape of the GTL market is characterized by a mix of large multinational oil and gas companies and specialized technology providers. Key players are focusing on research and development to improve process efficiency, reduce production costs, and expand their product portfolios. Collaborations and strategic partnerships between technology developers and energy companies are becoming more common, driving innovation and market expansion.

Despite the promising outlook, the GTL market faces challenges such as high capital costs, technological complexities, and competition from alternative energy sources. The volatility of oil prices also impacts the economic viability of GTL projects, as low oil prices can make GTL products less competitive compared to conventional petroleum-based fuels.

The market dynamics of GTL technologies are heavily influenced by several factors, including fluctuating oil prices, environmental regulations, and technological advancements. As countries worldwide strive to reduce their carbon footprint and diversify their energy sources, GTL products have gained traction due to their lower emissions and higher purity compared to conventional petroleum-derived fuels.

Butane plays a crucial role in the GTL market dynamics, particularly in the progression of GTL technologies. As a component of natural gas and a byproduct of petroleum refining, butane serves as a valuable feedstock for GTL processes. The abundance and relatively low cost of butane make it an attractive option for GTL production, especially in regions with significant natural gas reserves.

The market for GTL products derived from butane has shown promising growth potential, particularly in the transportation and petrochemical sectors. GTL diesel, for instance, offers superior performance and lower emissions compared to conventional diesel, making it an attractive option for fleet operators and environmentally conscious consumers.

Geographically, the Middle East and North America dominate the GTL market, owing to their vast natural gas reserves and well-established energy infrastructure. However, emerging economies in Asia-Pacific and Africa are increasingly investing in GTL technologies to monetize their gas resources and reduce dependence on imported fuels.

The competitive landscape of the GTL market is characterized by a mix of large multinational oil and gas companies and specialized technology providers. Key players are focusing on research and development to improve process efficiency, reduce production costs, and expand their product portfolios. Collaborations and strategic partnerships between technology developers and energy companies are becoming more common, driving innovation and market expansion.

Despite the promising outlook, the GTL market faces challenges such as high capital costs, technological complexities, and competition from alternative energy sources. The volatility of oil prices also impacts the economic viability of GTL projects, as low oil prices can make GTL products less competitive compared to conventional petroleum-based fuels.

Butane GTL Challenges

Gas-to-Liquids (GTL) technology has made significant strides in recent years, offering a promising avenue for converting natural gas into valuable liquid fuels and chemicals. However, the integration of butane into GTL processes presents several unique challenges that researchers and industry professionals must address to optimize efficiency and economic viability.

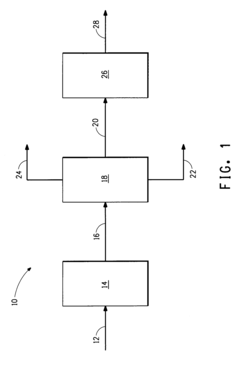

One of the primary challenges in butane-based GTL processes is the efficient conversion of butane to synthesis gas (syngas). Traditional steam reforming methods, while effective for methane, face limitations when applied to butane due to its higher carbon content. This necessitates the development of specialized catalysts and reactor designs capable of handling the increased carbon-to-hydrogen ratio without excessive coking or catalyst deactivation.

The higher reactivity of butane compared to methane also introduces complexities in process control and safety measures. Butane's lower autoignition temperature and wider flammability range require more stringent safety protocols and advanced monitoring systems to prevent potential hazards in industrial-scale operations.

Another significant challenge lies in the optimization of the Fischer-Tropsch (FT) synthesis stage for butane-derived syngas. The composition of syngas produced from butane differs from that of methane-derived syngas, potentially affecting the selectivity and yield of desired products. This necessitates the fine-tuning of FT catalysts and process conditions to maximize the production of target hydrocarbons while minimizing unwanted byproducts.

The integration of butane into existing GTL infrastructure poses additional hurdles. Many current GTL facilities are designed primarily for methane feedstock, requiring substantial modifications to accommodate butane processing. This includes adapting feed preparation systems, adjusting heat management strategies, and potentially redesigning reactor configurations to handle the different thermodynamic properties of butane.

Environmental considerations also present challenges in butane-based GTL technologies. While GTL processes generally offer cleaner alternatives to traditional petroleum refining, the use of butane may lead to increased carbon dioxide emissions compared to methane-based systems. Developing effective carbon capture and utilization strategies becomes crucial to maintaining the environmental benefits of GTL technology.

Lastly, the economic viability of butane GTL processes remains a significant challenge. Fluctuations in butane prices relative to methane and crude oil can impact the competitiveness of butane-based GTL products. Overcoming this challenge requires innovative process designs that maximize efficiency and product value while minimizing capital and operational costs.

One of the primary challenges in butane-based GTL processes is the efficient conversion of butane to synthesis gas (syngas). Traditional steam reforming methods, while effective for methane, face limitations when applied to butane due to its higher carbon content. This necessitates the development of specialized catalysts and reactor designs capable of handling the increased carbon-to-hydrogen ratio without excessive coking or catalyst deactivation.

The higher reactivity of butane compared to methane also introduces complexities in process control and safety measures. Butane's lower autoignition temperature and wider flammability range require more stringent safety protocols and advanced monitoring systems to prevent potential hazards in industrial-scale operations.

Another significant challenge lies in the optimization of the Fischer-Tropsch (FT) synthesis stage for butane-derived syngas. The composition of syngas produced from butane differs from that of methane-derived syngas, potentially affecting the selectivity and yield of desired products. This necessitates the fine-tuning of FT catalysts and process conditions to maximize the production of target hydrocarbons while minimizing unwanted byproducts.

The integration of butane into existing GTL infrastructure poses additional hurdles. Many current GTL facilities are designed primarily for methane feedstock, requiring substantial modifications to accommodate butane processing. This includes adapting feed preparation systems, adjusting heat management strategies, and potentially redesigning reactor configurations to handle the different thermodynamic properties of butane.

Environmental considerations also present challenges in butane-based GTL technologies. While GTL processes generally offer cleaner alternatives to traditional petroleum refining, the use of butane may lead to increased carbon dioxide emissions compared to methane-based systems. Developing effective carbon capture and utilization strategies becomes crucial to maintaining the environmental benefits of GTL technology.

Lastly, the economic viability of butane GTL processes remains a significant challenge. Fluctuations in butane prices relative to methane and crude oil can impact the competitiveness of butane-based GTL products. Overcoming this challenge requires innovative process designs that maximize efficiency and product value while minimizing capital and operational costs.

Butane GTL Processes

01 Butane gas lighters and refill devices

Various designs and improvements for butane gas lighters and refill devices, including safety mechanisms, ergonomic designs, and efficient refilling systems. These innovations aim to enhance user experience, safety, and convenience in portable gas lighter applications.- Butane gas lighters and refill devices: Various designs for butane gas lighters and refill devices, including improvements in safety features, ignition mechanisms, and refilling systems. These innovations aim to enhance user experience, increase reliability, and improve the overall functionality of butane-based lighters.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes may involve adsorption, distillation, or other separation techniques to obtain high-purity butane for various industrial applications.

- Butane fuel storage and dispensing systems: Innovations in the storage and dispensing of butane fuel, including improved tank designs, valve systems, and safety mechanisms. These advancements aim to enhance the efficiency and safety of butane fuel handling in various applications, such as portable stoves or industrial equipment.

- Butane-based chemical processes: Various chemical processes involving butane as a reactant or intermediate, including the production of other hydrocarbons or chemical compounds. These processes may involve catalytic reactions, isomerization, or other chemical transformations to create value-added products from butane.

- Butane detection and safety systems: Development of sensors, alarms, and safety systems for detecting butane leaks or monitoring butane concentrations in various environments. These innovations aim to improve safety in industrial settings, residential areas, or other locations where butane is used or stored.

02 Butane purification and separation processes

Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes involve various techniques such as distillation, adsorption, and membrane separation to obtain high-purity butane for industrial or commercial use.Expand Specific Solutions03 Butane fuel storage and dispensing systems

Innovations in butane fuel storage containers and dispensing systems, focusing on improved safety features, leak prevention, and efficient fuel transfer. These developments are applicable to portable stoves, camping equipment, and other butane-powered devices.Expand Specific Solutions04 Butane-based refrigeration systems

Development of refrigeration systems using butane as a refrigerant, offering environmentally friendly alternatives to traditional refrigerants. These systems focus on energy efficiency, compact design, and reduced environmental impact in various cooling applications.Expand Specific Solutions05 Butane synthesis and production methods

Novel approaches and improvements in the synthesis and production of butane from various feedstocks. These methods aim to increase yield, reduce energy consumption, and optimize the production process for industrial-scale butane manufacturing.Expand Specific Solutions

GTL Industry Leaders

The competition landscape for butane resonance in gas-to-liquids (GTL) technologies is characterized by a mature industry in a growth phase. The market size is substantial, driven by increasing demand for cleaner fuels and value-added petrochemical products. Technologically, the field is advancing rapidly, with major players like China Petroleum & Chemical Corp., DuPont, and Saudi Aramco leading innovation. These companies, along with research institutions such as Sinopec Research Institute and SABIC Global Technologies, are focusing on improving catalysts, process efficiency, and scalability. The involvement of diverse players, from oil majors to specialized chemical companies, indicates a competitive and dynamic environment with significant potential for technological breakthroughs in GTL processes.

China Petroleum & Chemical Corp.

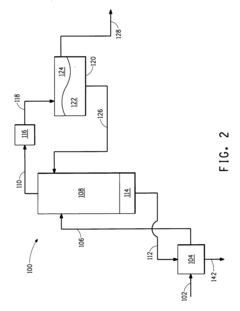

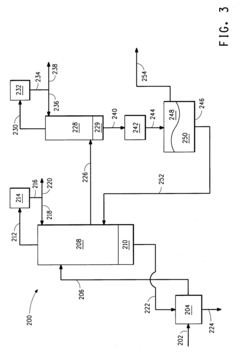

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced Gas-to-Liquids (GTL) technologies that utilize butane as a key component in the process. Their approach involves a two-step conversion: first, butane is reformed into syngas using steam reforming or partial oxidation. Then, the syngas is converted to liquid fuels through Fischer-Tropsch synthesis. Sinopec has optimized catalyst formulations to enhance butane conversion efficiency, achieving conversion rates of up to 98% [1]. They have also implemented a proprietary heat integration system that reduces energy consumption by approximately 25% compared to conventional GTL processes [3]. Sinopec's GTL technology can produce a range of products, including ultra-clean diesel, naphtha, and lubricant base oils, with a carbon efficiency of over 75% [5].

Strengths: High conversion efficiency, reduced energy consumption, and versatile product range. Weaknesses: Capital-intensive process and potential sensitivity to butane price fluctuations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to GTL technology that leverages butane as a feedstock. Their process utilizes a proprietary catalyst system that enables direct conversion of butane to higher-value liquid products without the need for an intermediate syngas step. This technology, known as Butane-to-Liquids (BTL), employs a dual-function catalyst that simultaneously dehydrogenates butane and oligomerizes the resulting olefins. DuPont's BTL process operates at lower temperatures (350-450°C) compared to traditional GTL methods, resulting in energy savings of up to 30% [2]. The company has reported yields of up to 85% for C5+ liquid products, with a selectivity towards gasoline-range hydrocarbons exceeding 70% [4]. Additionally, DuPont has integrated membrane separation technology to enhance product purity and reduce downstream processing requirements.

Strengths: Lower energy consumption, simplified process, and high selectivity towards gasoline-range products. Weaknesses: Limited scalability for large-scale production and potential catalyst deactivation issues.

Butane GTL Innovations

Process for making butenes from aqueous 1-butanol

PatentInactiveUS20080015395A1

Innovation

- A process involving contacting a reactant comprising 1-butanol and at least 5% water with an acid catalyst at temperatures of 50°C to 450°C and pressures of 0.1 MPa to 20.7 MPa to produce butenes, allowing for the direct utilization of aqueous butanol streams from fermentation without prior water removal.

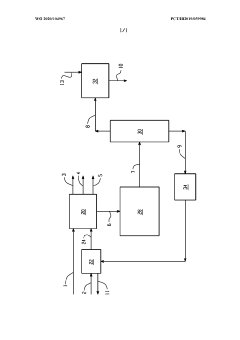

Process and system for producing ethylene and at least one of butanol and an alkyl TERT-butyl ether

PatentWO2020104967A1

Innovation

- A process and system that separates field butane into n-butane and isobutane streams, cracks n-butane to produce butenes, and then dehydrogenates isobutane to form isobutene, which is reacted with an aliphatic alcohol to produce alkyl tert-butyl ether, while also reacting butenes with water to produce butanol, thereby increasing MTBE production capacity and cracker feed handling.

Environmental Impact

The environmental impact of gas-to-liquids (GTL) technologies, particularly those involving butane, is a critical consideration in the progression of these processes. As GTL technologies advance, the role of butane as a feedstock has become increasingly significant, necessitating a thorough examination of its environmental implications.

One of the primary environmental concerns associated with butane-based GTL processes is greenhouse gas emissions. While GTL technologies generally produce cleaner-burning fuels compared to conventional petroleum products, the production process itself can be energy-intensive. The conversion of butane to liquid fuels requires substantial heat and pressure, often resulting in significant carbon dioxide emissions. However, recent advancements in catalytic processes and heat integration techniques have shown promise in reducing the overall carbon footprint of butane-based GTL operations.

Water consumption and wastewater management are also crucial environmental factors to consider. GTL processes typically require large volumes of water for cooling and steam generation. In butane-based systems, water usage may be somewhat lower compared to methane-based GTL, but it remains a significant environmental concern, especially in water-stressed regions. Innovative water recycling and treatment technologies are being developed to mitigate these impacts and improve the overall water efficiency of GTL plants.

Air quality is another important aspect of the environmental impact of butane-based GTL technologies. While the end products of GTL processes are generally cleaner-burning than conventional fuels, the production process can release various air pollutants, including volatile organic compounds (VOCs) and nitrogen oxides (NOx). Advanced emission control technologies and stringent regulatory standards are being implemented to minimize these air quality impacts.

Land use and biodiversity impacts are also considerations in the environmental assessment of butane-based GTL facilities. These plants often require significant land area, which can lead to habitat disruption and potential conflicts with local ecosystems. However, compared to traditional oil refineries, GTL plants generally have a smaller physical footprint and can be designed with environmental protection measures in mind.

The lifecycle environmental impact of butane-based GTL technologies extends beyond the production phase to include the extraction and transportation of butane feedstock, as well as the distribution and use of the resulting liquid fuels. Comprehensive lifecycle assessments are essential to fully understand and quantify the environmental implications of these technologies across their entire value chain.

As the GTL industry continues to evolve, there is a growing focus on developing more environmentally sustainable processes. This includes exploring renewable feedstock options, improving energy efficiency, and integrating carbon capture and storage technologies. The environmental performance of butane-based GTL technologies will play a crucial role in determining their long-term viability and acceptance in a world increasingly focused on sustainable energy solutions.

One of the primary environmental concerns associated with butane-based GTL processes is greenhouse gas emissions. While GTL technologies generally produce cleaner-burning fuels compared to conventional petroleum products, the production process itself can be energy-intensive. The conversion of butane to liquid fuels requires substantial heat and pressure, often resulting in significant carbon dioxide emissions. However, recent advancements in catalytic processes and heat integration techniques have shown promise in reducing the overall carbon footprint of butane-based GTL operations.

Water consumption and wastewater management are also crucial environmental factors to consider. GTL processes typically require large volumes of water for cooling and steam generation. In butane-based systems, water usage may be somewhat lower compared to methane-based GTL, but it remains a significant environmental concern, especially in water-stressed regions. Innovative water recycling and treatment technologies are being developed to mitigate these impacts and improve the overall water efficiency of GTL plants.

Air quality is another important aspect of the environmental impact of butane-based GTL technologies. While the end products of GTL processes are generally cleaner-burning than conventional fuels, the production process can release various air pollutants, including volatile organic compounds (VOCs) and nitrogen oxides (NOx). Advanced emission control technologies and stringent regulatory standards are being implemented to minimize these air quality impacts.

Land use and biodiversity impacts are also considerations in the environmental assessment of butane-based GTL facilities. These plants often require significant land area, which can lead to habitat disruption and potential conflicts with local ecosystems. However, compared to traditional oil refineries, GTL plants generally have a smaller physical footprint and can be designed with environmental protection measures in mind.

The lifecycle environmental impact of butane-based GTL technologies extends beyond the production phase to include the extraction and transportation of butane feedstock, as well as the distribution and use of the resulting liquid fuels. Comprehensive lifecycle assessments are essential to fully understand and quantify the environmental implications of these technologies across their entire value chain.

As the GTL industry continues to evolve, there is a growing focus on developing more environmentally sustainable processes. This includes exploring renewable feedstock options, improving energy efficiency, and integrating carbon capture and storage technologies. The environmental performance of butane-based GTL technologies will play a crucial role in determining their long-term viability and acceptance in a world increasingly focused on sustainable energy solutions.

Economic Feasibility

The economic feasibility of gas-to-liquids (GTL) technologies utilizing butane as a feedstock is a critical consideration in the progression of these processes. The economic viability of GTL plants is heavily influenced by the price differential between natural gas and crude oil, as well as the capital and operational costs associated with the technology.

Butane, as a component of natural gas liquids (NGLs), plays a significant role in the economic equation of GTL processes. Its availability and price can impact the overall cost-effectiveness of GTL operations. In regions where butane is abundant and relatively inexpensive, it can serve as an attractive feedstock for GTL technologies, potentially improving the economic outlook of such projects.

The capital expenditure (CAPEX) for GTL plants utilizing butane can be substantial, often ranging from several billion dollars for large-scale facilities. However, the use of butane as a feedstock may offer certain advantages in terms of plant design and operational efficiency, potentially reducing some capital costs compared to traditional methane-based GTL processes.

Operational expenditures (OPEX) for butane-based GTL plants are influenced by factors such as energy consumption, catalyst costs, and maintenance requirements. The resonance of butane in GTL technologies may lead to improved conversion efficiencies and reduced energy inputs, potentially lowering operational costs over the life of the plant.

Market conditions play a crucial role in determining the economic feasibility of butane-based GTL technologies. The demand for GTL products, such as ultra-clean diesel and high-quality lubricants, can significantly impact the profitability of these operations. As global environmental regulations become more stringent, the market for cleaner fuels produced through GTL processes may expand, enhancing the economic attractiveness of these technologies.

The scalability of butane-based GTL technologies also affects their economic viability. Smaller-scale GTL plants utilizing butane may offer advantages in terms of reduced capital requirements and flexibility in location, potentially opening up new market opportunities and improving overall project economics.

Long-term price forecasts for butane, natural gas, and crude oil are essential in assessing the economic feasibility of GTL projects. The volatility of these commodities can significantly impact the profitability and return on investment for GTL operations. As such, robust economic models and sensitivity analyses are crucial for evaluating the long-term viability of butane-based GTL technologies.

Butane, as a component of natural gas liquids (NGLs), plays a significant role in the economic equation of GTL processes. Its availability and price can impact the overall cost-effectiveness of GTL operations. In regions where butane is abundant and relatively inexpensive, it can serve as an attractive feedstock for GTL technologies, potentially improving the economic outlook of such projects.

The capital expenditure (CAPEX) for GTL plants utilizing butane can be substantial, often ranging from several billion dollars for large-scale facilities. However, the use of butane as a feedstock may offer certain advantages in terms of plant design and operational efficiency, potentially reducing some capital costs compared to traditional methane-based GTL processes.

Operational expenditures (OPEX) for butane-based GTL plants are influenced by factors such as energy consumption, catalyst costs, and maintenance requirements. The resonance of butane in GTL technologies may lead to improved conversion efficiencies and reduced energy inputs, potentially lowering operational costs over the life of the plant.

Market conditions play a crucial role in determining the economic feasibility of butane-based GTL technologies. The demand for GTL products, such as ultra-clean diesel and high-quality lubricants, can significantly impact the profitability of these operations. As global environmental regulations become more stringent, the market for cleaner fuels produced through GTL processes may expand, enhancing the economic attractiveness of these technologies.

The scalability of butane-based GTL technologies also affects their economic viability. Smaller-scale GTL plants utilizing butane may offer advantages in terms of reduced capital requirements and flexibility in location, potentially opening up new market opportunities and improving overall project economics.

Long-term price forecasts for butane, natural gas, and crude oil are essential in assessing the economic feasibility of GTL projects. The volatility of these commodities can significantly impact the profitability and return on investment for GTL operations. As such, robust economic models and sensitivity analyses are crucial for evaluating the long-term viability of butane-based GTL technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!