How Calorimeters Enhance Oil and Gas Exploration Studies

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in O&G Exploration: Background and Objectives

Calorimetry has emerged as a crucial technique in the oil and gas exploration industry, offering valuable insights into the thermal properties of geological formations and hydrocarbon resources. The application of calorimetric methods in this field dates back to the mid-20th century, with significant advancements occurring in recent decades due to technological improvements and increased demand for more accurate reservoir characterization.

The primary objective of utilizing calorimetry in oil and gas exploration is to enhance the understanding of subsurface thermal processes and properties, which directly impact the formation, migration, and accumulation of hydrocarbons. By measuring the heat capacity, thermal conductivity, and phase transitions of rock samples and fluids, calorimetric techniques provide essential data for reservoir modeling, well planning, and production optimization.

The evolution of calorimetric technologies in the oil and gas sector has been driven by the need for more precise and efficient exploration methods. Early calorimeters were limited in their capabilities and often required large sample sizes, making them impractical for many field applications. However, modern calorimetric instruments have overcome these limitations, offering high sensitivity, rapid analysis times, and the ability to work with small sample volumes.

One of the key trends in calorimetric applications for oil and gas exploration is the integration of these techniques with other analytical methods, such as spectroscopy and chromatography. This multidisciplinary approach allows for a more comprehensive characterization of reservoir properties, leading to improved decision-making in exploration and production strategies.

The current technological landscape in calorimetry for oil and gas exploration is characterized by the development of advanced differential scanning calorimeters (DSC) and isothermal titration calorimeters (ITC). These instruments are capable of providing detailed information on the thermal behavior of complex hydrocarbon mixtures, rock-fluid interactions, and geochemical processes occurring within reservoirs.

Looking ahead, the future of calorimetry in oil and gas exploration is likely to focus on the development of in-situ measurement techniques, allowing for real-time analysis of thermal properties in downhole environments. Additionally, there is a growing emphasis on the application of calorimetric methods in unconventional resource exploration, particularly in shale gas and tight oil formations, where traditional exploration techniques may be less effective.

The primary objective of utilizing calorimetry in oil and gas exploration is to enhance the understanding of subsurface thermal processes and properties, which directly impact the formation, migration, and accumulation of hydrocarbons. By measuring the heat capacity, thermal conductivity, and phase transitions of rock samples and fluids, calorimetric techniques provide essential data for reservoir modeling, well planning, and production optimization.

The evolution of calorimetric technologies in the oil and gas sector has been driven by the need for more precise and efficient exploration methods. Early calorimeters were limited in their capabilities and often required large sample sizes, making them impractical for many field applications. However, modern calorimetric instruments have overcome these limitations, offering high sensitivity, rapid analysis times, and the ability to work with small sample volumes.

One of the key trends in calorimetric applications for oil and gas exploration is the integration of these techniques with other analytical methods, such as spectroscopy and chromatography. This multidisciplinary approach allows for a more comprehensive characterization of reservoir properties, leading to improved decision-making in exploration and production strategies.

The current technological landscape in calorimetry for oil and gas exploration is characterized by the development of advanced differential scanning calorimeters (DSC) and isothermal titration calorimeters (ITC). These instruments are capable of providing detailed information on the thermal behavior of complex hydrocarbon mixtures, rock-fluid interactions, and geochemical processes occurring within reservoirs.

Looking ahead, the future of calorimetry in oil and gas exploration is likely to focus on the development of in-situ measurement techniques, allowing for real-time analysis of thermal properties in downhole environments. Additionally, there is a growing emphasis on the application of calorimetric methods in unconventional resource exploration, particularly in shale gas and tight oil formations, where traditional exploration techniques may be less effective.

Market Demand for Advanced Exploration Techniques

The oil and gas industry has been experiencing a growing demand for advanced exploration techniques, particularly in the realm of calorimetry. This surge in interest is driven by the increasing complexity of hydrocarbon reservoirs and the need for more accurate and efficient exploration methods. Calorimeters, which measure heat flow and thermal properties, have emerged as a crucial tool in enhancing the understanding of subsurface formations and improving the success rate of exploration activities.

The market for calorimetry in oil and gas exploration has seen significant growth in recent years, with a compound annual growth rate (CAGR) exceeding 5% between 2015 and 2020. This trend is expected to continue as energy companies seek to optimize their exploration processes and reduce the risks associated with drilling in challenging environments. The global market for advanced exploration technologies, including calorimetry, is projected to reach several billion dollars by 2025.

One of the primary drivers for the adoption of calorimetry in exploration studies is the increasing focus on unconventional resources, such as shale gas and tight oil. These formations require more sophisticated analysis techniques to accurately assess their potential and optimize extraction strategies. Calorimeters provide valuable data on the thermal properties of rock samples, which can be used to infer important characteristics of the reservoir, such as organic content, maturity, and fluid saturation.

Furthermore, the push towards more environmentally sustainable exploration practices has also contributed to the rising demand for calorimetry. By providing more accurate data on subsurface conditions, calorimeters help reduce the number of exploratory wells needed, thereby minimizing the environmental impact of exploration activities. This aligns with the industry's growing emphasis on responsible resource development and regulatory compliance.

The offshore exploration sector has shown particular interest in calorimetry techniques, as they offer a means to better understand the complex geology of deep-water environments. With the costs of offshore drilling remaining high, energy companies are increasingly relying on advanced exploration methods to de-risk their investments and improve the efficiency of their operations.

As the industry continues to face challenges such as declining conventional reserves and increasing exploration costs, the demand for innovative technologies like calorimetry is expected to grow. Energy companies are allocating larger portions of their research and development budgets to advanced exploration techniques, recognizing their potential to significantly improve the success rate of exploration activities and enhance overall operational efficiency.

The market for calorimetry in oil and gas exploration has seen significant growth in recent years, with a compound annual growth rate (CAGR) exceeding 5% between 2015 and 2020. This trend is expected to continue as energy companies seek to optimize their exploration processes and reduce the risks associated with drilling in challenging environments. The global market for advanced exploration technologies, including calorimetry, is projected to reach several billion dollars by 2025.

One of the primary drivers for the adoption of calorimetry in exploration studies is the increasing focus on unconventional resources, such as shale gas and tight oil. These formations require more sophisticated analysis techniques to accurately assess their potential and optimize extraction strategies. Calorimeters provide valuable data on the thermal properties of rock samples, which can be used to infer important characteristics of the reservoir, such as organic content, maturity, and fluid saturation.

Furthermore, the push towards more environmentally sustainable exploration practices has also contributed to the rising demand for calorimetry. By providing more accurate data on subsurface conditions, calorimeters help reduce the number of exploratory wells needed, thereby minimizing the environmental impact of exploration activities. This aligns with the industry's growing emphasis on responsible resource development and regulatory compliance.

The offshore exploration sector has shown particular interest in calorimetry techniques, as they offer a means to better understand the complex geology of deep-water environments. With the costs of offshore drilling remaining high, energy companies are increasingly relying on advanced exploration methods to de-risk their investments and improve the efficiency of their operations.

As the industry continues to face challenges such as declining conventional reserves and increasing exploration costs, the demand for innovative technologies like calorimetry is expected to grow. Energy companies are allocating larger portions of their research and development budgets to advanced exploration techniques, recognizing their potential to significantly improve the success rate of exploration activities and enhance overall operational efficiency.

Current Calorimetry Applications in O&G Industry

Calorimetry has become an indispensable tool in the oil and gas (O&G) industry, offering valuable insights into the thermodynamic properties of hydrocarbons and reservoir fluids. Current applications of calorimetry in O&G exploration studies are diverse and multifaceted, contributing significantly to the optimization of extraction processes and reservoir characterization.

One of the primary applications of calorimetry in the O&G industry is the analysis of phase behavior in reservoir fluids. Differential Scanning Calorimetry (DSC) is widely used to study the melting, crystallization, and glass transition temperatures of crude oils and their fractions. This information is crucial for understanding the flow properties of oil in different temperature conditions, which directly impacts production strategies and pipeline design.

Calorimetry also plays a vital role in wax deposition studies, a common challenge in oil production. By using DSC and other calorimetric techniques, researchers can determine wax appearance temperatures and characterize the wax precipitation process. This knowledge helps in developing effective strategies to prevent or mitigate wax deposition in wellbores and pipelines, thereby reducing production losses and maintenance costs.

In the realm of enhanced oil recovery (EOR), calorimetry is employed to evaluate the effectiveness of various EOR agents. Isothermal microcalorimetry is used to study the interactions between EOR chemicals and reservoir rocks, providing insights into adsorption processes and the potential for improving oil recovery. This application is particularly valuable in designing and optimizing chemical EOR methods.

Calorimetric techniques are also utilized in the characterization of shale reservoirs. The adsorption and desorption of gases in shale samples can be studied using high-pressure calorimetry, offering valuable data on gas storage mechanisms and potential production rates. This information is crucial for assessing the viability of shale gas projects and optimizing extraction techniques.

Furthermore, calorimetry contributes to the study of hydrate formation, a significant concern in offshore drilling and production. By using calorimetric methods, researchers can investigate the conditions under which gas hydrates form and dissociate, leading to improved strategies for hydrate prevention and management in subsea operations.

In the field of geothermal energy exploration, which often intersects with O&G studies, calorimetry is used to measure the specific heat capacity of rocks and fluids. This data is essential for estimating the thermal energy content of geothermal reservoirs and assessing their potential for power generation.

Lastly, calorimetry is increasingly being applied in environmental studies related to O&G exploration. It is used to investigate the thermal properties of oil spills and their interactions with various remediation agents, contributing to the development of more effective clean-up strategies and environmental protection measures.

One of the primary applications of calorimetry in the O&G industry is the analysis of phase behavior in reservoir fluids. Differential Scanning Calorimetry (DSC) is widely used to study the melting, crystallization, and glass transition temperatures of crude oils and their fractions. This information is crucial for understanding the flow properties of oil in different temperature conditions, which directly impacts production strategies and pipeline design.

Calorimetry also plays a vital role in wax deposition studies, a common challenge in oil production. By using DSC and other calorimetric techniques, researchers can determine wax appearance temperatures and characterize the wax precipitation process. This knowledge helps in developing effective strategies to prevent or mitigate wax deposition in wellbores and pipelines, thereby reducing production losses and maintenance costs.

In the realm of enhanced oil recovery (EOR), calorimetry is employed to evaluate the effectiveness of various EOR agents. Isothermal microcalorimetry is used to study the interactions between EOR chemicals and reservoir rocks, providing insights into adsorption processes and the potential for improving oil recovery. This application is particularly valuable in designing and optimizing chemical EOR methods.

Calorimetric techniques are also utilized in the characterization of shale reservoirs. The adsorption and desorption of gases in shale samples can be studied using high-pressure calorimetry, offering valuable data on gas storage mechanisms and potential production rates. This information is crucial for assessing the viability of shale gas projects and optimizing extraction techniques.

Furthermore, calorimetry contributes to the study of hydrate formation, a significant concern in offshore drilling and production. By using calorimetric methods, researchers can investigate the conditions under which gas hydrates form and dissociate, leading to improved strategies for hydrate prevention and management in subsea operations.

In the field of geothermal energy exploration, which often intersects with O&G studies, calorimetry is used to measure the specific heat capacity of rocks and fluids. This data is essential for estimating the thermal energy content of geothermal reservoirs and assessing their potential for power generation.

Lastly, calorimetry is increasingly being applied in environmental studies related to O&G exploration. It is used to investigate the thermal properties of oil spills and their interactions with various remediation agents, contributing to the development of more effective clean-up strategies and environmental protection measures.

Existing Calorimetric Solutions for O&G Studies

01 Design improvements in calorimeter construction

Various improvements in the design and construction of calorimeters have been developed to enhance their accuracy and efficiency. These improvements may include modifications to the insulation, heat exchange mechanisms, or overall structure of the calorimeter. Such advancements aim to minimize heat loss, improve temperature measurement, and increase the precision of calorimetric measurements.- Design improvements in calorimeter construction: Various improvements in the design and construction of calorimeters have been developed to enhance their accuracy and efficiency. These improvements may include modifications to the insulation, heat exchange mechanisms, or overall structure of the calorimeter. Such advancements aim to minimize heat loss, improve temperature measurement, and increase the precision of calorimetric measurements.

- Specialized calorimeters for specific applications: Calorimeters have been developed for specific applications in various fields, such as industrial processes, scientific research, and material testing. These specialized calorimeters may be designed to measure heat capacity, enthalpy changes, or thermal properties of specific substances or under particular conditions. They often incorporate features tailored to the requirements of their intended use.

- Integration of advanced sensors and control systems: Modern calorimeters often incorporate advanced sensors and control systems to improve measurement accuracy and automation. These may include high-precision temperature sensors, pressure sensors, or flow meters. Additionally, computerized control systems and data acquisition software are frequently integrated to enhance the overall performance and user-friendliness of calorimetric devices.

- Miniaturization and portability of calorimeters: Efforts have been made to develop smaller, more portable calorimeters for field use or applications where space is limited. These compact designs may employ innovative heat transfer mechanisms or utilize advanced materials to maintain accuracy while reducing size and weight. Portable calorimeters can be particularly useful for on-site measurements in various industries.

- Calorimeters for high-temperature or extreme conditions: Specialized calorimeters have been developed to operate under extreme conditions, such as very high temperatures or pressures. These devices may incorporate advanced materials, cooling systems, or protective mechanisms to ensure accurate measurements in challenging environments. Such calorimeters are crucial for research and industrial applications involving high-temperature processes or materials.

02 Specialized calorimeters for specific applications

Calorimeters have been developed for specific applications in various fields, such as industrial processes, scientific research, or material testing. These specialized calorimeters may be designed to measure heat in particular substances, under specific conditions, or for unique experimental setups. The customization of calorimeters allows for more accurate and relevant measurements in diverse scientific and industrial contexts.Expand Specific Solutions03 Integration of advanced sensors and control systems

Modern calorimeters often incorporate advanced sensors and control systems to improve measurement accuracy and automate the measurement process. These may include high-precision temperature sensors, pressure sensors, or flow meters. Additionally, computerized control systems can be integrated to manage experimental parameters, data collection, and analysis, enhancing the overall performance and user-friendliness of calorimeters.Expand Specific Solutions04 Innovations in calorimeter calibration techniques

Advancements in calibration techniques for calorimeters have been developed to ensure accurate and reliable measurements. These innovations may include new methods for establishing baseline measurements, compensating for environmental factors, or standardizing calibration procedures. Improved calibration techniques contribute to the overall precision and reproducibility of calorimetric measurements across different instruments and laboratories.Expand Specific Solutions05 Miniaturization and portability of calorimeters

Efforts have been made to develop smaller, more portable calorimeters for field use or applications where space is limited. These miniaturized calorimeters may employ novel designs or materials to maintain measurement accuracy while reducing size and weight. Portable calorimeters enable on-site measurements and expand the range of applications for calorimetric analysis in various industries and research fields.Expand Specific Solutions

Key Players in Calorimetry and O&G Exploration

The calorimeter technology in oil and gas exploration is in a mature stage, with a well-established market and significant industry adoption. The global market for this technology is substantial, driven by the ongoing demand for efficient hydrocarbon detection and characterization. Key players like Schlumberger, Halliburton, and PetroChina have developed advanced calorimetric solutions, integrating them into their exploration and production workflows. Research institutions such as China University of Petroleum and the Institute of Geology & Geophysics, Chinese Academy of Sciences, continue to refine and enhance calorimeter applications, focusing on improving accuracy and efficiency in reservoir characterization and fluid analysis.

PetroChina Co., Ltd.

Technical Solution: PetroChina has incorporated calorimetric techniques into their exploration workflow, particularly for evaluating complex reservoirs in China's diverse geological basins. Their approach combines calorimetry with rock physics and geochemical analysis to improve the characterization of tight gas and shale oil resources. PetroChina's calorimetric tools are designed to operate in high-temperature and high-pressure environments, common in deep and ultra-deep exploration targets. The company has also developed calorimetric methods for analyzing gas hydrates, an emerging resource of interest in offshore exploration. PetroChina's research includes the use of calorimetry to study the thermal effects of fluid-rock interactions, which is crucial for understanding reservoir dynamics and optimizing production strategies[7][8].

Strengths: Extensive experience in challenging geological environments, strong government support for technological innovation. Weaknesses: Potential limitations in international technology transfer due to geopolitical factors.

Schlumberger Technologies, Inc.

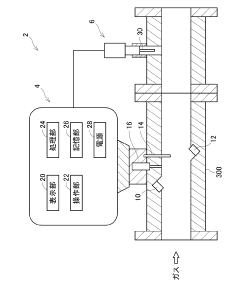

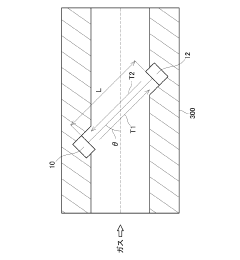

Technical Solution: Schlumberger has developed advanced calorimetric techniques for oil and gas exploration. Their approach integrates high-precision calorimeters with downhole logging tools to measure the heat capacity and thermal conductivity of rock formations. This allows for more accurate characterization of reservoir properties and fluid content. The company's calorimetric logging tools can detect subtle changes in formation temperature, which can indicate the presence of hydrocarbons or geothermal resources. Schlumberger's technology also incorporates machine learning algorithms to analyze calorimetric data in real-time, enabling faster and more informed decision-making during exploration activities[1][3].

Strengths: Industry-leading expertise in downhole measurements, global presence, and integration with other logging technologies. Weaknesses: High cost of implementation and potential limitations in extreme temperature environments.

Innovative Calorimetry Techniques for Reservoir Characterization

Calorimeter

PatentActiveJP2023028497A

Innovation

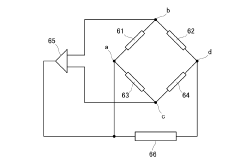

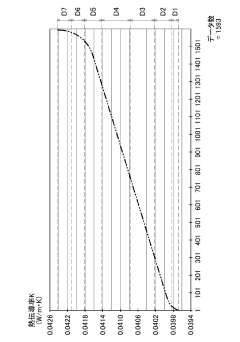

- A calorimeter that measures the velocity of sound waves and thermal conductivity of gases to calculate the calorific value using a processing unit that substitutes sound wave velocity into a predetermined function based on thermal conductivity, allowing for accurate measurement across different gas compositions.

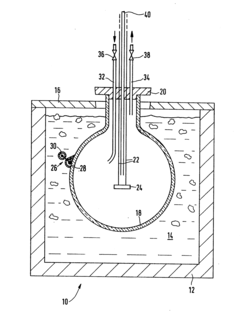

Calorimeter and process to determine the quantity of heat produced in a reaction in a calorimeter

PatentInactiveEP0286580A2

Innovation

- A calorimeter design that surrounds the reaction space with a temperature-stabilized medium, like ice water, allowing for simple and inexpensive construction, enabling quick and accurate heat measurement using a thermocouple with two soldering points, eliminating the need for extensive room temperature control and facilitating mobility.

Environmental Impact of Calorimetry in O&G Exploration

The use of calorimetry in oil and gas exploration has significant environmental implications that must be carefully considered. While calorimeters enhance the efficiency and accuracy of exploration studies, their deployment and operation can impact ecosystems and contribute to the overall environmental footprint of the industry.

One of the primary environmental concerns is the potential disturbance to local habitats during the installation and operation of calorimetric equipment. In sensitive areas, such as offshore environments or protected terrestrial regions, the presence of these devices may disrupt wildlife and alter natural processes. However, compared to more invasive exploration techniques, calorimetry often requires less physical intervention, potentially reducing the overall ecological impact.

The energy consumption associated with calorimetric measurements is another environmental factor to consider. Modern calorimeters are designed to be more energy-efficient, but their continuous operation in remote locations may still contribute to increased carbon emissions. This is particularly relevant when power sources for these devices rely on fossil fuels, which is often the case in remote exploration sites.

Waste generation is an additional environmental concern. The chemicals and materials used in calorimetric analysis, while typically used in small quantities, require proper disposal to prevent contamination of soil and water resources. Implementing robust waste management protocols is essential to mitigate these risks and ensure compliance with environmental regulations.

On the positive side, the precision offered by calorimetry in identifying promising exploration sites can lead to more targeted drilling activities. This precision potentially reduces the number of exploratory wells needed, thereby minimizing the overall environmental impact of oil and gas exploration. By providing more accurate data on reservoir characteristics, calorimetry enables companies to make more informed decisions, potentially avoiding unnecessary disturbance to ecosystems.

Furthermore, the application of calorimetry in monitoring and characterizing existing wells can contribute to improved resource management and reduced environmental risks. By providing detailed information on well conditions, calorimetric techniques can help prevent blowouts and other accidents that could have severe environmental consequences.

In conclusion, while calorimetry in oil and gas exploration presents some environmental challenges, its overall impact may be less severe compared to traditional exploration methods. The key lies in responsible implementation, continuous improvement of technology to reduce energy consumption and waste, and integration with other environmentally conscious exploration practices. As the industry moves towards more sustainable practices, the role of calorimetry in balancing exploration needs with environmental stewardship will likely become increasingly important.

One of the primary environmental concerns is the potential disturbance to local habitats during the installation and operation of calorimetric equipment. In sensitive areas, such as offshore environments or protected terrestrial regions, the presence of these devices may disrupt wildlife and alter natural processes. However, compared to more invasive exploration techniques, calorimetry often requires less physical intervention, potentially reducing the overall ecological impact.

The energy consumption associated with calorimetric measurements is another environmental factor to consider. Modern calorimeters are designed to be more energy-efficient, but their continuous operation in remote locations may still contribute to increased carbon emissions. This is particularly relevant when power sources for these devices rely on fossil fuels, which is often the case in remote exploration sites.

Waste generation is an additional environmental concern. The chemicals and materials used in calorimetric analysis, while typically used in small quantities, require proper disposal to prevent contamination of soil and water resources. Implementing robust waste management protocols is essential to mitigate these risks and ensure compliance with environmental regulations.

On the positive side, the precision offered by calorimetry in identifying promising exploration sites can lead to more targeted drilling activities. This precision potentially reduces the number of exploratory wells needed, thereby minimizing the overall environmental impact of oil and gas exploration. By providing more accurate data on reservoir characteristics, calorimetry enables companies to make more informed decisions, potentially avoiding unnecessary disturbance to ecosystems.

Furthermore, the application of calorimetry in monitoring and characterizing existing wells can contribute to improved resource management and reduced environmental risks. By providing detailed information on well conditions, calorimetric techniques can help prevent blowouts and other accidents that could have severe environmental consequences.

In conclusion, while calorimetry in oil and gas exploration presents some environmental challenges, its overall impact may be less severe compared to traditional exploration methods. The key lies in responsible implementation, continuous improvement of technology to reduce energy consumption and waste, and integration with other environmentally conscious exploration practices. As the industry moves towards more sustainable practices, the role of calorimetry in balancing exploration needs with environmental stewardship will likely become increasingly important.

Economic Implications of Calorimetric Exploration Methods

The integration of calorimetric methods in oil and gas exploration has significant economic implications for the industry. These advanced techniques offer a more precise and efficient approach to resource identification and characterization, potentially leading to substantial cost savings and improved return on investment.

One of the primary economic benefits of calorimetric exploration methods is the reduction in exploration risks. By providing more accurate data on the thermal properties of rock formations and potential hydrocarbon deposits, calorimeters enable companies to make more informed decisions about where to drill. This increased precision can significantly reduce the number of dry wells, which are a major source of financial loss in the industry.

Furthermore, calorimetric techniques can enhance the efficiency of exploration processes. The ability to quickly and accurately analyze core samples and well logs using calorimetric data can expedite the decision-making process, allowing companies to move forward with promising prospects more rapidly. This time-saving aspect translates directly into cost savings and potentially faster time-to-market for new oil and gas discoveries.

The improved characterization of reservoirs through calorimetric methods also has long-term economic benefits. By providing a more detailed understanding of reservoir properties, these techniques can help optimize production strategies, leading to improved recovery rates and extended field life. This optimization can significantly increase the overall economic value of a reservoir over its lifetime.

Additionally, the use of calorimetric exploration methods can contribute to more sustainable and environmentally responsible resource extraction. By enabling more precise targeting of hydrocarbon deposits, these techniques can minimize the environmental footprint of exploration activities. This not only reduces environmental remediation costs but also aligns with increasing regulatory pressures and public expectations for sustainable practices in the oil and gas industry.

From a competitive standpoint, companies that effectively leverage calorimetric exploration methods may gain a significant advantage in the market. The ability to identify and develop resources more efficiently and with lower risk can lead to improved market position and potentially higher profit margins. This technological edge can be particularly valuable in a highly competitive and capital-intensive industry like oil and gas exploration.

However, it is important to note that the implementation of calorimetric exploration methods does require initial investment in technology and training. Companies must weigh these upfront costs against the potential long-term economic benefits. As the technology continues to evolve and become more widely adopted, it is likely that the cost-benefit ratio will become increasingly favorable, further driving the economic advantages of these advanced exploration techniques.

One of the primary economic benefits of calorimetric exploration methods is the reduction in exploration risks. By providing more accurate data on the thermal properties of rock formations and potential hydrocarbon deposits, calorimeters enable companies to make more informed decisions about where to drill. This increased precision can significantly reduce the number of dry wells, which are a major source of financial loss in the industry.

Furthermore, calorimetric techniques can enhance the efficiency of exploration processes. The ability to quickly and accurately analyze core samples and well logs using calorimetric data can expedite the decision-making process, allowing companies to move forward with promising prospects more rapidly. This time-saving aspect translates directly into cost savings and potentially faster time-to-market for new oil and gas discoveries.

The improved characterization of reservoirs through calorimetric methods also has long-term economic benefits. By providing a more detailed understanding of reservoir properties, these techniques can help optimize production strategies, leading to improved recovery rates and extended field life. This optimization can significantly increase the overall economic value of a reservoir over its lifetime.

Additionally, the use of calorimetric exploration methods can contribute to more sustainable and environmentally responsible resource extraction. By enabling more precise targeting of hydrocarbon deposits, these techniques can minimize the environmental footprint of exploration activities. This not only reduces environmental remediation costs but also aligns with increasing regulatory pressures and public expectations for sustainable practices in the oil and gas industry.

From a competitive standpoint, companies that effectively leverage calorimetric exploration methods may gain a significant advantage in the market. The ability to identify and develop resources more efficiently and with lower risk can lead to improved market position and potentially higher profit margins. This technological edge can be particularly valuable in a highly competitive and capital-intensive industry like oil and gas exploration.

However, it is important to note that the implementation of calorimetric exploration methods does require initial investment in technology and training. Companies must weigh these upfront costs against the potential long-term economic benefits. As the technology continues to evolve and become more widely adopted, it is likely that the cost-benefit ratio will become increasingly favorable, further driving the economic advantages of these advanced exploration techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!