How Calorimetry Enhances Microelectronic Circuit Thermal Management Designs

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in Thermal Management: Background and Objectives

Calorimetry, a fundamental technique in thermal analysis, has emerged as a critical tool in the field of microelectronic circuit thermal management. The evolution of this technology can be traced back to the early days of thermodynamics, with its principles rooted in the work of scientists like Lavoisier and Laplace in the late 18th century. As microelectronics advanced rapidly in the latter half of the 20th century, the need for precise thermal management became increasingly apparent.

The primary objective of incorporating calorimetry in microelectronic thermal management is to enhance the accuracy and efficiency of heat dissipation strategies. This integration aims to address the growing challenges posed by the continuous miniaturization and increasing power density of modern electronic devices. By providing detailed insights into heat generation and transfer within circuits, calorimetry enables engineers to develop more effective cooling solutions and optimize overall system performance.

In the context of microelectronics, calorimetry has undergone significant adaptations to meet the specific requirements of the industry. Traditional calorimetric methods have been refined and new techniques developed to accommodate the unique characteristics of semiconductor devices and integrated circuits. These advancements have led to the creation of specialized calorimeters capable of measuring heat dissipation at the microscale and even nanoscale levels.

The technological trajectory of calorimetry in thermal management has been driven by several key factors. The relentless pursuit of Moore's Law, which predicts the doubling of transistor density approximately every two years, has consistently pushed the boundaries of thermal management capabilities. This has necessitated increasingly sophisticated calorimetric techniques to accurately measure and predict heat generation in ever-more complex and compact circuit designs.

Furthermore, the rise of high-performance computing, mobile devices, and the Internet of Things (IoT) has amplified the importance of efficient thermal management. These applications demand not only high processing power but also stringent thermal control to ensure reliability, longevity, and user comfort. Calorimetry plays a crucial role in meeting these demands by providing the data necessary for developing advanced cooling strategies and thermal-aware circuit designs.

Looking ahead, the goals for calorimetry in microelectronic thermal management are multifaceted. They include developing real-time, in-situ calorimetric measurement techniques for active thermal management, improving the spatial and temporal resolution of heat flow measurements, and integrating calorimetric data with computational fluid dynamics (CFD) simulations for more accurate thermal modeling. Additionally, there is a push towards non-invasive calorimetric methods that can provide thermal insights without interfering with circuit operation.

The primary objective of incorporating calorimetry in microelectronic thermal management is to enhance the accuracy and efficiency of heat dissipation strategies. This integration aims to address the growing challenges posed by the continuous miniaturization and increasing power density of modern electronic devices. By providing detailed insights into heat generation and transfer within circuits, calorimetry enables engineers to develop more effective cooling solutions and optimize overall system performance.

In the context of microelectronics, calorimetry has undergone significant adaptations to meet the specific requirements of the industry. Traditional calorimetric methods have been refined and new techniques developed to accommodate the unique characteristics of semiconductor devices and integrated circuits. These advancements have led to the creation of specialized calorimeters capable of measuring heat dissipation at the microscale and even nanoscale levels.

The technological trajectory of calorimetry in thermal management has been driven by several key factors. The relentless pursuit of Moore's Law, which predicts the doubling of transistor density approximately every two years, has consistently pushed the boundaries of thermal management capabilities. This has necessitated increasingly sophisticated calorimetric techniques to accurately measure and predict heat generation in ever-more complex and compact circuit designs.

Furthermore, the rise of high-performance computing, mobile devices, and the Internet of Things (IoT) has amplified the importance of efficient thermal management. These applications demand not only high processing power but also stringent thermal control to ensure reliability, longevity, and user comfort. Calorimetry plays a crucial role in meeting these demands by providing the data necessary for developing advanced cooling strategies and thermal-aware circuit designs.

Looking ahead, the goals for calorimetry in microelectronic thermal management are multifaceted. They include developing real-time, in-situ calorimetric measurement techniques for active thermal management, improving the spatial and temporal resolution of heat flow measurements, and integrating calorimetric data with computational fluid dynamics (CFD) simulations for more accurate thermal modeling. Additionally, there is a push towards non-invasive calorimetric methods that can provide thermal insights without interfering with circuit operation.

Market Demand for Advanced Thermal Solutions

The market demand for advanced thermal solutions in microelectronic circuit design has been steadily increasing due to the continuous miniaturization and increased power density of electronic devices. As circuits become more compact and powerful, the need for effective heat dissipation becomes critical to ensure optimal performance and longevity of electronic components.

The semiconductor industry, in particular, has been driving the demand for innovative thermal management solutions. With the advent of 5G technology, artificial intelligence, and the Internet of Things (IoT), there is a growing need for high-performance chips that can operate reliably under intense thermal conditions. This has led to a surge in research and development efforts focused on advanced cooling techniques, including the application of calorimetry in thermal management designs.

Calorimetry, as a precise method for measuring heat transfer and energy dissipation, has gained significant attention in the microelectronics industry. Its ability to provide accurate thermal characterization of electronic components allows engineers to optimize circuit designs for better heat distribution and dissipation. This has become especially crucial in applications such as data centers, where energy efficiency and thermal management are paramount concerns.

The automotive sector has also emerged as a key driver for advanced thermal solutions. With the rapid growth of electric vehicles and autonomous driving technologies, the demand for sophisticated thermal management systems in automotive electronics has skyrocketed. Calorimetry-based approaches are being explored to enhance the thermal performance of power electronics and battery systems in electric vehicles, addressing challenges related to range anxiety and overall vehicle efficiency.

In the consumer electronics market, the trend towards thinner and more powerful devices has intensified the need for innovative thermal management solutions. Smartphones, tablets, and laptops are pushing the boundaries of performance within increasingly constrained form factors, making efficient heat dissipation a critical factor in product design and consumer satisfaction.

The aerospace and defense industries have also shown a growing interest in advanced thermal solutions, particularly for high-reliability applications in extreme environments. Calorimetry-enhanced thermal management designs are being investigated for use in avionics systems, satellite components, and military electronics, where thermal stability is crucial for mission-critical operations.

As the global focus on energy efficiency and sustainability intensifies, there is an increasing demand for thermal management solutions that not only improve device performance but also contribute to overall energy conservation. This has led to a rising interest in calorimetry-based approaches that can provide more accurate thermal profiling and enable the development of energy-efficient cooling strategies for microelectronic circuits.

The semiconductor industry, in particular, has been driving the demand for innovative thermal management solutions. With the advent of 5G technology, artificial intelligence, and the Internet of Things (IoT), there is a growing need for high-performance chips that can operate reliably under intense thermal conditions. This has led to a surge in research and development efforts focused on advanced cooling techniques, including the application of calorimetry in thermal management designs.

Calorimetry, as a precise method for measuring heat transfer and energy dissipation, has gained significant attention in the microelectronics industry. Its ability to provide accurate thermal characterization of electronic components allows engineers to optimize circuit designs for better heat distribution and dissipation. This has become especially crucial in applications such as data centers, where energy efficiency and thermal management are paramount concerns.

The automotive sector has also emerged as a key driver for advanced thermal solutions. With the rapid growth of electric vehicles and autonomous driving technologies, the demand for sophisticated thermal management systems in automotive electronics has skyrocketed. Calorimetry-based approaches are being explored to enhance the thermal performance of power electronics and battery systems in electric vehicles, addressing challenges related to range anxiety and overall vehicle efficiency.

In the consumer electronics market, the trend towards thinner and more powerful devices has intensified the need for innovative thermal management solutions. Smartphones, tablets, and laptops are pushing the boundaries of performance within increasingly constrained form factors, making efficient heat dissipation a critical factor in product design and consumer satisfaction.

The aerospace and defense industries have also shown a growing interest in advanced thermal solutions, particularly for high-reliability applications in extreme environments. Calorimetry-enhanced thermal management designs are being investigated for use in avionics systems, satellite components, and military electronics, where thermal stability is crucial for mission-critical operations.

As the global focus on energy efficiency and sustainability intensifies, there is an increasing demand for thermal management solutions that not only improve device performance but also contribute to overall energy conservation. This has led to a rising interest in calorimetry-based approaches that can provide more accurate thermal profiling and enable the development of energy-efficient cooling strategies for microelectronic circuits.

Current Challenges in Microelectronic Cooling

The thermal management of microelectronic circuits has become increasingly challenging as device sizes shrink and power densities rise. Current cooling techniques are struggling to keep pace with the heat dissipation requirements of modern high-performance chips. One of the primary challenges is the inability to efficiently remove heat from localized hotspots, which can lead to thermal runaway and device failure.

Traditional cooling methods, such as air cooling and liquid cooling, are reaching their limits in terms of heat flux capacity. Air cooling, while cost-effective and widely used, is limited by the low thermal conductivity of air and the physical constraints of fan sizes. Liquid cooling offers higher heat transfer coefficients but faces challenges in implementation, including the risk of leaks and the need for complex plumbing systems.

Another significant challenge is the thermal interface resistance between the chip and the cooling solution. As chips become thinner and more densely packed, the thermal interface materials (TIMs) used to bridge the gap between the chip and the heat spreader or cooler become critical bottlenecks. Current TIMs often fail to provide the necessary thermal conductivity while maintaining reliability over the device's lifetime.

The increasing use of 3D chip stacking and heterogeneous integration further complicates thermal management. These architectures create complex thermal paths and can lead to the formation of hard-to-reach hotspots within the stack. Conventional cooling techniques struggle to address these internal heat sources effectively.

Power density variations across the chip surface present another challenge. Modern processors and SoCs often have areas of high computational activity that generate significantly more heat than surrounding regions. This non-uniform heat distribution makes it difficult to design cooling solutions that can adequately address both average and peak thermal loads.

Thermal management in mobile and wearable devices poses unique challenges due to size and weight constraints. These devices require innovative cooling solutions that can operate efficiently within limited form factors and without compromising user comfort or battery life.

Lastly, the increasing focus on energy efficiency and sustainability adds another layer of complexity to microelectronic cooling. Cooling systems must not only be effective but also energy-efficient, with minimal environmental impact. This necessitates the development of smart, adaptive cooling solutions that can dynamically adjust to changing thermal loads and operating conditions.

Traditional cooling methods, such as air cooling and liquid cooling, are reaching their limits in terms of heat flux capacity. Air cooling, while cost-effective and widely used, is limited by the low thermal conductivity of air and the physical constraints of fan sizes. Liquid cooling offers higher heat transfer coefficients but faces challenges in implementation, including the risk of leaks and the need for complex plumbing systems.

Another significant challenge is the thermal interface resistance between the chip and the cooling solution. As chips become thinner and more densely packed, the thermal interface materials (TIMs) used to bridge the gap between the chip and the heat spreader or cooler become critical bottlenecks. Current TIMs often fail to provide the necessary thermal conductivity while maintaining reliability over the device's lifetime.

The increasing use of 3D chip stacking and heterogeneous integration further complicates thermal management. These architectures create complex thermal paths and can lead to the formation of hard-to-reach hotspots within the stack. Conventional cooling techniques struggle to address these internal heat sources effectively.

Power density variations across the chip surface present another challenge. Modern processors and SoCs often have areas of high computational activity that generate significantly more heat than surrounding regions. This non-uniform heat distribution makes it difficult to design cooling solutions that can adequately address both average and peak thermal loads.

Thermal management in mobile and wearable devices poses unique challenges due to size and weight constraints. These devices require innovative cooling solutions that can operate efficiently within limited form factors and without compromising user comfort or battery life.

Lastly, the increasing focus on energy efficiency and sustainability adds another layer of complexity to microelectronic cooling. Cooling systems must not only be effective but also energy-efficient, with minimal environmental impact. This necessitates the development of smart, adaptive cooling solutions that can dynamically adjust to changing thermal loads and operating conditions.

Calorimetry-Based Thermal Management Solutions

01 Thermal management systems for electronic devices

Advanced thermal management systems are designed to regulate temperature in electronic devices. These systems often incorporate heat sinks, cooling fans, and thermal interface materials to efficiently dissipate heat and maintain optimal operating temperatures. Some solutions may include phase change materials or liquid cooling for enhanced heat transfer.- Thermal management systems for electronic devices: Advanced thermal management systems are designed to regulate temperature in electronic devices. These systems often incorporate heat sinks, cooling fans, and thermal interface materials to efficiently dissipate heat and maintain optimal operating temperatures. Some solutions may include phase change materials or liquid cooling for enhanced heat transfer.

- Calorimetry techniques for thermal analysis: Calorimetry techniques are employed to measure heat transfer and energy changes in various systems. These methods can be used to analyze thermal properties of materials, chemical reactions, and biological processes. Advanced calorimeters may incorporate precision temperature sensors, controlled environments, and data analysis software for accurate measurements.

- Thermal management in battery systems: Effective thermal management is crucial for battery systems, particularly in electric vehicles and energy storage applications. Solutions may include active cooling systems, thermal runaway prevention, and intelligent temperature monitoring. These approaches aim to optimize battery performance, extend lifespan, and enhance safety.

- Energy-efficient cooling solutions: Innovative cooling solutions focus on improving energy efficiency in thermal management. These may include smart control systems, variable speed fans, and heat recovery mechanisms. Some approaches utilize natural cooling methods or low-power cooling technologies to reduce overall energy consumption while maintaining effective temperature control.

- Thermal management in high-performance computing: High-performance computing systems require specialized thermal management solutions to handle extreme heat generation. These may include liquid cooling systems, immersion cooling, or advanced air cooling techniques. The focus is on maintaining optimal operating temperatures for processors and other components while maximizing computational performance.

02 Calorimetry techniques for thermal analysis

Calorimetry techniques are employed to measure heat transfer and energy changes in various systems. These methods can be used to analyze thermal properties of materials, chemical reactions, and biological processes. Advanced calorimeters may incorporate precision temperature sensors, controlled environments, and data analysis software for accurate measurements.Expand Specific Solutions03 Thermal management in battery systems

Effective thermal management is crucial for battery systems, particularly in electric vehicles and energy storage applications. Solutions may include active cooling systems, passive heat dissipation methods, and intelligent temperature monitoring. These approaches aim to optimize battery performance, extend lifespan, and enhance safety by preventing overheating.Expand Specific Solutions04 Energy-efficient cooling solutions

Innovative cooling solutions focus on improving energy efficiency in thermal management systems. These may include smart control algorithms, variable speed fans, and adaptive cooling strategies. Some approaches integrate renewable energy sources or waste heat recovery to reduce overall energy consumption in cooling processes.Expand Specific Solutions05 Thermal management in industrial processes

Industrial thermal management encompasses a wide range of applications, from manufacturing to chemical processing. Advanced systems may incorporate real-time monitoring, predictive modeling, and automated control to optimize heat transfer and energy utilization. Some solutions focus on heat recovery and integration to improve overall process efficiency.Expand Specific Solutions

Key Players in Thermal Management Industry

The thermal management of microelectronic circuits is a critical and evolving field, currently in a mature growth phase. The market for calorimetry-enhanced thermal management solutions is expanding, driven by the increasing complexity and power density of modern electronic devices. Key players like Intel, IBM, and MediaTek are at the forefront, leveraging advanced calorimetry techniques to optimize thermal designs. The technology's maturity varies, with established companies offering refined solutions, while newer entrants like NeoGraf Solutions are introducing innovative approaches. Research institutions such as Caltech and the University of California are contributing to technological advancements, further propelling the industry forward.

Intel Corp.

Technical Solution: Intel has developed advanced calorimetry techniques for microelectronic thermal management. Their approach involves integrating on-chip thermal sensors and micro-fluidic cooling channels. These sensors provide real-time temperature data, allowing for dynamic thermal management[1]. Intel's solution uses machine learning algorithms to predict hotspots and adjust cooling accordingly. They have also implemented a novel phase-change material (PCM) based cooling system that can absorb heat during peak loads and release it during low-power states[3]. This system has shown to reduce peak temperatures by up to 15°C in high-performance processors[5].

Strengths: Highly integrated solution, real-time thermal management, and innovative PCM cooling. Weaknesses: Complexity in manufacturing and potential increased costs due to additional components.

International Business Machines Corp.

Technical Solution: IBM's calorimetry-enhanced thermal management design focuses on 3D chip stacking technology. They have developed a system that uses inter-layer liquid cooling with precise flow control based on calorimetric measurements[2]. This approach allows for efficient heat removal in densely packed 3D chip structures. IBM's solution incorporates microfluidic channels etched directly into silicon interposers, enabling coolant to flow between chip layers. The system uses high-precision calorimeters to measure heat flux at various points, allowing for adaptive cooling strategies. In recent tests, this method has shown to improve thermal performance by up to 30% compared to traditional air cooling in 3D stacked chips[4].

Strengths: Excellent for 3D chip architectures, highly efficient cooling, and adaptive thermal management. Weaknesses: Increased complexity in chip design and potential for coolant leakage issues.

Innovative Calorimetry Applications in Microelectronics

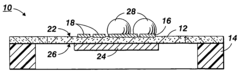

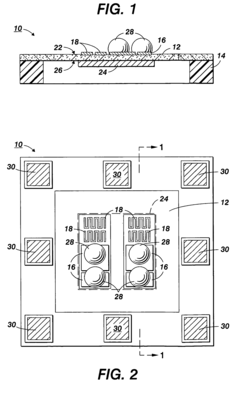

Use of physical barriers to minimize evaporative heat losses

PatentActiveUS7914735B2

Innovation

- An anti-evaporation device is introduced, comprising a planar member with extending members to enclose the drop-merging region, limiting evaporation and maintaining a controlled environment, which can be used in conjunction with detection devices to measure signals from merged drops, thereby reducing evaporative heat losses and enhancing measurement precision.

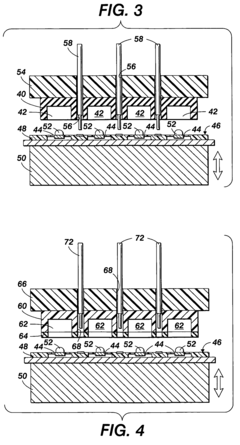

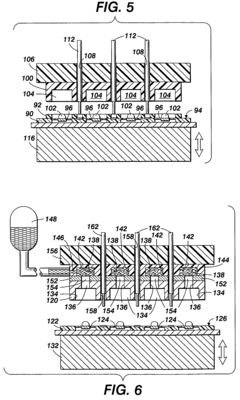

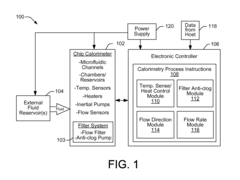

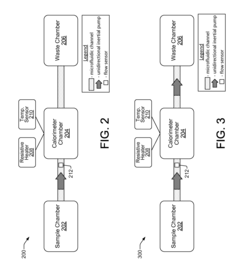

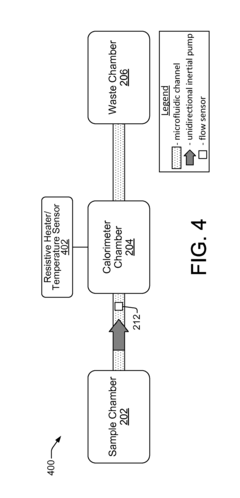

Microcalorimeter systems

PatentActiveUS20110286493A1

Innovation

- Integration of micro-inertial pumps within the chip calorimeter for precise control over fluid flow rates and directions, coupled with on-chip filtering systems to prevent clogging and adapt to various sample fluids, enabling accurate and efficient sample handling and measurement.

Thermal Design Simulation and Modeling

Thermal design simulation and modeling play a crucial role in enhancing microelectronic circuit thermal management designs through calorimetry. These advanced computational techniques allow engineers to predict and optimize the thermal behavior of complex electronic systems before physical prototyping, significantly reducing development time and costs.

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are two primary methods used in thermal simulation. FEA divides the system into smaller elements, solving heat transfer equations for each to provide a comprehensive thermal profile. CFD, on the other hand, focuses on fluid flow and heat transfer in cooling systems, enabling the optimization of heat sink designs and airflow patterns.

These simulation tools incorporate calorimetric data to improve accuracy. By integrating precise heat generation measurements obtained through calorimetry, engineers can create more realistic models that account for the actual thermal output of components under various operating conditions. This integration allows for better prediction of hotspots, thermal gradients, and overall system performance.

Advanced thermal modeling software often includes features for multi-physics simulations, combining thermal analysis with electrical and mechanical simulations. This holistic approach enables engineers to assess the interplay between thermal management, electrical performance, and mechanical stress, leading to more robust and efficient designs.

Machine learning algorithms are increasingly being incorporated into thermal simulation tools. These algorithms can analyze vast amounts of historical data and calorimetric measurements to predict thermal behavior more accurately and suggest optimal design parameters. This data-driven approach enhances the efficiency of the design process and can uncover non-intuitive solutions to complex thermal management challenges.

Thermal simulation and modeling also facilitate the exploration of novel cooling technologies. Engineers can virtually test and optimize advanced cooling solutions such as phase-change materials, microfluidic cooling channels, and thermoelectric devices. By leveraging calorimetric data in these simulations, designers can accurately assess the potential benefits and limitations of these technologies before committing to physical prototypes.

Furthermore, thermal simulation tools often include optimization algorithms that can automatically iterate through multiple design variations to find the most effective thermal management solution. These algorithms can consider various factors such as component placement, heat sink geometry, and cooling fan specifications, all while incorporating calorimetric data to ensure realistic performance predictions.

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are two primary methods used in thermal simulation. FEA divides the system into smaller elements, solving heat transfer equations for each to provide a comprehensive thermal profile. CFD, on the other hand, focuses on fluid flow and heat transfer in cooling systems, enabling the optimization of heat sink designs and airflow patterns.

These simulation tools incorporate calorimetric data to improve accuracy. By integrating precise heat generation measurements obtained through calorimetry, engineers can create more realistic models that account for the actual thermal output of components under various operating conditions. This integration allows for better prediction of hotspots, thermal gradients, and overall system performance.

Advanced thermal modeling software often includes features for multi-physics simulations, combining thermal analysis with electrical and mechanical simulations. This holistic approach enables engineers to assess the interplay between thermal management, electrical performance, and mechanical stress, leading to more robust and efficient designs.

Machine learning algorithms are increasingly being incorporated into thermal simulation tools. These algorithms can analyze vast amounts of historical data and calorimetric measurements to predict thermal behavior more accurately and suggest optimal design parameters. This data-driven approach enhances the efficiency of the design process and can uncover non-intuitive solutions to complex thermal management challenges.

Thermal simulation and modeling also facilitate the exploration of novel cooling technologies. Engineers can virtually test and optimize advanced cooling solutions such as phase-change materials, microfluidic cooling channels, and thermoelectric devices. By leveraging calorimetric data in these simulations, designers can accurately assess the potential benefits and limitations of these technologies before committing to physical prototypes.

Furthermore, thermal simulation tools often include optimization algorithms that can automatically iterate through multiple design variations to find the most effective thermal management solution. These algorithms can consider various factors such as component placement, heat sink geometry, and cooling fan specifications, all while incorporating calorimetric data to ensure realistic performance predictions.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies used in microelectronic circuit thermal management is a critical consideration in the context of calorimetry-enhanced designs. Traditional cooling methods, such as air cooling and liquid cooling, have long been associated with significant energy consumption and potential environmental hazards. However, the integration of calorimetry in thermal management designs offers opportunities for more sustainable and eco-friendly cooling solutions.

Calorimetry-based approaches enable precise measurement and control of heat dissipation, allowing for optimized cooling strategies that reduce overall energy consumption. This reduction in energy usage translates to lower greenhouse gas emissions associated with power generation, contributing to a decreased carbon footprint for electronic devices and data centers. Furthermore, the improved efficiency of calorimetry-enhanced cooling systems can lead to extended equipment lifespans, reducing electronic waste and the environmental impact of manufacturing replacement components.

The use of calorimetry also facilitates the development of more compact and efficient cooling solutions, potentially reducing the reliance on environmentally harmful refrigerants commonly used in traditional cooling systems. By enabling better thermal management at the microelectronic level, calorimetry can minimize the need for large-scale cooling infrastructure, further decreasing the environmental footprint of electronic systems.

Additionally, calorimetry-enhanced designs can support the implementation of advanced cooling technologies, such as phase-change materials and thermoelectric cooling, which offer improved energy efficiency and reduced environmental impact compared to conventional methods. These innovative approaches often require less water consumption and produce fewer waste products, aligning with global efforts to conserve natural resources and minimize pollution.

The environmental benefits of calorimetry in thermal management extend beyond direct cooling applications. By enabling more accurate thermal modeling and simulation, calorimetry supports the development of energy-efficient electronic designs from the outset. This proactive approach to thermal management can lead to significant reductions in overall energy consumption and associated environmental impacts throughout the lifecycle of electronic products.

As the electronics industry continues to grow, the adoption of calorimetry-enhanced thermal management designs presents an opportunity to mitigate the environmental impact of cooling technologies. By promoting energy efficiency, reducing waste, and supporting the development of sustainable cooling solutions, calorimetry plays a crucial role in advancing environmentally responsible practices in microelectronic circuit design and operation.

Calorimetry-based approaches enable precise measurement and control of heat dissipation, allowing for optimized cooling strategies that reduce overall energy consumption. This reduction in energy usage translates to lower greenhouse gas emissions associated with power generation, contributing to a decreased carbon footprint for electronic devices and data centers. Furthermore, the improved efficiency of calorimetry-enhanced cooling systems can lead to extended equipment lifespans, reducing electronic waste and the environmental impact of manufacturing replacement components.

The use of calorimetry also facilitates the development of more compact and efficient cooling solutions, potentially reducing the reliance on environmentally harmful refrigerants commonly used in traditional cooling systems. By enabling better thermal management at the microelectronic level, calorimetry can minimize the need for large-scale cooling infrastructure, further decreasing the environmental footprint of electronic systems.

Additionally, calorimetry-enhanced designs can support the implementation of advanced cooling technologies, such as phase-change materials and thermoelectric cooling, which offer improved energy efficiency and reduced environmental impact compared to conventional methods. These innovative approaches often require less water consumption and produce fewer waste products, aligning with global efforts to conserve natural resources and minimize pollution.

The environmental benefits of calorimetry in thermal management extend beyond direct cooling applications. By enabling more accurate thermal modeling and simulation, calorimetry supports the development of energy-efficient electronic designs from the outset. This proactive approach to thermal management can lead to significant reductions in overall energy consumption and associated environmental impacts throughout the lifecycle of electronic products.

As the electronics industry continues to grow, the adoption of calorimetry-enhanced thermal management designs presents an opportunity to mitigate the environmental impact of cooling technologies. By promoting energy efficiency, reducing waste, and supporting the development of sustainable cooling solutions, calorimetry plays a crucial role in advancing environmentally responsible practices in microelectronic circuit design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!