How Carbon Tetrachloride is Monitored in Laboratory Environments

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 Monitoring Background and Objectives

Carbon tetrachloride (CCl4) monitoring in laboratory environments has become increasingly crucial due to its potential health and environmental hazards. This toxic compound, once widely used in various industrial applications, is now strictly regulated and monitored to ensure workplace safety and environmental protection. The evolution of CCl4 monitoring techniques has been driven by the need for more accurate, sensitive, and real-time detection methods.

The primary objective of CCl4 monitoring in laboratories is to prevent exposure to this harmful substance and maintain a safe working environment. Early detection systems were limited in their sensitivity and response time, often relying on colorimetric methods or basic gas chromatography. However, as our understanding of CCl4's toxicity grew, so did the demand for more sophisticated monitoring technologies.

Over the years, the field has witnessed significant advancements in detection methodologies. From simple passive sampling techniques, the industry has progressed to active, continuous monitoring systems capable of detecting CCl4 at parts per billion (ppb) levels. This progression has been marked by the integration of various technologies, including infrared spectroscopy, mass spectrometry, and photoionization detection.

The development of portable and handheld devices has revolutionized CCl4 monitoring, allowing for on-the-spot measurements and increased flexibility in laboratory settings. These advancements have been complemented by improvements in data logging and analysis capabilities, enabling long-term trend monitoring and more informed decision-making regarding exposure control and risk management.

Current technological goals in CCl4 monitoring focus on enhancing sensitivity, reducing false positives, and developing more cost-effective solutions. There is a growing emphasis on creating multi-functional devices capable of detecting multiple hazardous substances simultaneously, thereby streamlining laboratory safety protocols. Additionally, the integration of Internet of Things (IoT) technology and cloud-based data management systems is paving the way for more comprehensive and interconnected monitoring networks.

The future of CCl4 monitoring in laboratories is likely to see further miniaturization of detection devices, increased automation in sampling and analysis processes, and the application of artificial intelligence for predictive maintenance and risk assessment. These advancements aim to not only improve the accuracy and reliability of CCl4 detection but also to create more proactive and preventive monitoring systems that can anticipate potential exposure risks before they occur.

The primary objective of CCl4 monitoring in laboratories is to prevent exposure to this harmful substance and maintain a safe working environment. Early detection systems were limited in their sensitivity and response time, often relying on colorimetric methods or basic gas chromatography. However, as our understanding of CCl4's toxicity grew, so did the demand for more sophisticated monitoring technologies.

Over the years, the field has witnessed significant advancements in detection methodologies. From simple passive sampling techniques, the industry has progressed to active, continuous monitoring systems capable of detecting CCl4 at parts per billion (ppb) levels. This progression has been marked by the integration of various technologies, including infrared spectroscopy, mass spectrometry, and photoionization detection.

The development of portable and handheld devices has revolutionized CCl4 monitoring, allowing for on-the-spot measurements and increased flexibility in laboratory settings. These advancements have been complemented by improvements in data logging and analysis capabilities, enabling long-term trend monitoring and more informed decision-making regarding exposure control and risk management.

Current technological goals in CCl4 monitoring focus on enhancing sensitivity, reducing false positives, and developing more cost-effective solutions. There is a growing emphasis on creating multi-functional devices capable of detecting multiple hazardous substances simultaneously, thereby streamlining laboratory safety protocols. Additionally, the integration of Internet of Things (IoT) technology and cloud-based data management systems is paving the way for more comprehensive and interconnected monitoring networks.

The future of CCl4 monitoring in laboratories is likely to see further miniaturization of detection devices, increased automation in sampling and analysis processes, and the application of artificial intelligence for predictive maintenance and risk assessment. These advancements aim to not only improve the accuracy and reliability of CCl4 detection but also to create more proactive and preventive monitoring systems that can anticipate potential exposure risks before they occur.

Laboratory Safety Demand Analysis

The demand for effective carbon tetrachloride monitoring in laboratory environments has grown significantly in recent years, driven by increasing awareness of workplace safety and stringent regulatory requirements. Carbon tetrachloride, a potent ozone-depleting substance and potential carcinogen, poses serious health risks to laboratory personnel and the environment. This has led to a surge in the adoption of advanced monitoring technologies and safety protocols across various research institutions, academic laboratories, and industrial facilities.

Market analysis indicates a robust growth trajectory for laboratory safety equipment, including carbon tetrachloride monitoring systems. The global laboratory safety market is expected to expand steadily, with a particular focus on chemical detection and air quality monitoring devices. This growth is fueled by factors such as stricter occupational safety regulations, increased research and development activities in pharmaceuticals and biotechnology, and growing concerns about worker health and environmental protection.

The demand for carbon tetrachloride monitoring solutions is particularly high in sectors such as pharmaceutical research, chemical manufacturing, and environmental testing laboratories. These industries require precise and reliable detection methods to ensure compliance with safety standards and to protect their workforce. Additionally, there is a rising demand for portable and real-time monitoring devices that can provide instant alerts in case of leaks or exposure, enabling rapid response to potential hazards.

Emerging trends in laboratory safety include the integration of Internet of Things (IoT) technology and artificial intelligence in monitoring systems. These advancements allow for continuous data collection, remote monitoring, and predictive maintenance of safety equipment. There is also a growing interest in multi-gas detection systems that can simultaneously monitor various hazardous substances, including carbon tetrachloride, providing a more comprehensive safety solution for laboratory environments.

The market is witnessing an increased focus on user-friendly interfaces and data management software that can simplify the monitoring process and improve overall laboratory safety management. This trend is driven by the need for efficient record-keeping, compliance reporting, and data analysis to identify potential safety issues proactively.

As awareness of the long-term health effects of carbon tetrachloride exposure grows, there is an expanding market for personal protective equipment (PPE) specifically designed for handling this chemical. This includes specialized respirators, gloves, and protective clothing that complement monitoring systems in providing comprehensive safety solutions for laboratory personnel.

Market analysis indicates a robust growth trajectory for laboratory safety equipment, including carbon tetrachloride monitoring systems. The global laboratory safety market is expected to expand steadily, with a particular focus on chemical detection and air quality monitoring devices. This growth is fueled by factors such as stricter occupational safety regulations, increased research and development activities in pharmaceuticals and biotechnology, and growing concerns about worker health and environmental protection.

The demand for carbon tetrachloride monitoring solutions is particularly high in sectors such as pharmaceutical research, chemical manufacturing, and environmental testing laboratories. These industries require precise and reliable detection methods to ensure compliance with safety standards and to protect their workforce. Additionally, there is a rising demand for portable and real-time monitoring devices that can provide instant alerts in case of leaks or exposure, enabling rapid response to potential hazards.

Emerging trends in laboratory safety include the integration of Internet of Things (IoT) technology and artificial intelligence in monitoring systems. These advancements allow for continuous data collection, remote monitoring, and predictive maintenance of safety equipment. There is also a growing interest in multi-gas detection systems that can simultaneously monitor various hazardous substances, including carbon tetrachloride, providing a more comprehensive safety solution for laboratory environments.

The market is witnessing an increased focus on user-friendly interfaces and data management software that can simplify the monitoring process and improve overall laboratory safety management. This trend is driven by the need for efficient record-keeping, compliance reporting, and data analysis to identify potential safety issues proactively.

As awareness of the long-term health effects of carbon tetrachloride exposure grows, there is an expanding market for personal protective equipment (PPE) specifically designed for handling this chemical. This includes specialized respirators, gloves, and protective clothing that complement monitoring systems in providing comprehensive safety solutions for laboratory personnel.

Current CCl4 Detection Technologies

Carbon tetrachloride (CCl4) detection in laboratory environments is crucial for ensuring safety and compliance with environmental regulations. Several technologies are currently employed for monitoring CCl4 levels, each with its own advantages and limitations.

Gas chromatography-mass spectrometry (GC-MS) is widely used for CCl4 detection due to its high sensitivity and specificity. This method involves separating the components of a gas mixture through a column and then identifying them based on their mass-to-charge ratios. GC-MS can detect CCl4 at very low concentrations, making it ideal for precise measurements in laboratory settings.

Infrared spectroscopy is another common technique for CCl4 detection. It relies on the absorption of infrared radiation by CCl4 molecules at specific wavelengths. Fourier-transform infrared (FTIR) spectroscopy, in particular, offers rapid and non-destructive analysis of CCl4 in air samples. This method is suitable for continuous monitoring and can provide real-time data on CCl4 concentrations.

Photoionization detectors (PIDs) are portable devices that use ultraviolet light to ionize gas molecules. While not specific to CCl4, PIDs can detect a wide range of volatile organic compounds (VOCs) and are often used for initial screening and leak detection in laboratories. Their portability and quick response time make them valuable for on-the-spot measurements.

Colorimetric detection methods utilize chemical reactions that produce color changes in the presence of CCl4. These techniques often involve reagent tubes or test strips that change color when exposed to CCl4 vapor. While less precise than instrumental methods, colorimetric tests offer a simple and cost-effective approach for rapid CCl4 detection in laboratory environments.

Electrochemical sensors are another option for CCl4 monitoring. These sensors measure changes in electrical properties when CCl4 interacts with a sensing element. They can be integrated into portable devices or fixed monitoring systems, providing continuous measurements of CCl4 levels in laboratory air.

Optical gas imaging cameras equipped with infrared technology can visualize CCl4 vapor plumes, making them useful for identifying leaks and emission sources in laboratory settings. While not quantitative, these cameras offer a visual method for detecting CCl4 releases and can complement other detection technologies.

Each of these detection technologies has its place in laboratory CCl4 monitoring, depending on factors such as required sensitivity, specificity, speed of analysis, and cost considerations. Many laboratories employ a combination of these methods to ensure comprehensive CCl4 detection and maintain a safe working environment.

Gas chromatography-mass spectrometry (GC-MS) is widely used for CCl4 detection due to its high sensitivity and specificity. This method involves separating the components of a gas mixture through a column and then identifying them based on their mass-to-charge ratios. GC-MS can detect CCl4 at very low concentrations, making it ideal for precise measurements in laboratory settings.

Infrared spectroscopy is another common technique for CCl4 detection. It relies on the absorption of infrared radiation by CCl4 molecules at specific wavelengths. Fourier-transform infrared (FTIR) spectroscopy, in particular, offers rapid and non-destructive analysis of CCl4 in air samples. This method is suitable for continuous monitoring and can provide real-time data on CCl4 concentrations.

Photoionization detectors (PIDs) are portable devices that use ultraviolet light to ionize gas molecules. While not specific to CCl4, PIDs can detect a wide range of volatile organic compounds (VOCs) and are often used for initial screening and leak detection in laboratories. Their portability and quick response time make them valuable for on-the-spot measurements.

Colorimetric detection methods utilize chemical reactions that produce color changes in the presence of CCl4. These techniques often involve reagent tubes or test strips that change color when exposed to CCl4 vapor. While less precise than instrumental methods, colorimetric tests offer a simple and cost-effective approach for rapid CCl4 detection in laboratory environments.

Electrochemical sensors are another option for CCl4 monitoring. These sensors measure changes in electrical properties when CCl4 interacts with a sensing element. They can be integrated into portable devices or fixed monitoring systems, providing continuous measurements of CCl4 levels in laboratory air.

Optical gas imaging cameras equipped with infrared technology can visualize CCl4 vapor plumes, making them useful for identifying leaks and emission sources in laboratory settings. While not quantitative, these cameras offer a visual method for detecting CCl4 releases and can complement other detection technologies.

Each of these detection technologies has its place in laboratory CCl4 monitoring, depending on factors such as required sensitivity, specificity, speed of analysis, and cost considerations. Many laboratories employ a combination of these methods to ensure comprehensive CCl4 detection and maintain a safe working environment.

Existing CCl4 Monitoring Solutions

01 Detection methods for carbon tetrachloride

Various detection methods have been developed for monitoring carbon tetrachloride levels. These include spectroscopic techniques, chromatography, and specialized sensors. These methods allow for accurate and sensitive detection of carbon tetrachloride in different environments, such as air, water, or soil samples.- Detection and analysis methods for carbon tetrachloride: Various techniques are employed for detecting and analyzing carbon tetrachloride in different environments. These methods may include spectroscopic analysis, chromatography, and other advanced analytical techniques to accurately measure and monitor carbon tetrachloride levels.

- Environmental monitoring systems for carbon tetrachloride: Specialized systems and equipment are developed for continuous monitoring of carbon tetrachloride in air, water, and soil. These systems often incorporate sensors, data logging capabilities, and real-time alert mechanisms to ensure effective environmental surveillance.

- Industrial applications and safety measures: Carbon tetrachloride monitoring is crucial in industrial settings where it may be used or produced. Safety measures and monitoring protocols are implemented to protect workers and prevent environmental contamination, including the use of personal protective equipment and regular air quality assessments.

- Remediation and treatment of carbon tetrachloride contamination: Techniques for remediating areas contaminated with carbon tetrachloride are developed, including chemical treatment, bioremediation, and physical removal methods. Monitoring plays a crucial role in assessing the effectiveness of these remediation efforts and ensuring environmental recovery.

- Regulatory compliance and reporting systems: Systems and methods are established for ensuring compliance with regulations regarding carbon tetrachloride use and emissions. These include standardized monitoring protocols, reporting mechanisms, and data management systems to meet environmental protection requirements and industry standards.

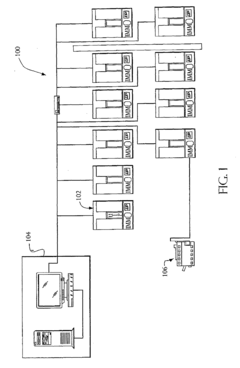

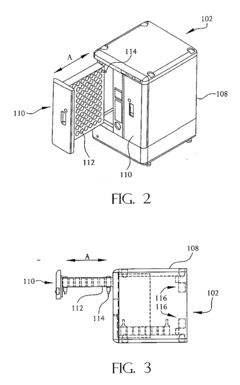

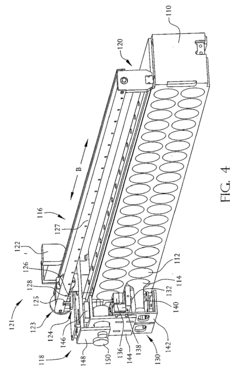

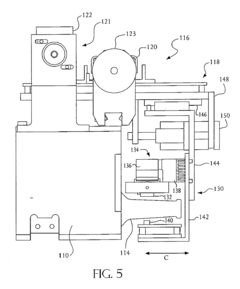

02 Continuous monitoring systems

Continuous monitoring systems have been designed for real-time detection of carbon tetrachloride. These systems often incorporate automated sampling and analysis techniques, allowing for constant surveillance of carbon tetrachloride levels in industrial settings, environmental monitoring stations, or other areas where ongoing assessment is necessary.Expand Specific Solutions03 Carbon tetrachloride remediation and treatment

Technologies have been developed for the remediation and treatment of carbon tetrachloride contamination. These may include chemical degradation methods, biological treatment processes, or physical removal techniques. Monitoring is often an integral part of these treatment systems to assess the effectiveness of the remediation efforts.Expand Specific Solutions04 Industrial process control and safety measures

Monitoring systems have been integrated into industrial processes that involve carbon tetrachloride to ensure safety and control. These systems may include alarms, automatic shut-off mechanisms, and data logging capabilities to prevent accidents and maintain regulatory compliance in industries where carbon tetrachloride is used or produced.Expand Specific Solutions05 Environmental impact assessment

Monitoring techniques have been developed to assess the environmental impact of carbon tetrachloride. These methods focus on detecting and quantifying carbon tetrachloride in various environmental matrices, such as air, water, and soil. The data collected is used to evaluate potential risks to ecosystems and human health, and to inform environmental management decisions.Expand Specific Solutions

Key Players in Lab Safety Equipment

The monitoring of Carbon Tetrachloride in laboratory environments is a critical aspect of safety and environmental protection, with the market currently in a mature stage. The global market size for laboratory safety equipment and monitoring systems is substantial, driven by stringent regulations and increasing awareness of workplace safety. Companies like Becton, Dickinson & Co. and DKK-TOA Corp. are at the forefront of developing advanced monitoring technologies. The technical maturity of Carbon Tetrachloride detection methods is high, with established players such as Shimadzu Corp. and Testo SE & Co. KGaA offering sophisticated analytical instruments. Universities like Yale and Tokyo University of Science contribute to ongoing research, enhancing detection sensitivity and accuracy. The competitive landscape is characterized by a mix of large multinational corporations and specialized environmental monitoring firms, with innovation focused on improving real-time detection capabilities and integration with laboratory management systems.

DuPont de Nemours, Inc.

Technical Solution: DuPont, leveraging its expertise in chemical manufacturing and safety, has developed monitoring solutions for various industrial chemicals, including carbon tetrachloride. Their approach combines advanced sensor technologies with comprehensive safety management systems. DuPont's personal protective equipment (PPE) line includes respirators and gas detection devices suitable for laboratory environments where carbon tetrachloride may be present[10]. The company also offers environmental monitoring services and consultancy, utilizing gas chromatography and mass spectrometry techniques for precise quantification of carbon tetrachloride in air and other media[11]. DuPont's integrated approach encompasses not only detection but also risk assessment and mitigation strategies tailored to laboratory settings[12].

Strengths: Comprehensive approach combining detection, PPE, and safety management; extensive experience in chemical handling and safety. Weaknesses: May not specialize in cutting-edge analytical instrumentation compared to dedicated instrument manufacturers.

Shimadzu Corp.

Technical Solution: Shimadzu Corporation has developed advanced gas chromatography-mass spectrometry (GC-MS) systems for monitoring carbon tetrachloride in laboratory environments. Their GCMS-QP2020 NX offers high-sensitivity detection of volatile organic compounds (VOCs) including carbon tetrachloride[1]. The system employs a quadrupole mass analyzer and electron ionization source, allowing for precise identification and quantification of carbon tetrachloride at low concentrations. Shimadzu's proprietary ClickTek technology enables tool-free column installation, reducing downtime and potential contamination[2]. The company has also integrated their LabSolutions software for streamlined data analysis and reporting, enhancing overall workflow efficiency in laboratory monitoring applications[3].

Strengths: High sensitivity and precision in VOC detection, user-friendly features for improved efficiency, comprehensive software integration. Weaknesses: Potentially higher cost compared to simpler monitoring methods, requires trained personnel for operation and maintenance.

Innovative CCl4 Detection Techniques

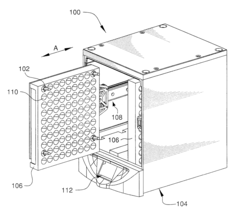

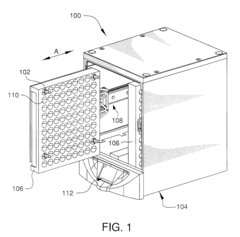

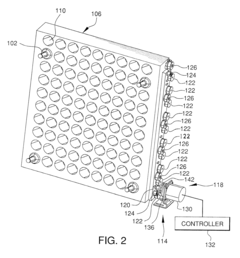

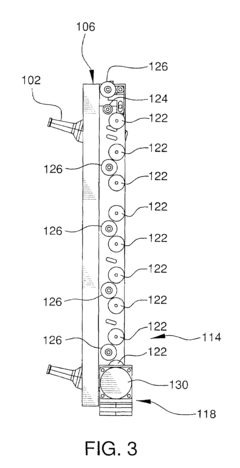

System and method for stirring suspended solids in a liquid media

PatentInactiveUS7517137B2

Innovation

- A system and method employing a ferrous metal-filled polymer stirrer within a tilted sample vessel, manipulated by a moving rare earth magnet to create a controlled stirring action, allowing for adjustable stirring intensity without changing the stirrer size, and maintaining a larger air-liquid interface for enhanced nutrient and gas exchange.

System and method for detecting the growth of microorganisms in a sample.

PatentInactiveEP1637586A2

Innovation

- A system employing infrared laser spectrography and dual wavelength modulation to directly monitor the concentration of gases like oxygen or carbon dioxide, or pressure, in sample vials, using an energy emitting device, detector, and signal analyzer to determine the presence of microorganisms without invasive probes or indicators.

Regulatory Framework for CCl4 Use

The regulatory framework for carbon tetrachloride (CCl4) use in laboratory environments is complex and multifaceted, reflecting the compound's hazardous nature and potential environmental impact. At the international level, the Montreal Protocol on Substances that Deplete the Ozone Layer, which came into force in 1989, has been instrumental in phasing out CCl4 production and consumption. This treaty has led to a significant reduction in CCl4 emissions globally, with exceptions made for essential uses, including laboratory and analytical applications.

In the United States, the Environmental Protection Agency (EPA) regulates CCl4 under various statutes. The Toxic Substances Control Act (TSCA) lists CCl4 as a priority chemical, subjecting it to risk evaluations and potential restrictions. The Clean Air Act classifies CCl4 as a hazardous air pollutant, requiring strict emission controls. Additionally, the Safe Drinking Water Act sets maximum contaminant levels for CCl4 in public water systems.

Occupational safety regulations concerning CCl4 are primarily enforced by the Occupational Safety and Health Administration (OSHA). OSHA has established permissible exposure limits (PELs) for CCl4 in the workplace, mandating that employee exposure must not exceed 10 ppm as an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) recommends even lower exposure limits and considers CCl4 a potential occupational carcinogen.

European regulations on CCl4 are similarly stringent. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation classifies CCl4 as a substance of very high concern. Its use is heavily restricted, with exemptions for research and analysis purposes under controlled conditions. The EU has also implemented directives to protect workers from the risks related to chemical agents at work, including specific provisions for CCl4.

In laboratory settings, these regulations translate into strict protocols for CCl4 handling, storage, and disposal. Institutions must implement comprehensive chemical hygiene plans, provide adequate personal protective equipment, and ensure proper ventilation systems. Regular monitoring of air quality and potential exposure pathways is mandatory. Waste management protocols for CCl4 are particularly stringent, often requiring specialized disposal services to prevent environmental contamination.

Compliance with these regulations necessitates ongoing training for laboratory personnel, regular audits, and meticulous record-keeping. Many institutions have adopted even more conservative approaches than required by law, implementing internal policies that further restrict CCl4 use or encourage the exploration of safer alternatives where possible.

In the United States, the Environmental Protection Agency (EPA) regulates CCl4 under various statutes. The Toxic Substances Control Act (TSCA) lists CCl4 as a priority chemical, subjecting it to risk evaluations and potential restrictions. The Clean Air Act classifies CCl4 as a hazardous air pollutant, requiring strict emission controls. Additionally, the Safe Drinking Water Act sets maximum contaminant levels for CCl4 in public water systems.

Occupational safety regulations concerning CCl4 are primarily enforced by the Occupational Safety and Health Administration (OSHA). OSHA has established permissible exposure limits (PELs) for CCl4 in the workplace, mandating that employee exposure must not exceed 10 ppm as an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) recommends even lower exposure limits and considers CCl4 a potential occupational carcinogen.

European regulations on CCl4 are similarly stringent. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation classifies CCl4 as a substance of very high concern. Its use is heavily restricted, with exemptions for research and analysis purposes under controlled conditions. The EU has also implemented directives to protect workers from the risks related to chemical agents at work, including specific provisions for CCl4.

In laboratory settings, these regulations translate into strict protocols for CCl4 handling, storage, and disposal. Institutions must implement comprehensive chemical hygiene plans, provide adequate personal protective equipment, and ensure proper ventilation systems. Regular monitoring of air quality and potential exposure pathways is mandatory. Waste management protocols for CCl4 are particularly stringent, often requiring specialized disposal services to prevent environmental contamination.

Compliance with these regulations necessitates ongoing training for laboratory personnel, regular audits, and meticulous record-keeping. Many institutions have adopted even more conservative approaches than required by law, implementing internal policies that further restrict CCl4 use or encourage the exploration of safer alternatives where possible.

Environmental Impact of CCl4 Monitoring

The environmental impact of Carbon Tetrachloride (CCl4) monitoring in laboratory environments is a critical aspect that requires careful consideration. CCl4 is a potent ozone-depleting substance and a greenhouse gas, making its monitoring essential for environmental protection. The process of monitoring CCl4 itself can have both direct and indirect environmental consequences.

Direct environmental impacts of CCl4 monitoring primarily stem from potential leaks or accidental releases during the monitoring process. Even small amounts of CCl4 released into the atmosphere can contribute to ozone depletion and global warming. Therefore, the monitoring equipment and procedures must be designed with utmost care to prevent any unintended emissions.

Indirect environmental impacts are associated with the energy consumption and waste generation of monitoring systems. Continuous monitoring equipment often requires significant power input, contributing to increased energy demand and associated carbon emissions. Additionally, the production and disposal of monitoring devices and consumables can lead to electronic waste and potential contamination if not managed properly.

However, the environmental benefits of CCl4 monitoring far outweigh these impacts. Effective monitoring enables early detection of leaks or emissions, preventing large-scale environmental damage. It also supports compliance with international regulations like the Montreal Protocol, which aims to phase out ozone-depleting substances.

The choice of monitoring technology can significantly influence the environmental footprint of CCl4 monitoring. Advanced techniques such as optical sensing methods and portable gas chromatography-mass spectrometry (GC-MS) systems offer improved sensitivity and reduced energy consumption compared to traditional methods. These technologies also minimize the need for chemical reagents, further reducing the environmental impact.

Proper disposal and recycling of monitoring equipment and materials are crucial in mitigating environmental risks. Many components of CCl4 monitoring systems contain hazardous materials that require specialized handling and disposal to prevent soil and water contamination.

In the broader context, CCl4 monitoring contributes to environmental research and policy-making. The data collected through monitoring efforts provide valuable insights into atmospheric chemistry and climate change, supporting evidence-based environmental protection strategies.

To minimize the environmental impact of CCl4 monitoring, laboratories should adopt best practices such as regular maintenance of equipment to prevent leaks, use of energy-efficient monitoring systems, and implementation of comprehensive waste management protocols. Additionally, integrating CCl4 monitoring into broader environmental management systems can enhance overall efficiency and reduce redundant monitoring efforts.

Direct environmental impacts of CCl4 monitoring primarily stem from potential leaks or accidental releases during the monitoring process. Even small amounts of CCl4 released into the atmosphere can contribute to ozone depletion and global warming. Therefore, the monitoring equipment and procedures must be designed with utmost care to prevent any unintended emissions.

Indirect environmental impacts are associated with the energy consumption and waste generation of monitoring systems. Continuous monitoring equipment often requires significant power input, contributing to increased energy demand and associated carbon emissions. Additionally, the production and disposal of monitoring devices and consumables can lead to electronic waste and potential contamination if not managed properly.

However, the environmental benefits of CCl4 monitoring far outweigh these impacts. Effective monitoring enables early detection of leaks or emissions, preventing large-scale environmental damage. It also supports compliance with international regulations like the Montreal Protocol, which aims to phase out ozone-depleting substances.

The choice of monitoring technology can significantly influence the environmental footprint of CCl4 monitoring. Advanced techniques such as optical sensing methods and portable gas chromatography-mass spectrometry (GC-MS) systems offer improved sensitivity and reduced energy consumption compared to traditional methods. These technologies also minimize the need for chemical reagents, further reducing the environmental impact.

Proper disposal and recycling of monitoring equipment and materials are crucial in mitigating environmental risks. Many components of CCl4 monitoring systems contain hazardous materials that require specialized handling and disposal to prevent soil and water contamination.

In the broader context, CCl4 monitoring contributes to environmental research and policy-making. The data collected through monitoring efforts provide valuable insights into atmospheric chemistry and climate change, supporting evidence-based environmental protection strategies.

To minimize the environmental impact of CCl4 monitoring, laboratories should adopt best practices such as regular maintenance of equipment to prevent leaks, use of energy-efficient monitoring systems, and implementation of comprehensive waste management protocols. Additionally, integrating CCl4 monitoring into broader environmental management systems can enhance overall efficiency and reduce redundant monitoring efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!