How Enzymatic Processes Can Neutralize Carbon Tetrachloride

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Enzymatic CCl4 Neutralization: Background and Objectives

Carbon tetrachloride (CCl4) has long been recognized as a significant environmental pollutant, posing serious threats to both human health and ecosystems. Its persistence in the environment and potential for ozone depletion have led to global efforts to reduce its production and use. However, existing CCl4 contamination remains a pressing issue, necessitating effective remediation strategies.

Enzymatic processes have emerged as a promising approach for neutralizing CCl4, offering a potentially more efficient and environmentally friendly alternative to traditional physical and chemical methods. This technological avenue leverages the power of biological catalysts to break down CCl4 into less harmful compounds, addressing the urgent need for sustainable remediation solutions.

The evolution of enzymatic CCl4 neutralization technology can be traced back to early studies on microbial degradation of chlorinated compounds. Over the past few decades, researchers have made significant strides in understanding the mechanisms by which certain enzymes can interact with and transform CCl4. This progress has been driven by advances in biotechnology, enzyme engineering, and a deeper comprehension of the biochemical pathways involved in xenobiotic metabolism.

The primary objective of enzymatic CCl4 neutralization is to develop a robust, scalable, and cost-effective method for treating CCl4-contaminated sites and industrial waste streams. This goal encompasses several key aspects, including the identification and optimization of suitable enzymes, the development of efficient delivery systems, and the integration of enzymatic processes into existing remediation frameworks.

Researchers aim to enhance the catalytic efficiency and stability of enzymes capable of CCl4 degradation, focusing on enzymes such as dehalogenases and reductive dehalogenases. Additionally, there is a strong emphasis on engineering these enzymes to function effectively under a wide range of environmental conditions, ensuring their applicability across diverse contamination scenarios.

Another critical objective is to elucidate the complete degradation pathways of CCl4 under enzymatic treatment, including the identification and characterization of intermediate compounds. This knowledge is essential for assessing the overall environmental impact of the process and ensuring that the end products are indeed less harmful than the original contaminant.

As the field progresses, there is a growing focus on developing immobilization techniques and bioreactor designs that can support large-scale application of enzymatic CCl4 neutralization. These technological advancements aim to bridge the gap between laboratory success and practical, field-level implementation, addressing challenges related to enzyme stability, reusability, and process efficiency in real-world conditions.

Enzymatic processes have emerged as a promising approach for neutralizing CCl4, offering a potentially more efficient and environmentally friendly alternative to traditional physical and chemical methods. This technological avenue leverages the power of biological catalysts to break down CCl4 into less harmful compounds, addressing the urgent need for sustainable remediation solutions.

The evolution of enzymatic CCl4 neutralization technology can be traced back to early studies on microbial degradation of chlorinated compounds. Over the past few decades, researchers have made significant strides in understanding the mechanisms by which certain enzymes can interact with and transform CCl4. This progress has been driven by advances in biotechnology, enzyme engineering, and a deeper comprehension of the biochemical pathways involved in xenobiotic metabolism.

The primary objective of enzymatic CCl4 neutralization is to develop a robust, scalable, and cost-effective method for treating CCl4-contaminated sites and industrial waste streams. This goal encompasses several key aspects, including the identification and optimization of suitable enzymes, the development of efficient delivery systems, and the integration of enzymatic processes into existing remediation frameworks.

Researchers aim to enhance the catalytic efficiency and stability of enzymes capable of CCl4 degradation, focusing on enzymes such as dehalogenases and reductive dehalogenases. Additionally, there is a strong emphasis on engineering these enzymes to function effectively under a wide range of environmental conditions, ensuring their applicability across diverse contamination scenarios.

Another critical objective is to elucidate the complete degradation pathways of CCl4 under enzymatic treatment, including the identification and characterization of intermediate compounds. This knowledge is essential for assessing the overall environmental impact of the process and ensuring that the end products are indeed less harmful than the original contaminant.

As the field progresses, there is a growing focus on developing immobilization techniques and bioreactor designs that can support large-scale application of enzymatic CCl4 neutralization. These technological advancements aim to bridge the gap between laboratory success and practical, field-level implementation, addressing challenges related to enzyme stability, reusability, and process efficiency in real-world conditions.

Market Demand for CCl4 Remediation Solutions

The market demand for Carbon Tetrachloride (CCl4) remediation solutions has been steadily increasing due to growing environmental concerns and stricter regulations on hazardous waste management. CCl4, a potent ozone-depleting substance and potential carcinogen, has been widely used in various industrial applications, leading to significant soil and groundwater contamination.

The global environmental remediation market, which includes CCl4 remediation, was valued at $85.5 billion in 2020 and is projected to reach $136.9 billion by 2028, with a compound annual growth rate (CAGR) of 6.1%. This growth is primarily driven by increasing awareness of environmental issues, government initiatives, and the implementation of stringent environmental regulations across various industries.

Specifically, the demand for CCl4 remediation solutions is particularly high in regions with a history of industrial activity, such as North America and Europe. These areas have seen extensive use of CCl4 in manufacturing processes, dry cleaning, and as a solvent in various industries. As a result, there is a significant need for effective remediation techniques to address legacy contamination issues.

The market for CCl4 remediation is also expanding in developing countries, where rapid industrialization has led to increased environmental pollution. Governments in these regions are implementing stricter environmental policies, creating new opportunities for remediation service providers and technology developers.

Key industries driving the demand for CCl4 remediation solutions include chemical manufacturing, petroleum refining, and electronics. These sectors are under increasing pressure to address historical contamination and prevent future environmental damage. Additionally, the real estate sector is showing growing interest in remediation solutions, as contaminated sites are being redeveloped for commercial or residential use.

The market is witnessing a shift towards more sustainable and cost-effective remediation technologies. Traditional methods such as pump-and-treat systems are being replaced by innovative approaches, including in-situ chemical oxidation, bioremediation, and enzymatic processes. This trend is fueled by the need for more efficient and environmentally friendly solutions that can address complex contamination scenarios.

Enzymatic processes for CCl4 neutralization are gaining particular attention due to their potential for lower environmental impact and reduced treatment costs compared to conventional methods. The market demand for these enzymatic solutions is expected to grow as more research demonstrates their effectiveness and scalability in real-world applications.

The global environmental remediation market, which includes CCl4 remediation, was valued at $85.5 billion in 2020 and is projected to reach $136.9 billion by 2028, with a compound annual growth rate (CAGR) of 6.1%. This growth is primarily driven by increasing awareness of environmental issues, government initiatives, and the implementation of stringent environmental regulations across various industries.

Specifically, the demand for CCl4 remediation solutions is particularly high in regions with a history of industrial activity, such as North America and Europe. These areas have seen extensive use of CCl4 in manufacturing processes, dry cleaning, and as a solvent in various industries. As a result, there is a significant need for effective remediation techniques to address legacy contamination issues.

The market for CCl4 remediation is also expanding in developing countries, where rapid industrialization has led to increased environmental pollution. Governments in these regions are implementing stricter environmental policies, creating new opportunities for remediation service providers and technology developers.

Key industries driving the demand for CCl4 remediation solutions include chemical manufacturing, petroleum refining, and electronics. These sectors are under increasing pressure to address historical contamination and prevent future environmental damage. Additionally, the real estate sector is showing growing interest in remediation solutions, as contaminated sites are being redeveloped for commercial or residential use.

The market is witnessing a shift towards more sustainable and cost-effective remediation technologies. Traditional methods such as pump-and-treat systems are being replaced by innovative approaches, including in-situ chemical oxidation, bioremediation, and enzymatic processes. This trend is fueled by the need for more efficient and environmentally friendly solutions that can address complex contamination scenarios.

Enzymatic processes for CCl4 neutralization are gaining particular attention due to their potential for lower environmental impact and reduced treatment costs compared to conventional methods. The market demand for these enzymatic solutions is expected to grow as more research demonstrates their effectiveness and scalability in real-world applications.

Current Challenges in Enzymatic CCl4 Degradation

The enzymatic degradation of carbon tetrachloride (CCl4) presents several significant challenges that hinder its widespread application and effectiveness. One of the primary obstacles is the inherent stability of the CCl4 molecule, which makes it resistant to enzymatic attack. The carbon-chlorine bonds in CCl4 are particularly strong, requiring substantial energy input for cleavage, which many enzymes struggle to provide under ambient conditions.

Another major challenge is the limited availability of naturally occurring enzymes capable of efficiently degrading CCl4. While some microorganisms have evolved mechanisms to metabolize chlorinated compounds, enzymes specifically adapted for CCl4 degradation are rare. This scarcity necessitates extensive research into enzyme engineering and directed evolution to develop more effective biocatalysts.

The toxicity of CCl4 and its degradation intermediates poses a significant hurdle in enzymatic processes. High concentrations of CCl4 can inhibit or denature enzymes, reducing their catalytic activity. Moreover, the formation of potentially harmful intermediates during the degradation process may further complicate the enzymatic approach, requiring careful management of reaction conditions and product removal.

Enzyme stability and longevity in the presence of CCl4 and other organic solvents represent another critical challenge. Many enzymes exhibit reduced activity or undergo rapid denaturation when exposed to organic solvents, limiting their practical application in CCl4 degradation. Developing enzymes with enhanced solvent tolerance or implementing enzyme immobilization techniques are essential strategies to overcome this limitation.

The slow kinetics of enzymatic CCl4 degradation compared to chemical methods is a significant drawback. Enzymatic reactions often proceed at slower rates, particularly for recalcitrant compounds like CCl4. This slow pace can limit the practical applicability of enzymatic processes in large-scale remediation efforts, necessitating the development of more efficient enzymatic systems or novel reactor designs to enhance reaction rates.

Scaling up enzymatic processes for industrial-level CCl4 degradation presents additional challenges. Factors such as enzyme production costs, reactor design, and process optimization become critical considerations. Ensuring consistent enzyme performance and stability in large-scale operations, as well as managing the economics of enzyme production and replacement, are crucial aspects that require further research and development.

Lastly, the environmental conditions in which CCl4 degradation occurs can significantly impact enzyme performance. Factors such as pH, temperature, and the presence of co-contaminants can affect enzyme activity and stability. Developing robust enzymatic systems capable of functioning effectively across a range of environmental conditions remains a key challenge in advancing enzymatic CCl4 degradation technologies.

Another major challenge is the limited availability of naturally occurring enzymes capable of efficiently degrading CCl4. While some microorganisms have evolved mechanisms to metabolize chlorinated compounds, enzymes specifically adapted for CCl4 degradation are rare. This scarcity necessitates extensive research into enzyme engineering and directed evolution to develop more effective biocatalysts.

The toxicity of CCl4 and its degradation intermediates poses a significant hurdle in enzymatic processes. High concentrations of CCl4 can inhibit or denature enzymes, reducing their catalytic activity. Moreover, the formation of potentially harmful intermediates during the degradation process may further complicate the enzymatic approach, requiring careful management of reaction conditions and product removal.

Enzyme stability and longevity in the presence of CCl4 and other organic solvents represent another critical challenge. Many enzymes exhibit reduced activity or undergo rapid denaturation when exposed to organic solvents, limiting their practical application in CCl4 degradation. Developing enzymes with enhanced solvent tolerance or implementing enzyme immobilization techniques are essential strategies to overcome this limitation.

The slow kinetics of enzymatic CCl4 degradation compared to chemical methods is a significant drawback. Enzymatic reactions often proceed at slower rates, particularly for recalcitrant compounds like CCl4. This slow pace can limit the practical applicability of enzymatic processes in large-scale remediation efforts, necessitating the development of more efficient enzymatic systems or novel reactor designs to enhance reaction rates.

Scaling up enzymatic processes for industrial-level CCl4 degradation presents additional challenges. Factors such as enzyme production costs, reactor design, and process optimization become critical considerations. Ensuring consistent enzyme performance and stability in large-scale operations, as well as managing the economics of enzyme production and replacement, are crucial aspects that require further research and development.

Lastly, the environmental conditions in which CCl4 degradation occurs can significantly impact enzyme performance. Factors such as pH, temperature, and the presence of co-contaminants can affect enzyme activity and stability. Developing robust enzymatic systems capable of functioning effectively across a range of environmental conditions remains a key challenge in advancing enzymatic CCl4 degradation technologies.

Existing Enzymatic Approaches for CCl4 Neutralization

01 Enzymatic neutralization in food processing

Enzymatic processes are used in food processing to neutralize undesirable components or adjust pH levels. This can improve taste, texture, and shelf life of food products. The process often involves specific enzymes that target particular compounds, allowing for precise control over the neutralization process.- Enzymatic neutralization in food processing: Enzymatic processes are used in food processing to neutralize undesirable components or adjust pH levels. This can improve taste, texture, and shelf life of food products. The process often involves specific enzymes that target particular compounds, allowing for precise control over the neutralization process.

- Neutralization of industrial waste and effluents: Enzymatic processes are employed to neutralize industrial waste and effluents, particularly in sectors like textile, paper, and chemical industries. These processes can break down complex pollutants, adjust pH levels, and reduce environmental impact. Specialized enzymes are selected based on the specific contaminants present in the waste stream.

- Enzymatic neutralization in biofuel production: In biofuel production, enzymatic processes are used to neutralize inhibitory compounds that can hinder fermentation. This includes breaking down complex carbohydrates, removing toxic byproducts, and adjusting pH levels to optimize microbial growth and ethanol production. The use of specific enzyme cocktails can significantly improve the efficiency of biofuel production processes.

- pH adjustment in pharmaceutical processes: Enzymatic neutralization is utilized in pharmaceutical processes to adjust pH levels of drug formulations or intermediates. This can enhance drug stability, solubility, or bioavailability. The process often involves carefully selected enzymes that can operate under specific conditions without affecting the active pharmaceutical ingredients.

- Enzymatic neutralization in wastewater treatment: Wastewater treatment plants employ enzymatic processes to neutralize various pollutants and adjust pH levels. This can include breaking down organic matter, removing nutrients, and neutralizing toxic compounds. The use of enzymes in this context can offer a more environmentally friendly and efficient alternative to traditional chemical treatments.

02 Neutralization of industrial waste and effluents

Enzymatic processes are employed to neutralize industrial waste and effluents, particularly in sectors like textile, paper, and chemical industries. These processes can break down complex pollutants, reduce toxicity, and adjust pH levels, making the waste safer for disposal or further treatment.Expand Specific Solutions03 Biocatalytic neutralization in pharmaceutical production

In pharmaceutical production, enzymatic processes are used for neutralization steps in the synthesis of active ingredients or intermediates. This can involve pH adjustment, removal of unwanted by-products, or conversion of precursor molecules. The high specificity of enzymes allows for efficient and selective neutralization reactions.Expand Specific Solutions04 Enzyme-based neutralization in biofuel production

Enzymatic processes play a crucial role in neutralizing inhibitory compounds during biofuel production, particularly in the conversion of lignocellulosic biomass. These processes can detoxify pretreatment liquors, improve fermentation efficiency, and increase overall yield of biofuels.Expand Specific Solutions05 Neutralization of environmental contaminants using enzymes

Enzymatic processes are utilized for the neutralization of environmental contaminants in soil, water, and air. This can include the breakdown of pesticides, removal of heavy metals, or degradation of persistent organic pollutants. The use of enzymes offers a more environmentally friendly alternative to chemical neutralization methods.Expand Specific Solutions

Key Players in Bioremediation Industry

The enzymatic neutralization of carbon tetrachloride is an emerging field in environmental remediation, currently in its early development stages. The market size is relatively small but growing, driven by increasing environmental regulations and sustainability initiatives. The technology's maturity is still evolving, with key players like BASF Corp., Bayer AG, and Covestro Deutschland AG leading research efforts. Academic institutions such as Cornell University and Arizona State University are contributing significantly to fundamental research. Companies like Veolia ES Technical Solutions LLC and Tredi SA are exploring practical applications in waste treatment. While the technology shows promise, it requires further development to achieve widespread commercial viability and cost-effectiveness in large-scale environmental cleanup operations.

Bayer AG

Technical Solution: Bayer AG has pioneered a groundbreaking enzymatic approach to neutralize carbon tetrachloride using genetically engineered bacterial strains. Their method employs specially designed bacteria that express enhanced levels of dehalogenase enzymes, capable of breaking down CCl4 into less harmful compounds. The process occurs in a two-phase system: an aqueous phase containing the engineered bacteria and an organic phase with CCl4. As the bacteria come into contact with CCl4 at the interface, they produce enzymes that catalyze its breakdown[2]. Bayer has also developed a proprietary immobilization technique that allows for the continuous production and secretion of these enzymes, significantly improving the longevity and efficiency of the process[4].

Strengths: Highly efficient, continuous process, potential for large-scale applications. Weaknesses: Requires careful control of bacterial populations, potential biosafety concerns.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed a novel enzymatic process for CCl4 neutralization using a combination of engineered enzymes and nanomaterials. Their approach utilizes a specially designed enzyme cocktail that includes modified dehalogenases and reductive dehalogenases. These enzymes are immobilized on nanostructured supports, which significantly enhance their stability and activity. The process takes place in a flow-through reactor system, where CCl4-contaminated water passes through enzyme-functionalized nanomaterials. This setup allows for efficient contact between the enzymes and CCl4, resulting in rapid degradation[5]. AIST's method also incorporates real-time monitoring of CCl4 levels using advanced sensors, enabling precise control of the neutralization process[7].

Strengths: High efficiency, scalable process, precise control. Weaknesses: Potentially high initial setup costs, requires specialized nanomaterials.

Innovative Enzymes for CCl4 Degradation

Process for the purification of carbon tetrachloride

PatentInactiveGB915784A

Innovation

- Reacting crude carbon tetrachloride with an aqueous solution of an inorganic sulphite, such as sodium sulphite, to convert sulfur chlorides into soluble salts, allowing for easy separation and avoiding sulfur precipitation, with vigorous mixing and a temperature range of 15-30°C.

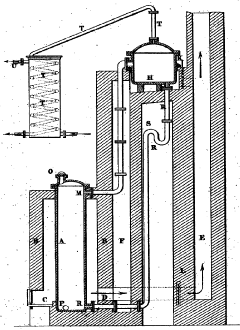

A Process and Apparatus for the Manufacture of Carbon Tetrachloride.

PatentInactiveGB190125688A

Innovation

- A process involving a vertical retort where sulfur chloride is passed over red-hot carbon, with a controlled introduction of gaseous chlorine to convert carbon bisulfide into carbon tetrachloride, utilizing a dephlegmator to recycle sulfur chloride and optimize carbon tetrachloride collection, ensuring continuous production without by-products.

Environmental Impact of Enzymatic CCl4 Neutralization

The enzymatic neutralization of carbon tetrachloride (CCl4) presents a promising approach for addressing environmental contamination, with potentially significant impacts on ecosystem health and human well-being. This process involves the use of specific enzymes to break down CCl4 into less harmful compounds, offering a more sustainable alternative to traditional remediation methods.

One of the primary environmental benefits of enzymatic CCl4 neutralization is the reduction of soil and groundwater contamination. CCl4 is a persistent organic pollutant that can remain in the environment for extended periods, posing long-term risks to ecosystems. Enzymatic processes can effectively degrade CCl4 in situ, minimizing the need for excavation or pump-and-treat methods that can be disruptive to local habitats.

The enzymatic approach also demonstrates a lower environmental footprint compared to conventional chemical treatments. Unlike harsh chemical oxidants or reductants, enzymes are biodegradable and non-toxic, reducing the risk of secondary pollution. This characteristic is particularly valuable in sensitive ecosystems where the introduction of additional chemicals could cause unintended harm.

Furthermore, the specificity of enzymes allows for targeted degradation of CCl4 without affecting other compounds in the environment. This selectivity minimizes collateral damage to beneficial soil microorganisms and plant life, preserving ecosystem balance and biodiversity. The preservation of soil health is crucial for maintaining ecological functions and supporting natural attenuation processes.

The potential for in situ application of enzymatic treatments offers advantages in terms of energy consumption and carbon emissions. Traditional ex situ remediation techniques often require significant energy inputs for excavation, transportation, and treatment of contaminated materials. In contrast, enzymatic processes can be implemented on-site, reducing the carbon footprint associated with remediation activities.

Another environmental benefit is the potential for accelerated site restoration. Enzymatic processes can work more rapidly than natural attenuation, allowing for faster recovery of contaminated areas. This quicker turnaround can lead to earlier reestablishment of native flora and fauna, contributing to ecosystem resilience and recovery.

However, it is important to consider potential challenges and limitations. The effectiveness of enzymatic treatments may vary depending on environmental conditions such as pH, temperature, and the presence of co-contaminants. Additionally, the long-term ecological effects of introducing engineered enzymes into natural systems require careful study to ensure no unintended consequences arise.

In conclusion, the environmental impact of enzymatic CCl4 neutralization appears largely positive, offering a green and efficient approach to remediation. As research in this field progresses, further refinements in enzyme design and application methods may enhance the environmental benefits while addressing potential concerns, ultimately contributing to more sustainable environmental management practices.

One of the primary environmental benefits of enzymatic CCl4 neutralization is the reduction of soil and groundwater contamination. CCl4 is a persistent organic pollutant that can remain in the environment for extended periods, posing long-term risks to ecosystems. Enzymatic processes can effectively degrade CCl4 in situ, minimizing the need for excavation or pump-and-treat methods that can be disruptive to local habitats.

The enzymatic approach also demonstrates a lower environmental footprint compared to conventional chemical treatments. Unlike harsh chemical oxidants or reductants, enzymes are biodegradable and non-toxic, reducing the risk of secondary pollution. This characteristic is particularly valuable in sensitive ecosystems where the introduction of additional chemicals could cause unintended harm.

Furthermore, the specificity of enzymes allows for targeted degradation of CCl4 without affecting other compounds in the environment. This selectivity minimizes collateral damage to beneficial soil microorganisms and plant life, preserving ecosystem balance and biodiversity. The preservation of soil health is crucial for maintaining ecological functions and supporting natural attenuation processes.

The potential for in situ application of enzymatic treatments offers advantages in terms of energy consumption and carbon emissions. Traditional ex situ remediation techniques often require significant energy inputs for excavation, transportation, and treatment of contaminated materials. In contrast, enzymatic processes can be implemented on-site, reducing the carbon footprint associated with remediation activities.

Another environmental benefit is the potential for accelerated site restoration. Enzymatic processes can work more rapidly than natural attenuation, allowing for faster recovery of contaminated areas. This quicker turnaround can lead to earlier reestablishment of native flora and fauna, contributing to ecosystem resilience and recovery.

However, it is important to consider potential challenges and limitations. The effectiveness of enzymatic treatments may vary depending on environmental conditions such as pH, temperature, and the presence of co-contaminants. Additionally, the long-term ecological effects of introducing engineered enzymes into natural systems require careful study to ensure no unintended consequences arise.

In conclusion, the environmental impact of enzymatic CCl4 neutralization appears largely positive, offering a green and efficient approach to remediation. As research in this field progresses, further refinements in enzyme design and application methods may enhance the environmental benefits while addressing potential concerns, ultimately contributing to more sustainable environmental management practices.

Regulatory Framework for Bioremediation Technologies

The regulatory framework for bioremediation technologies, particularly those involving enzymatic processes to neutralize carbon tetrachloride, is a complex and evolving landscape. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a pivotal role in overseeing and regulating bioremediation efforts. The EPA's Superfund program, established under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), provides guidelines for the cleanup of contaminated sites, including those affected by carbon tetrachloride.

The Resource Conservation and Recovery Act (RCRA) also comes into play, regulating the treatment, storage, and disposal of hazardous wastes. For enzymatic processes targeting carbon tetrachloride, compliance with RCRA standards is essential, particularly in terms of waste management and site remediation protocols. The Toxic Substances Control Act (TSCA) further governs the use and disposal of chemical substances, including carbon tetrachloride, and may impact the implementation of enzymatic neutralization processes.

At the state level, regulations can vary significantly, with some states adopting more stringent standards than federal requirements. California's Department of Toxic Substances Control, for instance, has implemented additional regulations for bioremediation technologies, including specific protocols for pilot studies and full-scale implementations. These state-level regulations often address local environmental concerns and may require additional permitting or monitoring for enzymatic remediation projects.

Internationally, the regulatory landscape becomes even more diverse. The European Union's Environmental Liability Directive provides a framework for preventing and remedying environmental damage, which includes guidelines for bioremediation technologies. In contrast, developing countries may have less stringent regulations, potentially creating opportunities for more rapid implementation of innovative enzymatic processes, albeit with potential environmental risks.

Regulatory bodies also consider the potential environmental impacts of the bioremediation process itself. For enzymatic neutralization of carbon tetrachloride, this includes assessing the safety of introduced enzymes, potential byproducts of the neutralization process, and the long-term effects on soil and groundwater ecosystems. The National Environmental Policy Act (NEPA) in the United States requires environmental impact assessments for major federal actions, which could include large-scale bioremediation projects.

As the field of enzymatic bioremediation advances, regulatory frameworks are likely to evolve. There is a growing emphasis on performance-based standards rather than prescriptive regulations, allowing for greater flexibility in implementing innovative technologies. However, this also places a greater burden on technology developers and implementers to demonstrate the efficacy and safety of their approaches.

The Resource Conservation and Recovery Act (RCRA) also comes into play, regulating the treatment, storage, and disposal of hazardous wastes. For enzymatic processes targeting carbon tetrachloride, compliance with RCRA standards is essential, particularly in terms of waste management and site remediation protocols. The Toxic Substances Control Act (TSCA) further governs the use and disposal of chemical substances, including carbon tetrachloride, and may impact the implementation of enzymatic neutralization processes.

At the state level, regulations can vary significantly, with some states adopting more stringent standards than federal requirements. California's Department of Toxic Substances Control, for instance, has implemented additional regulations for bioremediation technologies, including specific protocols for pilot studies and full-scale implementations. These state-level regulations often address local environmental concerns and may require additional permitting or monitoring for enzymatic remediation projects.

Internationally, the regulatory landscape becomes even more diverse. The European Union's Environmental Liability Directive provides a framework for preventing and remedying environmental damage, which includes guidelines for bioremediation technologies. In contrast, developing countries may have less stringent regulations, potentially creating opportunities for more rapid implementation of innovative enzymatic processes, albeit with potential environmental risks.

Regulatory bodies also consider the potential environmental impacts of the bioremediation process itself. For enzymatic neutralization of carbon tetrachloride, this includes assessing the safety of introduced enzymes, potential byproducts of the neutralization process, and the long-term effects on soil and groundwater ecosystems. The National Environmental Policy Act (NEPA) in the United States requires environmental impact assessments for major federal actions, which could include large-scale bioremediation projects.

As the field of enzymatic bioremediation advances, regulatory frameworks are likely to evolve. There is a growing emphasis on performance-based standards rather than prescriptive regulations, allowing for greater flexibility in implementing innovative technologies. However, this also places a greater burden on technology developers and implementers to demonstrate the efficacy and safety of their approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!