How Catalytic Converter Composition Affects LS Engine Emissions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Converter Evolution and Objectives

Catalytic converters have undergone significant evolution since their introduction in the 1970s, driven by increasingly stringent emissions regulations and the need for improved engine performance. The primary objective of catalytic converter technology has been to reduce harmful emissions from internal combustion engines, particularly in LS (Luxury Sport) engines, which are known for their high performance and power output.

The development of catalytic converters began with simple two-way converters, which primarily targeted carbon monoxide (CO) and hydrocarbons (HC). As environmental concerns grew, three-way catalytic converters emerged, capable of additionally reducing nitrogen oxides (NOx). This marked a crucial milestone in emissions control technology, significantly improving air quality in urban areas.

Over the years, the composition of catalytic converters has been refined to enhance their efficiency and durability. Early converters relied heavily on precious metals like platinum and palladium. However, the rising costs and limited availability of these materials prompted researchers to explore alternative compositions and more efficient designs.

Recent advancements have focused on optimizing the catalyst loading and distribution within the converter. Nanotechnology has played a crucial role in this aspect, allowing for increased surface area and improved catalytic activity with reduced precious metal content. This has not only improved the converter's performance but also made them more cost-effective and sustainable.

The evolution of catalytic converter technology has also been closely tied to advancements in engine management systems. Modern converters work in tandem with sophisticated oxygen sensors and electronic control units to continuously adjust the air-fuel mixture, ensuring optimal catalytic performance across various driving conditions.

Looking forward, the objectives for catalytic converter technology in LS engines are multifaceted. There is a continued push for even lower emissions, particularly in light of tightening global regulations. Researchers are exploring novel materials and structures that can withstand higher temperatures and provide better conversion efficiency, especially during cold starts when emissions are typically highest.

Another key objective is to develop catalytic converters that are more resistant to poisoning and fouling, thereby extending their operational lifespan. This is particularly important for high-performance LS engines, which can subject converters to more extreme conditions. Additionally, there is a growing focus on reducing the environmental impact of catalytic converter production and improving their recyclability at the end of their lifecycle.

The development of catalytic converters began with simple two-way converters, which primarily targeted carbon monoxide (CO) and hydrocarbons (HC). As environmental concerns grew, three-way catalytic converters emerged, capable of additionally reducing nitrogen oxides (NOx). This marked a crucial milestone in emissions control technology, significantly improving air quality in urban areas.

Over the years, the composition of catalytic converters has been refined to enhance their efficiency and durability. Early converters relied heavily on precious metals like platinum and palladium. However, the rising costs and limited availability of these materials prompted researchers to explore alternative compositions and more efficient designs.

Recent advancements have focused on optimizing the catalyst loading and distribution within the converter. Nanotechnology has played a crucial role in this aspect, allowing for increased surface area and improved catalytic activity with reduced precious metal content. This has not only improved the converter's performance but also made them more cost-effective and sustainable.

The evolution of catalytic converter technology has also been closely tied to advancements in engine management systems. Modern converters work in tandem with sophisticated oxygen sensors and electronic control units to continuously adjust the air-fuel mixture, ensuring optimal catalytic performance across various driving conditions.

Looking forward, the objectives for catalytic converter technology in LS engines are multifaceted. There is a continued push for even lower emissions, particularly in light of tightening global regulations. Researchers are exploring novel materials and structures that can withstand higher temperatures and provide better conversion efficiency, especially during cold starts when emissions are typically highest.

Another key objective is to develop catalytic converters that are more resistant to poisoning and fouling, thereby extending their operational lifespan. This is particularly important for high-performance LS engines, which can subject converters to more extreme conditions. Additionally, there is a growing focus on reducing the environmental impact of catalytic converter production and improving their recyclability at the end of their lifecycle.

Emission Reduction Market Analysis

The emission reduction market for LS engines is experiencing significant growth driven by stringent environmental regulations and increasing consumer awareness of air quality issues. The global catalytic converter market, a key component in emission reduction systems, is projected to reach $183.4 billion by 2025, with a compound annual growth rate of 7.5% from 2020 to 2025. This growth is particularly relevant for LS engines, which are widely used in high-performance vehicles and require advanced emission control technologies.

The demand for more efficient catalytic converters is rising as automotive manufacturers strive to meet increasingly strict emission standards, such as Euro 6 in Europe and Tier 3 in the United States. These standards are pushing the industry towards innovative solutions in catalytic converter composition to achieve lower emissions while maintaining engine performance. The market is seeing a shift towards advanced materials and designs that can handle higher temperatures and provide better conversion efficiency.

In the LS engine segment, there is a growing market for aftermarket performance catalytic converters that can maintain emission compliance while enhancing engine output. This niche market is estimated to grow at a rate of 5-6% annually, driven by enthusiasts and performance vehicle owners seeking to balance power with environmental responsibility.

The Asia-Pacific region is emerging as a significant market for emission reduction technologies, with China leading in both production and consumption. The rapid industrialization and increasing vehicle ownership in this region are creating substantial opportunities for catalytic converter manufacturers. North America and Europe continue to be major markets, with a focus on technological advancements and regulatory compliance.

The market is also witnessing a trend towards the use of precious metals in catalytic converters, particularly for LS engines. Platinum, palladium, and rhodium are crucial components, with their demand directly influencing the overall market dynamics. The volatility in precious metal prices is a key factor affecting the cost structure of catalytic converters and, consequently, the emission reduction market for LS engines.

Environmental concerns and the push for cleaner technologies are driving research into alternative materials and designs for catalytic converters. This includes the development of nanotechnology-based catalysts and the exploration of non-precious metal alternatives, which could potentially disrupt the current market structure and offer more cost-effective solutions for LS engine emissions reduction.

The demand for more efficient catalytic converters is rising as automotive manufacturers strive to meet increasingly strict emission standards, such as Euro 6 in Europe and Tier 3 in the United States. These standards are pushing the industry towards innovative solutions in catalytic converter composition to achieve lower emissions while maintaining engine performance. The market is seeing a shift towards advanced materials and designs that can handle higher temperatures and provide better conversion efficiency.

In the LS engine segment, there is a growing market for aftermarket performance catalytic converters that can maintain emission compliance while enhancing engine output. This niche market is estimated to grow at a rate of 5-6% annually, driven by enthusiasts and performance vehicle owners seeking to balance power with environmental responsibility.

The Asia-Pacific region is emerging as a significant market for emission reduction technologies, with China leading in both production and consumption. The rapid industrialization and increasing vehicle ownership in this region are creating substantial opportunities for catalytic converter manufacturers. North America and Europe continue to be major markets, with a focus on technological advancements and regulatory compliance.

The market is also witnessing a trend towards the use of precious metals in catalytic converters, particularly for LS engines. Platinum, palladium, and rhodium are crucial components, with their demand directly influencing the overall market dynamics. The volatility in precious metal prices is a key factor affecting the cost structure of catalytic converters and, consequently, the emission reduction market for LS engines.

Environmental concerns and the push for cleaner technologies are driving research into alternative materials and designs for catalytic converters. This includes the development of nanotechnology-based catalysts and the exploration of non-precious metal alternatives, which could potentially disrupt the current market structure and offer more cost-effective solutions for LS engine emissions reduction.

Catalytic Converter Technology Challenges

Catalytic converters face several significant technological challenges in their application to LS engine emissions control. One of the primary issues is the need for improved thermal management. LS engines, known for their high performance, generate substantial exhaust heat. This heat can cause thermal degradation of the catalytic converter's precious metal components, reducing its efficiency and lifespan. Engineers are working on developing more heat-resistant materials and improved cooling systems to address this challenge.

Another major hurdle is the optimization of catalyst formulations for LS engine-specific emissions profiles. LS engines produce a unique mix of pollutants, particularly during cold starts and high-load conditions. Current catalytic converter compositions may not be ideally suited to handle these specific emission characteristics, necessitating ongoing research into tailored catalyst materials and loadings.

The issue of catalyst poisoning also presents a significant challenge. LS engines, especially when modified or running on lower-quality fuels, can produce contaminants that gradually deactivate the catalytic converter. Sulfur, phosphorus, and other elements can accumulate on the catalyst surface, reducing its effectiveness over time. Developing more poison-resistant catalysts and improving fuel quality standards are crucial steps in addressing this problem.

Space constraints pose another technical challenge. LS engines are often used in vehicles where underbody space is limited. Designing compact yet highly efficient catalytic converters that can fit within these tight spaces without compromising performance is an ongoing engineering challenge. This often requires innovative packaging solutions and the development of higher cell density substrates.

The cost of precious metals used in catalytic converters remains a significant hurdle. LS engines require high-performance catalytic converters, which typically contain substantial amounts of platinum, palladium, and rhodium. The volatile prices and limited supply of these metals drive up costs and can impact the overall affordability of emission control systems. Research into alternative materials or more efficient use of precious metals is crucial for long-term sustainability.

Lastly, meeting increasingly stringent emission standards while maintaining engine performance is a constant challenge. As regulations become more demanding, catalytic converter technology must evolve to provide higher conversion efficiencies across a broader range of operating conditions. This requires advancements in catalyst design, substrate materials, and overall system integration to ensure that LS engines can meet future emission targets without sacrificing their renowned performance characteristics.

Another major hurdle is the optimization of catalyst formulations for LS engine-specific emissions profiles. LS engines produce a unique mix of pollutants, particularly during cold starts and high-load conditions. Current catalytic converter compositions may not be ideally suited to handle these specific emission characteristics, necessitating ongoing research into tailored catalyst materials and loadings.

The issue of catalyst poisoning also presents a significant challenge. LS engines, especially when modified or running on lower-quality fuels, can produce contaminants that gradually deactivate the catalytic converter. Sulfur, phosphorus, and other elements can accumulate on the catalyst surface, reducing its effectiveness over time. Developing more poison-resistant catalysts and improving fuel quality standards are crucial steps in addressing this problem.

Space constraints pose another technical challenge. LS engines are often used in vehicles where underbody space is limited. Designing compact yet highly efficient catalytic converters that can fit within these tight spaces without compromising performance is an ongoing engineering challenge. This often requires innovative packaging solutions and the development of higher cell density substrates.

The cost of precious metals used in catalytic converters remains a significant hurdle. LS engines require high-performance catalytic converters, which typically contain substantial amounts of platinum, palladium, and rhodium. The volatile prices and limited supply of these metals drive up costs and can impact the overall affordability of emission control systems. Research into alternative materials or more efficient use of precious metals is crucial for long-term sustainability.

Lastly, meeting increasingly stringent emission standards while maintaining engine performance is a constant challenge. As regulations become more demanding, catalytic converter technology must evolve to provide higher conversion efficiencies across a broader range of operating conditions. This requires advancements in catalyst design, substrate materials, and overall system integration to ensure that LS engines can meet future emission targets without sacrificing their renowned performance characteristics.

Current Catalytic Converter Designs

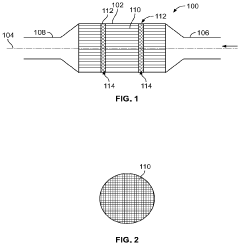

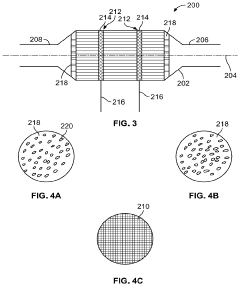

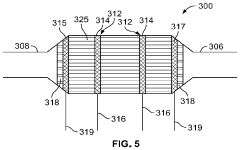

01 Catalytic converter design and structure

Innovations in catalytic converter design focus on improving the structure to enhance emissions reduction. This includes optimizing the internal geometry, substrate materials, and catalyst distribution to increase surface area and reaction efficiency. Advanced designs may incorporate multiple stages or zones to target different pollutants more effectively.- Catalytic converter design and structure: Innovations in catalytic converter design focus on improving efficiency and reducing emissions. This includes optimizing the internal structure, using advanced materials for the catalyst substrate, and enhancing the flow dynamics to maximize contact between exhaust gases and the catalytic surface.

- Emission monitoring and control systems: Advanced systems for monitoring and controlling emissions from catalytic converters have been developed. These include sensors to measure exhaust composition, real-time data analysis, and feedback mechanisms to adjust engine parameters for optimal catalytic converter performance.

- Novel catalyst materials and coatings: Research into new catalyst materials and coatings aims to improve the efficiency of catalytic converters in reducing emissions. This includes the development of nanoparticle catalysts, rare earth element combinations, and multi-layer coatings to enhance catalytic activity and durability.

- Integration with exhaust aftertreatment systems: Catalytic converters are being integrated with other exhaust aftertreatment technologies to create more comprehensive emission control systems. This includes combining catalytic converters with particulate filters, selective catalytic reduction (SCR) systems, and exhaust gas recirculation (EGR) to address a wider range of pollutants.

- Regeneration and self-cleaning mechanisms: Innovative approaches to maintain catalytic converter efficiency over time include the development of regeneration and self-cleaning mechanisms. These systems aim to remove accumulated contaminants and restore catalyst activity, extending the operational life of the converter and maintaining its emission reduction capabilities.

02 Catalyst composition and formulation

Development of novel catalyst compositions aims to improve the conversion of harmful emissions. This involves researching and formulating new combinations of precious metals, rare earth elements, and other materials to enhance catalytic activity, durability, and performance across a wide range of operating conditions.Expand Specific Solutions03 Emission monitoring and diagnostics

Advanced monitoring systems and diagnostic tools are being developed to assess catalytic converter performance and emissions in real-time. These technologies enable early detection of converter degradation, ensure compliance with emission standards, and optimize engine control strategies for better emissions reduction.Expand Specific Solutions04 Integration with engine management systems

Improved integration between catalytic converters and engine management systems enhances overall emissions control. This involves developing sophisticated algorithms and control strategies that adjust engine parameters based on converter performance, ensuring optimal emissions reduction across various driving conditions.Expand Specific Solutions05 Alternative materials and manufacturing processes

Research into alternative materials and manufacturing processes aims to reduce the cost and environmental impact of catalytic converters while maintaining or improving their performance. This includes exploring the use of non-precious metals, advanced ceramics, and innovative production techniques such as 3D printing.Expand Specific Solutions

Key Catalytic Converter Manufacturers

The catalytic converter composition for LS engine emissions is a highly competitive field in the mature automotive industry. The market is substantial, driven by stringent global emissions regulations and the widespread use of LS engines. Key players like GM Global Technology Operations, Ford Global Technologies, and Umicore SA are at the forefront, leveraging their extensive R&D capabilities and industry experience. The technology is well-established but continually evolving, with companies such as BASF SE and Toyota Motor Corp. investing in innovations to improve efficiency and reduce costs. Emerging trends include the use of advanced materials and nanotechnology, as demonstrated by smaller firms like SDCmaterials, Inc., indicating a dynamic landscape with opportunities for both established manufacturers and innovative startups.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced catalytic converter compositions tailored for LS engines to reduce emissions. Their technology utilizes a three-way catalyst system with optimized precious metal loadings, specifically platinum, palladium, and rhodium[1]. The converter incorporates a high cell density substrate (600-900 cells per square inch) to increase surface area for reactions[2]. GM's design also features a close-coupled catalyst position near the engine manifold for rapid light-off and improved cold-start emissions control[3]. Additionally, they've implemented advanced washcoat formulations with oxygen storage components to enhance conversion efficiency across a wide range of air-fuel ratios[4].

Strengths: Optimized precious metal usage, rapid light-off performance, and wide operating window. Weaknesses: Potentially higher production costs due to precious metal content and complex washcoat formulations.

Ford Global Technologies LLC

Technical Solution: Ford has innovated catalytic converter compositions for LS engines focusing on durability and efficiency. Their approach involves using advanced substrate materials like cordierite with improved thermal stability[1]. The catalyst employs a dual-layer washcoat structure, with the bottom layer containing high oxygen storage capacity materials and the top layer optimized for NOx reduction[2]. Ford's technology also incorporates zeolite-based selective catalytic reduction (SCR) components to enhance NOx control in lean-burn conditions[3]. To address sulfur poisoning, they've developed a sulfur trap integrated into the converter design, extending catalyst life and maintaining performance[4]. The company has also explored the use of perovskite materials as a potential replacement for some precious metals, aiming to reduce costs while maintaining efficiency[5].

Strengths: Enhanced durability, improved NOx reduction in various operating conditions, and potential for cost reduction. Weaknesses: Complexity in manufacturing multi-layer washcoats and potential challenges in optimizing the balance between different catalytic functions.

Innovative Catalyst Materials Research

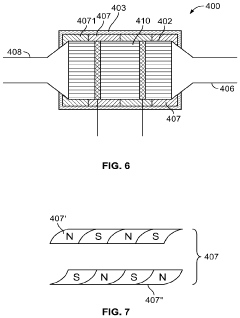

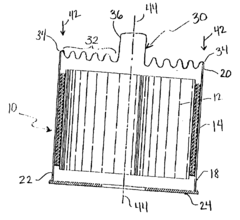

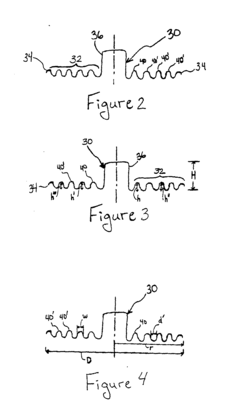

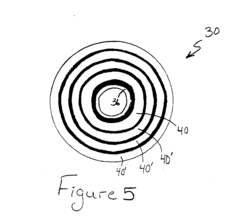

Catalytic converter

PatentPendingUS20230304427A1

Innovation

- Incorporation of heating elements and a support lattice coated with catalytic material, along with disruptor plates and a magnetic field to enhance gas circulation and particulate interaction, and the use of magnets to maintain a magnetic field within the catalytic converter.

Integrated catalytic converter and flexible endcone assembly

PatentInactiveUS20050036927A1

Innovation

- An integrated catalytic converter/flexible endcone assembly is developed, featuring a flexible bellow with undulating ribs and a mat support material, securely attached to the catalytic converter shell, allowing for flexible movement and fluid communication, thereby reducing vibrations and thermal stress.

Environmental Regulations Impact

Environmental regulations have played a crucial role in shaping the development and implementation of catalytic converter technology for LS engines. These regulations, primarily driven by concerns over air quality and public health, have become increasingly stringent over time, forcing automotive manufacturers to continually innovate and improve their emission control systems.

In the United States, the Environmental Protection Agency (EPA) sets and enforces national standards for vehicle emissions. The Clean Air Act, first enacted in 1970 and subsequently amended, provides the legal framework for these regulations. The EPA's Tier 3 emission standards, which began phasing in from 2017, have set even more rigorous limits on pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM).

Similarly, the European Union has implemented progressively stricter emission standards through its Euro 1 to Euro 6 regulations. The latest Euro 6d standard, which came into full effect in 2021, imposes significantly lower limits on NOx emissions compared to previous iterations. These regulations have directly influenced the composition and design of catalytic converters for LS engines, driving the need for more efficient and durable catalytic materials.

The impact of these regulations extends beyond just the technical specifications of catalytic converters. They have also influenced manufacturing processes, material sourcing, and even the overall design of LS engines. For instance, the need to meet stricter emission standards has led to the development of more advanced engine management systems that work in tandem with catalytic converters to optimize emission control.

Moreover, environmental regulations have spurred research into alternative catalytic materials. Traditional platinum group metals (PGMs) used in catalytic converters, while effective, are expensive and subject to supply constraints. This has led to increased interest in developing catalysts using more abundant and cost-effective materials, without compromising on emission reduction performance.

The global nature of the automotive industry means that manufacturers must design catalytic converters that can meet the most stringent regulations worldwide. This has led to a harmonization of emission control technologies across different markets, with catalytic converter compositions often exceeding local regulatory requirements to ensure global compliance.

Looking ahead, upcoming regulations are set to further challenge the automotive industry. For example, the proposed Euro 7 standards in Europe and the next phase of EPA regulations in the US are expected to push the boundaries of emission control technology even further. This ongoing regulatory pressure ensures that the composition and performance of catalytic converters for LS engines will remain a critical area of research and development in the automotive sector for years to come.

In the United States, the Environmental Protection Agency (EPA) sets and enforces national standards for vehicle emissions. The Clean Air Act, first enacted in 1970 and subsequently amended, provides the legal framework for these regulations. The EPA's Tier 3 emission standards, which began phasing in from 2017, have set even more rigorous limits on pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM).

Similarly, the European Union has implemented progressively stricter emission standards through its Euro 1 to Euro 6 regulations. The latest Euro 6d standard, which came into full effect in 2021, imposes significantly lower limits on NOx emissions compared to previous iterations. These regulations have directly influenced the composition and design of catalytic converters for LS engines, driving the need for more efficient and durable catalytic materials.

The impact of these regulations extends beyond just the technical specifications of catalytic converters. They have also influenced manufacturing processes, material sourcing, and even the overall design of LS engines. For instance, the need to meet stricter emission standards has led to the development of more advanced engine management systems that work in tandem with catalytic converters to optimize emission control.

Moreover, environmental regulations have spurred research into alternative catalytic materials. Traditional platinum group metals (PGMs) used in catalytic converters, while effective, are expensive and subject to supply constraints. This has led to increased interest in developing catalysts using more abundant and cost-effective materials, without compromising on emission reduction performance.

The global nature of the automotive industry means that manufacturers must design catalytic converters that can meet the most stringent regulations worldwide. This has led to a harmonization of emission control technologies across different markets, with catalytic converter compositions often exceeding local regulatory requirements to ensure global compliance.

Looking ahead, upcoming regulations are set to further challenge the automotive industry. For example, the proposed Euro 7 standards in Europe and the next phase of EPA regulations in the US are expected to push the boundaries of emission control technology even further. This ongoing regulatory pressure ensures that the composition and performance of catalytic converters for LS engines will remain a critical area of research and development in the automotive sector for years to come.

Cost-Benefit Analysis of Catalytic Solutions

The cost-benefit analysis of catalytic solutions for LS engine emissions is a critical consideration for automotive manufacturers and environmental regulators. This analysis involves evaluating the economic implications of implementing various catalytic converter compositions against their effectiveness in reducing harmful emissions.

Catalytic converters typically use precious metals such as platinum, palladium, and rhodium as active catalysts. These materials are expensive, with prices fluctuating based on global market conditions. The cost of these metals can significantly impact the overall production cost of catalytic converters. However, their effectiveness in converting harmful emissions into less harmful substances is unparalleled, making them a necessary component in meeting stringent emission standards.

Recent advancements in catalytic technology have led to the development of more efficient converter designs that require less precious metal content while maintaining or even improving emission reduction capabilities. This trend has helped to offset the rising costs of raw materials to some extent. Additionally, research into alternative catalyst materials, such as base metals and metal oxides, shows promise in further reducing costs while maintaining acceptable performance levels.

The benefits of advanced catalytic solutions extend beyond mere compliance with emission regulations. Improved air quality resulting from reduced vehicle emissions has significant public health implications, potentially leading to reduced healthcare costs and improved quality of life in urban areas. Furthermore, vehicles equipped with more efficient catalytic converters may experience improved fuel economy, providing long-term cost savings to consumers.

However, the initial investment required for developing and implementing new catalytic technologies can be substantial. Manufacturers must weigh these upfront costs against the long-term benefits and potential market advantages. Factors such as regulatory compliance, consumer demand for environmentally friendly vehicles, and potential fuel efficiency gains all play a role in this complex cost-benefit equation.

In conclusion, while the implementation of advanced catalytic solutions for LS engines does incur significant costs, the long-term benefits in terms of emission reduction, regulatory compliance, and potential fuel efficiency improvements often justify the investment. As technology continues to evolve, the cost-benefit ratio is likely to improve further, making catalytic solutions an increasingly attractive option for automotive manufacturers and environmental stakeholders alike.

Catalytic converters typically use precious metals such as platinum, palladium, and rhodium as active catalysts. These materials are expensive, with prices fluctuating based on global market conditions. The cost of these metals can significantly impact the overall production cost of catalytic converters. However, their effectiveness in converting harmful emissions into less harmful substances is unparalleled, making them a necessary component in meeting stringent emission standards.

Recent advancements in catalytic technology have led to the development of more efficient converter designs that require less precious metal content while maintaining or even improving emission reduction capabilities. This trend has helped to offset the rising costs of raw materials to some extent. Additionally, research into alternative catalyst materials, such as base metals and metal oxides, shows promise in further reducing costs while maintaining acceptable performance levels.

The benefits of advanced catalytic solutions extend beyond mere compliance with emission regulations. Improved air quality resulting from reduced vehicle emissions has significant public health implications, potentially leading to reduced healthcare costs and improved quality of life in urban areas. Furthermore, vehicles equipped with more efficient catalytic converters may experience improved fuel economy, providing long-term cost savings to consumers.

However, the initial investment required for developing and implementing new catalytic technologies can be substantial. Manufacturers must weigh these upfront costs against the long-term benefits and potential market advantages. Factors such as regulatory compliance, consumer demand for environmentally friendly vehicles, and potential fuel efficiency gains all play a role in this complex cost-benefit equation.

In conclusion, while the implementation of advanced catalytic solutions for LS engines does incur significant costs, the long-term benefits in terms of emission reduction, regulatory compliance, and potential fuel efficiency improvements often justify the investment. As technology continues to evolve, the cost-benefit ratio is likely to improve further, making catalytic solutions an increasingly attractive option for automotive manufacturers and environmental stakeholders alike.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!