How Cylinder Deactivation Affects LS Engine Fuel Economy

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Evolution

The LS engine series, introduced by General Motors in 1997, has undergone significant evolution over the years, particularly in terms of fuel economy improvements. The journey of LS engine development reflects a broader industry trend towards increased efficiency without sacrificing performance.

Initially, the LS1 engine set a new standard for V8 performance and efficiency. As environmental concerns and fuel prices became more prominent, subsequent iterations focused on enhancing fuel economy. The introduction of technologies like variable valve timing and direct injection in later LS versions marked important milestones in this evolution.

A pivotal advancement in LS engine fuel economy came with the implementation of cylinder deactivation technology, also known as Active Fuel Management (AFM) or Displacement on Demand (DoD). This technology allows the engine to operate on fewer cylinders under light load conditions, significantly reducing fuel consumption during cruising and idle situations.

The evolution of cylinder deactivation in LS engines has been remarkable. Early versions could switch between eight and four-cylinder operation, while more advanced systems offer more flexible cylinder deactivation patterns. This progression has led to increasingly sophisticated fuel management systems, capable of real-time adjustments based on driving conditions and performance demands.

Concurrent with cylinder deactivation, LS engines saw improvements in materials and manufacturing processes. Lightweight materials and precision engineering techniques allowed for reduced engine weight and improved thermal efficiency, both contributing to better fuel economy.

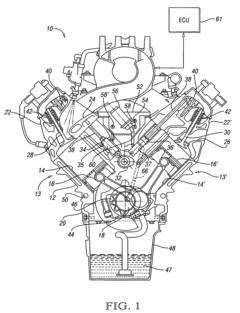

The integration of advanced electronic control units (ECUs) has been crucial in the LS engine's evolution. These sophisticated computers optimize engine operation in real-time, balancing performance and fuel efficiency. They manage complex systems like cylinder deactivation, adjusting parameters instantaneously based on driving conditions and driver input.

As the LS engine family evolved, so did its applications. From high-performance sports cars to trucks and SUVs, the versatility of the LS platform allowed for widespread implementation of fuel-saving technologies across various vehicle types. This broad application accelerated the refinement and effectiveness of fuel economy measures.

Recent developments in LS engine technology have focused on integrating cylinder deactivation with other fuel-saving technologies. This includes combining it with start-stop systems, advanced thermal management, and even mild hybrid systems in some applications, further pushing the boundaries of V8 engine efficiency.

Initially, the LS1 engine set a new standard for V8 performance and efficiency. As environmental concerns and fuel prices became more prominent, subsequent iterations focused on enhancing fuel economy. The introduction of technologies like variable valve timing and direct injection in later LS versions marked important milestones in this evolution.

A pivotal advancement in LS engine fuel economy came with the implementation of cylinder deactivation technology, also known as Active Fuel Management (AFM) or Displacement on Demand (DoD). This technology allows the engine to operate on fewer cylinders under light load conditions, significantly reducing fuel consumption during cruising and idle situations.

The evolution of cylinder deactivation in LS engines has been remarkable. Early versions could switch between eight and four-cylinder operation, while more advanced systems offer more flexible cylinder deactivation patterns. This progression has led to increasingly sophisticated fuel management systems, capable of real-time adjustments based on driving conditions and performance demands.

Concurrent with cylinder deactivation, LS engines saw improvements in materials and manufacturing processes. Lightweight materials and precision engineering techniques allowed for reduced engine weight and improved thermal efficiency, both contributing to better fuel economy.

The integration of advanced electronic control units (ECUs) has been crucial in the LS engine's evolution. These sophisticated computers optimize engine operation in real-time, balancing performance and fuel efficiency. They manage complex systems like cylinder deactivation, adjusting parameters instantaneously based on driving conditions and driver input.

As the LS engine family evolved, so did its applications. From high-performance sports cars to trucks and SUVs, the versatility of the LS platform allowed for widespread implementation of fuel-saving technologies across various vehicle types. This broad application accelerated the refinement and effectiveness of fuel economy measures.

Recent developments in LS engine technology have focused on integrating cylinder deactivation with other fuel-saving technologies. This includes combining it with start-stop systems, advanced thermal management, and even mild hybrid systems in some applications, further pushing the boundaries of V8 engine efficiency.

Fuel Economy Demands

The global automotive industry is facing increasing pressure to improve fuel economy and reduce emissions due to stringent environmental regulations and consumer demand for more efficient vehicles. This has led to a surge in research and development efforts focused on enhancing engine efficiency, with cylinder deactivation emerging as a promising technology for improving fuel economy in LS engines.

Fuel economy demands are driven by several factors, including government regulations, consumer preferences, and economic considerations. In the United States, Corporate Average Fuel Economy (CAFE) standards have been progressively tightened, requiring automakers to achieve higher fleet-wide fuel efficiency. Similar regulations have been implemented in other major automotive markets, such as the European Union and China, further intensifying the need for improved fuel economy technologies.

Consumer demand for fuel-efficient vehicles has also grown significantly in recent years, driven by rising fuel costs and increased environmental awareness. This shift in consumer preferences has prompted automakers to prioritize fuel economy as a key selling point, leading to increased investment in technologies like cylinder deactivation.

The economic benefits of improved fuel economy extend beyond consumer savings at the pump. Reduced fuel consumption contributes to lower operating costs for fleet operators and businesses that rely heavily on transportation. Additionally, improved fuel efficiency can lead to reduced dependence on fossil fuels, potentially impacting global energy markets and geopolitical dynamics.

In the context of LS engines, which are known for their performance capabilities, the challenge lies in maintaining power output while simultaneously improving fuel economy. Cylinder deactivation technology offers a potential solution by allowing the engine to operate more efficiently under various load conditions. By selectively deactivating cylinders during low-load situations, such as highway cruising, the engine can reduce fuel consumption without significantly compromising performance when full power is needed.

The demand for fuel economy improvements in LS engines is further driven by the popularity of these engines in various vehicle segments, including performance cars, trucks, and SUVs. As these vehicle types traditionally have higher fuel consumption, there is significant potential for improvement through technologies like cylinder deactivation.

Fuel economy demands are driven by several factors, including government regulations, consumer preferences, and economic considerations. In the United States, Corporate Average Fuel Economy (CAFE) standards have been progressively tightened, requiring automakers to achieve higher fleet-wide fuel efficiency. Similar regulations have been implemented in other major automotive markets, such as the European Union and China, further intensifying the need for improved fuel economy technologies.

Consumer demand for fuel-efficient vehicles has also grown significantly in recent years, driven by rising fuel costs and increased environmental awareness. This shift in consumer preferences has prompted automakers to prioritize fuel economy as a key selling point, leading to increased investment in technologies like cylinder deactivation.

The economic benefits of improved fuel economy extend beyond consumer savings at the pump. Reduced fuel consumption contributes to lower operating costs for fleet operators and businesses that rely heavily on transportation. Additionally, improved fuel efficiency can lead to reduced dependence on fossil fuels, potentially impacting global energy markets and geopolitical dynamics.

In the context of LS engines, which are known for their performance capabilities, the challenge lies in maintaining power output while simultaneously improving fuel economy. Cylinder deactivation technology offers a potential solution by allowing the engine to operate more efficiently under various load conditions. By selectively deactivating cylinders during low-load situations, such as highway cruising, the engine can reduce fuel consumption without significantly compromising performance when full power is needed.

The demand for fuel economy improvements in LS engines is further driven by the popularity of these engines in various vehicle segments, including performance cars, trucks, and SUVs. As these vehicle types traditionally have higher fuel consumption, there is significant potential for improvement through technologies like cylinder deactivation.

Cylinder Deactivation

Cylinder deactivation is a fuel-saving technology that has gained significant traction in the automotive industry, particularly for large displacement engines like the LS series. This technology allows an engine to temporarily deactivate a subset of its cylinders under light load conditions, effectively reducing fuel consumption without compromising overall performance when full power is needed.

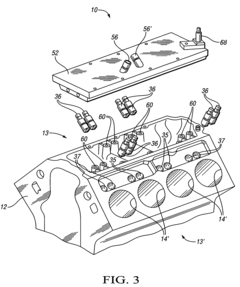

In the context of LS engines, cylinder deactivation typically involves shutting down half of the engine's cylinders during cruising or low-demand situations. This is achieved through a sophisticated system that can disable the valves of selected cylinders, preventing fuel injection and ignition in those cylinders. The remaining active cylinders then operate at a higher efficiency to maintain the desired power output.

The primary mechanism behind the fuel economy improvements is the reduction of pumping losses. When an engine operates at partial load, the throttle is partially closed, creating a vacuum that the pistons must work against. By deactivating cylinders, the engine can operate the remaining cylinders at a higher load, allowing for a more open throttle position and reducing these pumping losses.

Furthermore, cylinder deactivation in LS engines often leads to improved thermal efficiency. With fewer cylinders firing, the active cylinders operate at higher temperatures and pressures, which can result in more complete combustion and better overall efficiency. This effect is particularly noticeable in highway driving scenarios where constant speed and low power demands are common.

The impact on fuel economy can be substantial, with many manufacturers reporting improvements of 5-15% in real-world driving conditions. However, the actual fuel savings can vary widely depending on driving conditions, vehicle weight, and specific engine tuning. City driving, with its frequent stops and starts, typically sees less benefit from cylinder deactivation compared to highway cruising.

It's important to note that the implementation of cylinder deactivation in LS engines requires careful engineering to maintain smooth operation and seamless transitions between full and partial cylinder modes. This includes sophisticated engine control units, specialized valve train components, and often modifications to the engine mounts and exhaust system to manage noise, vibration, and harshness (NVH) issues that can arise from the changing cylinder firing patterns.

While cylinder deactivation offers significant fuel economy benefits, it also introduces additional complexity to the engine design and potential long-term reliability concerns. Engineers must balance these factors against the fuel savings to determine the overall value proposition for different vehicle applications and market segments.

In the context of LS engines, cylinder deactivation typically involves shutting down half of the engine's cylinders during cruising or low-demand situations. This is achieved through a sophisticated system that can disable the valves of selected cylinders, preventing fuel injection and ignition in those cylinders. The remaining active cylinders then operate at a higher efficiency to maintain the desired power output.

The primary mechanism behind the fuel economy improvements is the reduction of pumping losses. When an engine operates at partial load, the throttle is partially closed, creating a vacuum that the pistons must work against. By deactivating cylinders, the engine can operate the remaining cylinders at a higher load, allowing for a more open throttle position and reducing these pumping losses.

Furthermore, cylinder deactivation in LS engines often leads to improved thermal efficiency. With fewer cylinders firing, the active cylinders operate at higher temperatures and pressures, which can result in more complete combustion and better overall efficiency. This effect is particularly noticeable in highway driving scenarios where constant speed and low power demands are common.

The impact on fuel economy can be substantial, with many manufacturers reporting improvements of 5-15% in real-world driving conditions. However, the actual fuel savings can vary widely depending on driving conditions, vehicle weight, and specific engine tuning. City driving, with its frequent stops and starts, typically sees less benefit from cylinder deactivation compared to highway cruising.

It's important to note that the implementation of cylinder deactivation in LS engines requires careful engineering to maintain smooth operation and seamless transitions between full and partial cylinder modes. This includes sophisticated engine control units, specialized valve train components, and often modifications to the engine mounts and exhaust system to manage noise, vibration, and harshness (NVH) issues that can arise from the changing cylinder firing patterns.

While cylinder deactivation offers significant fuel economy benefits, it also introduces additional complexity to the engine design and potential long-term reliability concerns. Engineers must balance these factors against the fuel savings to determine the overall value proposition for different vehicle applications and market segments.

Current Solutions

01 Engine design optimization

Optimizing the design of LS engines to improve fuel economy. This includes modifications to engine components, combustion chamber design, and overall engine architecture to enhance efficiency and reduce fuel consumption.- Engine design optimization: Optimizing the design of LS engines to improve fuel economy. This includes modifications to engine components, combustion chamber design, and overall engine architecture to enhance efficiency and reduce fuel consumption.

- Fuel injection and management systems: Implementing advanced fuel injection and management systems in LS engines to improve fuel economy. This involves precise control of fuel delivery, optimized injection timing, and sophisticated engine control units to maximize efficiency.

- Transmission and drivetrain improvements: Enhancing transmission and drivetrain components to reduce power loss and improve overall fuel economy in vehicles equipped with LS engines. This includes optimizing gear ratios, reducing friction, and implementing advanced transmission control strategies.

- Lubricant and additive technologies: Developing and utilizing advanced lubricants and additives specifically formulated for LS engines to reduce friction, improve engine efficiency, and ultimately enhance fuel economy.

- Engine monitoring and diagnostics: Implementing sophisticated engine monitoring and diagnostic systems to ensure optimal performance and fuel efficiency of LS engines. This includes real-time data analysis, predictive maintenance, and adaptive engine control strategies.

02 Fuel injection and management systems

Implementation of advanced fuel injection and management systems in LS engines. These systems precisely control fuel delivery, timing, and mixture, leading to improved combustion efficiency and reduced fuel consumption.Expand Specific Solutions03 Transmission and drivetrain improvements

Enhancements to transmission and drivetrain components to reduce power loss and improve overall vehicle efficiency. This includes optimizing gear ratios, reducing friction, and implementing advanced transmission control strategies.Expand Specific Solutions04 Engine monitoring and diagnostics

Integration of sophisticated engine monitoring and diagnostic systems to ensure optimal performance and fuel efficiency. These systems can detect and address issues that may negatively impact fuel economy, allowing for timely maintenance and adjustments.Expand Specific Solutions05 Lubricant and additive technologies

Development and use of advanced lubricants and fuel additives specifically designed for LS engines. These formulations can reduce friction, improve engine cleanliness, and enhance overall efficiency, contributing to better fuel economy.Expand Specific Solutions

Key Manufacturers

The cylinder deactivation technology for LS engines is in a mature stage of development, with several major automotive manufacturers implementing it to improve fuel economy. The market for this technology is substantial, driven by increasing fuel efficiency regulations and consumer demand for more economical vehicles. Companies like Ford Global Technologies LLC, GM Global Technology Operations LLC, and Honda Motor Co., Ltd. have been at the forefront of developing and implementing cylinder deactivation systems. The technology's maturity is evident in its widespread adoption across various vehicle models, with ongoing refinements focusing on optimizing performance and efficiency. As the automotive industry continues to prioritize fuel economy, the cylinder deactivation market is expected to grow, with potential for further innovations and applications in different engine types.

GM Global Technology Operations LLC

Technical Solution: GM's Dynamic Fuel Management (DFM) system for LS engines employs advanced cylinder deactivation technology. It can deactivate any number of cylinders, from one to seven, in a variety of combinations depending on driving conditions[1]. The system uses sophisticated software algorithms to continuously determine the number of cylinders required to meet the driver's torque demand. DFM can make up to 80 firing fractions per second, ensuring seamless transitions between cylinder patterns[2]. This technology is particularly effective in V8 engines, where it can improve fuel economy by up to 15% under certain driving conditions[3].

Strengths: Highly flexible cylinder deactivation, seamless operation, significant fuel economy improvements. Weaknesses: Complex system requiring advanced control algorithms, potential for increased maintenance costs due to system complexity.

Honda Motor Co., Ltd.

Technical Solution: Honda's Variable Cylinder Management (VCM) system for their LS-like V6 engines focuses on deactivating three cylinders during light load conditions. The system uses SOHC VTEC (Variable Valve Timing and Lift Electronic Control) to deactivate the valves of the rear bank of cylinders[4]. When deactivated, these cylinders' valves remain closed, and fuel injection is halted, effectively turning them into air springs. Honda's VCM can transition between 3- and 6-cylinder operation in as little as 0.04 seconds, ensuring smooth power delivery[5]. This technology has been shown to improve fuel economy by up to 12% in city driving conditions[6].

Strengths: Simple and reliable design, quick transition between modes, proven fuel economy benefits. Weaknesses: Less flexible than systems that can deactivate individual cylinders, limited to specific engine configurations.

Core Innovations

Valve deactivation system

PatentInactiveEP1221541A3

Innovation

- A valve deactivation system comprising a deactivation rocker arm assembly with a sliding center post and a free motion spring assembly that utilizes existing space and conventional valve train components, reducing the number of parts and enabling operation across a wide range of engine conditions.

Cylinder deactivation apparatus

PatentActiveUS7503296B2

Innovation

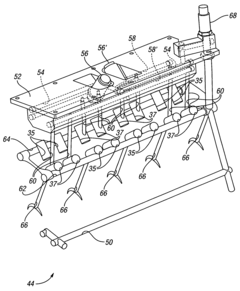

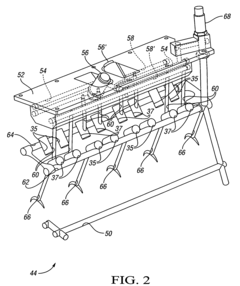

- A system where fewer solenoid-actuated hydraulic control valves are used to selectively communicate pressurized oil to switching hydraulic lifters, allowing for the deactivation of multiple cylinders by leveraging an oil manifold assembly and a rotatable camshaft to manage cylinder deactivation and reactivation timing.

Emissions Regulations

Emissions regulations have played a significant role in shaping the development and implementation of cylinder deactivation technology in LS engines. As governments worldwide have imposed increasingly stringent emissions standards, automakers have been compelled to explore innovative solutions to improve fuel economy and reduce harmful emissions. Cylinder deactivation has emerged as a key strategy to meet these regulatory requirements while maintaining engine performance.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind the adoption of cylinder deactivation technology. These standards, first introduced in 1975 and periodically updated, set specific fuel efficiency targets for vehicle manufacturers. The most recent CAFE standards aim to achieve an average fuel economy of 54.5 miles per gallon for cars and light-duty trucks by 2025. This ambitious target has pushed automakers to invest heavily in fuel-saving technologies, including cylinder deactivation for LS engines.

Similarly, the European Union has implemented its own set of emissions regulations, known as the Euro standards. These standards have progressively tightened limits on carbon dioxide (CO2) emissions from passenger vehicles. The current Euro 6 standard, introduced in 2014, sets a fleet average CO2 emissions target of 95 grams per kilometer by 2021. This regulatory pressure has encouraged European automakers to adopt cylinder deactivation technology in their LS engine variants to meet these stringent requirements.

China, the world's largest automotive market, has also introduced its own emissions regulations modeled after European standards. The China 6 standard, implemented in phases starting from 2019, aims to reduce vehicle emissions by up to 50% compared to previous standards. This regulatory environment has created a strong incentive for manufacturers to incorporate cylinder deactivation technology in LS engines sold in the Chinese market.

The impact of emissions regulations on cylinder deactivation technology extends beyond passenger vehicles. Heavy-duty trucks and commercial vehicles are also subject to increasingly strict emissions standards. In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) have jointly established greenhouse gas emissions and fuel efficiency standards for medium- and heavy-duty engines and vehicles. These regulations have prompted manufacturers to explore cylinder deactivation as a means to improve fuel economy in larger LS engine applications.

As emissions regulations continue to evolve globally, cylinder deactivation technology in LS engines is likely to see further refinement and widespread adoption. Future regulatory frameworks may include more comprehensive well-to-wheel emissions assessments, potentially favoring technologies that offer real-world fuel economy improvements. This regulatory landscape will continue to drive innovation in cylinder deactivation systems, pushing manufacturers to develop more sophisticated and efficient solutions for LS engines across various vehicle segments.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind the adoption of cylinder deactivation technology. These standards, first introduced in 1975 and periodically updated, set specific fuel efficiency targets for vehicle manufacturers. The most recent CAFE standards aim to achieve an average fuel economy of 54.5 miles per gallon for cars and light-duty trucks by 2025. This ambitious target has pushed automakers to invest heavily in fuel-saving technologies, including cylinder deactivation for LS engines.

Similarly, the European Union has implemented its own set of emissions regulations, known as the Euro standards. These standards have progressively tightened limits on carbon dioxide (CO2) emissions from passenger vehicles. The current Euro 6 standard, introduced in 2014, sets a fleet average CO2 emissions target of 95 grams per kilometer by 2021. This regulatory pressure has encouraged European automakers to adopt cylinder deactivation technology in their LS engine variants to meet these stringent requirements.

China, the world's largest automotive market, has also introduced its own emissions regulations modeled after European standards. The China 6 standard, implemented in phases starting from 2019, aims to reduce vehicle emissions by up to 50% compared to previous standards. This regulatory environment has created a strong incentive for manufacturers to incorporate cylinder deactivation technology in LS engines sold in the Chinese market.

The impact of emissions regulations on cylinder deactivation technology extends beyond passenger vehicles. Heavy-duty trucks and commercial vehicles are also subject to increasingly strict emissions standards. In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) have jointly established greenhouse gas emissions and fuel efficiency standards for medium- and heavy-duty engines and vehicles. These regulations have prompted manufacturers to explore cylinder deactivation as a means to improve fuel economy in larger LS engine applications.

As emissions regulations continue to evolve globally, cylinder deactivation technology in LS engines is likely to see further refinement and widespread adoption. Future regulatory frameworks may include more comprehensive well-to-wheel emissions assessments, potentially favoring technologies that offer real-world fuel economy improvements. This regulatory landscape will continue to drive innovation in cylinder deactivation systems, pushing manufacturers to develop more sophisticated and efficient solutions for LS engines across various vehicle segments.

Performance Impact

Cylinder deactivation technology has a significant impact on the performance of LS engines, particularly in terms of fuel economy. This innovative approach allows the engine to operate more efficiently by selectively shutting down cylinders when full power is not required, resulting in improved fuel consumption without compromising overall performance.

When cylinder deactivation is engaged, the LS engine typically experiences a reduction in power output. However, this decrease is carefully managed to ensure that the engine still delivers sufficient performance for most driving conditions. The system is designed to activate and deactivate cylinders seamlessly, with the transition being virtually imperceptible to the driver. This smooth operation helps maintain a consistent driving experience while maximizing fuel efficiency.

One of the key performance benefits of cylinder deactivation is the improvement in fuel economy during light-load conditions, such as highway cruising. By operating on fewer cylinders, the engine reduces pumping losses and increases thermal efficiency, leading to substantial fuel savings. Studies have shown that cylinder deactivation can improve fuel economy by up to 7-8% in real-world driving scenarios, with even greater improvements possible under specific conditions.

It's important to note that the performance impact of cylinder deactivation varies depending on the specific LS engine model and vehicle application. Factors such as engine size, vehicle weight, and transmission gearing all play a role in determining the overall effectiveness of the technology. Generally, larger displacement engines tend to benefit more from cylinder deactivation, as they have greater potential for reducing fuel consumption during partial load operations.

While cylinder deactivation primarily focuses on improving fuel economy, it can also have secondary performance benefits. For instance, the reduced engine load during deactivation can lead to lower engine temperatures, potentially extending engine life and reducing wear on components. Additionally, the technology can contribute to reduced emissions, helping manufacturers meet increasingly stringent environmental regulations without sacrificing performance.

It's worth noting that the performance impact of cylinder deactivation is not limited to steady-state driving conditions. Modern systems are sophisticated enough to rapidly reactivate cylinders when additional power is needed, such as during acceleration or when climbing hills. This dynamic capability ensures that the LS engine can provide full power on demand, maintaining its performance characteristics while still offering improved fuel efficiency during less demanding driving situations.

When cylinder deactivation is engaged, the LS engine typically experiences a reduction in power output. However, this decrease is carefully managed to ensure that the engine still delivers sufficient performance for most driving conditions. The system is designed to activate and deactivate cylinders seamlessly, with the transition being virtually imperceptible to the driver. This smooth operation helps maintain a consistent driving experience while maximizing fuel efficiency.

One of the key performance benefits of cylinder deactivation is the improvement in fuel economy during light-load conditions, such as highway cruising. By operating on fewer cylinders, the engine reduces pumping losses and increases thermal efficiency, leading to substantial fuel savings. Studies have shown that cylinder deactivation can improve fuel economy by up to 7-8% in real-world driving scenarios, with even greater improvements possible under specific conditions.

It's important to note that the performance impact of cylinder deactivation varies depending on the specific LS engine model and vehicle application. Factors such as engine size, vehicle weight, and transmission gearing all play a role in determining the overall effectiveness of the technology. Generally, larger displacement engines tend to benefit more from cylinder deactivation, as they have greater potential for reducing fuel consumption during partial load operations.

While cylinder deactivation primarily focuses on improving fuel economy, it can also have secondary performance benefits. For instance, the reduced engine load during deactivation can lead to lower engine temperatures, potentially extending engine life and reducing wear on components. Additionally, the technology can contribute to reduced emissions, helping manufacturers meet increasingly stringent environmental regulations without sacrificing performance.

It's worth noting that the performance impact of cylinder deactivation is not limited to steady-state driving conditions. Modern systems are sophisticated enough to rapidly reactivate cylinders when additional power is needed, such as during acceleration or when climbing hills. This dynamic capability ensures that the LS engine can provide full power on demand, maintaining its performance characteristics while still offering improved fuel efficiency during less demanding driving situations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!