How different substrates affect AMOLED display flexibility?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Flexibility Goals

The evolution of AMOLED display technology has been driven by the increasing demand for flexible and foldable devices in the consumer electronics market. The primary goal for AMOLED flexibility is to create displays that can bend, fold, and even roll without compromising image quality or durability. This objective encompasses several key aspects that researchers and manufacturers are striving to achieve.

One of the primary aims is to develop AMOLED displays with a high degree of flexibility while maintaining excellent visual performance. This includes achieving a low bending radius, which allows for tighter folds and more compact designs in foldable devices. The target is to reach a bending radius of less than 1mm without causing damage to the display or affecting its functionality.

Another crucial goal is to enhance the durability and lifespan of flexible AMOLED displays. This involves improving the resistance to repeated bending and folding cycles, with the aim of withstanding hundreds of thousands of folds without degradation in performance or visible creases. Manufacturers are working towards displays that can maintain their structural integrity and visual quality even after years of regular use in foldable devices.

Reducing the overall thickness of the display stack is also a significant objective in AMOLED flexibility research. Thinner displays not only contribute to more flexible designs but also allow for sleeker and lighter devices. The goal is to achieve a total thickness of less than 100 micrometers for the entire display stack, including the substrate, OLED layers, and encapsulation.

Improving the optical properties of flexible AMOLED displays under various bending conditions is another key focus. This includes maintaining consistent brightness, color accuracy, and viewing angles when the display is flat, curved, or folded. Researchers are working on advanced light management techniques and materials to minimize distortions and color shifts in flexible configurations.

Lastly, a critical goal in AMOLED flexibility is to develop manufacturing processes that enable mass production of flexible displays with high yield rates and cost-effectiveness. This involves refining existing fabrication techniques and exploring new methods that can reliably produce large quantities of flexible AMOLED panels while maintaining consistent quality and performance across all units.

One of the primary aims is to develop AMOLED displays with a high degree of flexibility while maintaining excellent visual performance. This includes achieving a low bending radius, which allows for tighter folds and more compact designs in foldable devices. The target is to reach a bending radius of less than 1mm without causing damage to the display or affecting its functionality.

Another crucial goal is to enhance the durability and lifespan of flexible AMOLED displays. This involves improving the resistance to repeated bending and folding cycles, with the aim of withstanding hundreds of thousands of folds without degradation in performance or visible creases. Manufacturers are working towards displays that can maintain their structural integrity and visual quality even after years of regular use in foldable devices.

Reducing the overall thickness of the display stack is also a significant objective in AMOLED flexibility research. Thinner displays not only contribute to more flexible designs but also allow for sleeker and lighter devices. The goal is to achieve a total thickness of less than 100 micrometers for the entire display stack, including the substrate, OLED layers, and encapsulation.

Improving the optical properties of flexible AMOLED displays under various bending conditions is another key focus. This includes maintaining consistent brightness, color accuracy, and viewing angles when the display is flat, curved, or folded. Researchers are working on advanced light management techniques and materials to minimize distortions and color shifts in flexible configurations.

Lastly, a critical goal in AMOLED flexibility is to develop manufacturing processes that enable mass production of flexible displays with high yield rates and cost-effectiveness. This involves refining existing fabrication techniques and exploring new methods that can reliably produce large quantities of flexible AMOLED panels while maintaining consistent quality and performance across all units.

Flexible Display Market

The flexible display market has experienced significant growth in recent years, driven by the increasing demand for innovative and portable electronic devices. This market segment encompasses a wide range of applications, including smartphones, smartwatches, tablets, and automotive displays. The flexibility of these displays offers numerous advantages, such as improved durability, lighter weight, and the ability to create unique form factors.

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has emerged as a key player in the flexible display market due to its superior image quality, energy efficiency, and adaptability to various substrates. The choice of substrate material plays a crucial role in determining the overall flexibility and performance of AMOLED displays.

The market for flexible AMOLED displays has seen substantial expansion, with major manufacturers investing heavily in research and development to improve the technology and increase production capacity. This growth is expected to continue as consumer demand for more versatile and durable devices rises.

One of the primary drivers of the flexible display market is the smartphone industry. Major smartphone manufacturers have introduced devices with curved or foldable displays, showcasing the potential of flexible AMOLED technology. These innovative designs have captured consumer interest and are likely to become more prevalent in the coming years.

Beyond smartphones, the automotive industry has shown increasing interest in flexible displays for dashboard and infotainment systems. The ability to conform to curved surfaces and integrate seamlessly into vehicle interiors makes flexible AMOLED displays an attractive option for car manufacturers seeking to enhance the user experience and differentiate their products.

The wearable technology sector, including smartwatches and fitness trackers, has also benefited from advancements in flexible display technology. These devices require displays that can withstand frequent bending and conform to the contours of the human body, making flexible AMOLED screens an ideal solution.

As the flexible display market continues to evolve, manufacturers are exploring new substrate materials to further enhance the flexibility, durability, and performance of AMOLED displays. The choice of substrate affects not only the physical properties of the display but also its manufacturing process and cost.

The market is also seeing increased competition among display manufacturers, leading to accelerated innovation and more diverse product offerings. This competition is likely to drive down costs and improve the accessibility of flexible display technology across various consumer and industrial applications.

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has emerged as a key player in the flexible display market due to its superior image quality, energy efficiency, and adaptability to various substrates. The choice of substrate material plays a crucial role in determining the overall flexibility and performance of AMOLED displays.

The market for flexible AMOLED displays has seen substantial expansion, with major manufacturers investing heavily in research and development to improve the technology and increase production capacity. This growth is expected to continue as consumer demand for more versatile and durable devices rises.

One of the primary drivers of the flexible display market is the smartphone industry. Major smartphone manufacturers have introduced devices with curved or foldable displays, showcasing the potential of flexible AMOLED technology. These innovative designs have captured consumer interest and are likely to become more prevalent in the coming years.

Beyond smartphones, the automotive industry has shown increasing interest in flexible displays for dashboard and infotainment systems. The ability to conform to curved surfaces and integrate seamlessly into vehicle interiors makes flexible AMOLED displays an attractive option for car manufacturers seeking to enhance the user experience and differentiate their products.

The wearable technology sector, including smartwatches and fitness trackers, has also benefited from advancements in flexible display technology. These devices require displays that can withstand frequent bending and conform to the contours of the human body, making flexible AMOLED screens an ideal solution.

As the flexible display market continues to evolve, manufacturers are exploring new substrate materials to further enhance the flexibility, durability, and performance of AMOLED displays. The choice of substrate affects not only the physical properties of the display but also its manufacturing process and cost.

The market is also seeing increased competition among display manufacturers, leading to accelerated innovation and more diverse product offerings. This competition is likely to drive down costs and improve the accessibility of flexible display technology across various consumer and industrial applications.

Substrate Challenges

The development of flexible AMOLED displays has been hindered by several substrate-related challenges. Traditional glass substrates, while offering excellent barrier properties and thermal stability, lack the flexibility required for next-generation displays. This has led to a shift towards plastic substrates, which bring their own set of challenges.

One of the primary issues with plastic substrates is their higher coefficient of thermal expansion (CTE) compared to glass. This mismatch in CTE between the substrate and the thin-film transistor (TFT) layers can lead to stress and potential delamination during the high-temperature processes involved in display manufacturing. Additionally, plastic substrates are more permeable to oxygen and moisture, which can degrade the organic materials in OLED devices, significantly reducing their lifespan.

The mechanical properties of plastic substrates also present challenges. While they offer improved flexibility compared to glass, they are more susceptible to scratches and physical damage. This necessitates the development of robust protective layers that can maintain the display's integrity without compromising its flexibility.

Another critical challenge is the dimensional stability of plastic substrates. During the manufacturing process, which involves multiple high-temperature steps, plastic substrates can undergo dimensional changes. This can lead to misalignment issues in the subsequent layers of the display, affecting the overall performance and yield of the production process.

The surface roughness of plastic substrates is another factor that impacts AMOLED display performance. Unlike the ultra-smooth surface of glass, plastic substrates often have higher surface roughness, which can lead to non-uniform electrical characteristics in the TFT layers and potentially cause visual defects in the final display.

Achieving high optical transparency in flexible substrates while maintaining other desirable properties is also challenging. The substrate must allow for maximum light transmission to ensure the brightness and color accuracy of the AMOLED display. However, some materials that offer good barrier properties or mechanical strength may compromise optical clarity.

The choice of substrate material also affects the maximum processing temperature that can be used during manufacturing. Many high-performance TFT technologies require processing temperatures that exceed the thermal stability limits of most plastic substrates. This constraint has driven research into low-temperature processes and alternative TFT materials that can deliver high performance at lower processing temperatures.

Addressing these substrate challenges requires a multidisciplinary approach, combining materials science, chemical engineering, and process innovation. Researchers are exploring various strategies, including multi-layer substrate designs, novel barrier coatings, and hybrid organic-inorganic materials to overcome these limitations and pave the way for truly flexible, durable, and high-performance AMOLED displays.

One of the primary issues with plastic substrates is their higher coefficient of thermal expansion (CTE) compared to glass. This mismatch in CTE between the substrate and the thin-film transistor (TFT) layers can lead to stress and potential delamination during the high-temperature processes involved in display manufacturing. Additionally, plastic substrates are more permeable to oxygen and moisture, which can degrade the organic materials in OLED devices, significantly reducing their lifespan.

The mechanical properties of plastic substrates also present challenges. While they offer improved flexibility compared to glass, they are more susceptible to scratches and physical damage. This necessitates the development of robust protective layers that can maintain the display's integrity without compromising its flexibility.

Another critical challenge is the dimensional stability of plastic substrates. During the manufacturing process, which involves multiple high-temperature steps, plastic substrates can undergo dimensional changes. This can lead to misalignment issues in the subsequent layers of the display, affecting the overall performance and yield of the production process.

The surface roughness of plastic substrates is another factor that impacts AMOLED display performance. Unlike the ultra-smooth surface of glass, plastic substrates often have higher surface roughness, which can lead to non-uniform electrical characteristics in the TFT layers and potentially cause visual defects in the final display.

Achieving high optical transparency in flexible substrates while maintaining other desirable properties is also challenging. The substrate must allow for maximum light transmission to ensure the brightness and color accuracy of the AMOLED display. However, some materials that offer good barrier properties or mechanical strength may compromise optical clarity.

The choice of substrate material also affects the maximum processing temperature that can be used during manufacturing. Many high-performance TFT technologies require processing temperatures that exceed the thermal stability limits of most plastic substrates. This constraint has driven research into low-temperature processes and alternative TFT materials that can deliver high performance at lower processing temperatures.

Addressing these substrate challenges requires a multidisciplinary approach, combining materials science, chemical engineering, and process innovation. Researchers are exploring various strategies, including multi-layer substrate designs, novel barrier coatings, and hybrid organic-inorganic materials to overcome these limitations and pave the way for truly flexible, durable, and high-performance AMOLED displays.

Current Substrate Tech

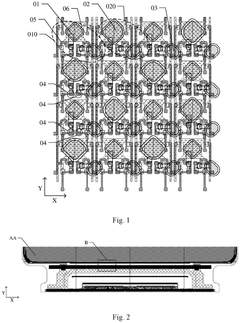

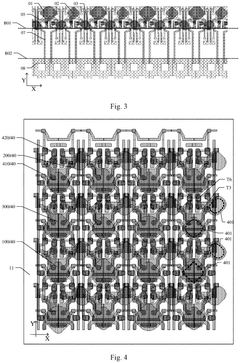

01 Flexible AMOLED display structure

AMOLED displays can be made flexible by using a combination of flexible substrates, thin-film transistors, and organic light-emitting materials. This structure allows the display to bend and conform to various shapes while maintaining functionality.- Flexible AMOLED display structure: AMOLED displays can be made flexible by using a combination of thin-film transistors (TFTs) and organic light-emitting diodes (OLEDs) on a flexible substrate. This structure allows the display to bend and flex without compromising its functionality, enabling the creation of curved or foldable devices.

- Stress distribution in flexible displays: To enhance flexibility, AMOLED displays incorporate stress distribution techniques. These may include using specialized materials or structural designs that help distribute stress evenly across the display when bent or folded, preventing damage to the sensitive components.

- Touch sensitivity in flexible AMOLED displays: Flexible AMOLED displays often integrate touch sensitivity, requiring special considerations to maintain touch functionality when the display is bent or flexed. This may involve using flexible touch sensors or developing algorithms to compensate for changes in touch response due to bending.

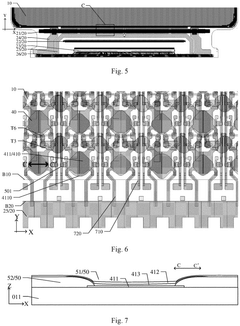

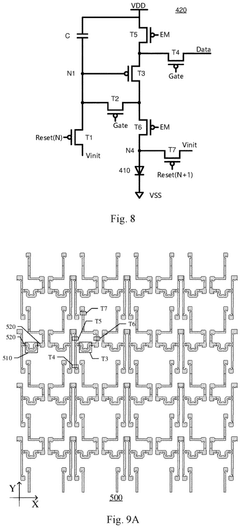

- Pixel compensation in flexible displays: As flexible AMOLED displays bend, the light emission characteristics of individual pixels may change. To maintain image quality, these displays often incorporate pixel compensation techniques, which adjust the driving signals to ensure consistent brightness and color across the curved or bent surface.

- Encapsulation of flexible AMOLED displays: Flexible AMOLED displays require specialized encapsulation techniques to protect the sensitive organic materials from moisture and oxygen while maintaining flexibility. This may involve using thin-film encapsulation layers or flexible barrier materials that can bend without cracking or losing their protective properties.

02 Foldable AMOLED display technology

Foldable AMOLED displays incorporate hinges and flexible components to allow the screen to fold without damaging the display elements. This technology enables the creation of devices with larger screens that can be folded into more compact forms.Expand Specific Solutions03 Touch sensitivity in flexible AMOLED displays

Integrating touch sensitivity into flexible AMOLED displays involves developing touch sensors that can maintain functionality while being bent or flexed. This may include the use of specialized materials and manufacturing techniques to ensure consistent touch response across the flexible surface.Expand Specific Solutions04 Durability and protection of flexible AMOLED displays

Enhancing the durability of flexible AMOLED displays involves developing protective layers and encapsulation techniques that can withstand repeated bending and folding. This may include the use of specialized polymers and barrier films to protect the sensitive organic materials from environmental factors.Expand Specific Solutions05 Driving circuits for flexible AMOLED displays

Designing driving circuits for flexible AMOLED displays requires the development of components that can maintain performance while being bent or flexed. This may involve the use of stretchable conductors and specialized circuit layouts to ensure consistent image quality across the flexible display.Expand Specific Solutions

Key AMOLED Players

The AMOLED display flexibility market is in a growth phase, driven by increasing demand for flexible smartphones and wearables. The global market size is projected to expand significantly in the coming years. Technologically, AMOLED flexibility is advancing rapidly, with key players like BOE Technology, China Star Optoelectronics, and Everdisplay Optronics leading innovation. These companies are developing various substrate materials, including plastic and ultra-thin glass, to enhance display flexibility while maintaining performance. The competition is intensifying as more manufacturers enter the market, pushing for improved durability, bendability, and production efficiency in flexible AMOLED displays.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible AMOLED displays using various substrate materials. Their primary focus has been on polyimide (PI) substrates, which offer excellent flexibility and durability. BOE's technology allows for the fabrication of ultra-thin AMOLED panels with a thickness of less than 1mm, enabling foldable and rollable displays[1]. They have also explored the use of ultra-thin glass substrates in collaboration with Corning, which provides better moisture barrier properties compared to plastic substrates[2]. BOE's flexible AMOLED displays incorporate a multi-layer structure, including a flexible encapsulation layer to protect the organic materials from oxygen and moisture[3].

Strengths: Advanced manufacturing capabilities, diverse substrate options, and strong R&D in flexible display technologies. Weaknesses: Higher production costs compared to rigid displays and potential yield issues with new substrate materials.

Corning, Inc.

Technical Solution: Corning has focused on developing ultra-thin, flexible glass substrates for AMOLED displays as an alternative to plastic-based options. Their Willow Glass technology offers a thickness of less than 100 micrometers while maintaining superior barrier properties against moisture and oxygen compared to plastic substrates[7]. Corning's flexible glass can withstand higher processing temperatures, allowing for the integration of higher-performance TFT backplanes. They have also developed specialized handling and processing techniques to enable roll-to-roll manufacturing of flexible glass substrates, potentially reducing production costs for flexible AMOLED displays[8].

Strengths: Superior barrier properties, high-temperature processing capability, and potential for roll-to-roll manufacturing. Weaknesses: Higher initial costs compared to plastic substrates and greater fragility requiring careful handling during production.

Substrate Innovations

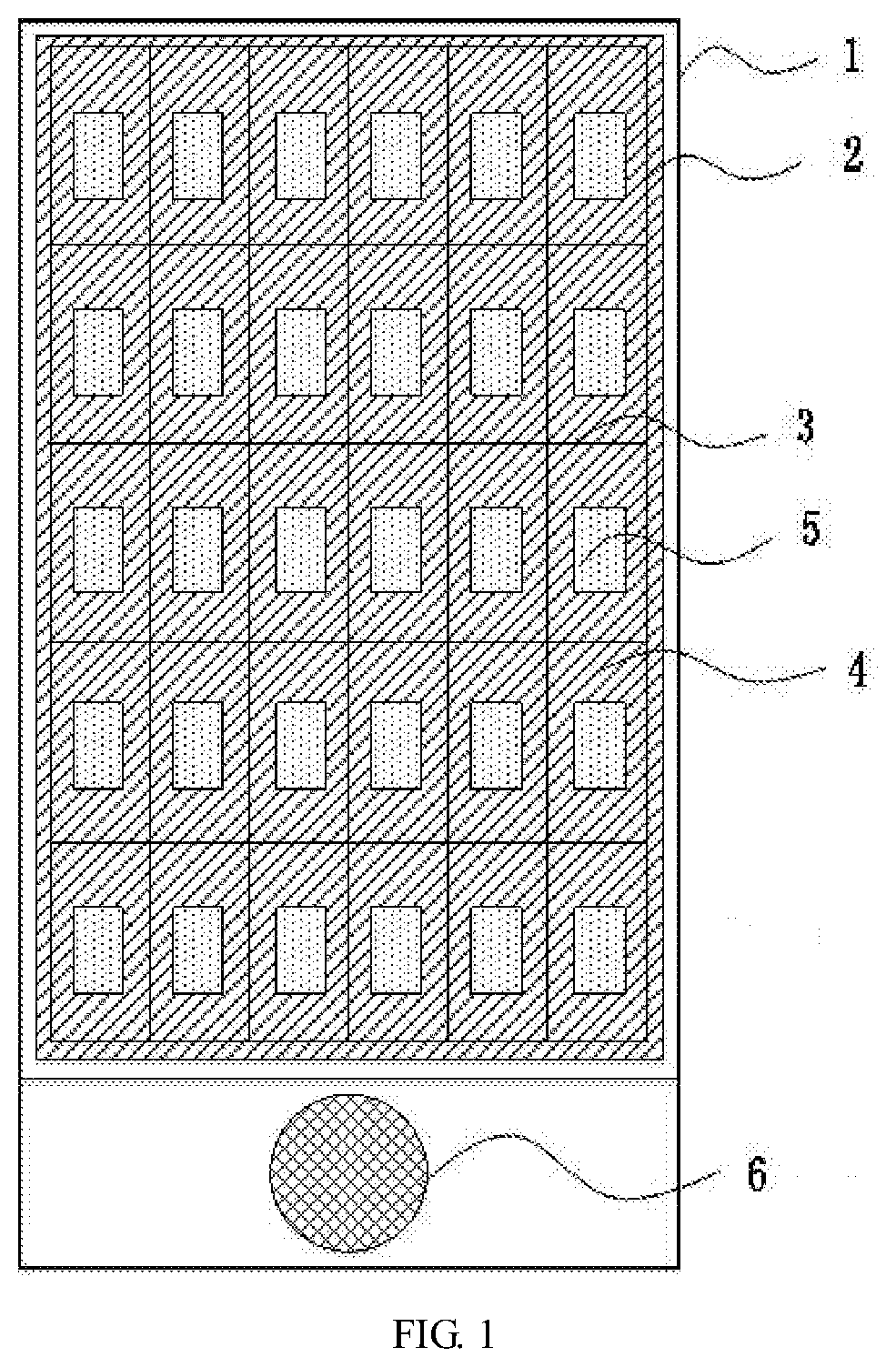

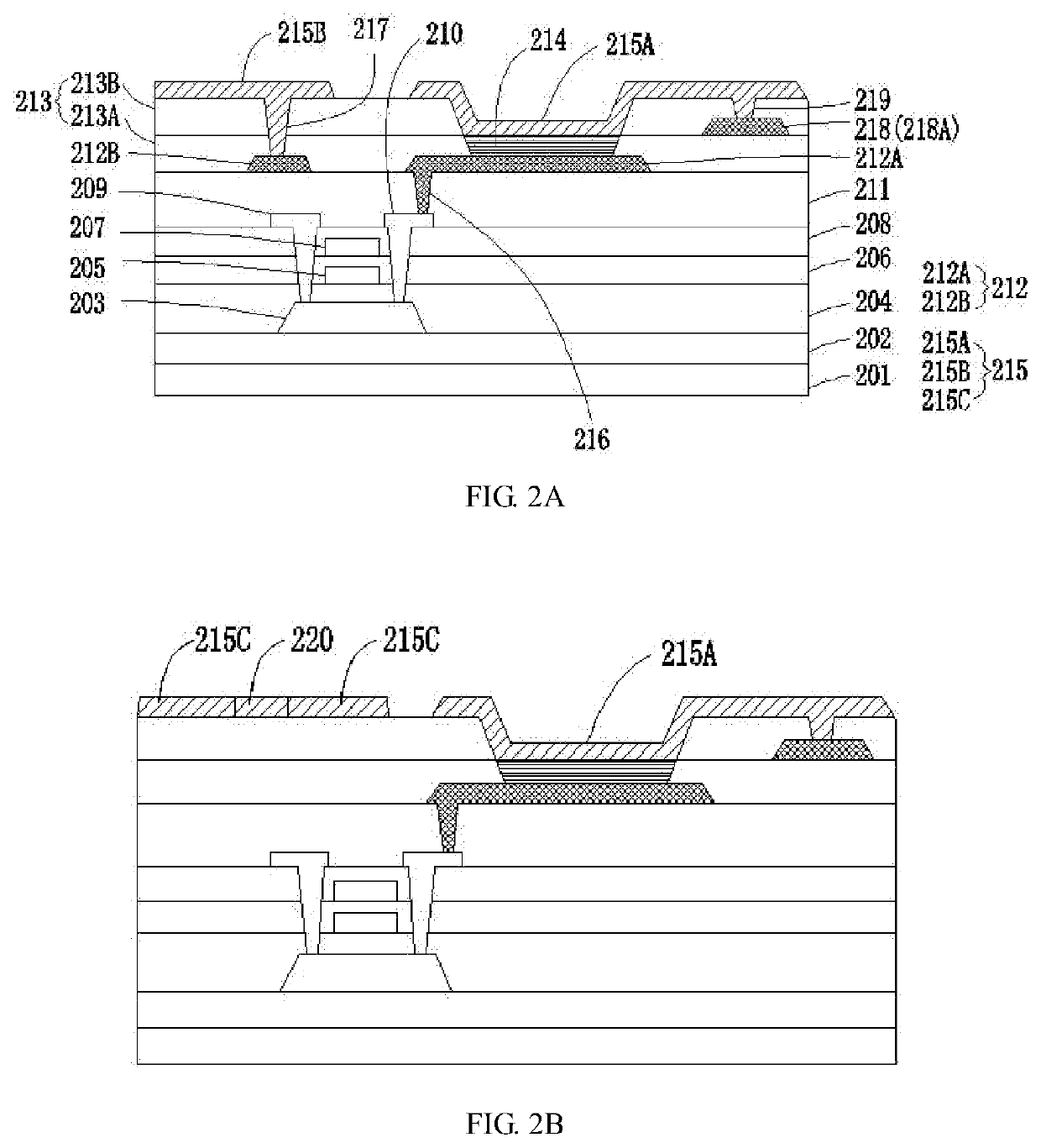

Display substrate and display apparatus

PatentPendingEP4443415A1

Innovation

- The design involves a display substrate with a pixel circuit where the light-emitting control transistor is positioned on the side of the driving transistor away from the bonding area, allowing for a more compact layout and efficient use of pixel space, thereby narrowing the lower border of the display device.

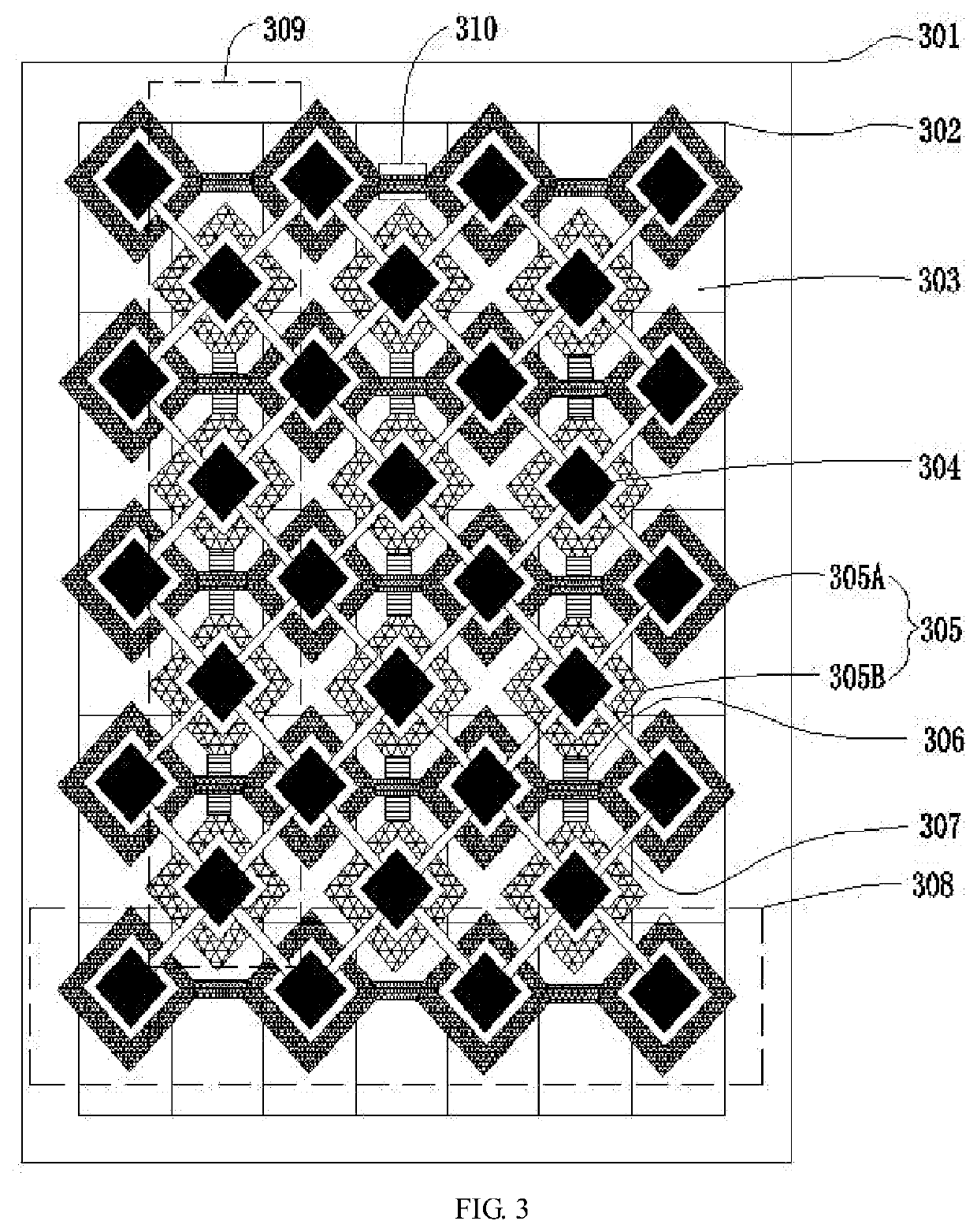

Active matrix organic light emitting diode (amoled) display panel

PatentInactiveUS20210343972A1

Innovation

- The integration of sensing electrodes into the AMOLED display panel allows for underscreen fingerprint identification, utilizing a patterned cathode layer with insulated first and second electrode rows and conductive bridges to form capacitors for fingerprint recognition, thereby embedding fingerprint identification within the screen and increasing the display area ratio.

Manufacturing Process

The manufacturing process for AMOLED displays with flexible substrates involves several critical steps that directly impact the overall flexibility and performance of the final product. The choice of substrate material plays a crucial role in determining the manufacturing approach and the resulting display characteristics.

Traditionally, glass has been the primary substrate for AMOLED displays due to its excellent barrier properties and thermal stability. However, the shift towards flexible displays has necessitated the exploration of alternative substrate materials, such as plastic films and ultra-thin glass. Each substrate type requires specific manufacturing considerations to ensure optimal performance and flexibility.

For plastic-based substrates, such as polyimide (PI) or polyethylene naphthalate (PEN), the manufacturing process typically begins with the deposition of a planarization layer to create a smooth surface for subsequent thin-film transistor (TFT) fabrication. This is followed by the deposition of the TFT layers, including the semiconductor, dielectric, and electrode materials. The low-temperature processes used for plastic substrates, often below 200°C, present challenges in achieving high-performance TFTs comparable to those on glass substrates.

Ultra-thin glass substrates, while offering improved barrier properties compared to plastic, require specialized handling techniques due to their fragility. The manufacturing process for ultra-thin glass-based AMOLED displays often involves temporary bonding to a carrier substrate during TFT fabrication, followed by debonding for final assembly.

The OLED layers are then deposited onto the TFT backplane using techniques such as vacuum thermal evaporation or solution processing, depending on the specific materials and desired performance characteristics. For flexible displays, the organic layers and cathode must be carefully engineered to withstand bending stresses without compromising device performance or lifetime.

Encapsulation is a critical step in the manufacturing process, particularly for flexible AMOLED displays. Thin-film encapsulation (TFE) techniques, such as atomic layer deposition (ALD) of inorganic barrier layers alternating with organic layers, are commonly employed to protect the sensitive OLED materials from moisture and oxygen ingress while maintaining flexibility.

The final steps in the manufacturing process include the integration of touch sensors, polarizers, and other functional layers, which must all be compatible with the flexible substrate and maintain overall display flexibility. The entire display stack is then subjected to various reliability tests, including repeated bending cycles, to ensure durability and performance under real-world usage conditions.

Traditionally, glass has been the primary substrate for AMOLED displays due to its excellent barrier properties and thermal stability. However, the shift towards flexible displays has necessitated the exploration of alternative substrate materials, such as plastic films and ultra-thin glass. Each substrate type requires specific manufacturing considerations to ensure optimal performance and flexibility.

For plastic-based substrates, such as polyimide (PI) or polyethylene naphthalate (PEN), the manufacturing process typically begins with the deposition of a planarization layer to create a smooth surface for subsequent thin-film transistor (TFT) fabrication. This is followed by the deposition of the TFT layers, including the semiconductor, dielectric, and electrode materials. The low-temperature processes used for plastic substrates, often below 200°C, present challenges in achieving high-performance TFTs comparable to those on glass substrates.

Ultra-thin glass substrates, while offering improved barrier properties compared to plastic, require specialized handling techniques due to their fragility. The manufacturing process for ultra-thin glass-based AMOLED displays often involves temporary bonding to a carrier substrate during TFT fabrication, followed by debonding for final assembly.

The OLED layers are then deposited onto the TFT backplane using techniques such as vacuum thermal evaporation or solution processing, depending on the specific materials and desired performance characteristics. For flexible displays, the organic layers and cathode must be carefully engineered to withstand bending stresses without compromising device performance or lifetime.

Encapsulation is a critical step in the manufacturing process, particularly for flexible AMOLED displays. Thin-film encapsulation (TFE) techniques, such as atomic layer deposition (ALD) of inorganic barrier layers alternating with organic layers, are commonly employed to protect the sensitive OLED materials from moisture and oxygen ingress while maintaining flexibility.

The final steps in the manufacturing process include the integration of touch sensors, polarizers, and other functional layers, which must all be compatible with the flexible substrate and maintain overall display flexibility. The entire display stack is then subjected to various reliability tests, including repeated bending cycles, to ensure durability and performance under real-world usage conditions.

Durability Assessment

The durability of AMOLED displays is significantly influenced by the choice of substrate materials. Different substrates exhibit varying levels of resistance to mechanical stress, environmental factors, and repeated flexing, which directly impact the longevity and performance of flexible AMOLED displays.

Plastic substrates, such as polyimide (PI) and polyethylene terephthalate (PET), are commonly used for flexible AMOLED displays due to their inherent flexibility. However, these materials present distinct durability challenges. PI substrates demonstrate superior thermal stability and chemical resistance compared to PET, making them more suitable for withstanding harsh environmental conditions. Nevertheless, PI is more susceptible to moisture absorption, which can lead to dimensional instability and potential delamination of display layers over time.

The mechanical properties of substrates play a crucial role in determining the display's resistance to bending and folding stress. Substrates with higher elastic modulus and yield strength tend to offer better protection to the OLED layers against repeated flexing. However, excessive rigidity can lead to stress concentration and eventual failure at bending points. Therefore, achieving an optimal balance between flexibility and strength is essential for enhancing durability.

Surface roughness of the substrate material is another critical factor affecting display durability. Smoother surfaces provide better adhesion for subsequent layers and reduce the risk of defects in the OLED stack. However, ultra-smooth surfaces may increase the visibility of any imperfections that do occur. Some manufacturers employ surface treatment techniques, such as plasma etching or application of planarization layers, to optimize substrate surface characteristics and improve overall durability.

The coefficient of thermal expansion (CTE) mismatch between the substrate and other display components can lead to thermal stress and potential delamination during temperature fluctuations. Substrates with CTEs closely matched to those of the OLED layers and encapsulation materials exhibit superior durability under varying thermal conditions. This consideration is particularly important for displays intended for outdoor use or automotive applications.

Barrier properties of the substrate material significantly impact the display's resistance to moisture and oxygen permeation. While plastic substrates offer excellent flexibility, they typically have poor barrier properties compared to glass. To address this, manufacturers often employ multi-layer barrier films or hybrid structures combining plastic and ultra-thin glass layers. These approaches aim to enhance the overall durability of flexible AMOLED displays by mitigating environmental degradation of sensitive OLED materials.

Plastic substrates, such as polyimide (PI) and polyethylene terephthalate (PET), are commonly used for flexible AMOLED displays due to their inherent flexibility. However, these materials present distinct durability challenges. PI substrates demonstrate superior thermal stability and chemical resistance compared to PET, making them more suitable for withstanding harsh environmental conditions. Nevertheless, PI is more susceptible to moisture absorption, which can lead to dimensional instability and potential delamination of display layers over time.

The mechanical properties of substrates play a crucial role in determining the display's resistance to bending and folding stress. Substrates with higher elastic modulus and yield strength tend to offer better protection to the OLED layers against repeated flexing. However, excessive rigidity can lead to stress concentration and eventual failure at bending points. Therefore, achieving an optimal balance between flexibility and strength is essential for enhancing durability.

Surface roughness of the substrate material is another critical factor affecting display durability. Smoother surfaces provide better adhesion for subsequent layers and reduce the risk of defects in the OLED stack. However, ultra-smooth surfaces may increase the visibility of any imperfections that do occur. Some manufacturers employ surface treatment techniques, such as plasma etching or application of planarization layers, to optimize substrate surface characteristics and improve overall durability.

The coefficient of thermal expansion (CTE) mismatch between the substrate and other display components can lead to thermal stress and potential delamination during temperature fluctuations. Substrates with CTEs closely matched to those of the OLED layers and encapsulation materials exhibit superior durability under varying thermal conditions. This consideration is particularly important for displays intended for outdoor use or automotive applications.

Barrier properties of the substrate material significantly impact the display's resistance to moisture and oxygen permeation. While plastic substrates offer excellent flexibility, they typically have poor barrier properties compared to glass. To address this, manufacturers often employ multi-layer barrier films or hybrid structures combining plastic and ultra-thin glass layers. These approaches aim to enhance the overall durability of flexible AMOLED displays by mitigating environmental degradation of sensitive OLED materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!