How Heptane Enhances Polymer Plasticity in Extrusion Processes

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane-Polymer Interaction Background

Heptane, a straight-chain alkane hydrocarbon, has been increasingly recognized for its role in enhancing polymer plasticity during extrusion processes. This interaction between heptane and polymers has its roots in the fundamental principles of polymer science and materials engineering. The study of this phenomenon dates back to the mid-20th century when researchers began exploring the effects of various solvents on polymer behavior.

The interaction between heptane and polymers is primarily governed by the principles of solubility and plasticization. Heptane, being a non-polar solvent, has a particular affinity for non-polar polymer chains. This affinity allows heptane molecules to penetrate the polymer matrix, effectively increasing the free volume between polymer chains. This increased free volume results in enhanced chain mobility, which is a key factor in improving the plasticity of the polymer during extrusion.

The plasticizing effect of heptane on polymers is not uniform across all polymer types. Its effectiveness is particularly pronounced in polyolefins, such as polyethylene and polypropylene, due to their similar chemical nature. The degree of plasticization depends on several factors, including the molecular weight of the polymer, the concentration of heptane, and the processing conditions.

Historical developments in polymer processing have significantly contributed to our understanding of heptane-polymer interactions. Early experiments in the 1960s and 1970s focused on the swelling behavior of polymers in various solvents, including heptane. These studies laid the groundwork for understanding how small molecules like heptane can influence the physical properties of polymers.

The advent of more sophisticated analytical techniques in the 1980s and 1990s, such as differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA), allowed researchers to quantify the effects of heptane on polymer properties more precisely. These advancements revealed that heptane not only affects the mechanical properties of polymers but also influences their thermal behavior, often lowering the glass transition temperature and melting point.

In recent years, the focus has shifted towards understanding the molecular-level interactions between heptane and polymer chains. Advanced spectroscopic techniques and molecular dynamics simulations have provided insights into how heptane molecules orient themselves within the polymer matrix and how this orientation affects the overall polymer structure and properties.

The industrial application of heptane in polymer extrusion processes has evolved alongside these scientific developments. Initially used primarily as a processing aid, heptane's role has expanded to include its use as a temporary plasticizer in specific applications. This evolution has led to improvements in product quality, processing efficiency, and the ability to manufacture products with unique properties that were previously difficult to achieve.

The interaction between heptane and polymers is primarily governed by the principles of solubility and plasticization. Heptane, being a non-polar solvent, has a particular affinity for non-polar polymer chains. This affinity allows heptane molecules to penetrate the polymer matrix, effectively increasing the free volume between polymer chains. This increased free volume results in enhanced chain mobility, which is a key factor in improving the plasticity of the polymer during extrusion.

The plasticizing effect of heptane on polymers is not uniform across all polymer types. Its effectiveness is particularly pronounced in polyolefins, such as polyethylene and polypropylene, due to their similar chemical nature. The degree of plasticization depends on several factors, including the molecular weight of the polymer, the concentration of heptane, and the processing conditions.

Historical developments in polymer processing have significantly contributed to our understanding of heptane-polymer interactions. Early experiments in the 1960s and 1970s focused on the swelling behavior of polymers in various solvents, including heptane. These studies laid the groundwork for understanding how small molecules like heptane can influence the physical properties of polymers.

The advent of more sophisticated analytical techniques in the 1980s and 1990s, such as differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA), allowed researchers to quantify the effects of heptane on polymer properties more precisely. These advancements revealed that heptane not only affects the mechanical properties of polymers but also influences their thermal behavior, often lowering the glass transition temperature and melting point.

In recent years, the focus has shifted towards understanding the molecular-level interactions between heptane and polymer chains. Advanced spectroscopic techniques and molecular dynamics simulations have provided insights into how heptane molecules orient themselves within the polymer matrix and how this orientation affects the overall polymer structure and properties.

The industrial application of heptane in polymer extrusion processes has evolved alongside these scientific developments. Initially used primarily as a processing aid, heptane's role has expanded to include its use as a temporary plasticizer in specific applications. This evolution has led to improvements in product quality, processing efficiency, and the ability to manufacture products with unique properties that were previously difficult to achieve.

Market Demand Analysis

The market demand for heptane as a polymer plasticity enhancer in extrusion processes has been steadily growing, driven by the increasing need for high-performance plastics in various industries. The global plastics market, valued at over $570 billion in 2022, is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) of 3.7% projected through 2030. Within this broader market, the demand for specialized additives like heptane is experiencing even more rapid growth.

The automotive industry, in particular, has emerged as a significant driver of demand for heptane-enhanced polymers. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing trend towards replacing metal components with high-performance plastics. These materials require enhanced plasticity to meet the stringent requirements of automotive applications, making heptane an increasingly valuable additive in the extrusion process.

Another key market segment contributing to the demand for heptane in polymer extrusion is the packaging industry. With the global push towards sustainable and recyclable packaging solutions, there is a rising need for plastics that can maintain their structural integrity while being thinner and lighter. Heptane's ability to enhance polymer plasticity allows for the production of packaging materials that meet these criteria, driving its adoption in the industry.

The construction sector is also showing increased interest in heptane-enhanced polymers. As building regulations become more stringent regarding energy efficiency and durability, there is a growing demand for advanced plastic materials in construction applications. Heptane's role in improving the extrusion process for these materials is becoming increasingly recognized, leading to higher demand in this sector.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for heptane-enhanced polymers, driven by rapid industrialization and urbanization in countries like China and India. North America and Europe are also significant markets, with a focus on high-value applications in aerospace, medical devices, and advanced manufacturing.

The demand for heptane in polymer extrusion is further bolstered by ongoing research and development efforts aimed at expanding its applications. As new polymer formulations are developed to meet evolving industry needs, the role of heptane in enhancing plasticity during the extrusion process is likely to become even more critical, potentially opening up new market opportunities.

The automotive industry, in particular, has emerged as a significant driver of demand for heptane-enhanced polymers. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing trend towards replacing metal components with high-performance plastics. These materials require enhanced plasticity to meet the stringent requirements of automotive applications, making heptane an increasingly valuable additive in the extrusion process.

Another key market segment contributing to the demand for heptane in polymer extrusion is the packaging industry. With the global push towards sustainable and recyclable packaging solutions, there is a rising need for plastics that can maintain their structural integrity while being thinner and lighter. Heptane's ability to enhance polymer plasticity allows for the production of packaging materials that meet these criteria, driving its adoption in the industry.

The construction sector is also showing increased interest in heptane-enhanced polymers. As building regulations become more stringent regarding energy efficiency and durability, there is a growing demand for advanced plastic materials in construction applications. Heptane's role in improving the extrusion process for these materials is becoming increasingly recognized, leading to higher demand in this sector.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for heptane-enhanced polymers, driven by rapid industrialization and urbanization in countries like China and India. North America and Europe are also significant markets, with a focus on high-value applications in aerospace, medical devices, and advanced manufacturing.

The demand for heptane in polymer extrusion is further bolstered by ongoing research and development efforts aimed at expanding its applications. As new polymer formulations are developed to meet evolving industry needs, the role of heptane in enhancing plasticity during the extrusion process is likely to become even more critical, potentially opening up new market opportunities.

Current Challenges

The extrusion process for enhancing polymer plasticity using heptane faces several significant challenges that require careful consideration and innovative solutions. One of the primary obstacles is maintaining precise control over the heptane concentration throughout the extrusion process. Fluctuations in heptane levels can lead to inconsistent plasticity in the final product, compromising its quality and performance characteristics.

Another critical challenge lies in the volatile nature of heptane. Its low boiling point and high vapor pressure make it prone to evaporation during the extrusion process, particularly at elevated temperatures. This volatility not only affects the consistency of the polymer-heptane mixture but also raises safety concerns due to the potential formation of explosive atmospheres in the processing environment.

The integration of heptane into existing extrusion equipment and processes presents additional hurdles. Many current systems are not designed to handle volatile organic compounds like heptane, necessitating significant modifications to ensure safe and efficient operation. This includes the implementation of specialized sealing systems, vapor recovery units, and explosion-proof electrical components, all of which can substantially increase production costs and complexity.

Furthermore, the environmental impact of using heptane in polymer extrusion processes is a growing concern. Stringent regulations on volatile organic compound (VOC) emissions require manufacturers to implement sophisticated emission control systems, adding another layer of complexity and cost to the production process.

The optimization of the polymer-heptane interaction during extrusion also remains a significant technical challenge. Achieving the ideal balance between enhanced plasticity and other desired material properties, such as strength and durability, requires extensive research and fine-tuning of process parameters. This optimization process is further complicated by the diverse range of polymer types and grades used in various applications, each potentially requiring a unique approach to heptane incorporation.

Lastly, the scalability of heptane-enhanced extrusion processes from laboratory to industrial scale presents its own set of challenges. Factors such as heat transfer, mixing efficiency, and residence time distribution can vary significantly between small-scale experiments and full-scale production, necessitating careful scaling strategies and potentially costly pilot-scale testing.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer science, chemical engineering, process safety, and environmental management. As the industry continues to explore the potential of heptane in enhancing polymer plasticity, overcoming these obstacles will be crucial for the widespread adoption and success of this innovative extrusion technique.

Another critical challenge lies in the volatile nature of heptane. Its low boiling point and high vapor pressure make it prone to evaporation during the extrusion process, particularly at elevated temperatures. This volatility not only affects the consistency of the polymer-heptane mixture but also raises safety concerns due to the potential formation of explosive atmospheres in the processing environment.

The integration of heptane into existing extrusion equipment and processes presents additional hurdles. Many current systems are not designed to handle volatile organic compounds like heptane, necessitating significant modifications to ensure safe and efficient operation. This includes the implementation of specialized sealing systems, vapor recovery units, and explosion-proof electrical components, all of which can substantially increase production costs and complexity.

Furthermore, the environmental impact of using heptane in polymer extrusion processes is a growing concern. Stringent regulations on volatile organic compound (VOC) emissions require manufacturers to implement sophisticated emission control systems, adding another layer of complexity and cost to the production process.

The optimization of the polymer-heptane interaction during extrusion also remains a significant technical challenge. Achieving the ideal balance between enhanced plasticity and other desired material properties, such as strength and durability, requires extensive research and fine-tuning of process parameters. This optimization process is further complicated by the diverse range of polymer types and grades used in various applications, each potentially requiring a unique approach to heptane incorporation.

Lastly, the scalability of heptane-enhanced extrusion processes from laboratory to industrial scale presents its own set of challenges. Factors such as heat transfer, mixing efficiency, and residence time distribution can vary significantly between small-scale experiments and full-scale production, necessitating careful scaling strategies and potentially costly pilot-scale testing.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer science, chemical engineering, process safety, and environmental management. As the industry continues to explore the potential of heptane in enhancing polymer plasticity, overcoming these obstacles will be crucial for the widespread adoption and success of this innovative extrusion technique.

Existing Heptane Solutions

01 Heptane as a solvent in polymer processing

Heptane is used as a solvent in polymer processing to enhance plasticity. It can improve the flow characteristics of polymers during manufacturing processes, allowing for better molding and shaping of plastic materials. The use of heptane as a solvent can also affect the final properties of the plastic product, such as flexibility and durability.- Heptane as a solvent in plastic formulations: Heptane is utilized as a solvent in various plastic formulations to enhance plasticity. It can improve the flow and moldability of plastic materials during processing, allowing for better shaping and forming of plastic products. The use of heptane as a solvent can also affect the final properties of the plastic, such as flexibility and durability.

- Heptane in polymer blending and compatibilization: Heptane plays a role in polymer blending and compatibilization processes. It can be used to improve the miscibility of different polymer components, leading to enhanced plasticity of the resulting blends. This application of heptane is particularly useful in creating polymer composites with tailored properties for specific applications.

- Heptane-based plasticizers for improved flexibility: Heptane derivatives can be used as plasticizers to improve the flexibility and workability of plastic materials. These plasticizers can be incorporated into polymer formulations to reduce brittleness and enhance overall plasticity. The use of heptane-based plasticizers allows for the production of more pliable and durable plastic products.

- Heptane in polymer modification and functionalization: Heptane can be employed in polymer modification and functionalization processes to alter the plasticity of materials. It can serve as a reaction medium or a reagent in chemical modifications of polymers, leading to changes in their physical properties, including plasticity. This approach allows for the tailoring of polymer characteristics to meet specific requirements.

- Heptane in polymer processing and manufacturing: Heptane is used in various polymer processing and manufacturing techniques to influence plasticity. It can be employed in processes such as solution casting, spin coating, or as a component in polymer melts during extrusion or injection molding. The presence of heptane can affect the flow behavior and final properties of the processed polymers, including their plasticity.

02 Heptane in rubber compounding

Heptane is utilized in rubber compounding processes to modify the plasticity of rubber materials. It can act as a plasticizer, improving the workability of rubber compounds during mixing and shaping. The addition of heptane can influence the final properties of rubber products, including elasticity and resistance to deformation.Expand Specific Solutions03 Heptane-based formulations for adhesives

Heptane is incorporated into adhesive formulations to adjust their plasticity and bonding properties. It can serve as a carrier solvent or diluent in pressure-sensitive adhesives, influencing their tack, peel strength, and shear resistance. The use of heptane in adhesive systems can also affect their drying time and overall performance.Expand Specific Solutions04 Heptane in pharmaceutical and cosmetic applications

Heptane is employed in pharmaceutical and cosmetic formulations to modify the plasticity and texture of various products. It can be used as a solvent or carrier for active ingredients, influencing the spreadability and absorption of creams, ointments, and other topical preparations. The inclusion of heptane can affect the overall sensory properties and efficacy of these products.Expand Specific Solutions05 Heptane in material testing and characterization

Heptane is utilized in various material testing and characterization methods to assess the plasticity and other properties of materials. It can be used as a standard solvent in analytical techniques, such as chromatography, to evaluate the composition and behavior of polymers and other substances. The use of heptane in these applications helps in understanding and predicting material performance under different conditions.Expand Specific Solutions

Key Industry Players

The market for heptane-enhanced polymer plasticity in extrusion processes is in a growth phase, driven by increasing demand for improved polymer performance in various industries. The global market size for this technology is expanding, with significant potential in packaging, automotive, and consumer goods sectors. Technologically, the field is advancing rapidly, with major players like ExxonMobil Chemical Patents, Dow Global Technologies, and NOVA Chemicals leading innovation. These companies are developing proprietary formulations and processes to optimize heptane's plasticizing effects. While the technology is maturing, there's still room for breakthrough advancements, particularly in enhancing efficiency and sustainability. Emerging players like Kaneka Corp. and DuPont de Nemours are also contributing to the competitive landscape, focusing on specialized applications and eco-friendly solutions.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a novel approach to enhance polymer plasticity using heptane in extrusion processes. Their method involves introducing heptane as a plasticizer during the extrusion of polyolefins, particularly polyethylene and polypropylene. The heptane is injected into the extruder barrel at a specific point, where it can effectively dissolve into the polymer melt. This process reduces the melt viscosity, allowing for lower processing temperatures and improved flow characteristics[1]. The company has also implemented a controlled venting system to remove excess heptane post-extrusion, ensuring optimal final product properties[3]. ExxonMobil's research has shown that this technique can increase throughput by up to 20% while maintaining or even improving the mechanical properties of the extruded polymer[5].

Strengths: Increased throughput, lower processing temperatures, improved flow characteristics. Weaknesses: Potential for residual heptane in final product, additional equipment required for heptane injection and venting.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a sophisticated approach to utilizing heptane for enhancing polymer plasticity in extrusion processes. Their technology, known as the Heptane-Assisted Polymer Extrusion (HAPE) system, involves a precise metering of heptane into the extruder at multiple injection points. This allows for optimal distribution and interaction with the polymer chains throughout the extrusion process[2]. Dow's research has demonstrated that this method can reduce the required extrusion pressure by up to 30%, leading to significant energy savings[4]. Additionally, they have developed a proprietary heptane recovery system that captures and recycles up to 95% of the heptane used, making the process more environmentally friendly and cost-effective[6]. The HAPE system has been particularly effective with high-density polyethylene (HDPE) and polypropylene (PP), showing improvements in surface finish and dimensional stability of extruded products[8].

Strengths: Significant reduction in extrusion pressure, energy savings, high heptane recovery rate, improved product quality. Weaknesses: Complex system requiring specialized equipment, potential safety concerns with heptane handling.

Core Heptane-Polymer Research

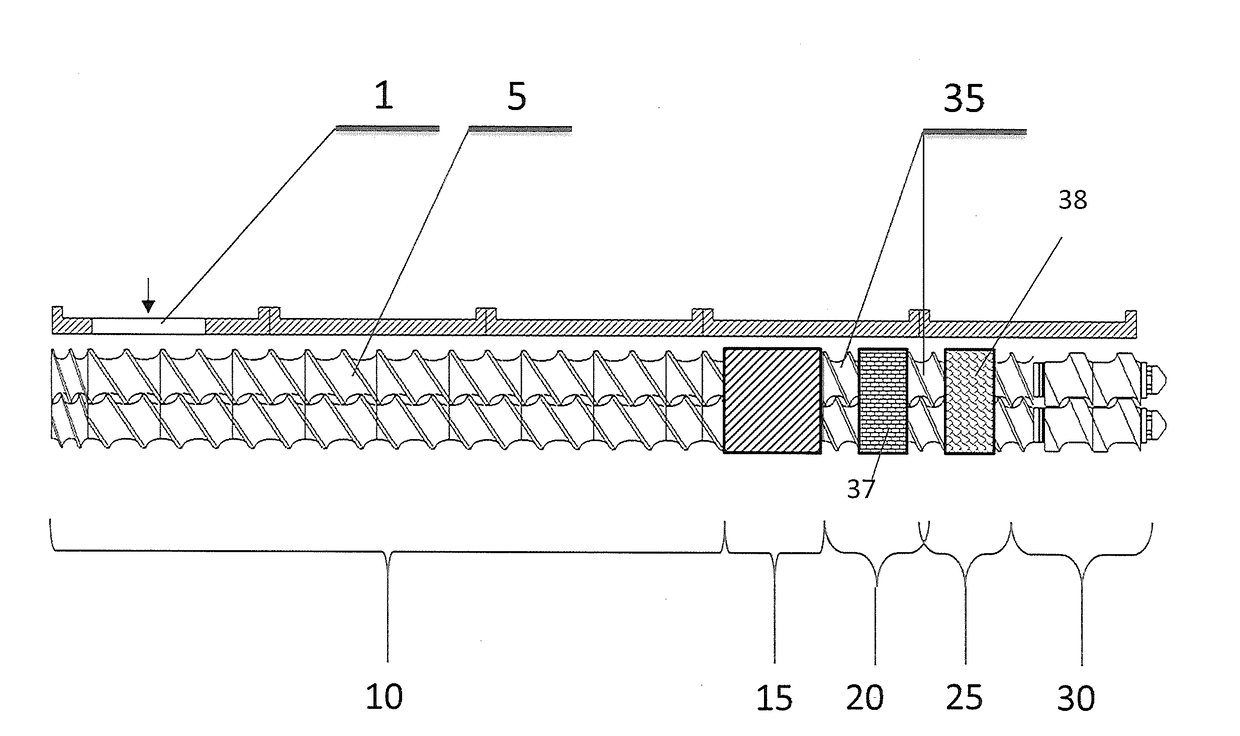

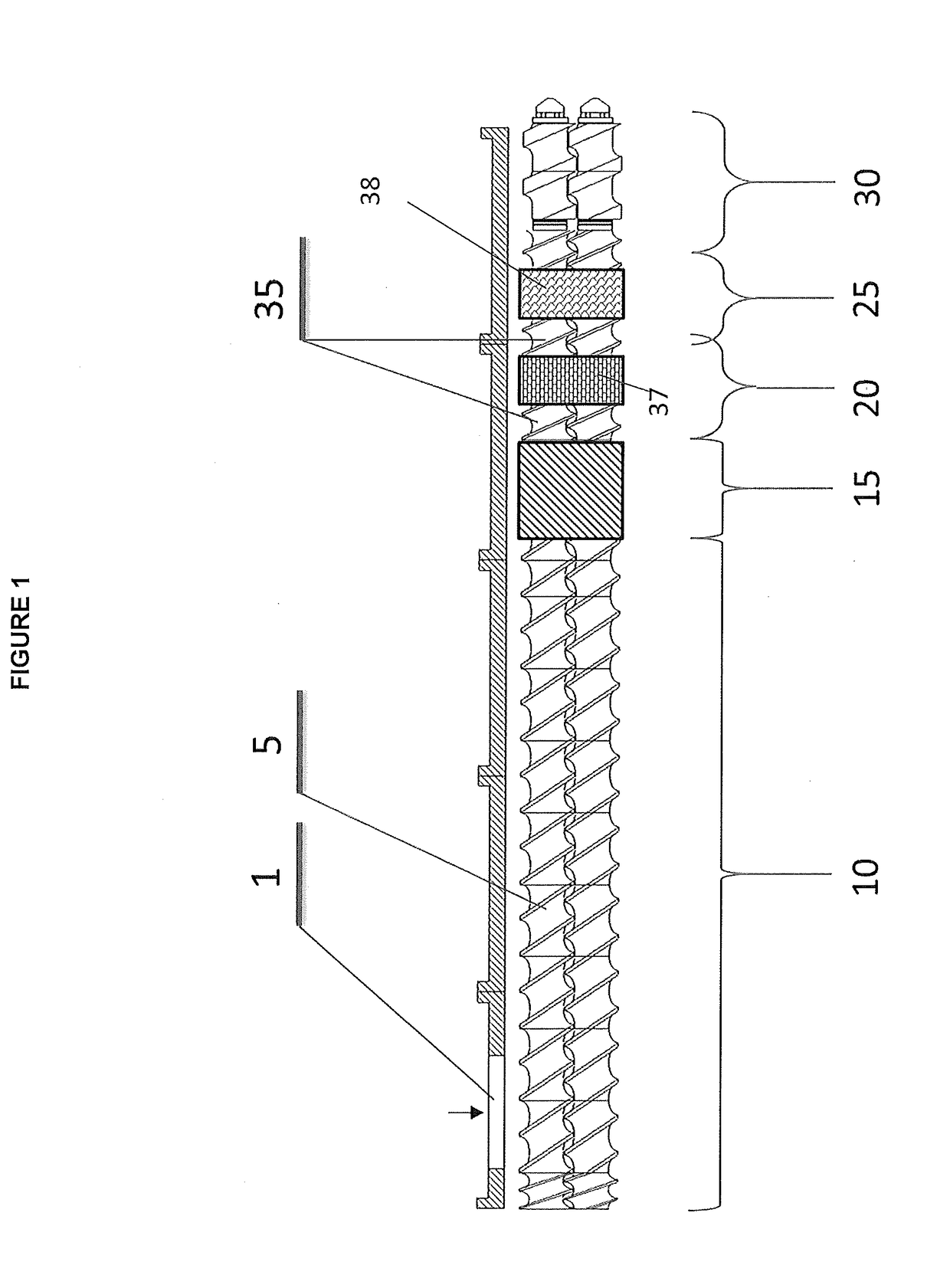

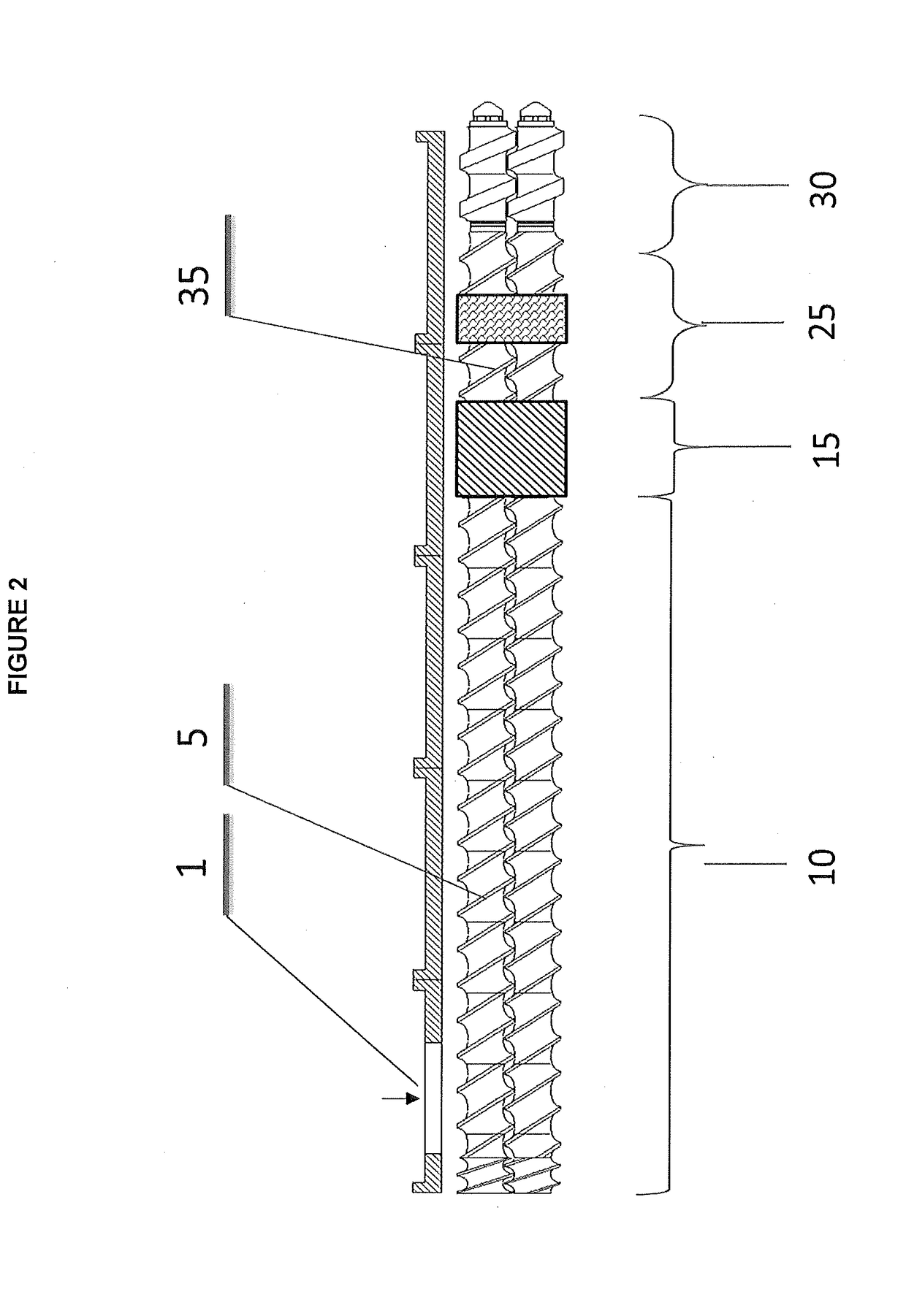

Method of extrusion of compositions of linear polyethylene and polyacetal and films thereof

PatentInactiveEP0324263A2

Innovation

- Incorporating small amounts (less than 1 weight percent) of polyacetal polymer, specifically polyoxymethylene-based resins, into the linear ethylene polymers to reduce melt fracture, head pressure, and extruder torque, thereby improving extrudability and film quality.

Extrusion process for polyethylene polymers

PatentActiveUS20170120499A1

Innovation

- Optimizing the screw configuration of a conventional co-rotating twin screw extruder by introducing a balanced dispersive mixing and polymer melt temperature control, using appropriate kneading blocks and an optimized polymer melting zone, to reduce gels and homogenize high molecular weight fractions without the need for additional expensive equipment.

Environmental Impact Assessment

The use of heptane in polymer extrusion processes raises several environmental concerns that require careful assessment. Heptane, a volatile organic compound (VOC), can contribute to air pollution and potentially impact local air quality. During the extrusion process, heptane emissions may occur, leading to the formation of ground-level ozone and smog when exposed to sunlight and nitrogen oxides. This can have adverse effects on human health and vegetation in the surrounding areas.

Water contamination is another significant environmental risk associated with heptane usage. Improper handling, storage, or disposal of heptane-containing materials can result in soil and groundwater pollution. Given heptane's low water solubility and tendency to form a separate phase, it can persist in aquatic environments and potentially harm aquatic ecosystems.

The production and transportation of heptane also contribute to the overall carbon footprint of the extrusion process. As a petroleum-derived compound, heptane's lifecycle involves greenhouse gas emissions from extraction, refining, and transportation activities. This aspect should be considered when evaluating the environmental impact of using heptane as a plasticizer in polymer extrusion.

Waste management is a critical concern in heptane-enhanced extrusion processes. Proper disposal methods for heptane-contaminated materials and byproducts must be implemented to prevent environmental contamination. Recycling and recovery systems for heptane can help mitigate its environmental impact and reduce the demand for new production.

The potential for accidental releases and spills during handling and storage of heptane presents additional environmental risks. Such incidents can lead to soil contamination, affecting local flora and fauna. Emergency response plans and containment measures are essential to minimize the environmental impact of potential accidents.

To address these environmental concerns, industries employing heptane in extrusion processes should implement robust emission control technologies, such as vapor recovery systems and thermal oxidizers. Regular monitoring of air and water quality in the vicinity of production facilities is crucial to ensure compliance with environmental regulations and to detect any potential impacts early.

Exploring alternative, more environmentally friendly plasticizers or process enhancements could help reduce the reliance on heptane and its associated environmental risks. Research into bio-based or recyclable plasticizers may offer more sustainable solutions for enhancing polymer plasticity in extrusion processes while minimizing environmental impact.

Water contamination is another significant environmental risk associated with heptane usage. Improper handling, storage, or disposal of heptane-containing materials can result in soil and groundwater pollution. Given heptane's low water solubility and tendency to form a separate phase, it can persist in aquatic environments and potentially harm aquatic ecosystems.

The production and transportation of heptane also contribute to the overall carbon footprint of the extrusion process. As a petroleum-derived compound, heptane's lifecycle involves greenhouse gas emissions from extraction, refining, and transportation activities. This aspect should be considered when evaluating the environmental impact of using heptane as a plasticizer in polymer extrusion.

Waste management is a critical concern in heptane-enhanced extrusion processes. Proper disposal methods for heptane-contaminated materials and byproducts must be implemented to prevent environmental contamination. Recycling and recovery systems for heptane can help mitigate its environmental impact and reduce the demand for new production.

The potential for accidental releases and spills during handling and storage of heptane presents additional environmental risks. Such incidents can lead to soil contamination, affecting local flora and fauna. Emergency response plans and containment measures are essential to minimize the environmental impact of potential accidents.

To address these environmental concerns, industries employing heptane in extrusion processes should implement robust emission control technologies, such as vapor recovery systems and thermal oxidizers. Regular monitoring of air and water quality in the vicinity of production facilities is crucial to ensure compliance with environmental regulations and to detect any potential impacts early.

Exploring alternative, more environmentally friendly plasticizers or process enhancements could help reduce the reliance on heptane and its associated environmental risks. Research into bio-based or recyclable plasticizers may offer more sustainable solutions for enhancing polymer plasticity in extrusion processes while minimizing environmental impact.

Regulatory Compliance

The use of heptane in polymer extrusion processes is subject to various regulatory requirements and compliance standards. These regulations primarily focus on environmental protection, worker safety, and product quality assurance. Environmental regulations, such as the Clean Air Act in the United States, set limits on volatile organic compound (VOC) emissions, which include heptane. Manufacturers must implement appropriate emission control technologies and monitoring systems to ensure compliance with these standards.

Occupational safety and health regulations, such as those enforced by OSHA in the US, require proper handling, storage, and disposal procedures for heptane due to its flammability and potential health hazards. This includes providing adequate ventilation, personal protective equipment, and emergency response plans. Material Safety Data Sheets (MSDS) must be readily available, and workers must be trained on the safe handling of heptane and associated risks.

Product safety regulations, such as those enforced by the FDA for food-contact materials, may apply when the extruded polymers are intended for specific applications. These regulations often require extensive testing and documentation to demonstrate that the use of heptane does not result in harmful migration or contamination of the final product. Manufacturers must maintain detailed records of their production processes, including the use of heptane, to ensure traceability and compliance with these standards.

International regulations, such as REACH in the European Union, may impose additional requirements on the registration, evaluation, and authorization of heptane use in polymer extrusion processes. Manufacturers exporting products to different regions must be aware of and comply with these varying regulatory frameworks.

Quality management systems, such as ISO 9001, often incorporate regulatory compliance as a key component. Manufacturers using heptane in extrusion processes should implement robust quality control measures to ensure consistent compliance with all applicable regulations. This may include regular audits, documentation of standard operating procedures, and continuous monitoring of process parameters.

As regulations evolve, manufacturers must stay informed about changes that may affect their use of heptane in polymer extrusion. This requires ongoing engagement with regulatory bodies, industry associations, and legal experts to ensure continued compliance and to anticipate future regulatory trends that may impact their operations.

Occupational safety and health regulations, such as those enforced by OSHA in the US, require proper handling, storage, and disposal procedures for heptane due to its flammability and potential health hazards. This includes providing adequate ventilation, personal protective equipment, and emergency response plans. Material Safety Data Sheets (MSDS) must be readily available, and workers must be trained on the safe handling of heptane and associated risks.

Product safety regulations, such as those enforced by the FDA for food-contact materials, may apply when the extruded polymers are intended for specific applications. These regulations often require extensive testing and documentation to demonstrate that the use of heptane does not result in harmful migration or contamination of the final product. Manufacturers must maintain detailed records of their production processes, including the use of heptane, to ensure traceability and compliance with these standards.

International regulations, such as REACH in the European Union, may impose additional requirements on the registration, evaluation, and authorization of heptane use in polymer extrusion processes. Manufacturers exporting products to different regions must be aware of and comply with these varying regulatory frameworks.

Quality management systems, such as ISO 9001, often incorporate regulatory compliance as a key component. Manufacturers using heptane in extrusion processes should implement robust quality control measures to ensure consistent compliance with all applicable regulations. This may include regular audits, documentation of standard operating procedures, and continuous monitoring of process parameters.

As regulations evolve, manufacturers must stay informed about changes that may affect their use of heptane in polymer extrusion. This requires ongoing engagement with regulatory bodies, industry associations, and legal experts to ensure continued compliance and to anticipate future regulatory trends that may impact their operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!